Mechanical Engineering

Editor's pick

Research Article

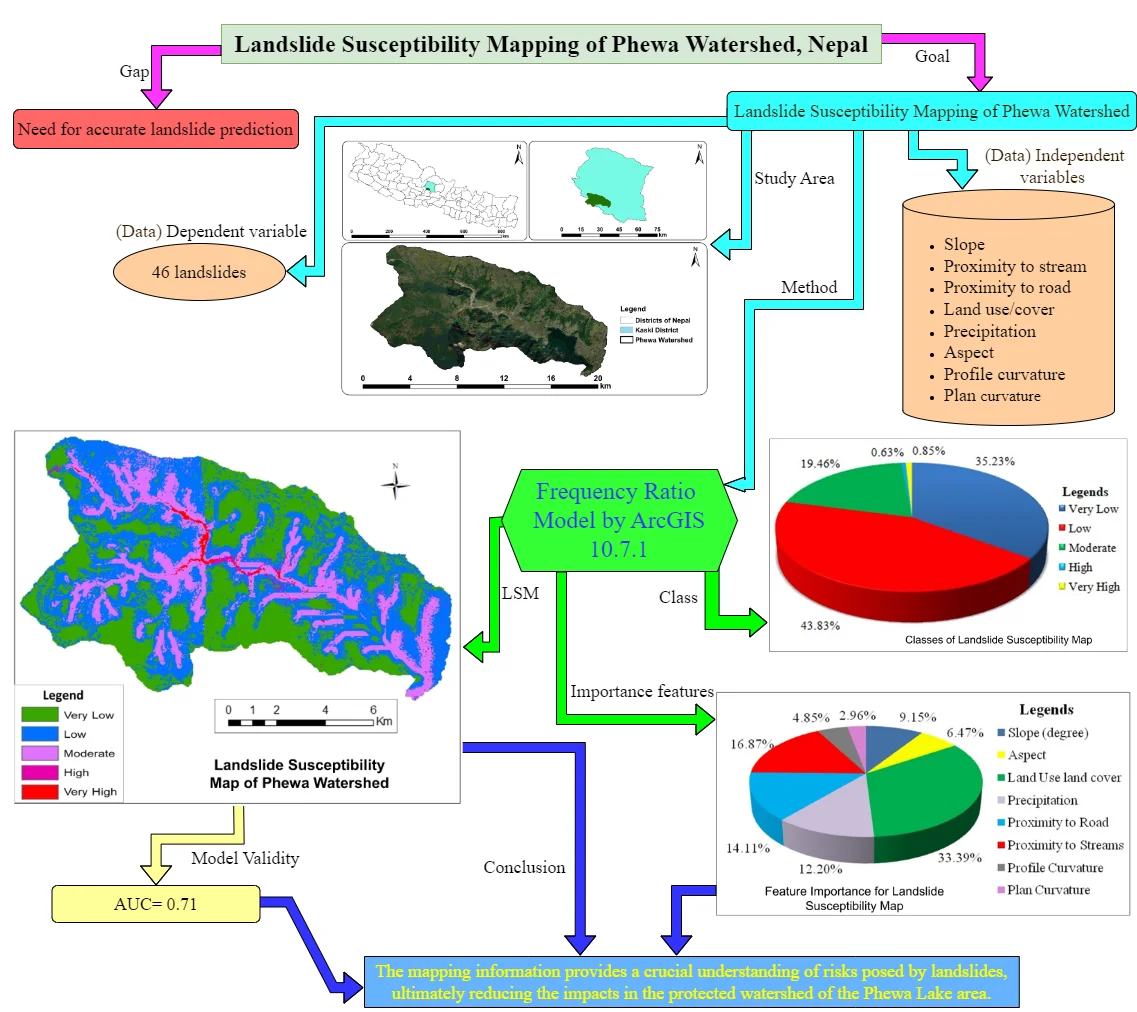

Landslide susceptibility mapping of Phewa Watershed, Kaski, Nepal

By Bimal Bahadur Kunwar, Nantakan Muensit, Kuaanan Techato, Saroj Gyawali

Heavy and incessant rainfall in Nepal, particularly during the monsoon season, leads to water-induced risks like landslides, necessitating the use of Landslide Susceptibility Mapping (LSM) for the prediction of landslide risks. We aim to determine the degrees of connection and connective factors among landslide incidents to generate an updated landslide susceptibility map of the Phewa watershed in Kaski District, Nepal. The most dependable and popular statistical approach for determining LSMs is the frequency ratio model, which was created in ArcGIS 10.7.1 by identifying 46 landslides in the area and analyzing eight causal factors. The LSM categorized the area into five classes, with the low class representing a large percentage (43.27 %) and the high class a small percentage (0.63 %). In FR techniques, slope, proximity to a stream or road, land use/cover, and precipitation were assigned greater weight than aspect, profile curvature, and plan curvature. Using the area under the curve approach, the applied model’s accuracy revealed a good performance value of 0.717. Taken together, the mapping information provides a crucial understanding of risks posed by landslides, ultimately reducing the impacts in the protected watershed of the Phewa Lake area.

August 22, 2024

Informatics

Most cited

Research Article

A portable breast cancer detection system based on smartphone with infrared camera

By Jian Ma, Pengchao Shang, Chen Lu, Safa Meraghni, Khaled Benaggoune, Juan Zuluaga, Noureddine Zerhouni, Christine Devalland, Zeina Al Masry

September 26, 2019

Biomechanics

Most cited

Research Article

Optimization of palm methyl ester and its effect on fatty acid compositions and cetane number

By Sharath Satya, Aditya Kolakoti, Naga Raju B., Shyam Sundar R., Ranga Rao

March 31, 2019

Informatics

Most cited

Research Article

Mathematical modeling of forced oscillations of semidefinite vibro-impact system sliding along rough horizontal surface

By Vitaliy Korendiy, Volodymyr Gursky, Oleksandr Kachur, Volodymyr Gurey, Oleksandr Havrylchenko, Oleh Kotsiumbas

December 2, 2021

Informatics

Most cited

Research Article

Performance of PID-Fuzzy control for cab isolation mounts of soil compactors

By Vanliem Nguyen, Renqiang Jiao, Vanquynh Le, Anhtan Hoang

December 31, 2019

Informatics

Journal of Mechanical Engineering, Automation and Control Systems

Research Article

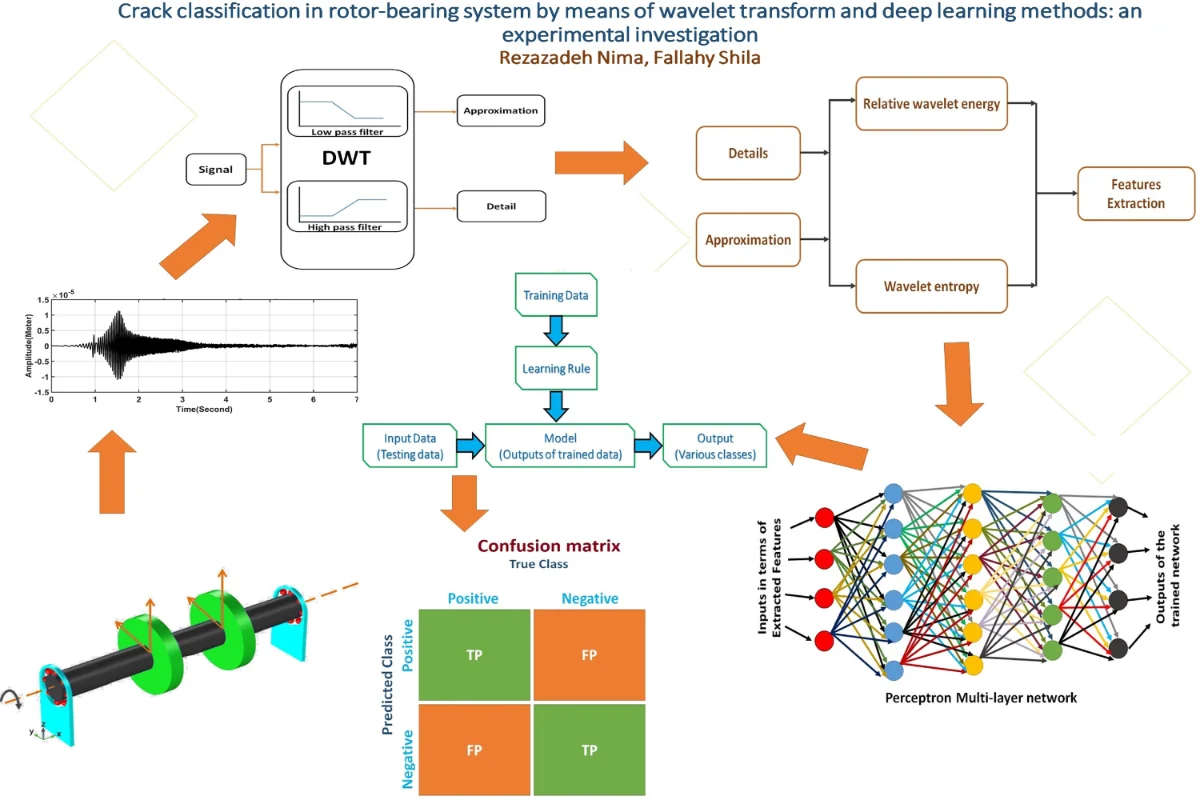

Crack classification in rotor-bearing system by means of wavelet transform and deep learning methods: an experimental investigation

Parallel with significant growth in industry, especially mysteries related to energy engineering, condition monitoring of rotating systems have been experiencing a noticeable increase. One of the prevalent faults in these systems is fatigue crack, so finding reliable procedures in identification of cracks in rotating shafts has become a pressing problem among engineers during recent decades. While a vast majority of cracked rotors can operate for a specific period of time, to prevent catastrophic failures, crack detection and measuring its characteristics (i.e. size and its location) seem to be essential. In the present essay, a hybrid procedure, consisting of Deep Learning and Discrete Wavelet transform (DWT), is applied in detection of a breathing transverse crack and its depth in a rotor-bearing-disk system. DWT with Daubechies 32(db32) as wavelet mother function is applied in signal noise reduction until level 6, also its Relative Wavelet Energy (RWE) and Wavelet entropy (WE) are extracted. A characteristic vector that is a combination of RWE and WE is considered as input to a multi-layer Artificial Neural Network (ANN). In this supervised learning classifier, a multi-layer Perceptron neural network is used; in addition, Rectified Linear Unit (ReLU) function is exerted as activation function in both hidden and output layers. By comparing the results, it can be seen that the applied procedure has strong capacity in identification of crack and its size in the rotor system.

December 11, 2020

Industrial Engineering

Research Article

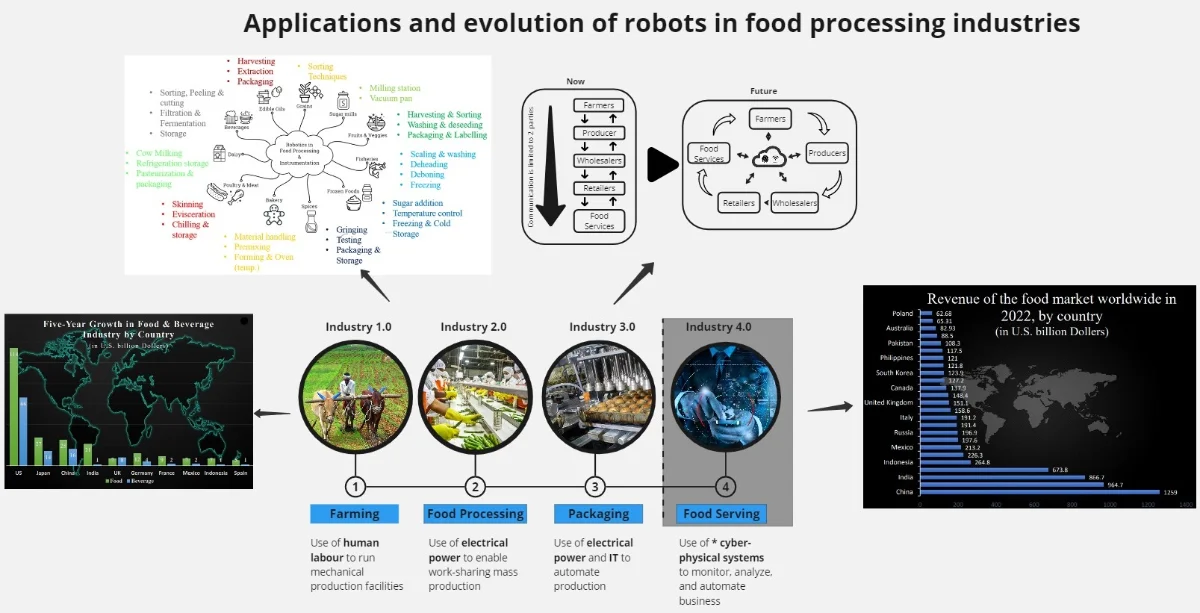

Prospects of robotics in food processing: an overview

Mechanical progressions in different spaces have widened the application skyline of advanced mechanics to an unbelievable degree. Packaging and processing are some of the important aspects involved in the food industry. As the global population continues to rise with increasing consumer demand for a wider variety of food products, food manufacturing is exploring various strategies, techniques, and methods to meet the demand and adapt to the change. Industrial robots are being integrated into every part of the food manufacturing sector to increase production rates and improve food quality and hygiene. The introduction of more stringent legislation is forcing the food sector to update its production process. On the vigorous review of 50 papers, this paper provides a comprehensive review of robotics in food processing and investigates its analysis in terms of the level of automation applied in various food processing industries. The expectation of food-Robo in the food sectors and robotics with an optimized protocol to fetch various ingredients and shape them into a final product.

June 21, 2023

Industrial Engineering

Research Article

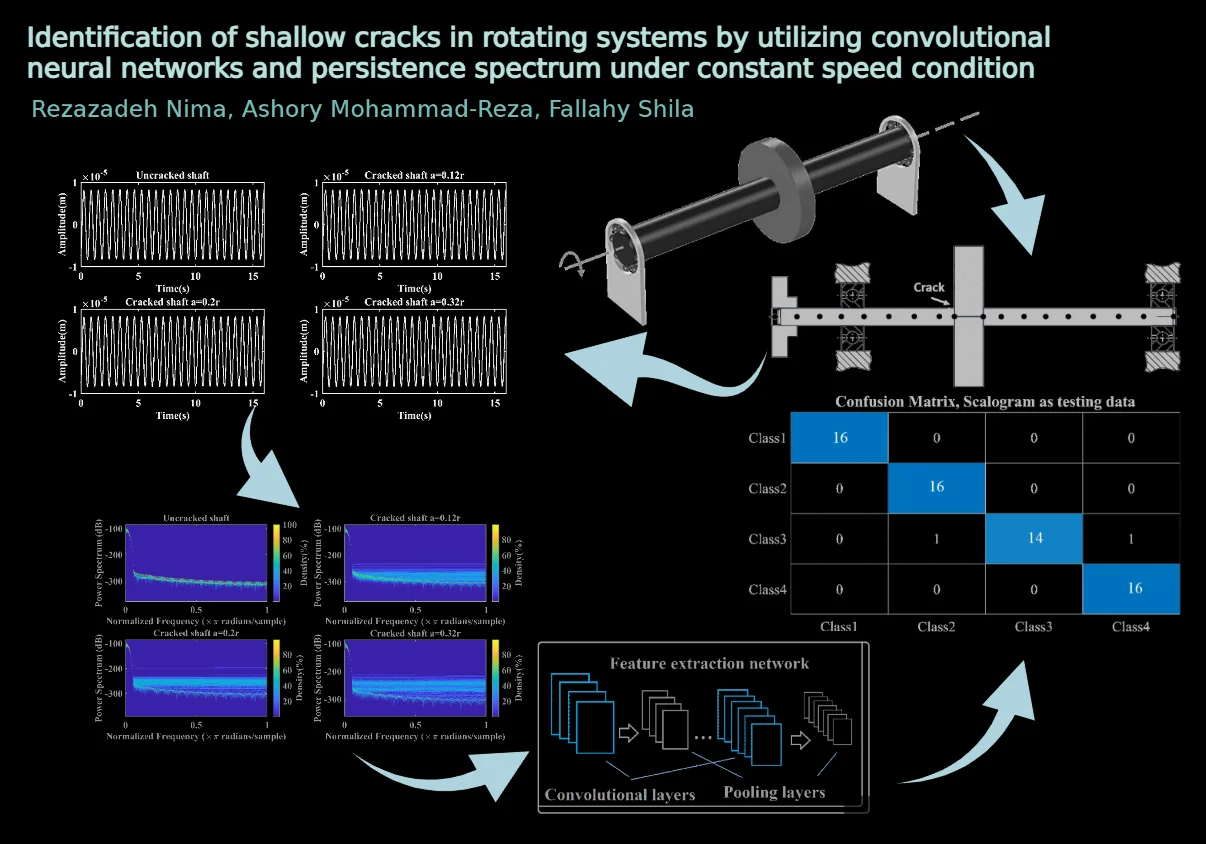

Identification of shallow cracks in rotating systems by utilizing convolutional neural networks and persistence spectrum under constant speed condition

The positive benefits of early faults detection in rotating systems have led scientists to develop automated methods. Although unbalancing is the most prevalent defect in rotor systems, this fault normally is accompanied by other defects such as crack. In this article, an effective self-acting procedure is addressed in identifying shallow cracks in rotor systems throughout the steady-state operation. To classify rotor systems suffering cracks with three various depths, firstly, healthy and cracked systems are modeled by employing the finite element method (FEM). In the following, systems' vibration signals are calculated in different situations numerically; for pre-processing stage, the persistence spectrum is implemented. Finally, by using a supervised convolutional neural network (CNN), rotor systems are classified by regarding the crack depths. The result of the testing step revealed that this hybrid method has rational capacity in distinguishing shallow cracks in steady-state operation where many other methods are somehow powerless.

December 15, 2021

Industrial Engineering

Research Article

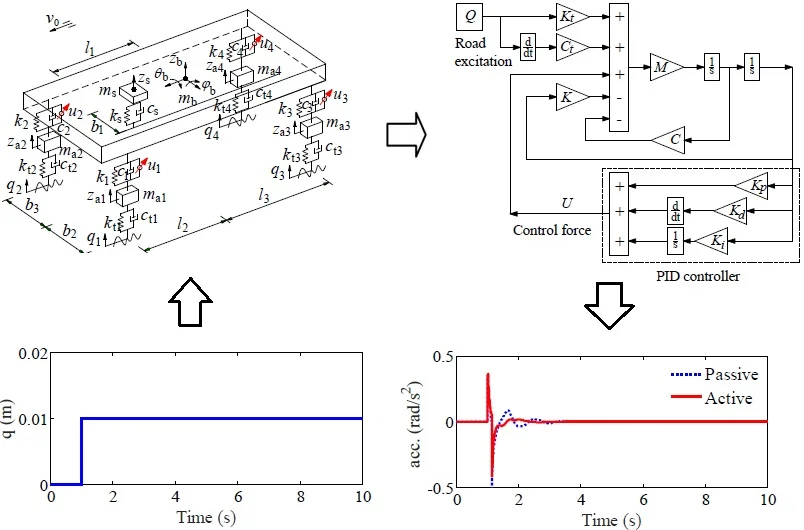

Control performance of suspension system of cars with PID control based on 3D dynamic model

To evaluate the control performance of the PID controller for the cars, a 3D car dynamic model with 8-DOF which can fully reflect the pitch and roll of the car body is proposed in this study. The PID controller is then researched and applied to control the active suspension system of the cars under the different excitations of the road surface and the various car speeds. The control performance for improving the ride comfort of the driver is evaluated via the root-mean-square (RMS) of acceleration responses of the vertical driver’s seat, pitching and rolling car body angles. The research results show that the PID controller for the car suspension system have an obvious impact on reducing the vibration and controlling the car body shaking in comparison with the passive suspension system.

June 30, 2020

Industrial Engineering

Journal of Mechanical Engineering, Automation and Control Systems

Novel and innovative insights to the field of mechanical engineering

APC

Free of charge

Best of Theme

Most cited

Research article

June 2, 2020

Optimization and modelling of mahua oil biodiesel using RSM and genetic algorithm techniques

By Aditya Kolakoti, Panchanand Jha, Prakasa Rao Mosa, Manohar Mahapatro, Tulasi Ganesh Kotaru

Most cited

Research article

August 11, 2021

Positioning algorithm for AGV autonomous driving platform based on artificial neural networks

By Patryk Bałazy, Paweł Gut, Paweł Knap

Most cited

Research article

November 28, 2019

Dynamic pressure on lock gate structure coupled with fluid

By Deepak Kumar Singh, Priyaranjan Pal, Shashi Kant Duggal

Most cited

Research article

October 19, 2020

An improved mesh stiffness calculation model of spur gear pair under mixed EHL friction with spalling effect

By Siyu Wang, Rupeng Zhu

You might also like

Most downloaded

Research Article

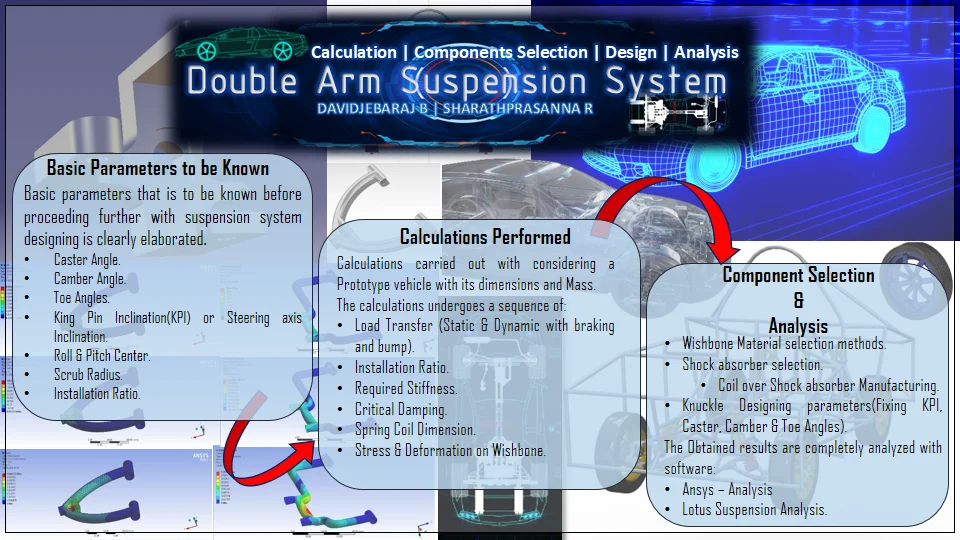

Design and calculation of double arm suspension of a car

By David Jebaraj B, Sharath Prasanna R

Suspension system is one of the challenging portions in designing a vehicle. The complete stability of the vehicle under dynamic conditions depends on the suspension system of the vehicle. Suspension system of a vehicle is interlinked with other systems such as steering, Wheels and Brakes. The main objective of this document is to provide complete guidance in designing and calculation of an independent suspension system with double control arms. The required parameters are calculated on considering a prototype vehicle with gross weight of 350 kg such as required stiffness of shock absorbers, Ride frequency, Motion ratio, Coefficient of damping etc. A CADD model was made with CATIA v5 r20 and SOLIDWORKS on the basis of calculations obtained and stress analysis was carried out for this model in various software such as Ansys. The complete assembled model was tested in LOTUS Shark and the result was obtained.

June 30, 2020

Industrial Engineering

Most downloaded

Research Article

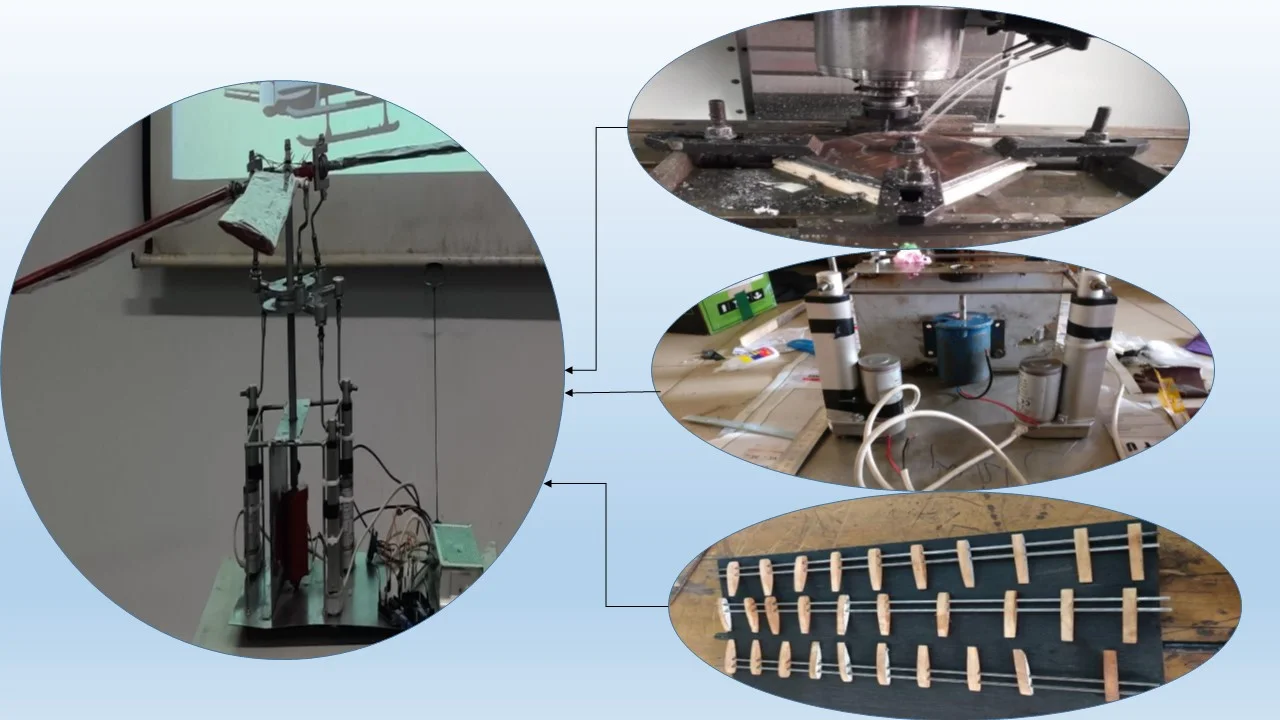

Design, analysis and fabrication of a fully articulated helicopter main rotor system

By Arafat Ahmed Shamol, Samin Yaser Ahmed, Md. Ariful Islam Shubho, Towsibur Rahman

This study describes an integrated framework in which the basic elements of Aerospace Engineering (performance, aerodynamics and structure) and functional elements (suspension, visibility and production) are integrated and considered. In this study, a fully functional rotor system has been fabricated that can be used as one of the training resources for Aeronautical students. For making the rotor system, various parts of the system have been designed on Solidworks and complete mechanism has been simulated with ANSYS. System analysis has been done at various RPM's and Angles of Attack (AOA). In terms of merit the right items have been selected and processed to provide them with the right shape. In terms of the design and implementation, various machines such as gas welding, arc welding, CNC milling and radial machinery have been used. Certain parts such as electric motors, linear actuators and loading cells have been used. All the fabricated components and electric motor, actuator, load cells are then assembled. This rotor system can produce less lift due to high dead weight and low power motor and having some safety issues.

June 11, 2021

Industrial Engineering

Mathematical modeling of first order process with dead time using various tuning methods for industrial applications

The proposed research involves Mathematical modeling for first order process with dead time using various tuning methods for industrial applications. Different tuning methods are proposed. Proposed method selection depends on plant operating conditions and also depending upon the process dynamics. The PID controller is most widely used for industrial process control. Modeling were developed for modified internal control model [4-6] in this proposed research. The proposed work is the modeling and simulation of three different first order processes with dead time. The standard controller tuning method is used to obtain the steady state response of first order with dead time.

Design of a high-payload Mecanum-wheel ground vehicle (MWGV)

With the rapid developments of Industry 4.0 and Smart Manufacturing, customized manufacturing has been becoming greatly needed. Meanwhile, the challenge of production automation has become more bigger, especially for the automation of moving, picking, placing and manipulating objects. Many researchers have begun to work on Autonomous Ground Vehicles (AGVs). Most AGVs were utilized to carry middle or small objects, as the high-payload AGVs were rarely developed. This paper focused on the design of a High-Payload Mecanum-Wheel Ground Vehicle (MWGV), which was 1.7 m wide and 2.04 m long. The weight of the vehicle was 740 kg and it was able to carry the payload as its own weight (i.e. around 7,300 N). The safety factor of the structural strength was greater than 1.66 and the safety factor of the axial design was at least 6.24. The vehicle was designed to carry 150-kg weight with a reach of 1.375 m without falling. The design of Mecanum wheels provided great flexibility on movement with small rotational radius. Mathematical descriptions about how Mecanum wheels were controlled was also introduced in this paper. Furthermore, the mechatronics and software integrations were demonstrated. The final experimental results showed the developed MWGV was able to perform the desired movement properly.