Abstract

In order to improve the anti-vibration properties and bearing capacity of solidified sludge, this article takes silt soil as the research object and selects sludge solidification materials with good solidification performance. The chemical element composition of muddy soil was analyzed using an energy dispersive X-ray spectrometer (EDS). The microstructure and characteristics of muddy soil and solidifying agent were characterized by transmission electron microscopy experiments (TEM). The optimal moisture content and maximum dry density of solidified sludge were analyzed using compaction tests. The unconfined compressive strength test was used to evaluate the bearing capacity and strength variation of solidified sludge. The vibration characteristics of sludge under different testing times and frequencies was studied. The research results indicate that the solidifying agent could reduce the moisture content of muddy soil significantly, improve the anti-vibration properties and bearing capacity of muddy soil effectively, which provide relevant basis for improving the performance and anti-vibration performance of solidified sludge used for roadbed filling. This study could provide innovative reference for the vibration and performance of solidified sludge used in roadbed filling.

Highlights

- The chemical element composition of muddy soil was analyzed using an energy dispersive X-ray spectrometer (EDS).

- The microstructure and characteristics of muddy soil and solidifying agent were characterized by transmission electron microscopy experiments (TEM).

- The vibration characteristics of sludge under different testing times and frequencies was studied.

1. Introduction

Mud has high moisture content, high organic matter and salt content, poor bearing capacity and engineering performance, and is prone to deterioration of bearing capacity under external vibration disturbance. It cannot be directly used for roadbed filling [1]-[2]. During engineering construction, the surface silt needs to be excavated and then backfilled with roadbed fill. The excavated silt not only occupies a large area of the site, but also occupies the surrounding farmland when selecting a borrow pit, seriously violating the sustainability and green development goals of the transportation industry [3]. Therefore, in practical engineering, it is particularly important to use curing agents for on-site solidification treatment of surface sludge to reduce project volume and cost. The regulations on silt soil are limited to treatment methods such as replacement and filling, stone throwing and squeezing, overloading and preloading, and back pressure protection [4]. They do not provide relevant guidance and suggestions for the construction of on-site solidified silt, and no control indicators for the construction of solidified silt have been proposed. At present, research on the solidification of sludge with solidifying agents at home and abroad is mostly limited to the types and dosages of solidifying agents under different initial moisture content conditions, as well as the performance of solidified sludge. However, there are few reports on the effects of the types and dosages of solidifying agents on sludge with different properties under the optimal moisture content conditions. Therefore, in this paper, the chemical element composition of muddy soil was analyzed using an energy dispersive X-ray spectrometer (EDS). The microstructure and characteristics of muddy soil and solidifying agent were characterized by transmission electron microscopy experiments. The optimal moisture content and maximum dry density of solidified sludge were analyzed using compaction tests. The unconfined compressive strength test was used to evaluate the bearing capacity and strength variation of solidified sludge. The vibration characteristics of sludge under different testing times and frequencies was studied. This study could provide references for the vibration and performance of solidified sludge used in roadbed filling.

2. Materials and methodology

2.1. Materials

2.1.1. Sludge

Representative sludge samples from the project site were selected for physical and chemical index testing to analyze the performance and characteristics of the shallow sediment in the project site, providing corresponding scientific basis for the selection and research of curing agents in the later stage. Based on the physical and chemical properties of the sediment samples from the project site, the specific test results are shown in Table 1.

Table 1Basic physical property indicators of sludge

Types | Initial moisture content (%) | Plastic limit (%) | Density (g/cm3) | Cohesive force (KPa) | Internal friction angle (º) |

sludge | 72.3 | 23.4 | 2.72 | 5.6 | 3.7 |

2.1.2. Curing agent

Modified methyl cellulose (hereinafter referred to as HC powder) belongs to the natural extraction type of bonding and solidification materials. This type of material, when added to the soil, forms a network or spatial structure, fills the pores in the soil, and binds the soil particles. Composite HC material with cement material and auxiliary materials to prepare sludge solidification agent CVH.

2.2. Methodology

2.2.1. EDS

The EDS energy spectrum analyzer model is EDAX, with a detection accuracy of 0~130eV. EDS can provide elemental analysis of sample surface micro areas, as well as point, line scan, and mapping analysis of specific areas.

2.2.2. TEM

The experiment was conducted using JEM-3010 (Japan Electronics Co., Ltd.) high-resolution transmission electron microscope (TEM). The maximum acceleration voltage of JEM-3010 is 300 KV, with a point resolution of 0.17nm and a maximum amplification factor of 1.5 million times.

2.2.3. Compaction test

Six compaction test samples were prepared with different moisture contents (7 %, 10 %, 13 %, 15 %, 18 %, 20 %). Heavy compaction is adopted and the heavy II method is used. The compaction test is conducted using a standard electric compaction instrument, with the instrument model DZY-II.

2.2.4. Unconfined compressive strength test

The unconfined compressive strength test uses the compressive strength testing machine, model HZ-1003B. The sludge is prepared as the test material under the optimal moisture content conditions according to the proposed curing agent dosage.

2.2.5. Vibration detection

The SE830I vibration sensor is used for vibration detection, mainly to detect the vibration acceleration of soil under different testing times and frequencies. The sensitivity of the vibration sensor is 100 mv/g, and the output impedance is less than 100 ohm.

3. Results and discussion

3.1. EDS

To analyze the elemental composition of silt soil, energy spectrum analysis was conducted using the JEM-3010 transmission electron microscope micro area composition analysis function. The experimental results are shown in Table 2. From Table 2, it can be seen that the main elemental composition of silt soil is Ca, Fe, O, and there are small amounts of metal elements such as Al and Mg.

Table 2Element composition table of silt soil

Material | Weight ratio / % | |||||||

C | O | Mg | Al | Si | K | Ca | Fe | |

Silt soil | 9.05 | 13.47 | 1.31 | 3.73 | 8.66 | 2.44 | 34.89 | 26.45 |

3.2. TEM

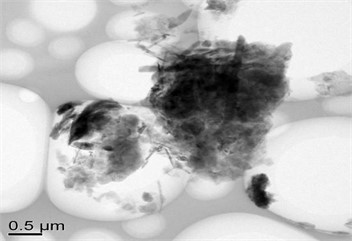

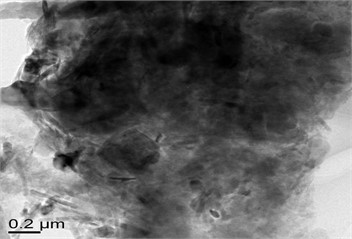

3.2.1. Sludge

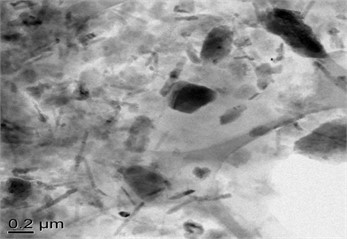

TEM testing was conducted on the silt using projection scanning electron microscopy to analyze the microstructure of the silt. The TEM test results of the silt under different resolution conditions are shown in Fig. 1. From Fig. 1, it could be seen that the shape and size of the silt particles are irregular, with uneven dispersion and agglomeration phenomenon. Further magnification of the sample reveals that the surface morphology and texture of the silt particles are unclear, presenting an irregular shape.

Fig. 1TEM result of sludge

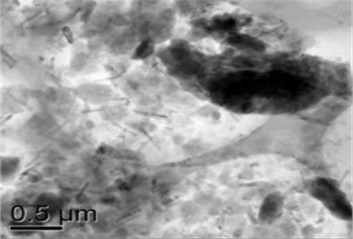

3.2.2. Curing sludge

From Fig. 2, it can be seen that the solidifying agent is uniformly dispersed in the silt soil. At the interface of the silt soil particles, the two cannot be clearly distinguished. The solidifying agent and the silt soil blend together, forming a protective film on the surface of the silt soil particles. At the same time, the particle size of the silt soil decreases, and the phenomenon of soil particle aggregation is significantly reduced. This is because the solidifying agent absorbs the water in the silt soil and enters between the soil particles, reducing the bonding force between the silt soil particles and making the soil particles more evenly dispersed, thereby making the structure of the silt soil particles more dense and enhancing the internal structure of the silt soil.

Fig. 2TEM result of curing sludge

3.3. Compaction test

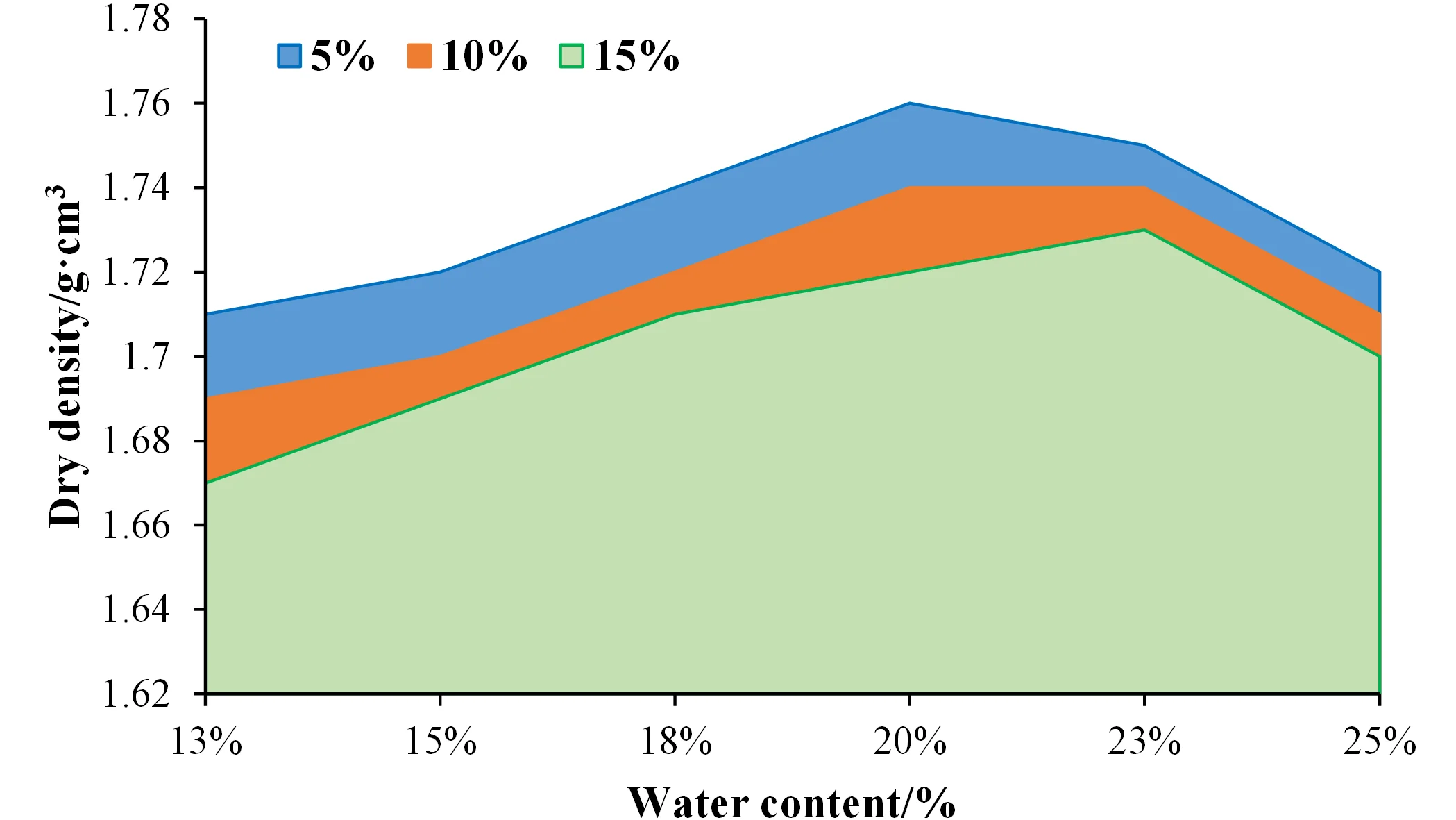

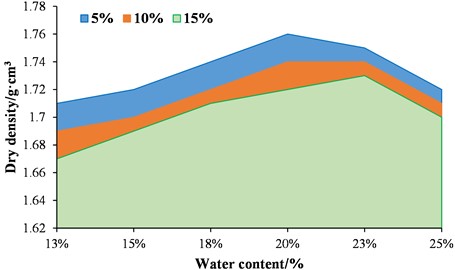

Six different moisture content compaction test samples, including 15 %, 18 %, 20 %, 23 %, 25 %, and 28 %, were prepared and the compaction test was conducted. Using heavy compaction, a total of 6 groups and 36 specimens were used. The compaction test results of the solidified sludge with CVH curing agent are shown in Fig. 3.

Fig. 3Compaction curve of solidified sludge with CVH curing agent

According to the compaction curve in Fig. 3, the optimal moisture content and maximum dry density corresponding to different curing agent dosages are shown in Table 3. From the above figure, it could be seen that after adding a certain amount of curing agent, the optimal moisture content of solidified sludge increases. When the dosage reaches a certain limit, the increase in the optimal moisture content is no longer significant, and the highest is generally around 25 %. The addition of curing agents not only affects the optimal moisture content, but also has an impact on the mechanical indicators such as the strength of solidified sludge.

Table 3Optimal moisture content and maximum dry density of solidified sludge

Curing agent dosage (%) | 5 % | 10 % | 15 % |

Optimal moisture content (%) | 21.4 % | 23.7 % | 24.6 % |

Maximum dry density (g/cm3) | 1.77 | 1.75 | 1.72 |

3.4. Unconfined compressive strength test

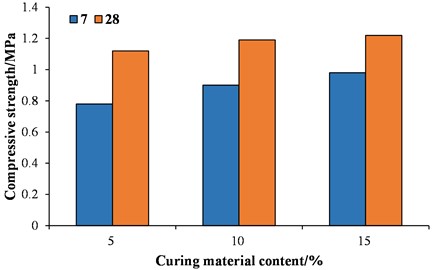

The results of the unconfined compressive strength test using CVH curing agent to solidify the sludge are shown in Fig. 4. According to the results of the unconfined compressive strength test of solidified sludge with CVH curing agent, it can be analyzed that the addition of CVH curing agent helps to improve the strength of solidified sludge. When the dosage of the curing agent increased from 0 to 15 %, the 7-days compressive strength of the sludge increased by 46.3 %, and the 28-days compressive strength increased by 16.2 %, indicating that the addition of the curing agent significantly improved the early strength of the solidified sludge. After solidification by CVH, the compressive strength of the sludge can meet the requirements of the specifications for the strength of the road subgrade.

Fig. 4Unconfined compressive strength of solidified sludge

3.5. Vibration detection

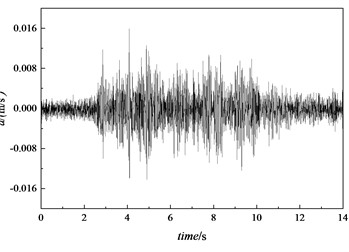

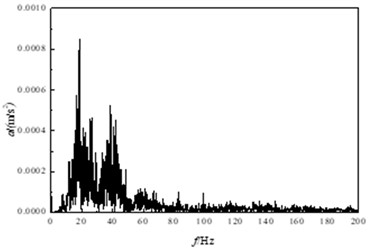

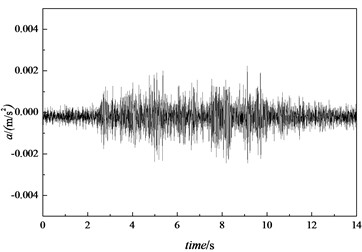

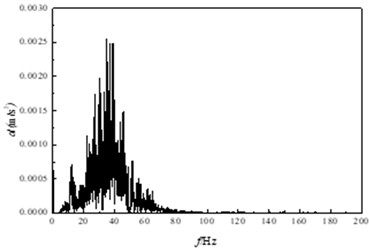

The results of the vibration detection of sludge and solidified sludge are shown in Figs. 5 and 6. According to the results of the vibration detection, unsolidified sludge exhibits significant vibration behavior under external loads. Within the full frequency range, the vibration acceleration of the sludge maintains a certain amplitude of variation. The variation is more significant in the low-frequency region, while stable vibration acceleration is maintained in the high-frequency region. For solidified sludge, the vibration acceleration changes are maintained within a small range. Under different frequency conditions, the solidified sludge only exhibits significant vibration acceleration peaks and variation patterns in the low-frequency region, and no significant vibration acceleration in the high-frequency region. This indicates that the solidified sludge has good strength and bearing capacity. When subjected to external loads, its internal vibration amplitude is relatively small and can remain stable overall.

Fig. 5Vibration detection result of unsolidified sludge

Fig. 6Vibration detection result of solidified sludge

4. Conclusions

1) The solidifying agent absorbs the water in the silt soil and enters between the soil particles, reducing the bonding force between the silt particles and making the soil particles more evenly dispersed.

2) After adding a certain amount of curing agent, the optimal moisture content of solidified sludge increases. When the dosage reaches a certain limit, the increase in the optimal moisture content is no longer significant, and the highest is generally around 25 %.

3) When the dosage of the curing agent increased from 0 to 15 %, the 7-days compressive strength of the sludge increased by 46.3 %, and the 28-days compressive strength increased by 16.2 %.

4) The solidified sludge has good strength and bearing capacity. When subjected to external loads, its internal vibration amplitude is relatively small and can remain stable overall.

References

-

J. Werther and T. Ogada, “Sewage sludge combustion,” Progress in Energy and Combustion Science, Vol. 25, No. 1, pp. 55–116, Feb. 1999, https://doi.org/10.1016/s0360-1285(98)00020-3

-

B. Wu, X. Dai, and X. Chai, “Critical review on dewatering of sewage sludge: Influential mechanism, conditioning technologies and implications to sludge re-utilizations,” Water Research, Vol. 180, p. 115912, Aug. 2020, https://doi.org/10.1016/j.watres.2020.115912

-

M. Schnell, T. Horst, and P. Quicker, “Thermal treatment of sewage sludge in Germany: a review,” Journal of Environmental Management, Vol. 263, p. 110367, Jun. 2020, https://doi.org/10.1016/j.jenvman.2020.110367

-

B. Yu et al., “Species, fractions, and characterization of phosphorus in sewage sludge: A critical review from the perspective of recovery,” Science of The Total Environment, Vol. 786, p. 147437, Sep. 2021, https://doi.org/10.1016/j.scitotenv.2021.147437

About this article

This paper describes research activities mainly requested and sponsored by Guizhou Transportation Planning Survey & Design Academe Co. Ltd. Technical Project under grant number ZLKY2023015.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.