Abstract

According to the characteristics of the soft soil subgrade in the Haiou Island section of Nansha Bridge, a comprehensive geological survey and soil analysis were conducted. Based on the analysis results, a corresponding design scheme for the soft soil subgrade was formulated to ensure bridge safety and stability. Furthermore, various reinforcement measures such as compaction, drainage, and lightweight soil were implemented to mitigate the impact of soft soil filling on the bridge structure. To evaluate the effectiveness of our treatment method, post-construction effect testing was performed using both static pressure and vibration acceleration methods. The static pressure method provided crucial parameters related to bearing capacity and compressibility of the soft soil subgrade while vibration acceleration analysis reflected response characteristics under dynamic load conditions. By comparing and analyzing results obtained from these two methods comprehensively evaluated feasibility of our treatment approach. Finally, based on experimental study findings and data analysis outcomes, it is recommended that post-construction effect testing for Haiou Island section's soft soil subgrade should employ both static pressure method and vibration acceleration method along with targeted reinforcement measures selected specifically to minimize adverse impacts on bridge structure.

Highlights

- CPT tests are carried out on loess after compacted lime soil.

- CPT has a strong advantage in the analysis of the effect of compacted pile in the treatment of pile length.

- Static penetration testing and vibration acceleration analysis to assess post-construction effectiveness of treatment methods.

1. Introduction

In coastal areas, the construction of highways often requires a significant number of bridges due to the presence of soft soil foundations. The connection between these bridges and highways necessitates the implementation of wide and high subgrades to ensure smooth road conditions [1-2]. However, if a thick layer of soft soil exists beneath the bridge abutment subgrade, lateral deformation occurs when bearing the load from the overlying embankment. Consequently, abutment piles endure lateral loads induced by horizontal soil movement, particularly during early stages of embankment construction where greater lateral earth pressure is exerted on already built abutment piles [3-5]. Furthermore, within the soft soil layer, an embankment slope may form a critical sliding surface whereby deep sliding surfaces pose risks for abutment piles located within their influence range as any movement or creep above this sliding belt generates substantial thrust on pile foundations that can result in foundation damage [6]. Additionally, considering that filling heights at bridge heads are generally high while soft soils have limited capacity for vertical loading; backfill pressures may exceed foundation soil's bearing capacity causing underlying soft soils to slip towards riverbanks thereby jeopardizing both safety aspects associated with abutment pile foundations and superstructures alike. Therefore, when constructing expressway bridges on coastal soft soil foundations it is imperative to thoroughly assess how roadbed filling affects pile foundations.

In the research by Franx et al. [7], they conducted a comprehensive analysis of the observational data from bridge and viaduct engineering, revealing significant deviations in the abutment and its pile foundation due to lateral soil deformation. These findings clearly demonstrate that the influence of embankment filling on adjacent abutment pile foundations extends beyond the construction period and persists for an extended duration on soft soil foundations.

Additionally, it is crucial to consider the creep behavior of embankment fillings behind platforms and their impact on adjacent abutment piles. To accurately determine the closest distance at which earth embankments affect existing pile-based structures, Heyman et al. [8] conducted a test involving earth embankment filling beside a building. The results indicated that when the distance between piles and embankment slope foot exceeded approximately four times the thickness of the underlying soft soil layer, any influence from embankment filling could be disregarded. Furthermore, Nicu et al. [9] performed field observations on abutment pile foundations constructed atop 13.5-meter-thick hard clay layers. The results revealed that when settlement in abutment wing walls reached 55 mm, noticeable lateral displacement towards the direction of embankments occurred. Therefore, it is crucial to fully consider the characteristics and effects of soft soil foundations in bridge and viaduct design and construction to ensure project stability and safety.

In light of this, this study aims to mitigate the impact of deep soft soil embankment filling on bridges through targeted design approaches for Nansha Bridge and Haiou Island interchange soft soil embankments. The contributions are the utilizing of static penetration testing and vibration acceleration analysis to evaluate the post-construction efficacy of treatment methods Through comprehensive data analysis and experimental research, we have derived a series of valuable conclusions that offer practical insights for similar projects.

2. Project overview

The Nansha Bridge, situated in Guangdong Province, China, serves as a crucial component of the Guanglong Expressway (S6) within the comprehensive planning of the Guangdong Expressway network. It bears the significant responsibility of connecting two major cities, namely Guangzhou and Dongguan, while serving as a primary thoroughfare for east-west traffic flow. The bridge commences at Dongchong Town in Nansha District, Guangzhou City, closely linked with the southern ring section of the main national highway - Guangzhou Ring Road - and also connects with the Guangzhu North Line Expressway. Subsequently traversing through Nansha District and Panyu District in Guangzhou City, it crosses Dasha Waterway, Haiou Island, and Nizhou Waterway before reaching Humen Port. Finally entering Shatian Town in Dongguan City, it seamlessly integrates with both the Guangshen Yanjiang Expressway and Pan-Dongguan Expressway. With a total length measuring 12.886 km, its geographical location holds immense significance.

The Nansha Bridge project commenced in late 2013 and, following nearly six years of rigorous construction, was officially completed and opened to traffic on April 2, 2019. This project adheres to the standard of a two-way eight-lane highway with a design speed of 100 km/h. The subgrade boasts a standard cross-section width of 41.0 m, while the bridge itself spans across an impressive width of 40.5m. Such grand proportions exemplify China's exceptional prowess in highway construction.

The Haiou Island Interchange Project constitutes a vital component within the broader Nansha Bridge endeavor. To mitigate any potential adverse effects stemming from soft foundation earth filling during the construction process, the engineering team must devise scientifically sound and rational treatment schemes while diligently evaluating their implementation. The site view is shown in Fig. 1.

Given the sequential construction of the bridge infrastructure and toll plaza, the engineering team faced the challenge of mitigating the pushing effect on piers during embankment filling in the deep soft foundation section. Particularly when dealing with a large fish pond adjacent to this section, effective control measures were crucial to ensure bridge safety and stability.

Fig. 1Site view of the bridge

3. Treatment plan design

The construction of the bridge lower structure predates the construction of the toll square, necessitating measures to prevent filling of the toll square roadbed on the bridge pier in the deep soft foundation section. To address this, the entrance ramp and exit ramp at the toll station employ increased bridge spans, cement mixing pile treatment, and light soil filling at their respective bridge heads, as shown in Figs. 2 and 3. Additionally, two layers of φ4.2 mm steel mesh are installed at both top and bottom surfaces of the light soil roadbed to enhance its cracking resistance. Mixing piles are also added near the ramp piers (which include high pier ramps and a fish pond on their outer side).

Fig. 2Construction of a lightweight soil roadbed at the bridgehead

Fig. 3Construction of cement mixing pile

The space between the ramp and the toll square is a deep soft-foundation fish pond, which has not undergone any treatment. Ordinary soil has been utilized to backfill the area in order to prevent displacement of the main bridge pier. Additionally, an extra back pressure revetment has been incorporated along the southern side of the ramp's section with deep soft-foundation fish pond. An 8 m wide back pressure revetment, filled with ordinary soil, has been constructed on the outer edge of the road. Firstly, filling was carried out on the southern side road, followed by filling of the toll square’s roadbed.

Bridge head employ bidirectional cement mixing pile treatment, with a spacing of 1.2 m and lengths ranging from 22.0-24.8 m. To facilitate beam construction, the preloading period for the plastic drainage plate section is eliminated to prevent excessive pressure on the main pier. Instead, coarse sand or stone chips are used to fill the roadbed at a pre-throwing height of 0.5 m. The roadbed and settlement compensation sections utilize gravel and sand filling for proper settlement compensation. Plastic drainage plates and preloading are employed for subsequent land delivery, while only a few village roads require cement mixing pile treatment due to their specific conditions. Cement mixing piles are implemented in place of level crossing drainage plate stacking to mitigate road traffic disruption caused by sea gulls, water and soil erosion, as well as splicing issues with intersecting sea gull roads.

4. Treatment effect identification

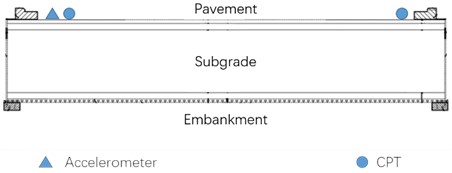

In order to assess the treatment effect, both vibration acceleration testing of the road surface and cone penetration testing (CPT) of the soil were conducted. The arrangement plan for the measuring points is illustrated in Fig. 4.

Fig. 4Measurement setup

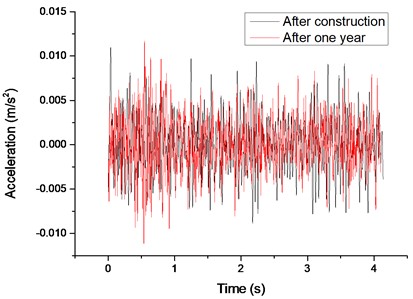

The results from the site test indicate the surface vibration acceleration of the road when vehicles pass through (Fig. 5). The vibration acceleration data were collected at the identical location, with a one-year interval, using consistent vehicles and under uniform weather conditions throughout the testing period. The acceleration time history curve at the measuring point shows a relatively smooth pattern after completion of treatment, suggesting no significant interference vibration source at the test site. After one year of operation, the ride quality at the site is comparable to that during construction, demonstrating effective subgrade treatment and reinforcement.

Fig. 5Vibration acceleration on the pavement

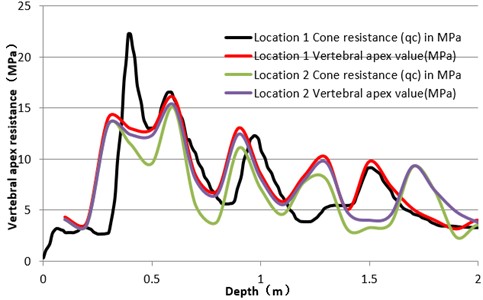

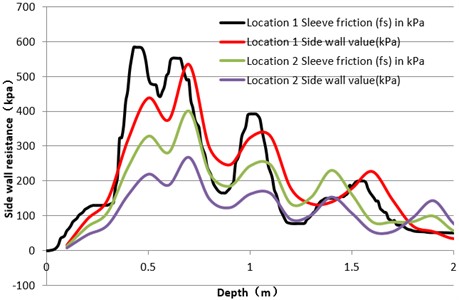

The physical and mechanical properties of the treated soft soil subgrade under treatment conditions were evaluated through CPT conducted at two designated sites, with a spacing of approximately 50 m between them. Similar to vibration measurements, CPT was also conducted at the same locations with one-year interval. The corresponding results are presented in Figs. 6 and 7.

Through field investigation, the aforementioned measures were implemented to mitigate the impact of deep soft soil filling on the constructed bridge piers. The road section for soft soil treatment exhibits a smooth profile, demonstrating commendable road capacity and favorable service conditions, as shown in Fig. 8. It is recommended to conduct displacement monitoring on the bridge piers within the soil filling segment.

Fig. 6Cone tip resistance and depth curve of treated soft soil

Fig. 7Curve of sidewall resistance and depth of treated soft soil

Fig. 8Photograph depicting the field effect after treatment

5. Conclusions

Firstly, considering the characteristics of the soft soil subgrade connecting Nansha Bridge and Haiou Island, we conducted comprehensive geological exploration and soil property analysis. Based on the analysis results, a suitable design scheme for the soft soil subgrade was formulated to ensure bridge safety and stability. Additionally, various reinforcement measures such as compaction, drainage, and lightweight soil were implemented to mitigate the impact of soft soil subgrade filling on the bridge structure.

Secondly, in order to accurately evaluate the effectiveness of the treatment method employed, post-construction effect testing was carried out using both static penetration method and vibration acceleration method. The static penetration method provided key parameters related to bearing capacity and compressibility of the soft soil subgrade while vibration acceleration analysis reflected dynamic load response characteristics of this type of subgrade material. By comparing and analyzing results obtained from these two methods comprehensively evaluated feasibility of our treatment approach.

Finally, based on experimental research findings and data analysis outcomes, it is imperative that both static penetration method and vibration acceleration method be utilized for post-construction effect testing of the soft soil subgrade corresponding to Nansha Bridge and Haiou Island. In addition, the selection of targeted reinforcement measures in the soft soil subgrade design is of paramount importance for mitigating adverse impacts on the bridge structure.

References

-

W. A. M. Ogila, “Effectiveness of fresh cement kiln dust as a soil stabilizer and stabilization mechanism of high swelling clays,” Environmental Earth Sciences, Vol. 80, p. 283, 2021.

-

H. Zhang and J. Wang, “Study on influencing factors of bearing capacity of cement mixing piles in Yasi highway subgrade,” Forest Engineering, Vol. 38, No. 6, pp. 124–129, 2022.

-

M. Xie, J. Zheng, J. Dong, and C. Miao, “Foundation improvement with lattice-shaped diaphragm wall treatment for high embankment culverts on soft foundation,” Tunnelling and Underground Space Technology, Vol. 104, p. 103535, 2020.

-

S. L. Lee and G. P. Karunaratne, “Treatment of soft ground by Fibredrain and high-energy impact in highway embankment construction,” Ground Improvement, Vol. 11, No. 4, pp. 181–193, 2007.

-

Z. Guan and Y. Wang, “CPT-based probabilistic liquefaction assessment considering soil spatial variability, interpolation uncertainty and model uncertainty,” Computers and Geotechnics, Vol. 141, p. 104504, 2022.

-

J. Harris, “The design and construction of a grade-separated interchange over soft alluvial and estuarine soils, A38 trunk road, Plymouth (England),” Quarterly Journal of Engineering Gelogy, Vol. 20, No. 3, pp. 199–220, 1987.

-

C. Franx and G. C. Boonstra, “Horizontal pressures on pile foundations,” in 2nd International Conference on Soil Mechanics and Foundation Engineering, 1948.

-

L. Heyman and F. Boersma, “Bending moments in piles due to lateral earth pressure,” in 5th International Conference on Soil Mechanics and Foundation Engineering (Rotterdam), 1961.

-

N. D. Nicu, D. R. Antes, and R. S. Kessler, “Field measurement on instrumental piles under an overpass abutment,” Highway Research Record, Vol. 354, pp. 90–102, 1971.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.