Biomechanics

Editor's pick

Research Article

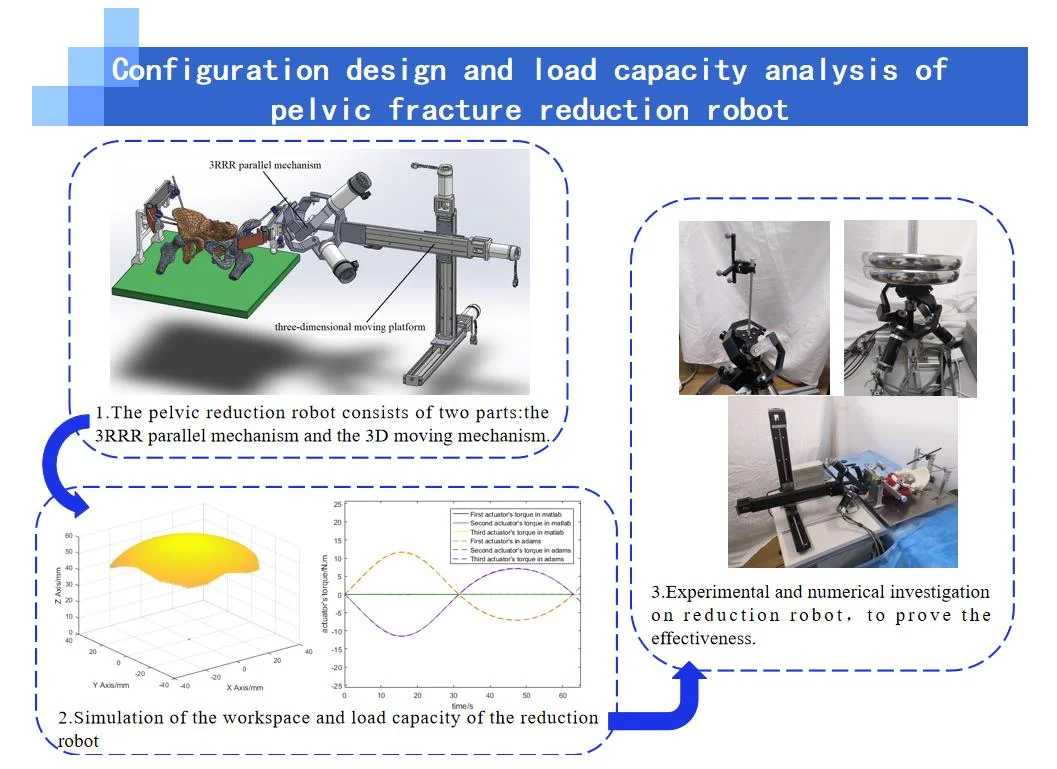

Configuration design and load capacity analysis of pelvic fracture reduction robot

By Shenyang Cai, Jingtao Lei, Jinjun Rao

Robot-assisted reduction of pelvic fracture requires large workspace and large load capacity. A kind of six degree-of-freedom (DOF) robot for pelvic fracture reduction is designed, which is a hybrid configuration composed of three-revolute-revolute-revolute (3RRR) parallel mechanism and three-dimensional guide rail. The hybrid configuration can ensure that the robot meet the needs of large workspace and large load capacity. Through the comparative analysis of dynamic and virtual prototype simulation, the reduction force of the designed reduction robot can reach 200 N. The experimental results show that the robot not only has the characteristics of high precision and high load of parallel robot, but also has the characteristics of large workspace of series robot.

April 13, 2023

Biomechanics

Most cited

Research Article

A portable breast cancer detection system based on smartphone with infrared camera

By Jian Ma, Pengchao Shang, Chen Lu, Safa Meraghni, Khaled Benaggoune, Juan Zuluaga, Noureddine Zerhouni, Christine Devalland, Zeina Al Masry

September 26, 2019

Biomechanics

Most cited

Research Article

Positioning algorithm for AGV autonomous driving platform based on artificial neural networks

By Patryk Bałazy, Paweł Gut, Paweł Knap

August 11, 2021

Biomechanics

Most cited

Research Article

Study of CO2 emissions from energy consumption in Spanish hospitals

By Justo García-Sanz-Calcedo

September 26, 2019

Biomechanics

Most cited

Research Article

A pilot study on automated quantitative grading of facial functions

By Amira Gaber, Mona F. Taher, Manal Abdel Wahed

April 2, 2020

Biomechanics

Robotic Systems and Applications

Research Article

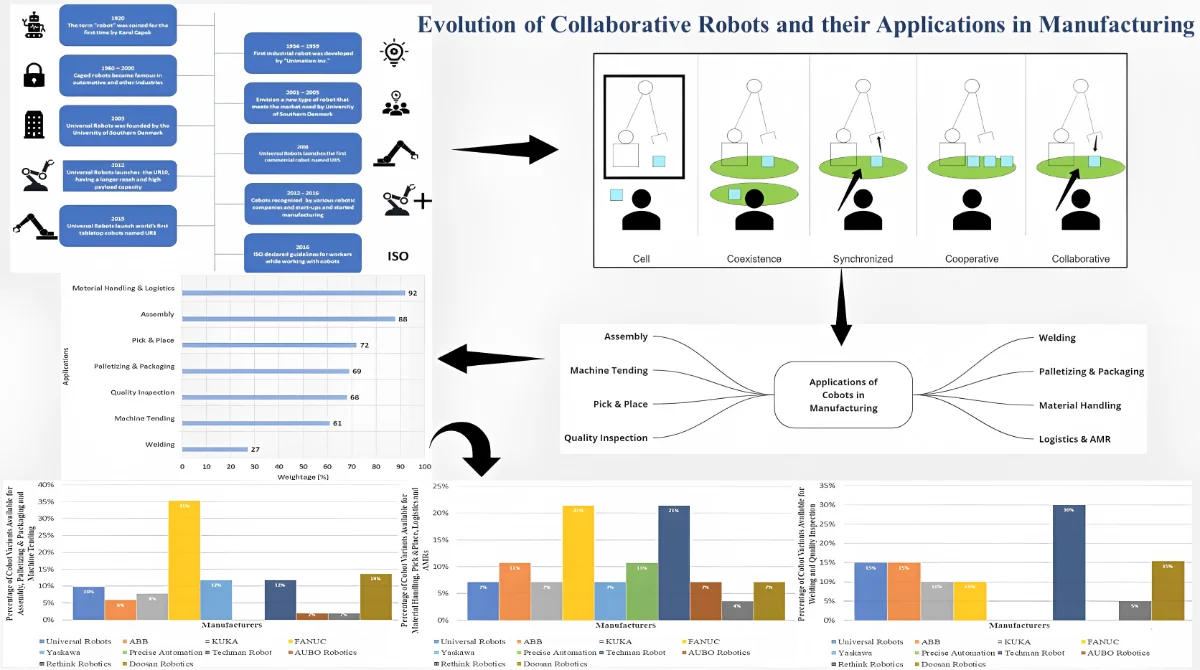

Applications of collaborative robots in agile manufacturing: a review

Collaborative robots are machines that work hand in hand with humans; or as the name suggests, collaborate with them in a specific workspace. These robots are not enclosed in confined safety zones like traditional robots, as they interact very closely with humans. Though this is the case, appropriate measures are captivated while designing these robots considering human safety. These robots are well-versed in adapting to changes and frequent upgrades. They are flexible enough to carry out complex tasks. Due to these abilities, they become a significant asset in the manufacturing field. It’s been many years now since cobots are introduced in the industry sector. So, this is the right time to review various applications of cobots in manufacturing. First, the paper starts with a brief introduction followed by an extensive literature review which was structured after reviewing 76 research papers and articles. It ends with some essential conclusions. This paper discusses the diverse applications of cobots used in the manufacturing sector and their advantages. Further, it highlights the future of cobots and how they will be a boon for a technology-driven world.

June 26, 2023

Biomechanics

Research Article

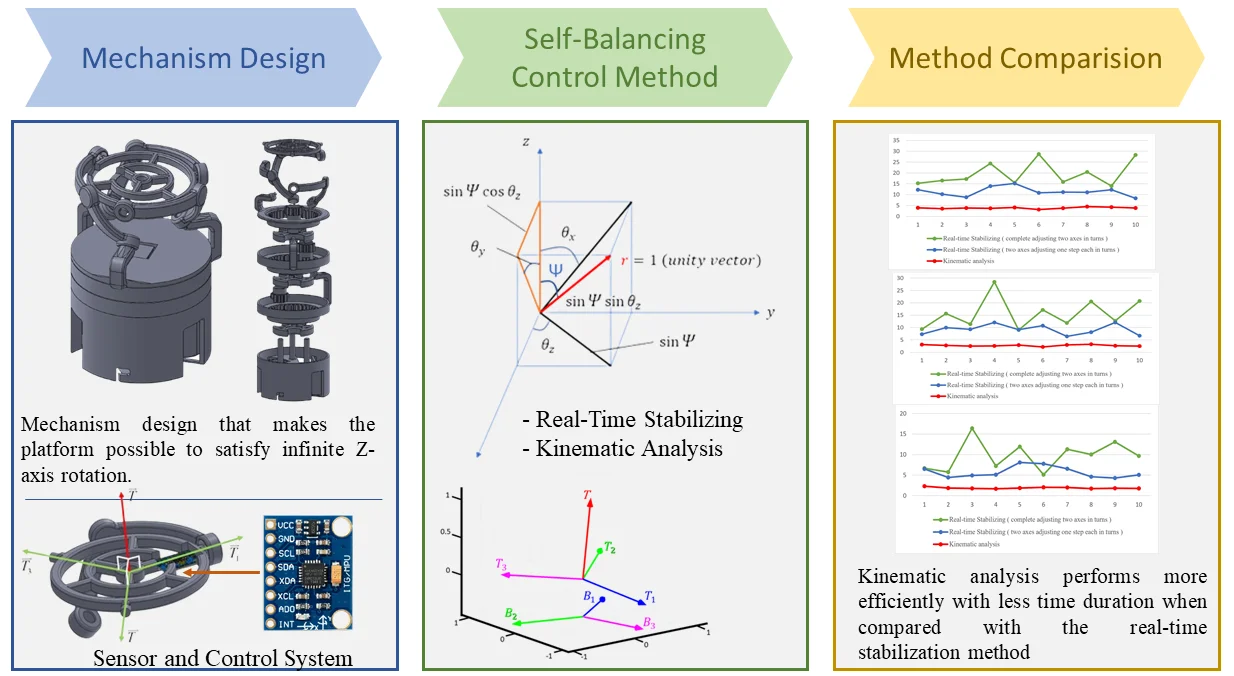

Designing and controlling a self-balancing platform mechanism based on 3-RCC spherical parallel manipulator

Motion control platforms have various applications in the manufacturing and automation industries. Different literature provides multiple issues related to the kinematics and dynamics of self-guided robots for transportation regarding platform balancing. Self-balancing platforms are utilized in many deliveries, stabilization, and transportation systems, and they are especially well suited for outdoor activities when the ground surface is not flat or structured. This paper describes developing a control technique for a self-balancing platform using the 3-RCC spherical parallel manipulator. This mechanism was designed to support an AGV (Automated Guided Vehicle) for transporting and lifting heavy weights for industrial applications. The AGV carries a robotic arm on top for different tasks. When the AGV encounters a steep slope or a rough surface, the AGV tilts, and the robotic arm’s performance is significantly affected. So, this study gives a solution to avoid these circumstances with a novel approach for the platform’s self-balancing mechanism consisting of a 3-RCC spherical parallel manipulator. Real-time stabilization and kinematics analysis methods are used to achieve the self-balancing system of the platform. When both methods are observed through different tilting angles for automation stability, Kinematic analysis performs more efficiently with less time duration when compared with the real-time stabilization method.

March 2, 2023

Biomechanics

Research Article

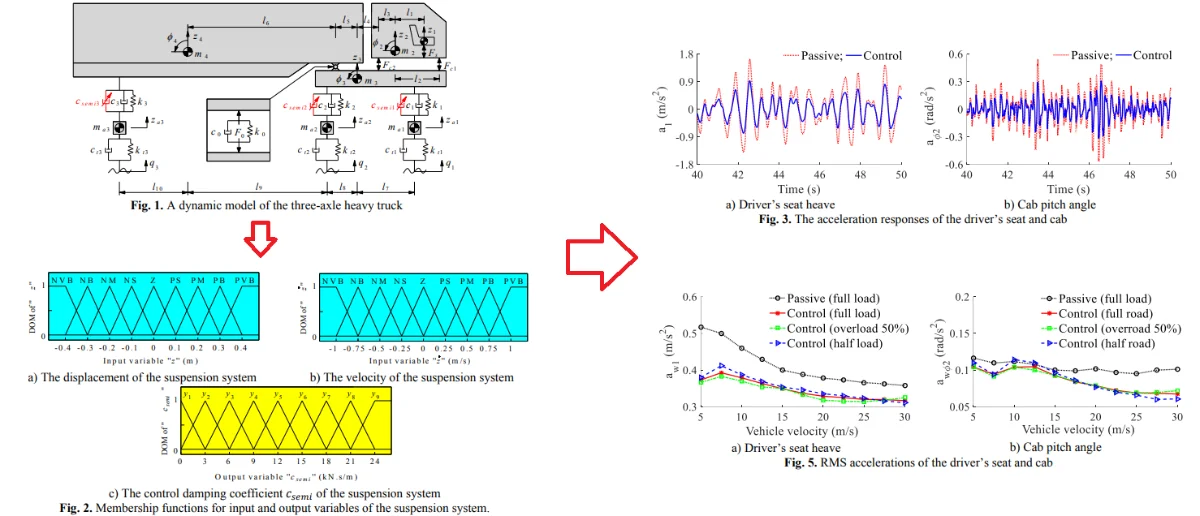

Improving ride comfort and road friendliness of heavy truck using semi-active suspension system

To enhance the ride comfort and improve the road friendliness of the heavy truck, based on the dynamic model of the heavy truck, the semi-active suspension system of the vehicle is proposed and controlled based on the fuzzy logic control and Matlab/Simulink software. The efficiency of the semi-active suspension system is then evaluated based on the indexes of the root mean square acceleration of the driver’s seat, the root mean square acceleration of the cab's pitching angle, and the dynamic load coefficient of the wheel axles. The results show that with the semi-active suspension system of the heavy truck controlled by the fuzzy logic control, the acceleration responses of the heavy truck and the dynamic forces of the wheel axles are greatly reduced in comparison with the passive suspension system under various operating conditions of the loads and speeds. Especially, with the semi-active suspension system controlled by the fuzzy logic control, the root mean square accelerations of the driver’s seat and cab pitch angle; and the dynamic load coefficient at 2nd axle of the wheel are clearly reduced by 23.7 %, 27.2 %, and 20.9 % in comparison with the passive suspension system, respectively. Thus, both ride comfort and road friendliness of the heavy truck are improved by the semi-active suspension system. In addition, the vehicle load insignificantly affects ride comfort. However, it greatly affects the road damage, especially with the half load condition of the vehicle. Thus, to improve road friendliness, the full load condition of the vehicle should be used.

March 13, 2023

Biomechanics

Research Article

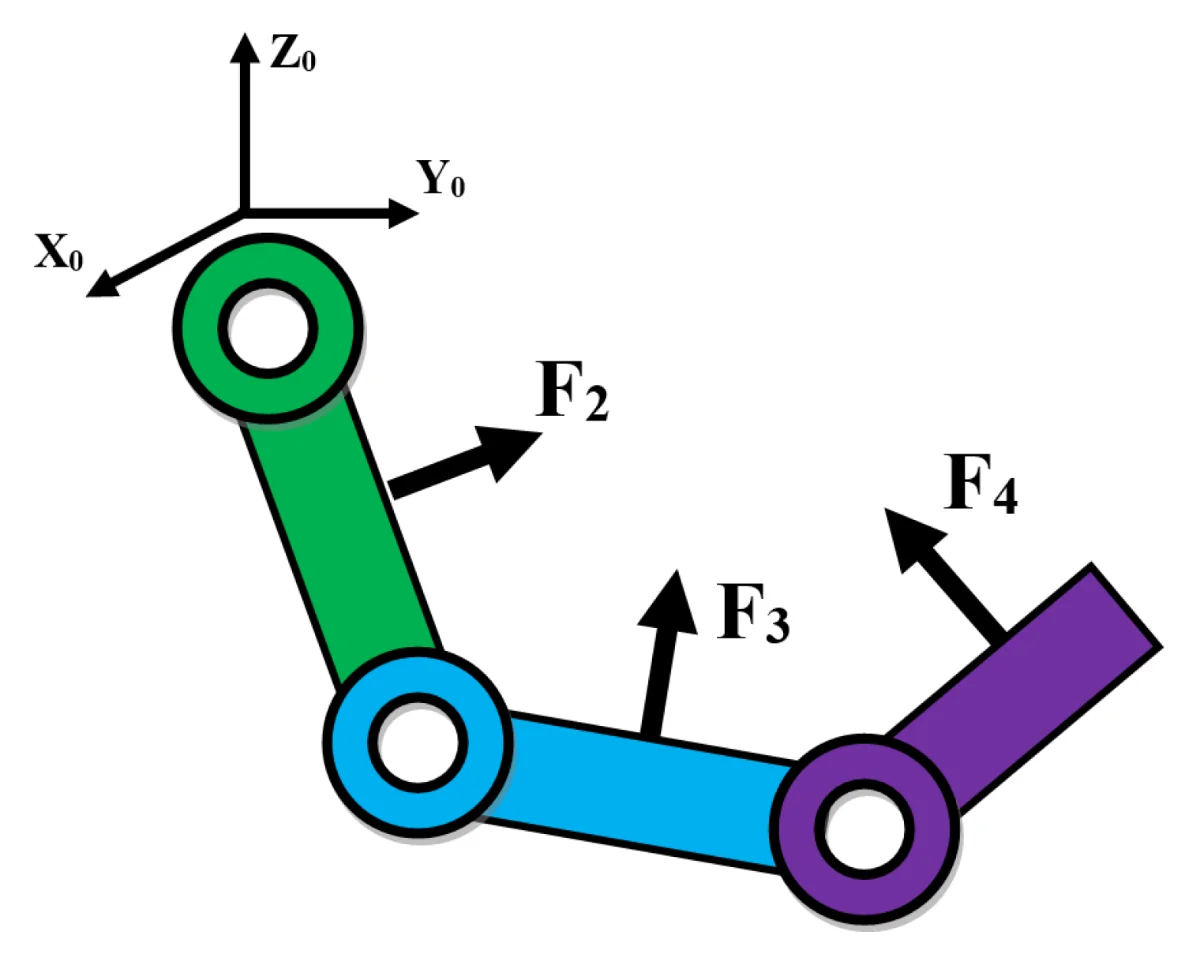

Feedback hybrid force and position control of an upper limb exoskeleton to support human movement

In the paper, a feedback hybrid control including a force feedback control and a position control is proposed to control a four degree of freedom (4-dof) upper limb exoskeleton for supporting human movement at the shoulder, elbow and wrist joints. The novelty of the paper is that it has been able to control all the interaction forces at all links in the exoskeleton robot by using the proposed control. The desired interaction forces at the links and desired position are compared with the measured interaction forces and position, respectively. Then the torque at the shoulder, the torque elbow and the torque wrist joints are controlled to compensate the force error and the position error. The gains of the proposed controller are optimized by using the Balancing Composite Motion Optimization (BCMO). The simulation and control of the 4-dof upper limb exoskeleton using the proposed control is carried out in the paper to show that the interaction forces and the position of the exoskeleton track their desired values.

November 19, 2023

Biomechanics

Robotic Systems and Applications

Fundamental and applied aspects in robotics

APC

Free of charge

Best of Theme

Most cited

Research article

May 15, 2020

Hybrid artificial genetic – neural network model to predict the transmission of vibration to the head during whole-body vibration training

By M. Alshabi, N. Nawayseh, M. Bettayeb

Most cited

Research article

August 15, 2019

Design and simulation analysis of an improved wearable power knee exoskeleton

By Fangzheng Wang, Lei Yan, Jiang Xiao, Lei Fan

Most cited

Research article

October 19, 2019

Level set medical image segmentation aided by cooperative quantum particle optimization with Lévy flights

By Desheng Li, Na Deng, Xu Chen

Most cited

Research article

February 11, 2023

Developing of a wearable ankle rehabilitation robotic device

By Nursultan Zhetenbayev, Gani Balbayev, Duisebayeva Aknur, Algazy Zhauyt, Beibit Shingissov

You might also like

Most downloaded

Research Article

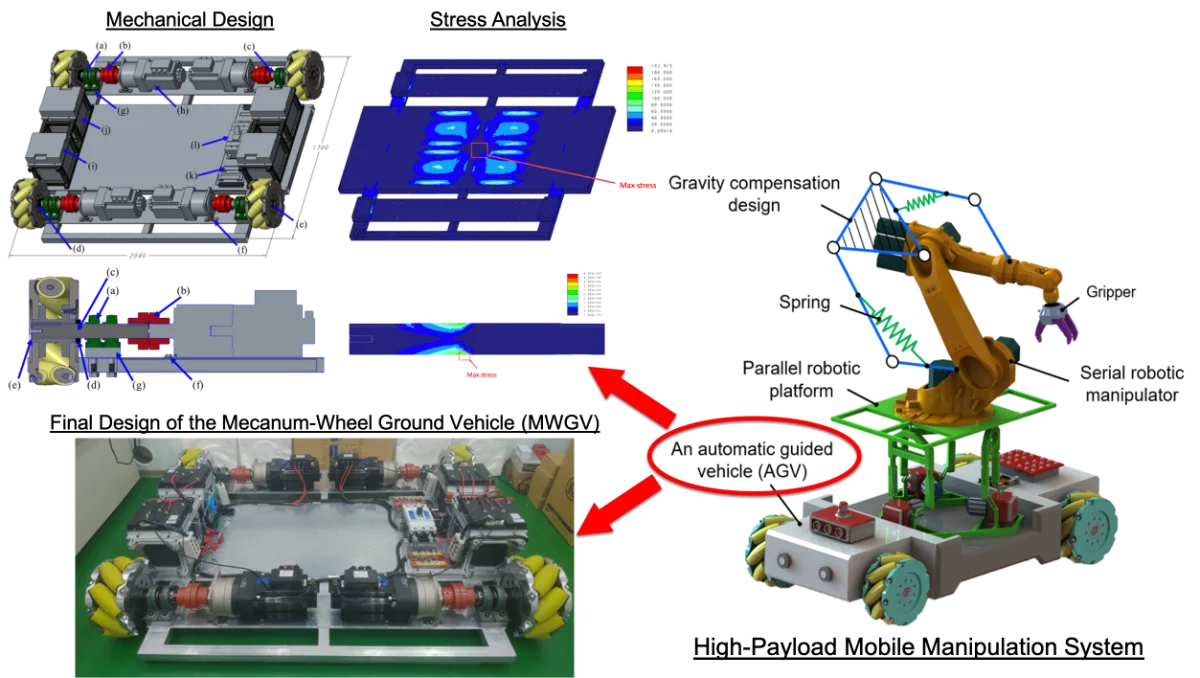

Design of a high-payload Mecanum-wheel ground vehicle (MWGV)

By Zi-Yin Chen, Pei-Ren Liaw, Vu Linh Nguyen, Po Ting Lin

With the rapid developments of Industry 4.0 and Smart Manufacturing, customized manufacturing has been becoming greatly needed. Meanwhile, the challenge of production automation has become more bigger, especially for the automation of moving, picking, placing and manipulating objects. Many researchers have begun to work on Autonomous Ground Vehicles (AGVs). Most AGVs were utilized to carry middle or small objects, as the high-payload AGVs were rarely developed. This paper focused on the design of a High-Payload Mecanum-Wheel Ground Vehicle (MWGV), which was 1.7 m wide and 2.04 m long. The weight of the vehicle was 740 kg and it was able to carry the payload as its own weight (i.e. around 7,300 N). The safety factor of the structural strength was greater than 1.66 and the safety factor of the axial design was at least 6.24. The vehicle was designed to carry 150-kg weight with a reach of 1.375 m without falling. The design of Mecanum wheels provided great flexibility on movement with small rotational radius. Mathematical descriptions about how Mecanum wheels were controlled was also introduced in this paper. Furthermore, the mechatronics and software integrations were demonstrated. The final experimental results showed the developed MWGV was able to perform the desired movement properly.

June 30, 2021

Biomechanics

Most downloaded

Research Article

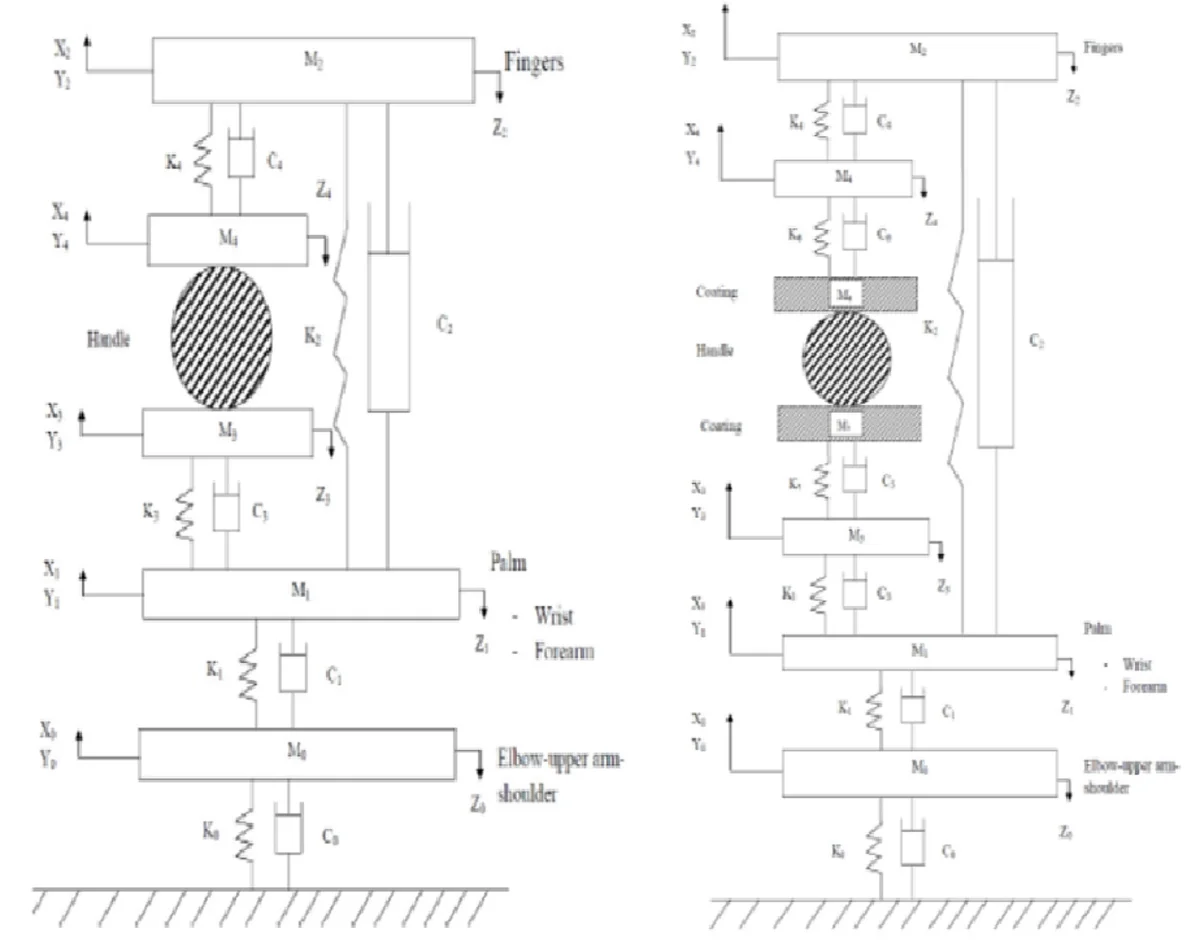

An analytical study – dynamic behavior of the human hand to hold mechanical handle with and without coating

By Jain A. R. Tony Benedict, Alphin Masilamany Santha

The primary objective of the study is analytically predicting the anti-vibration coating on the handles and to evaluate the vibration isolation effectiveness. The ISO 10068:2012 two-point driving human physical models are coated with Foam-A material, Foam-B material, and Gel material. The coated ISO models are applied to predict the effectiveness of three different anti-vibrations coating in terms of vibration transmitted to the finger, palm, and the shoulder. The results are obtained as a vibration transmissibility magnitude in the three orthogonal directions (xh, yh, zh) and the results are also compared with uncoated models. A significant level of vibration reductions was found. The proposed model may also be useful for further analysis of anti-vibration coating materials and help designers to develop better handles for vibrating tools.

December 13, 2018

Biomechanics

On application of dynamical system methods in biomedical engineering

The spectrum of various methods and tools used for solving bioengineering problems is sufficiently wide. Dynamical systems (including the symbolic ones) in many cases become a base for design and implementation of methods of investigation and computer modeling complex processes. Whereas for solving direct problems we have many well-developed methods, results for inverse problems are much more modest. We discuss two methods for such tasks: Takens’ method for reconstruction attractor by a time series, and the based on ideas of symbolic dynamics method for digital image analysis using stationary flow on graph and weighted entropy. The results of numerical experiments are given.

Control system design of multi-dimensional lumbar traction treatment bed

A multi-dimensional lumbar traction treatment bed is designed with two degrees of freedom, which can realize controllable traction treatment of lumbar through flexion, extension and rotation motion. Two linear actuators are used to provide motion. Building a mathematical model of the device by least squares identification. PID controller and Kalman filter constitute two groups of control modes: (i) speed control; (ii) position control. Using MATLAB to perform simulation experiments. The results show that the designed controller can achieve high control accuracy. The motion speed of lumbar platform is stable and the position of traction treatment set by user is approached exactly, which ensuring the security and stability of this device.