Abstract

The problems of subgrade settlement failure and uneven settlement are quite prominent due to hydraulic migration. The loess in the natural state has the characteristics of high strength and low compressibility. Composite foundation method is to set a certain proportion of reinforcement (pile) in the natural foundation, so that the pile and soil jointly bear the load, and has the effect of compaction method and displacement method. Based on the actual case of a highway disease in Shanxi Province, this paper studies the influence of treatment measures of rotary jet grouting pile penetrating or not penetrating the loess soil on the uneven settlement of highway subgrade in loess region by means of field investigation, analysis and numerical calculation. The results found that the lateral friction resistance of rotary-jet grouting pile penetrates through the loess is small. When the rotarjet pile is long and the underlying soft layer is relatively thick (4.5 m), the settlement of the foundation also quickly enters the stable state. When the underlying loess is deep, the settlement of the foundation increases with time.

Highlights

- The problems of subgrade settlement failure and uneven settlement are quite prominent due to hydraulic migration.

- Composite foundation method is to set a certain proportion of reinforcement (pile) in the natural foundation.

- When the underlying loess is deep, the settlement of the foundation increases with time.

1. Introduction

Shanxi Province, China is located in the temperate continental monsoon climate, four distinct seasons, rain and heat synchronization. The distribution of precipitation in the province is uneven with the seasons, the precipitation is relatively concentrated from June to August in summer, and the distribution of precipitation in the province is greatly affected by topography. The problems of subgrade settlement failure and uneven settlement are quite prominent due to hydraulic migration. The loess in the natural state has the characteristics of high strength and low compressibility. Once it is affected by water, the soil structure will be destroyed rapidly, additional subsidence will occur, strength sag will occur, and deformation will increase suddenly [1]. Because of the special properties of loess, various engineering diseases are common in road engineering. For example, the settlement of the high fill embankment is uneven, the bearing capacity of the foundation is low, and the roadbed cracks. The deformation and destruction of column foundation caused by load friction seriously harm the maintenance of roadbed.

Composite foundation method is to set a certain proportion of reinforcement (pile) in the natural foundation, so that the pile and soil jointly bear the load, and has the effect of compaction method and displacement method [2]. The specific methods are high-pressure rotary jet, powder jet pile, lime soil compaction pile and so on. High-pressure rotary-jet grouting method is to use a drill to drill the grouting pipe with a nozzle into the predetermined depth of the soil layer, and then spray the slurry or water from the nozzle at a pressure of 20-40 MPa to form a jet to impact and destroy the soil layer. The treatment of collapsible loess by high pressure rotary jet grouting can not only improve the bearing capacity of foundation soil, but also reduce the settlement. Consoli et al. [3] conducted triaxial compression and unconfined compressive strength tests for soil-cement characteristics, and the test results showed that the unconfined compressive strength of soil-cement increased linearly with the decrease of porosity of the mixture and the increase of cement content. Consoli et al. [4] analyzed several factors affecting the stiffness and strength of soil-cement and pointed out that the ratio of porosity to cement incorporation is a more appropriate index to evaluate the unconfined compressive strength and initial stiffness of soil-cement. Alamgira et al. [5] proposed a theoretical method to simply predict the deformation characteristics of pile and soil around pile after soft soil foundation is strengthened by gravel pile, lime pile, compacting sand pile or soil-cement pile.

According to the investigation, the rotary-jet grouting pile has good effect in most cases. However, some piedmont sections and multi-layer loess sections have too large settlement after construction. The reason for this phenomenon may be that the distance between geological holes is large, the geological changes of some piedmont sections are great, and the geological data do not fully reflect the actual situation. The pile length is designed according to the geological prospecting data, which leads to the situation that the pile hanging does not penetrate the loess layer. In addition, this phenomenon may also be found in the case of multi-layer interbedded loess areas, where multi-layer loess is distributed and the design only penetrates one layer, or the design scheme adopts suspended rotary-jet pile.

Therefore, based on the actual case of a highway disease in Shanxi Province, this paper studies the influence of treatment measures of rotary jet grouting pile penetrating or not penetrating the loess soil on the uneven settlement of highway subgrade in loess region by means of field investigation, analysis and numerical calculation, in order to provide reference for similar projects.

2. Project summary

A highway was built according to the standard of two-way four-lane highway with a design speed of 80 km/h. It was officially opened to traffic on October 16, 2014. The geology along the road is mostly collapsible loess and red clay with weak expansibility. The terrain along the road is complicated, and it is hot and rainy in summer, and dry and snowy in winter. The climate difference is obvious. After its operation, Cokelin expressway was affected by loess subsidence, geological landslide and other adverse geological disasters, alternating changes of temperature and humidity environment, vehicle load and surface water erosion and other factors. Many diseases such as roadbed and pavement subsidence and slope water destruction appeared along the expressway, which seriously affected the road comfort and posed great potential safety risks.

The main disease form of roadbed along the line is subgrade subsidence. With the aggravation of roadbed disease, longitudinal or fan-shaped cracking, subsidence and middle zonal cracking occur on the road surface, as shown in Fig. 1.

Fig. 1The subsidence of the subgrade caused the road surface to crack

a)

b)

The main causes of roadbed diseases are as follows:

1) The area where the highway is located is dominated by loess, with typical collapsibility, permeability and macro porosity, which is easy to disintegrate in case of water. This special structure is beneficial to rainfall infiltration, and the cementation ability of the soil under the drainage system decreases after flooding, resulting in foundation settlement and deformation. In case of extreme rainfall, water flow will further cut away and form a cavity in the lower part of the protective engineering foundation, and soil particles will quickly mix with water to form mud, which will continuously wash the lower part of the foundation until damage occurs.

2) In the area where the highway is located, the loess vertical joints are developed and the gullies are deeply cut, so the slope is large, so some drainage ditches are designed with large slope. However, rainfall occurs frequently in summer, and it is a short period of heavy rainfall. The drainage ditches of large longitudinal slope promote the ability of water scour, resulting in intense erosion of soil at the foot of slope. If the surface runoff fails to discharge the ditch smoothly, the rainfall will overflow the ditch and scour the broken surface, forming secondary damage. In addition, part of the drainage ditch design is too long or small size, resulting in a large flow, cannot quickly discharge water; No reasonable protection and energy dissipation measures have been set up at the inlet and outlet of ditches, resulting in scouring and destruction at the inlet and outlet sections.

3) The damage of drainage channels of some road sections caused a large area of drainage to scour the slope, and the slope protection facilities were more than the protection capacity. After the drainage damage, the slope body suffered large area of soil erosion. Under the repeated erosion of rainfall for many years, the water flows back to the filling soil under the emergency driveway after the loss of slope soil, resulting in the settlement of the subgrade under the emergency driveway, thus causing the settlement of the road surface.

For the subsidence disease of road surface, which belongs to the vertical subsidence disease of subgrade, it is advisable to use high-pressure rotary jet grouting pile to treat it.

Specific as follows:

1) Rotary jet grouting piles are arranged according to the quincunx shape, with pile spacing of 1.5 m, row spacing of 1.3 m and pile diameter of 50 cm.

2) The use of water cement ratio of 1:1 (weight ratio) cement slurry, cement strength grade is not less than 32.5 Portland cement, add solid strength should not be less than 3 MPa.

3) The construction of single tube method is adopted. The grouting pressure is 20-25 MPa, the rotary spraying speed is 30-40 r/min. The lifting speed is 0.25-0.3 m/min. The diameter of the nozzle is 2-3 mm. The slurry flow is 80-120 L/min. The cement consumption per meter is not less than 234.6 kg. The grouting quantity per meter is not less than 0.352 m3.

3. Numerical model

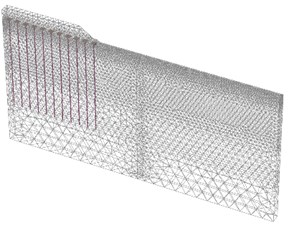

The highway section was selected for numerical analysis, which was filled with 4.8m high soil and treated by rotary jet grouting pile. See Table 1 and Table 2 for the distribution and model parameters of cross-section soil layer. Loess adopts the elastoplastic model, and other foundation soil and embankment fill adopts the harden soil model. The established section is shown in Fig. 2.

Fig. 2Finite element model

Table 1Physical and mechanical parameters of soil layers

Layers | Thickness (m) | Density (Kg/m³) | Natural porosity ratio | Cohesion (kPa) | Friction angle (°) | Horizontal permeability coefficient (cm/s) | Vertical permeability coefficient (cm/s) |

Artificial filled soil layer #1 | 1.6 | 18.9 | 0.943 | 10.6 | 24.7 | 1.2×10-7 | 1.2×10-7 |

Artificial filled soil layer #2 | 1.4 | 18.9 | 0.943 | 10.6 | 24.7 | 1.2×10-7 | 1.2×10-7 |

Collapsible loess #1 | 11.3 | 16.4 | 1.762 | 9.5 | 11.2 | 0.8×10-7 | 0.8×10-7 |

Collapsible loess #2 | 7.5 | 17.4 | 1.301 | 9.5 | 11.2 | 1.3×10-5 | 1.3×10-7 |

Silty #1 | 2.7 | 17.8 | 1.379 | 13.8 | 24.0 | 2.0×10-7 | 2.0×10-7 |

Silty #2 | 9.5 | 17.6 | 1.266 | 13.8 | 24.0 | 3.0×10-7 | 3.0×10-7 |

Embankment fill | 4.8 | 19.0 | 0.60 | 10.0 | 23.0 | – | – |

Table 2Design parameters of high-pressure jet grouting pile

Section | Buried depth of loess (m) | Treatment depth of jet grouting pile (m) | Thickness of loess underlying layer (m) |

1 | 24.5 | 25.0 | Break through |

2 | 23.8 | 20.0 | 3.8 |

3 | 23.8 | 15.0 | 8.8 |

4 | 23.8 | 10.0 | 13.8 |

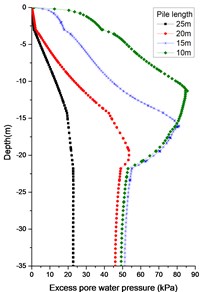

4. Analysis of consolidation condition of foundation

Fig. 3 shows the time-varying curve of soil excess pore pressure at different depths below the center line of subgrade. It can be seen from the figure that the excess pore pressure in foundation soil accumulates gradually during embankment filling, but the excess pore pressure in the strengthened soil is significantly smaller than that in the underlying soil. After preloading, the excess pore pressure in foundation soil decreases rapidly during unloading. The excess pore pressure dissipated to zero almost 6 years after the pavement construction resumed.

Fig. 3Variation curve of excess pore water pressure of soil along the centerline with depth (end of filling)

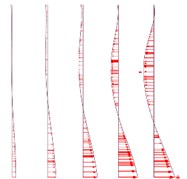

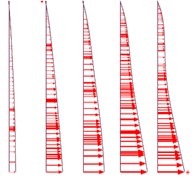

5. Horizontal displacement of pile body (15 years after construction)

As shown in Fig. 4, Rotary jet grouting pile driving through the loess: compared with the end of filling, 15 years after construction, the horizontal displacement of pile top and pile tip has little change, and the horizontal displacement of the middle part of the pile is inverted inward, and the maximum inverted displacement of the pile is 6.3 mm.

The rotary jet grouting pile does not penetrate the loess: compared with the end of filling, the horizontal displacement of pile body continues to increase, especially when the pile length is 10 m, the maximum horizontal displacement of pile bottom reaches 19.11 cm 15 years after construction, and there are hidden dangers in foundation stability.

Fig. 4Horizontal displacement distribution diagram of pile with different length

a) 25 m

b) 20 m

c) 15 m

d) 10 m

6. Foundation settlement and post-construction settlement

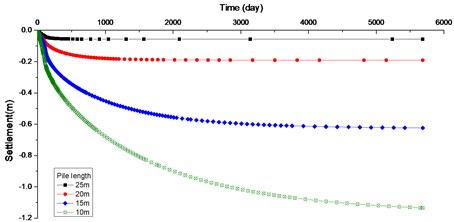

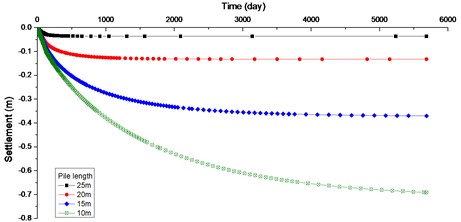

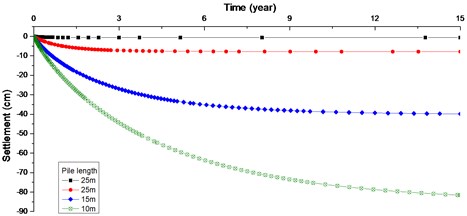

When the rotary-jet grouting pile penetrates the loess soil (pile length 25 m), the settlement of the foundation quickly reaches a stable state, and the total settlement of the foundation is small (0.06 m) and the post-construction settlement is small (0.66 cm), as shown in Figs. 5 to 7.

When the soft layer is not thick (4.5 m), the settlement of the foundation quickly enters a stable state. The settlement and post-construction settlement of the foundation are both within the limit of the code. After 15 years, the post-construction settlement value of the foundation is 7.86 cm.

When the pile length is 10 m and the soft underlying layer is 13.8m thick, the ground settlement and the soft underlying layer settlement still do not reach a stable state 15 years after construction. The foundation settlement value is 1.13 m and the post-construction settlement reaches 81.61 cm. The bottom of the pile is inserted into the underlying loess layer 0.44 m.

Fig. 5Curve of foundation settlement with time

Fig. 6Curve of pile bottom settlement with time

Fig. 7Curve of settlement of foundation after construction with time

7. Conclusions

This paper studies the influence of treatment measures of rotary jet grouting pile penetrating or not penetrating the loess soil on the uneven settlement of highway subgrade in loess region by means of field investigation, and the following conclusions are drawn: 1) Rotary-jet grouting pile penetrates through the loess: the lateral friction resistance of rotary-jet grouting pile penetrates through the loess is small, but the long friction resistance and tip reaction of rotary-jet grouting pile entering into the bearing layer are large. The settlement value of the foundation after construction is small and can be controlled within the limit value of the code. 2) The rotary jet grouting pile does not penetrate into the soil: the pile produces a large horizontal displacement, and the horizontal displacement of the pile increases gradually along the depth, and the horizontal displacement of the pile tip is the largest. The horizontal displacement of the pile tip (external extrusion) increases with the shorter the length of the rotary jet grouting pile and the greater the thickness of the soft underlying layer. 3) The rotarjet pile does not penetrate the loess: when the rotarjet pile is long and the underlying soft layer is relatively thick, the settlement of the foundation also quickly enters the stable state, and the settlement and post-construction settlement of the foundation are within the limit of the specification. 4) The rotary-jet pile does not penetrate the loess: when the underlying loess is deep, the settlement of the foundation increases with time. The settlement of the ground surface and the settlement of the weak underlying layer still did not reach a stable state 15 years after construction, and the penetration value of the pile body into the weak underlying layer was very large.

References

-

E. Levenberg, “Analysis of pavement response to subsurface deformations,” Computers and Geotechnics, Vol. 50, pp. 79–88, May 2013, https://doi.org/10.1016/j.compgeo.2012.12.011

-

J.-B. M. Dassekpo, X. Zha, and J. Zhan, “Synthesis reaction and compressive strength behavior of loess-fly ash based geopolymers for the development of sustainable green materials,” Construction and Building Materials, Vol. 141, pp. 491–500, Jun. 2017, https://doi.org/10.1016/j.conbuildmat.2017.03.034

-

N. C. Consoli, D. Foppa, L. Festugato, and K. S. Heineck, “Key parameters for strength control of artificially cemented soils,” Journal of Geotechnical and Geoenvironmental Engineering, Vol. 133, No. 2, pp. 197–205, Feb. 2007, https://doi.org/10.1061/(asce)1090-0241(2007)133:2(197)

-

N. C. Consoli, A. V. D. Fonseca, S. R. Silva, R. C. Cruz, and A. Fonini, “Parameters controlling stiffness and strength of artificially cemented soils,” Géotechnique, Vol. 62, No. 2, pp. 177–183, Feb. 2012, https://doi.org/10.1680/geot.8.p.084

-

M. Alamgir, N. Miura, H. B. Poorooshasb, and M. R. Madhav, “Deformation analysis of soft ground reinforced by columnar inclusions,” Computers and Geotechnics, Vol. 18, No. 4, pp. 267–290, Jan. 1996, https://doi.org/10.1016/0266-352x(95)00034-8

About this article

Funding support (No. 20-JKKJ-32, No. 18-JKKJ-23) of Shanxi Transportation Holdings Group Co., LTD, National Natural Science Foundation of China (51808329) are appreciated.