Abstract

Matrix and SBS modified asphalt mortar were prepared by replacing mineral powder with cement under different filler-asphalt ratios. The variation laws of ductility, softening point, penetration, cone penetration, and Brookfield rotational viscosity of the two kinds of pastes with filler-asphalt ratio were studied. The shear strength of the two kinds of asphalt mortar was calculated. And the viscosity-temperature curve was established. The best filler-asphalt ratio was recommended. The results show that the addition of cement and the increase of filler-asphalt ratio will reduce the ductility, penetration, and cone penetration of asphalt mortar, while improve the softening point, shear strength, and viscosity. In a specific range of filler-asphalt ratios, cement can improve the high-temperature performance of asphalt mortar without significant impact on the low-temperature performance.

1. Introduction

The modern mortar theory states that asphalt mortar plays a crucial role in the viscoelasticity of the asphalt mixture as a first-stage dispersion system [1-3]. Asphalt mortar comprises asphalt and filler, which have complex and diverse interactions. A filler can affect the thickness of asphalt film and then affect the adhesion of asphalt and the stiffness of the asphalt mixture. Thus, it is essential to study the influence of filler on mortar performance [4-6].

At present, limestone powder is widely used in engineering for its well bonding with asphalt. Research indicates that slaked lime has an alkaline effect on cement, which can improve the high and low temperature performance of asphalt mortar as well as the water stability of asphalt mixtures [7]. The high and low-temperature properties of the mortar can be improved when the replacement amount of cement was no more than 40 %. Furthermore, the high-temperature properties of the mortar were improved when the replacement amount of hydrated lime was no more than 20 % [8]. Chen et al. investigated the effects of temperature and powder/binder ratio on the performance of asphalt mortar mixed with limestone mineral powder, cement and coal fly ash. The research showed that reduced temperature or increased filler-asphalt ratio improved the rutting resistance of the mortar with a disadvantageous influence on the low-temperature performance [9-10]. Chen and Li found that replacing all mineral powder with cement improved the workability of the asphalt mixture [11-12].

The existing research has primarily concentrated on the cement to mineral powder ratio, with only a handful of studies delving into the filler-asphalt ratio of cement and the compatibility of cement with various types of asphalt. The aim of this paper is to establish a connection between the filler-asphalt ratio and the high and low-temperature performance, as well as shear performance, of both matrix asphalt and SBS modified asphalt mortar. Furthermore, the paper seeks to suggest the optimal filler-asphalt ratio.

2. Material and methods

2.1. Raw material

The asphalts selected in this test are SK 90# and SBS modified asphalt. The softening point, penetration, and 5℃ ductility of SK 90# base asphalt are 46 ℃, 89 (0.1 mm), and 7.1 cm, respectively, and that of SBS modified asphalt is 61 ℃, 99 (0.1 mm), and 13.5 cm, respectively. The cement is P·O42.5 produced by Jidong Cement Plant with no agglomeration on the cement surface and screened through a 0.075 mm sieve, of which the loss on ignition is 1.59 %, and the content of magnesium oxide is less than 1.94 %.

2.2. Experimental design and mortar preparation

The filler-asphalt ratio is 0.8, 1.0, 1.2, 1.4, and 1.6, respectively. The cement, base asphalt, and SBS modified asphalt were put into a 140 ℃ oven for 1h to ensure that the temperature difference between cement and asphalt was slight [13]. The cement was added in three times to prevent the cement from agglomerating rapidly under the action of asphalt surface tension and affecting the uniformity of asphalt mortar. It was mixed close to the bottom of the container during the mixing process to avoid precipitation and ensure the mortar remained uniform.

2.3. Test methods

The tests of ductility are carried out at 5 °C and 15 °C, and penetration are carried out at 25 °C. The shear strength are carried out at 145 °C, 155 °C, 165 °C and 175 °C, respectively. Lastly, Brookfield rotational viscosity is determined at 185 °C for test purposes. In addition, with reference to the penetration test method, the penetration depth of asphalt mortar at 45 ℃ is evaluated by the cone penetration test (penetration mass is 94.69 g), and the shear strength of the two kinds mortar is calculated according to the cone penetration value [14]. The standard deviation is to be calculated and a graph with error bars is to be plotted, based on five repetitions for each experimental group.

3. Results and discussion

3.1. Ductility analysis

The mean and standard deviation of five repeated experiments in each group were calculated to draw a column chart with error bars. Based on Eq. (1), the confidence interval (CI) with a confidence level of 95 % was computed. The CI, being an interval, can be expressed as:

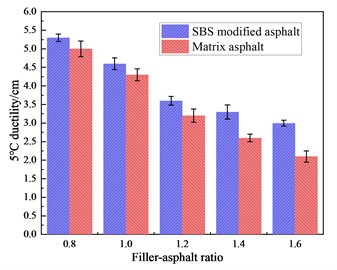

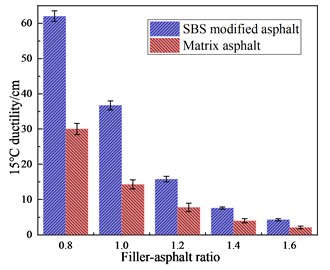

where μ represents the sample mean, σ represents the sample standard deviation, and Z represents the critical value corresponding to a 95 % confidence level. As a result, the experimental results are distributed within the 95 % confidence interval (CI). Fig. 1 and Fig. 2 depict the ductility changes of matrix asphalt mortar and SBS modified asphalt at temperatures of 5 °C and 15 °C.

The ductility of the asphalt emulsion decreases with increasing filler-asphalt ratio, whereas the ductility of the matrix asphalt and SBS modified asphalt mortar measure 30 cm and 62 cm, respectively. During the tensile process, the middle part elongates uniformly as filaments, and the fracture exhibits typical viscous failure. However, when the filler-asphalt ratio exceeds 1.2, the ductility reduces significantly, and the fracture form transitions from viscous to brittle, indicating that the cement filler has a substantial impact on the asphalt mortar's ductility. To ensure desirable asphalt mortar properties at low temperatures, the filler-asphalt ratio is typically not allowed to exceed 1.2 in mix proportion design for engineering applications. Additionally, at the same temperature and filler-asphalt ratio, SBS modified asphalt mortar exhibits better ductility than base asphalt mortar because SBS modification provides better low-temperature performance, and cement does not alter the structure of modified asphalt.

Fig. 1Ductility of mortar at 5 ℃

Fig. 2Ductility of mortar at 15 ℃

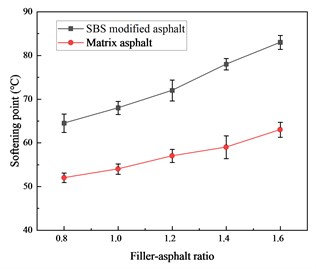

3.2. Softening point analysis

Fig. 3 shows the variation trend of softening point of different asphalt pastes with filler-asphalt ratio. It can be seen from the figure that the softening point of asphalt mortar after adding cement was higher than that of matrix asphalt. For both base asphalt and SBS modified asphalt, the softening point of mortar gradually increases, with the increase of filler-asphalt ratio. In addition to promoting asphalt mortar hardening, cement was shown to have positive effects. Cement content increases asphalt mortar hardening, indicating that cement can enhance asphalt mortar’s performance at high temperatures, and the greater filler-asphalt ratio led to the better high-temperature performance.

Fig. 3Softening point changes with filler-asphalt ratio

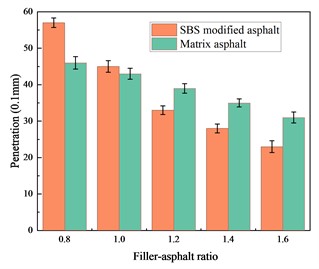

Fig. 4Penetration varies with the filler-asphalt ratio

3.3. Shear strength analysis

In this section, we present the results of an investigation into the effect of cement filler on the penetration of asphalt mortar. Fig. 4 illustrates the penetration variation law with filler-asphalt ratio. The addition of cement to asphalt mortar resulted in a significant decrease in penetration when compared to matrix asphalt. The penetration of both asphalt mortars decreased as the filler-asphalt ratio increased, with the downward trend being more pronounced in SBS modified asphalt mortar. The interaction between asphalt and cement resulted in the rearrangement of asphalt on the cement surface, forming a film with a specific thickness. This asphalt film was structural and determined the cohesion between particles, ultimately affecting the viscosity of asphalt mortar.

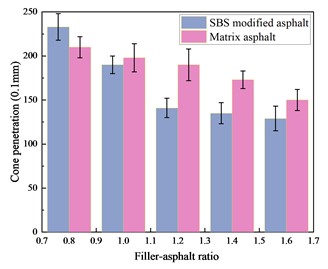

We also analyzed the variation of cone penetration with the change of filler-asphalt ratio at 45 ℃, as shown in Fig. 5. We found that both penetration and cone penetration exhibited the same trend of decrease with increasing filler-asphalt ratio. In comparison to the base asphalt mortar, SBS modified asphalt mortar demonstrated a more significant reduction in both penetration and cone penetration. As the filler-asphalt ratio increased from 0.8 to 1.2, the cone penetration of SBS and matrix asphalt mortar decreased by 39.5 % and 9.5 %, respectively, while the penetration decreased by 42.1 % and 15.2 %, respectively. These results indicate that cement filler has a more pronounced effect on the high-temperature performance of SBS modified asphalt compared to matrix asphalt.

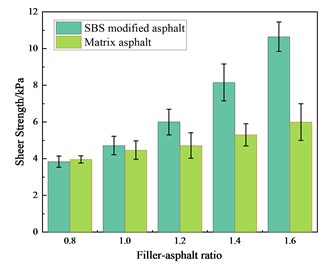

In order to further reflect the change in asphalt mortar performance with filler-asphalt ratio, the cone penetration of two kinds of asphalt mortar under different filler-asphalt ratios was calculated by penetration, as shown in Fig. 6. The shear strength increased with the filler-asphalt ratio for matrix and SBS asphalt mortar. The increase of shear strength of SBS asphalt mortar was higher than that of matrix asphalt. The shear strength more intuitively reflected the influence of filler-asphalt ratio on the high-temperature performance of asphalt mortar. Although the shear strength of the two kinds of asphalt mortar increased with the filler-asphalt ratio, the penetration and cone penetration of asphalt mortar should also be fully considered to ensure the workability of the mixture, so that the filler-asphalt ratio is not recommended to be too large.

Fig. 5Cone penetration changes with filler-asphalt ratio

Fig. 6Shear strength changes with filler-asphalt ratio

3.4. Analysis of viscosity-temperature characteristics

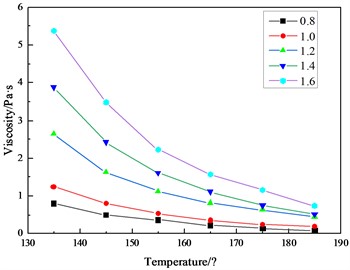

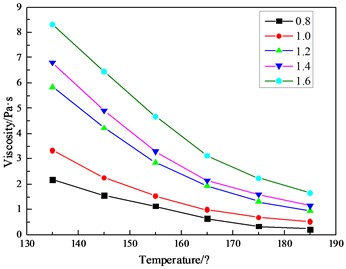

The viscosities of the two asphalt pastes at five powder to binder ratios and 135 ℃, 145 ℃, 155 ℃, 165 ℃, 175 ℃, and 185 ℃ were measured by Brookfield DV II rotary viscometer and 27# rotor, and the viscosity-temperature curves shown in Fig. 7 and Fig. 8. The viscosity of the two asphalt pastes decreased with the increase in temperature and increased with the increase of filler-asphalt ratio. The two asphalt pastes showed the same trend with the temperature change, denoting that increasing the filler-asphalt ratio can significantly improve the viscosity of asphalt mortar. The greater filler-asphalt ratio contributed to more significant hardening effect of asphalt mortar. Furthermore, the greater the viscosity is more beneficial the water stability of the asphalt mixture. However, it is suggested that the filler-asphalt ratio should be controlled between 1.0-1.4, considering the construction workability and mixing uniformity.

The viscosity and temperature of two kinds of asphalt mortar under different filler-asphalt ratios were regressed according to Eq. (2):

where y is the viscosity of asphalt mortar (Pa·s), x is the temperature (℃), A and B are the regression coefficient. Table 1 shows the viscosity-temperature regression analysis of matrix asphalt mortar and SBS modified asphalt mortar under different filler-asphalt ratios. With the increase of filler-asphalt ratio, there is a gradual increase in the regression coefficient A for both matrix and SBS asphalt mortar. The index B also gradually increased, indicating that greater temperature sensitivity corresponded to greater viscosity of asphalt mortar. The A value of SBS asphalt mortar is always greater than that of matrix asphalt mortar, indicating that its viscosity is significantly higher than that of matrix asphalt mortar. By comparing the value of B, the B value of matrix asphalt mortar was greater than that of SBS modified asphalt when the filler-asphalt ratio was 0.8 to 1.2.

Fig. 7Viscosity-temperature curve of matrix asphalt mortar

Fig. 8Viscosity-temperature curve of SBS modified asphalt mortar

Table 1Regression analysis of asphalt mortars viscosity-temperature curves

Filler-asphalt ratio | Types of asphalt mortar | Regression equation | Correlation coefficient R2 |

0.8 | Matrix asphalt | y=1.2746e-0.4390X | R2= 0.9947 |

SBS modified asphalt | y= 3.9747e-0.4770X | R2= 0.9981 | |

1.0 | Matrix asphalt | y= 1.7149e-0.3766X | R2=0.9934 |

SBS modified asphalt | y= 4.7553e-0.3790X | R2= 0.9982 | |

1.2 | Matrix asphalt | y= 3.4004e-0.3446X | R2= 0.9878 |

SBS modified asphalt | y= 8.6129e-0.3714X | R2= 0.9984 | |

1.4 | Matrix asphalt | y= 5.4832e-0.3964X | R2= 0.9948 |

SBS modified asphalt | y= 9.8037e-0.3636X | R2= 0.9929 | |

1.6 | Matrix asphalt | y= 7.6038e-0.3885X | R2= 0.9949 |

SBS modified asphalt | y= 12.128e-0.3390X | R2= 0.9929 |

4. Conclusions

1) With the increase of filler-asphalt ratio, the ductility value shows a decreasing trend, indicating that the addition of cement reduced the low-temperature performance of asphalt mortar.

2) The softening point of the two kinds of asphalt mortar increased gradually with the increase of filler-asphalt ratio, and the filler-asphalt ratio improved the high-temperature performance of asphalt mortar.

3) The penetration and cone penetration rates of the two asphalt mortars decrease with an increase of the filler-asphalt ratio. The shear strength also reflected that the filler-asphalt ratio increased the viscosity of the two kinds of asphalt mortar.

4) The viscosity of the two asphalt pastes decreases with the increase of temperature under the same filler-asphalt ratio. The viscosity of matrix and SBS asphalt mortar was increased with the increase of filler-asphalt ratio. The regression analysis showed that the elevated filler-asphalt ratio increased the viscosity and temperature sensitivity of asphalt mortar.

5) The high-temperature performance of asphalt mortar improved with the increase of filler-asphalt ratio, while the low-temperature performance decreased. To balance the high and low-temperature performance, the filler-asphalt ratio is recommended 1.2.

References

-

H. Chen, C. Niu, D. Kuang, J. Tian, and K. Yang, “Effects of fillers on viscoelastic response of recycled asphalt cement,” Journal of Zhengzhou University Engineering Science, Vol. 38, No. 2, pp. 72–77, 2017, https://doi.org/10.13705/j.issn.1671-6833.2017.02.016

-

H. T. T. Nguyen, T. V. Tu, V.-R. Phan, and B.-G. Phan, “Analysis of stress and strain in flexible pavement structures comprised of conventional and high modulus asphalt using viscoelastic theory,” in Critical Thinking in the Sustainable Rehabilitation and Risk Management of the Built Environment, pp. 207–219, 2021, https://doi.org/10.1007/978-3-030-61118-7_18

-

H. Zhang, L. Meng, and G. Zhang, “Comparative study on mechanical performance of asphalt-cement mortar and emulsified asphalt-cement mortar,” Road Materials and Pavement Design, Vol. 18, No. 5, pp. 1239–1250, Sep. 2017, https://doi.org/10.1080/14680629.2016.1202857

-

G. Zeng, L. Liu, and F. Bai, “A damage-coupled viscoplastic model for compressed asphalt concrete,” in Journal of Physics: Conference Series, Vol. 1748, No. 6, p. 062059, Jan. 2021, https://doi.org/10.1088/1742-6596/1748/6/062059

-

J. Han, G. Zhao, X. Xiao, and X. Jin, “Effect of cement asphalt mortar damage location on dynamic behavior of high-speed track,” Advances in Mechanical Engineering, Vol. 10, No. 4, p. 168781401877077, Apr. 2018, https://doi.org/10.1177/1687814018770779

-

J. Ouyang, J. Zhao, and Y. Tan, “Modeling mechanical properties of cement asphalt emulsion mortar with different asphalt to cement ratios and temperatures,” Journal of Materials in Civil Engineering, Vol. 30, No. 10, p. 04018, Oct. 2018, https://doi.org/10.1061/(asce)mt.1943-5533.0002480

-

C. Xing, Z. Liang, Y. Tan, D. Wang, and C. Zhai, “Skeleton filling system evaluation method of asphalt mixture based on compressible packing model,” Journal of Transportation Engineering, Part B: Pavements, Vol. 147, No. 4, p. 04021, Dec. 2021, https://doi.org/10.1061/jpeodx.0000320

-

Y. Liu, F. Wang, W. Zhang, and S. Hu, “Rheological properties of sulfoaluminate cement-asphalt emulsion paste,” Journal of Materials in Civil Engineering, Vol. 31, No. 1, p. 04018, Jan. 2019, https://doi.org/10.1061/(asce)mt.1943-5533.0002546

-

T. Chen, Y. Luan, T. Ma, J. Zhu, X. Huang, and S. Ma, “Mechanical and microstructural characteristics of different interfaces in cold recycled mixture containing cement and asphalt emulsion,” Journal of Cleaner Production, Vol. 258, p. 120674, Jun. 2020, https://doi.org/10.1016/j.jclepro.2020.120674

-

P. Nanthavisit, “Influence of cement and asphalt emulsion ratios on cement-asphalt emulsion mortar,” International Journal of Geomate, Vol. 17, No. 64, pp. 77–84, Dec. 2019, https://doi.org/10.21660/2019.64.08722

-

T. Chen, T. Ma, X. Huang, S. Ma, F. Tang, and S. Wu, “Microstructure of synthetic composite interfaces and verification of mixing order in cold-recycled asphalt emulsion mixture,” Journal of Cleaner Production, Vol. 263, p. 121467, Aug. 2020, https://doi.org/10.1016/j.jclepro.2020.121467

-

C. Li, Z. Liu, J. Chen, and Q. Yuan, “Comparative research on tensile properties of cement-emulsified asphalt-standard sand (CAS) mortar and cement-emulsified asphalt-rubber particle (CAR) mortar,” Materials, Vol. 13, No. 18, p. 4042, Sep. 2020, https://doi.org/10.3390/ma13184042

-

G. Nie et al., “Designing of an anti-rutting and high ductility asphalt mixture based on mortar performance,” Construction and Building Materials, Vol. 316, p. 125837, Jan. 2022, https://doi.org/10.1016/j.conbuildmat.2021.125837

-

C. Yang, J. Li, Z. Zhu, S. Wang, and Y. Liu, “Characterization of sulphoaluminate cement-asphalt emulsion mortar for cement and asphalt mortar repair,” Frontiers in Materials, Vol. 7, p. 101, May 2020, https://doi.org/10.3389/fmats.2020.00101

About this article

The research was supported by the Transportation Science and Technology Project in Shaanxi Province (No. 20-16 K), the Key R&D Program in Shaanxi Province (No. 2022GY-422).

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.