Abstract

In asphalt pavement thermal regeneration, incorporation of regenerant can restore the properties of aged SBS modified asphalt, but the effect of regenerant on the recovery of aged asphalt and the dosage of regenerant are not clear. In this study, experiments are carried to determine the effect of regenerant on the performance of aged SBS modified asphalt and the appropriate dose. Accelerated aging test is conducted by rolling thin film oven test (RTFOT) at different times. Then, different doses of regenerant (2 %, 4 %, 6 %, 8 %, 10 %, 12 %) are added to the specimens before and after aging, and test its technical indexes such as penetration, softening point and ductility to analyze the effect of regenerant on the properties of aged asphalt. The results show that: with the increase of the amount of regenerating agent, the aging asphalt performance indexes are restored, the softening point of regenerated asphalt is reduced, and the ductility and needle penetration are increased. Based on the analysis of the relationship between the aging time of SBS modified asphalt and the amount of regenerant, interpolation fitting is carried out to obtain the formula for the best amount of regenerant, so as to determine the best regenerant dosage for aged asphalt mixes in actual engineering applications.

1. Introduction

At present, SBS modified asphalt is widely used in the asphalt pavement surface of highways in China. However, as time goes by, under the combined effect of air, sunlight and rain erosion, the performance of aged asphalt will be degraded, and this change is hard to be reversed [1-3]. Therefore, scholars in the industry have conducted a lot of experimental researches on aging asphalt pavements and have proposed a variety of asphalt pavement regeneration schemes [4, 5]. The use of regenerant to improve the performance index of aging asphalt has also been proposed to restore the technical index of the original asphalt [6]. SBS modified asphalt is different from other road petroleum asphalt that it can improve the performance of high temperature rutting resistance and low temperature cracking resistance at the same time, so it is widely used in road construction. At the microscopic level, asphalt aging is reflected in two aspects. On the one hand, it is mainly based on oxidation, with the combination of chemical functional groups, such as carbonyl groups, and on the other hand, aging is reflected on the loss of mass caused by the volatilization of light components such as aromatic fractions. At the macro level, asphalt aging is manifested as follows: as the service life increases, the softening point and viscosity of asphalt gradually increase, and the ductility and needle penetration gradually decrease, which leads to the deterioration of asphalt performance. As the performance of asphalt pavement decreases, the problem of asphalt pavement regeneration arises. In response to this problem, Qiu Longliang et al conducted an in-depth study on the mechanism of aging and regeneration of SBS modified asphalt [7-9]; Wu Shaopeng et al conducted a study on the effect of regenerant on the performance index and recovery of SBS modified asphalt [10].

Thermal regeneration technology is used to recycle the original pavement asphalt mixture by adding regenerant to the original pavement asphalt mixture in order to restore the indicators of the asphalt [11-14]. Since the existing asphalt recycling tests mostly use trichloroethylene as the solvent, and it is difficult to remove all trichloroethylene during the recycling process, it is impossible to accurately determine the aging degree of the original pavement asphalt. In this paper, we use asphalt RTFOT to simulate the aging of asphalt in the actual application process, analyze the recovery effect of aging SBS modified asphalt by adding different doses of regenerant, and further study the optimal amount of regenerating agent, which is of guiding significance for the improvement and promotion of in-situ thermal regeneration technology.

2. Materials and methods

2.1. Experiment design

SBS modified asphalt is used as the test material, and its main physical property indexes are tested and compared under five different aging times. Six different doses of regenerants are added to each RTFOT aging period to form recycled asphalt, and the performance indexes of the recycled asphalt and the original asphalt are analyzed to study the development pattern of asphalt properties.

To prepare specimens representing different aging degrees, the aging test time periods are set as 160, 200, 240, 280 and 320 min, and the aging oven temperature is set at 163 °C. The softening point, ductility and penetration of the specimens are tested after aging for different periods to analyze and compare the changes of their indexes. In order to prepare the regenerated asphalt, different doses of regenerants are added to the aged asphalt. According to the change law of asphalt performance before and after regeneration, the best dosage of regenerant for different aging time asphalt is achieved.

2.2. Experiment

2.2.1. Technical indexes of material

The test is conducted using SBS modified asphalt produced by SK in Korea, and the regenerant is RA100 asphalt regenerant produced by Jiangsu Subtec New Materials Co. LTD. The regenerant works by adjusting the viscosity of the old asphalt, softening the brittle and hard old asphalt mixture, and adjusting the structure of the asphalt colloid. The performance indexes of modified asphalt and regenerant are shown in Table 1 and Table 2.

Table 1Technical indexed of original asphalt

Items | Technical index | Test value |

Component | Resins / % | 25.17 |

Asphaltenes / % | 13.18 | |

Aromatics / % | 54.21 | |

Saturates / % | 6.03 | |

Physical index | Ductility (10 ℃) / cm | 40.6 |

Penetration (25 ℃) / (0.1 mm) | 60.1 | |

Viscosity (135 ℃) / (Pa·s) | 2098 | |

Soften point / ℃ | 60.2 |

Table 2Technical indexes of regenerant

Item | Technical index | Test value |

Component | Resins / % | 12.7 |

Asphaltenes / % | 8.1 | |

Aromatics / % | 61.8 | |

Saturates / % | 15.6 | |

Physical Index | Flashing point / ℃ | 237 |

Viscosity (60 ℃) / (Pa·s) | 615 | |

Viscosity ratio after RTFOT | 1.8 | |

Mass loss after RTFOT / % | –2.3 |

2.2.2. Asphalt aging test

Firstly, clean the bottles with trichloroethylene, weigh them, and inject SBS modified asphalt (35±0.5) g. Then weight them and put the 8 bottles with asphalt in the oven after that. Close the oven door and turn on the rotating switch with the rotating speed 15±0.2 r/min. Meanwhile, the hot air with the flow rate 4000±200 mL/min is sprayed into the specimen in the rotating sample dish. Set the oven temperature so that it recovers to 163 ℃ in 15 min, and heat the specimens for 160, 200, 240, 280, 320 min respectively. After reaching the heating time, stop the injection of hot air and stop the rotation of the ring frame. Then, immediately remove the bottles and pour the aged asphalt into the molds for determining the 3 major indicators of asphalt according to the requirements of the specification [9]. All test items should be completed within 72 h.

2.2.3. Regenerant test

Put the regenerant in the oven at 140 ℃ for 30 min to make it flowing. Remove the aging asphalt 10 min before it is about to reach the aging time, and then inject the heated regenerant (2 %, 4 %, 6 %, 8 %, 10 %, 12 %). The dosage of regenerant is equal to the mass ratio of regenerant to aging asphalt. After that, put the specimen into the rotating oven immediately. Rotate and heat until the regenerated asphalt specimens reach the aging time and take them out.

2.2.4. Dynamic shear rheological test

The asphalt sample is prepared according to the method in 2.3. Dynamic shear rheological test is carried out on aging asphalt with different amount of regenerant. The 70 ℃ rutting factor (G*/sinδ) of the specimen is measured by temperature scanning mode, where G* is the complex shear modulus of asphalt material, δ is the phase angle of the bituminous material.

3. Results and analysis

3.1. Changes in technical indexes and data analysis after the addition of regenerant

In accordance with the requirements of “Highway Engineering Asphalt and Asphalt Mixture Test Procedure JTG E20-2011”, the needle penetration, softening point and ductility of the recycled asphalt specimens are tested, and the results are shown in Table 3-7.

Table 3Technical indexes of regenerate asphalt after ageing for 160 min

Dosage of regenerant / % | Needle penetration (25 ℃) / (0.1 mm) | Ductility (10 ℃) / cm | Softening point / ℃ |

2 | 39.8 | 15.2 | 63.6 |

4 | 45.6 | 16.3 | 62.4 |

6 | 51.7 | 18.2 | 61.3 |

8 | 59.8 | 26.2 | 60.1 |

10 | 62.7 | 29.6 | 58.6 |

12 | 64.1 | 34.2 | 56.3 |

Non-regenerant | 37.5 | 14.0 | 64.5 |

From Table 3 to 7, it can be seen that the indicators of needle penetration and ductility of recycled asphalt recovered well, while the indicators of softening point did not recover significantly.

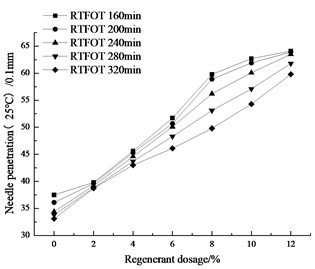

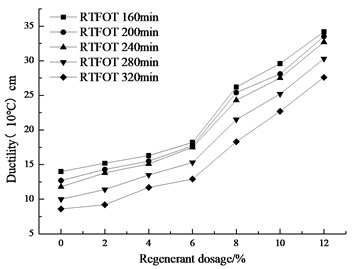

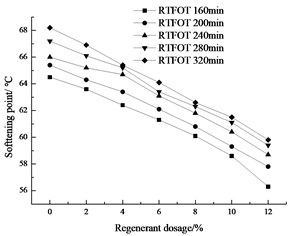

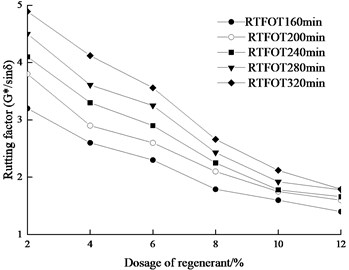

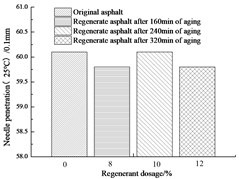

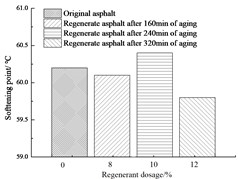

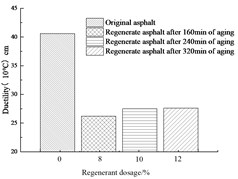

Line charts are drawn to directly reflect the relationship between the physical indexes of recycled asphalt and the variation of the regenerant dosage, shown in Figs. 1-3.

From Figs. 1-3, it can be seen that with the increase of regenerant dosage, all the performance indexes of aged asphalt are restored, with the softening point of regenerated asphalt reduced, and the ductility and needle penetration increased. Once the asphalt is aged, the proportion of aromatics decreases, and the proportion of asphaltenes increases. The mechanism of asphalt regeneration is to readjust the content of the components of aged asphalt, that is, by adding regenerating agents and other methods to obtain recycled asphalt that can meet the performance of the road [8].

Table 4Technical indexes of regenerate asphalt after ageing for 200 min

Dosage of regenerant / % | Needle penetration (25 ℃) / (0.1 mm) | Ductility (10 ℃) / cm | Softening point / ℃ |

2 | 39.6 | 14.3 | 64.3 |

4 | 45.3 | 15.5 | 63.4 |

6 | 50.7 | 17.7 | 62.1 |

8 | 58.9 | 25.4 | 60.8 |

10 | 61.9 | 28.1 | 59.3 |

12 | 63.9 | 33.5 | 57.8 |

Non-regenerant | 36.1 | 12.7 | 65.4 |

Table 5Technical indexes of regenerate asphalt after ageing for 240 min

Dosage of regenerant / % | Needle penetration (25 ℃) / (0.1 mm) | Ductility (10 ℃) / cm | Softening point / ℃ |

2 | 39.2 | 13.8 | 65.2 |

4 | 44.6 | 15.1 | 64.7 |

6 | 50.1 | 17.5 | 63.1 |

8 | 56.2 | 24.3 | 61.8 |

10 | 60.1 | 27.5 | 60.4 |

12 | 63.5 | 32.7 | 58.7 |

Non-regenerant | 34.4 | 11.8 | 66.0 |

Table 6Technical indexes of regenerate asphalt after ageing for 280 min

Dosage of regenerant / % | Needle penetration (25 ℃) / (0.1 mm) | Ductility (10 ℃) / cm | Softening point / ℃ |

2 | 38.8 | 11.4 | 66.1 |

4 | 43.7 | 13.5 | 65.2 |

6 | 48.3 | 15.3 | 63.4 |

8 | 53.1 | 21.5 | 62.3 |

10 | 57.1 | 25.2 | 61.1 |

12 | 61.8 | 30.3 | 59.4 |

Non-regenerant | 33.8 | 10.0 | 67.2 |

Table 7Technical indexes of regenerate asphalt after ageing for 320 min

Dosage of regenerant / % | Needle penetration (25 ℃) / (0.1 mm) | Ductility (10 ℃) / cm | Softening point / ℃ |

2 | 38.7 | 9.2 | 66.9 |

4 | 43.0 | 11.7 | 65.4 |

6 | 46.1 | 12.9 | 64.1 |

8 | 49.8 | 18.3 | 62.6 |

10 | 54.3 | 22.7 | 61.5 |

12 | 59.8 | 27.6 | 59.8 |

Non-regenerant | 33.1 | 8.6 | 68.2 |

3.2. Analysis of dynamic shear rheological test results

Rutting factor (G*/sinδ) can characterize the high-temperature performance of asphalt materials. The higher the rutting factor, the stronger the resistance to denaturation under high temperature conditions. The change trend of 70 ℃ rutting factor with aging time and the amount of regenerant is shown in Fig. 4. It can be seen from the figure that the rutting factor of recycled asphalt decreases with the increase of the amount of regenerant, indicating that the addition of regenerant will affect the high temperature performance of asphalt. This is because the addition of regenerant can improve the rheological properties of recycled asphalt, but when the amount is too high, it will have an adverse impact on the high-temperature shear resistance of asphalt, so the appropriate amount of regenerant should be selected.

Fig. 1The relationship between needle penetration and regenerant dosage

Fig. 2The relationship between ductility and regenerant dosage

Fig. 3The relationship between softening point and regenerant dosage

3.3. Analysis on the optimal dosage of regenerant

In Table 3, after 160 mins of RTFOT on SBS modified asphalt, the regenerated asphalt with 8 % regenerant addition receives the closest needle penetration and softening point to the original modified asphalt. So, 8 % regenerant is selected as the optimal dosage of regenerant for asphalt performance recovery after 160 mins of RTFOT. In Table 4, for SBS modified asphalt after 200 mins of ageing, the needle penetration and softening point of the recycled asphalt obtained by adding 8 % regenerant and 10 % regenerant are closer to the original modified asphalt, so the index of needle penetration is compared to select optimal dosage of regenerant. The interpolation equation is shown in Eq. (1). In Table 5, the regenerated asphalt with 10% regenerant addition receives the closest needle penetration and softening point to the original modified asphalt. So, 10 % regenerant is selected as the optimal dosage of regenerant for asphalt performance recovery after 240 mins of aging. In Table 6, for SBS modified asphalt after 280 mins of ageing, the needle penetration and softening point of the recycled asphalt obtained by adding 10 % regenerant and 12 % regenerant are closer to the original modified asphalt, so the index of needle penetration is compared to select optimal dosage of regenerant. The interpolation equation is shown in Eq. (2). In Table 7, the regenerated asphalt with 12 % regenerant addition receives the closest needle penetration and softening point to the original modified asphalt. So, 12 % regenerant is selected as the optimal dosage of regenerant for asphalt performance recovery after 320 mins of aging:

Fig. 4Relationship between rutting factor and regenerant dosage

Since the optimal dosages of 8.8 % and 11.3 % are calculated, in order to describe the recovery of the indicators of recycled asphalt more visually, the recovery of the indicators of the original asphalt and the recycled asphalt with 8 %, 10 % and 12 % regenerant are as shown in Fig. 5.

Fig. 5Technical indexes recovery of regenerated asphalt

a) Needle penetration

b) Ductility

c) Softening point

As can be seen from Fig. 5, the regenerant can recover needle penetration and softening point of aging asphalt effectively, but the recovery of its ductility is not obvious. The reason is that the regenerant ignores the low temperature plasticity of asphalt. Therefore, in order to achieve better regeneration effect, a certain amount of the same new asphalt is added along with regenerant. Regenerant works as supplement to the aromatics and helps to adjust the chemical components and content, but it cannot repair the degraded molecular chain. The new asphalt added can not only adjust its chemical components, but also join chemical grafting reaction with aging asphalt degradation products based on its original epoxy groups. Thus, the broken SBS molecular chains of aged asphalt are reconnected, and the ductility of aged asphalt can be well restored.

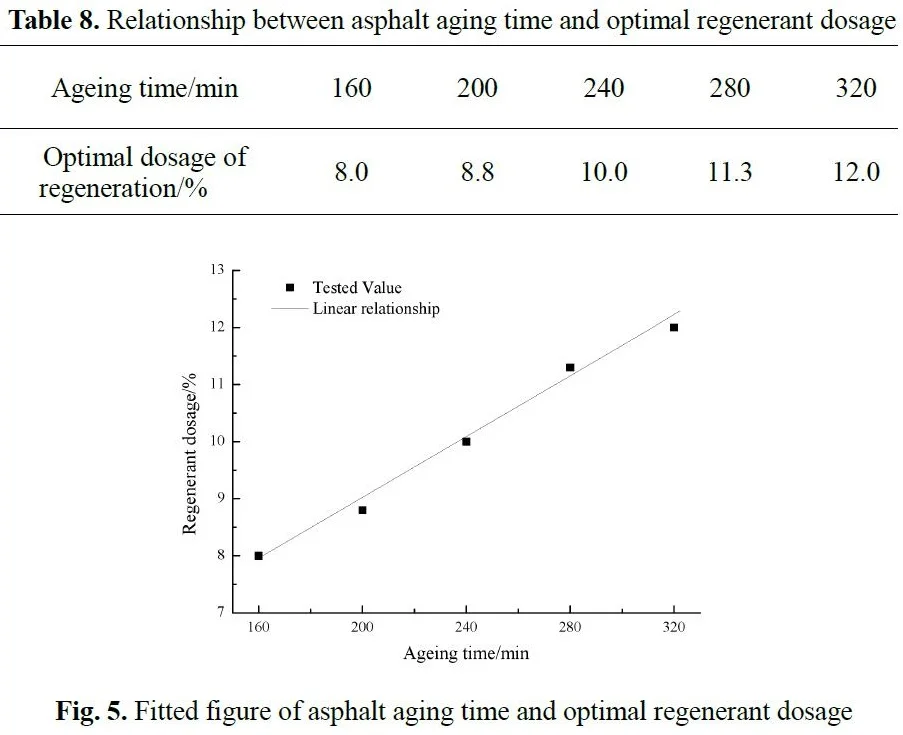

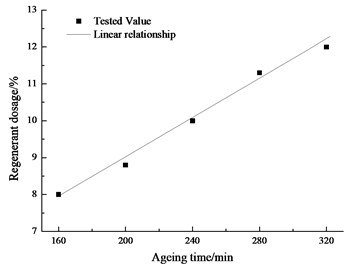

The relationship between asphalt aging time and optimal regenerant dosage is summarized in Table 8, and their fitted figure is shown in Fig. 5.

Table 8Relationship between asphalt aging time and optimal regenerant dosage

Ageing time / min | 160 | 200 | 240 | 280 | 320 |

Optimal dosage of regeneration / % | 8.0 | 8.8 | 10.0 | 11.3 | 12.0 |

From Fig. 6, the fitted linear relationship between the optimal regenerant dosage and asphalt aging time is obvious, when the correlation index R2 is greater than 0.987, the correlation is better. The linear equation between the asphalt aging time and the regenerant dosage is in Eq. (3):

where X is the ageing time, (min); Y is the dosage of regenerant, (%).

In practical applications, the three major indicators of the original asphalt pavement recycling asphalt can be measured and compared with those of asphalt without regenerant in Table 3-7. Then, according to the aging degree of asphalt, the aging time of the tested asphalt can be determined by using numerical interpolation, and then be substituted into the above linear equation to find the optimal regenerant dosage.

Fig. 6Fitted figure of asphalt aging time and optimal regenerant dosage

4. Conclusions

By adding suitable dosage of regenerant in aged SBS modified asphalt, its resins, asphaltenes, aromatics and saturates can be adjusted to recover the technical indexes of aged asphalt.

With addition of regenerant in recycled asphalt, the ductility cannot be recovered to original index. To solve this problem, a certain amount of new asphalt of same component is added, since it can reconnect the broken SBS molecular chains of aged asphalt by adjusting asphalt chemical components and joining chemical grafting reaction with aging asphalt degradation products based on its original epoxy groups.

To select optimal dosage of regenerant, different dosages of regenerant can be added in aged asphalt and then the needle penetration and ductility are compared. When the needle penetration and ductility are close to the original asphalt, the dosage can be selected as the optimal one.

References

-

H. Majidifard, N. Tabatabaee, and W. Buttlar, “Investigating short-term and long-term binder performance of high-RAP mixtures containing waste cooking oil,” Journal of Traffic and Transportation Engineering (English Edition), Vol. 6, No. 4, pp. 396–406, Aug. 2019, https://doi.org/10.1016/j.jtte.2018.11.002

-

M. Zahoor, S. Nizamuddin, S. Madapusi, and F. Giustozzi, “Sustainable asphalt rejuvenation using waste cooking oil: A comprehensive review,” Journal of Cleaner Production, Vol. 278, p. 123304, Jan. 2021, https://doi.org/10.1016/j.jclepro.2020.123304

-

X. Jia, B. Huang, B. F. Bowers, and S. Zhao, “Infrared spectra and rheological properties of asphalt cement containing waste engine oil residues,” Construction and Building Materials, Vol. 50, pp. 683–691, Jan. 2014, https://doi.org/10.1016/j.conbuildmat.2013.10.012

-

K. Yan, Y. Peng, and L. You, “Use of tung oil as a rejuvenating agent in aged asphalt: Laboratory evaluations,” Construction and Building Materials, Vol. 239, p. 117783, Apr. 2020, https://doi.org/10.1016/j.conbuildmat.2019.117783

-

D. X. Lu, M. Saleh, and N. H. T. Nguyen, “Effect of rejuvenator and mixing methods on behaviour of warm mix asphalt containing high RAP content,” Construction and Building Materials, Vol. 197, pp. 792–802, Feb. 2019, https://doi.org/10.1016/j.conbuildmat.2018.11.205

-

X. Zhang, J. Zhu, C. Wu, Q. Wu, K. Liu, and K. Jiang, “Preparation and properties of wood tar-based rejuvenated asphalt,” Materials, Vol. 13, No. 5, p. 1123, Mar. 2020, https://doi.org/10.3390/ma13051123

-

R. L. Nogueira, J. B. Soares, and S. A. Soares, “Rheological evaluation of cotton seed oil fatty amides as a rejuvenating agent for RAP oxidized asphalts,” Construction and Building Materials, Vol. 223, pp. 1145–1153, Oct. 2019, https://doi.org/10.1016/j.conbuildmat.2019.06.128

-

Z. Cao et al., “Influence of characteristics of recycling agent on the early and long-term performance of regenerated SBS modified bitumen,” Construction and Building Materials, Vol. 237, pp. 1–12, Mar. 2020.

-

R. B. Ahmed and K. Hossain, “Waste cooking oil as an asphalt rejuvenator: A state-of-the-art review,” Construction and Building Materials, Vol. 230, p. 116985, Jan. 2020, https://doi.org/10.1016/j.conbuildmat.2019.116985

-

D. Zhang, M. Chen, S. Wu, J. Liu, and S. Amirkhanian, “Analysis of the relationships between waste cooking oil qualities and rejuvenated asphalt properties,” Materials, Vol. 10, No. 5, p. 508, May 2017, https://doi.org/10.3390/ma10050508

-

H. Wang, Z. Ma, X. Chen, and M. R. Mohd Hasan, “Preparation process of bio-oil and bio-asphalt, their performance, and the application of bio-asphalt: A comprehensive review,” Journal of Traffic and Transportation Engineering (English Edition), Vol. 7, No. 2, pp. 137–151, Apr. 2020, https://doi.org/10.1016/j.jtte.2020.03.002

-

R. Cao, Z. Leng, and S.-C. Hsu, “Comparative eco-efficiency analysis on asphalt pavement rehabilitation alternatives: Hot in-place recycling and milling-and-filling,” Journal of Cleaner Production, Vol. 210, pp. 1385–1395, Feb. 2019, https://doi.org/10.1016/j.jclepro.2018.11.122

-

M. B. Bouraima, X. H. Zhang, A. Rahman, and Y. Qiu, “A comparative study on asphalt binder and mixture performance of two traffic lanes during hot in-place recycling (HIR) procedure,” Construction and Building Materials, Vol. 223, pp. 33–43, Oct. 2019, https://doi.org/10.1016/j.conbuildmat.2019.06.201

-

Z. H. Al-Saffar et al., “Evaluating the chemical and rheological attributes of aged asphalt: synergistic effects of maltene and waste engine oil rejuvenators,” Arabian Journal for Science and Engineering, Vol. 45, No. 10, pp. 8685–8697, Oct. 2020, https://doi.org/10.1007/s13369-020-04842-7