Abstract

Adding self-melting snow material to asphalt pavement can improve driving safety in winter weather. Self-melting materials can melt the snow on the road surface, without too much negative impact on asphalt pavement. Two commonly used self-melting snow materials are particle type and powder type. Through indoor experiments, the effects of two self-melting snow materials on the high-temperature performance, low-temperature performance, water stability, and anti-stripping performance of asphalt mixtures are compared. The experiment shows that these self-melting snow materials have little effect on the high-temperature and low-temperature performance of the asphalt mixture, and the low-temperature performance of the mixture decreased after freeze-thaw environment. After freeze-thaw cycle or immersion, the snow melt components in the mixture gradually precipitate, leading to the water stability and anti-spalling performance.

1. Introduction

Snow melting pavement is a composite material that can melt snow and prevent freezing in an ordinary asphalt mixture. It ensures that the asphalt mixture meets the requirements of normal road performance, and endows it with functions of self-melting snow and anti-freezing [1]. The most widely used materials for self-melting snow are gradual “GS” particles and powder “PAI” powder which mainly consist of snow melting salt. However, over time, the salt content in these materials may decrease due to precipitation and lost under different water temperature conditions [2]. This can affect the composition and volume index of the asphalt mixture and subsequently impact its performance. The durability of snowmelt asphalt pavement is analyzed by comparing the performance changes of two snowmelt asphalt mixtures under different water temperature conditions in laboratory tests [3, 4].

2. Mixture design

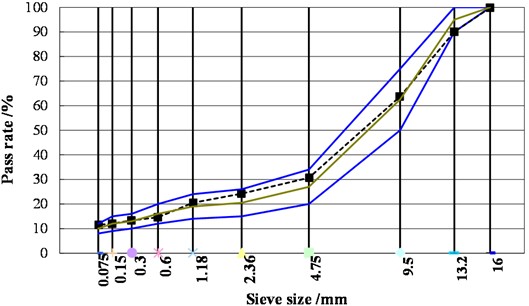

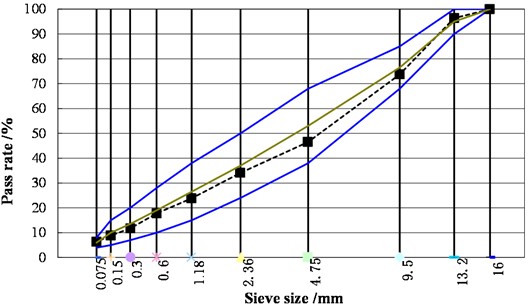

Two mixtures of AC-13 and SMA-13 were designed using the same mineral through the Marshall Design method. The grading curves of the mixtures are shown in Fig. 1 and Fig. 2 respectively. The Marshall Design method was used 75 times for the AC-13 mixture and 50 times for the SMA-13 mixture. The optimum ratio of oil to stone of AC-13 mixture was 4.9 % and the amount of mineral powder was 4.5 %. The optimum ratio of oil to stone for SMA-13 mixture is 5.9 % and the amount of mineral powder is 9 %.

Three groups of samples were prepared. The first group served as the control group of an ordinary mixture, and the second group added an additional 5.5 % granular GS material. The other group used PAI to replace part of the mineral powder of the mixture. For the AC-13 mixture, the PAI equivalent volume was used to replace all the mineral powder. For the SMA-13 mixture, 5 % PAI equivalent volume was used to replace part of the mineral powder.

Fig. 1Grading curve of SMA mixture

Fig. 2Grading curve ofAC-13 mixture

3. Effect of self-melting snow materials on high-temperature performance

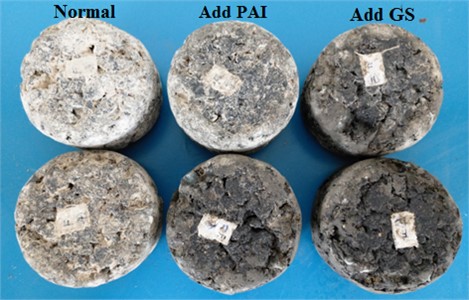

The high temperature performance of asphalt mixture was compared using an indoor rutting test. After adding GSto the mixture, there were crushed white snowmelt material particles on the surface of the sample, as shown in Fig. 3. After the mixing process, the sample mixed with self-melting snow material was placed for 24h, and the GS particles on the surface of the sample were rinsed with clean water [5]. Then, the rutting test was carried out. The rutting test results are shown in Table 1.

Fig. 3Surface effect of mixed GS

Table 1Results of asphalt mixture rutting test

Mixtures | 60 min deflection (mm) | Dynamic stability (frequency / mm) | |

AC-13 | Normal | 2.43 | 3571 |

Add GS | 2.58 | 3707 | |

Add PAI | 2.67 | 2965 | |

SMA-13 | Normal | 1.97 | 5741 |

Add GS | 2.31 | 5603 | |

Add PAI | 2.26 | 4354 | |

It can be seen from Table 1 that the dynamic stability of AC-13 and SMA-13 mixed with GS is not significantly different from that of ordinary mixtures. When using PAI replacing the mineral powder in the mixture, the dynamic stability of the two mixtures decreased significantly. PAI has a negative effect on the high-temperature performance of asphalt mixtures, but it can meet the standard requirements.

4. Effect of self-melting snow materials on low-temperature performance

Self-melting snow pavements are mainly used in the cold winter areas of the north, and the temperature shrinkage cracks are the main disease of these pavements. The effect of self-melting snow materials on the low-temperature performance of the mixture is particularly noteworthy [6]. The flexural and tensile strength and strain that a mixture can withstand at low-temperatures are important indexes for determining its resistance to low-temperature damage and deformation. The effect of adding self-melting snow materials on the low-temperature performance of the mixture was verified through low-temperature bending tests. To analyze the effect of freeze-thaw environment on the low-temperature performance of the mixtures, the samples of each mixture were divided into two groups. One group underwent a freeze-thaw cycle and then a low-temperature bending test. The freeze-thaw cycle conditions were maintained in a –18 ℃ incubator for 16 h, and then placed in a 60 ℃ constant temperature tank for 24h. The test results are shown in Table 2.

Table 2Low-temperature bending test results of asphalt mixtures

Items | Mixtures | Flexural tensile strength (MPa) | Bending strain | Stiffness modulus (MPa) | |

Standard test | AC-13 | Normal | 12.3 | 2731 | 4504 |

Add GS | 11.2 | 2852 | 3927 | ||

Add PAI | 11.2 | 2952 | 3794 | ||

SMA-13 | Normal | 11.7 | 3463 | 3379 | |

Add GS | 10.8 | 3336 | 3237 | ||

Add PAI | 9.9 | 3536 | 2800 | ||

Freeze-thaw cycle test | AC-13 | Normal | 12.7 | 2687 | 4726 |

Add GS | 9.8 | 2304 | 4253 | ||

Add PAI | 10.3 | 2604 | 3955 | ||

SMA-13 | Normal | 13.1 | 3279 | 3995 | |

Add GS | 9.1 | 2831 | 3214 | ||

Add PAI | 9.4 | 3054 | 3078 | ||

From Table 2, it can be seen that under standard test conditions, there is no significant difference in low-temperature bending strain between the mixture containing self-melting snow material and the ordinary mixture. After freeze-thaw cycle, the low-temperature bending strain of ordinary asphalt mixture has little change. The low temperature bending of the two asphalt mixtures mixed with GS decreases by 19 % and 15 %, respectively. The low-temperature bending strain of the two asphalt mixtures doped with PAI is reduced by 12 % and 14 % respectively. After freeze-thaw cycle, snowmelt components in the mixture dissolved and precipitated. The low-temperature performance of the mixture decreases significantly. Self-melting snow material reduces the low-temperature durability of asphalt pavement.

5. Effect of self-melting snow materials on low-temperature performance

GS has a strong hygroscopic property, and under natural conditions, water droplets will form on the surface of the mixture [7-8]. After a certain amount of water environment, the deicing salt gradually dissolved. The void ratio of the mixture increased, and the snowmelt components in PAI also precipitated with age. Snowmelt materials have a negative effect on the stability of the mixture water. In this section, the water stability of two grades of self-melting asphalt mixtures was evaluated through immersion Marshall Test and freeze-thaw splitting test, respectively. To ensure that the experimental data have enough representativeness, the test samples of each mixture shall be prepared by taking materials from the construction site, and the time quantity shall not be less than 10. The data with deviations greater than 10 % was removed from the data statistics. The test results are shown in Table 3 and Table 4.

Table 3Results of submerged Marshall test

Mixtures | Residual stability (%) | |

AC-13 | Normal | 88.2 |

Addition of GS | 82.1 | |

Addition of PAI | 85.3 | |

SMA-13 | Normal | 93.8 |

Addition of GS | 83.2 | |

Addition of PAI | 87.2 | |

It can be seen from Table 3 that the residual stability of the mixture after adding two kinds of self-melting snow materials decreased significantly. After the addition of PAI, the residual stability of AC-13 and SMA-13 decreased by 3 % and 7 %, respectively. After adding GS, the residual stability of AC-13 and SMA-13 decreased by 7 % and 11 %, respectively. It is worth noting that AC-13 after adding SG is 85 % lower than the standard value, which does not meet the requirements of the standard.

Table 4Results of freeze-thaw splitting test

Mixtures | Splitting strength ratio (%) | |

AC-13 | Normal | 86.1 |

Add GS | 70.5 | |

Add PAI | 83.1 | |

SMA-13 | Normal | 90.1 |

Add GS | 75.3 | |

Add PAI | 89.5 | |

It can be seen from Table 4 that the splitting strength ratio of AC-13 mixture decreased slightly after adding PAI. While the splitting strength ratio of SMA-13 mixture remained unchanged basically. After adding GS, the freeze-thaw splitting strength ratio of the two types of mixture decreased significantly. It was less than 80 % of the standard value and cannot meet the standard requirements. From this, it can be seen that the freeze-thaw environment and soaking conditions cause precipitation of snowmelt components, which has an adverse effect on the stability of water in self-melting asphalt mixtures. Granular GS has the greatest influence on the stability of the mixture water, and does not meet the standard requirements.

6. Effect of self-melting snow materials on resistance to spalling

The components of snowmelt dissolve and precipitate after experiencing a water temperature environment, affecting the bonding between asphalt and aggregates. Flight tests can evaluate the anti-stripping performance of asphalt mixtures. This section compares and analyzes the anti-stripping performance of snowmelt mixtures after a certain water temperature process through flight tests under different water temperature conditions. The number of samples for each flight test shall not be less than 9 to ensure that the experimental data conforms to a normal distribution.

Table 5Flight test results under different water temperature conditions

Mixtures | Test | Flight loss rate (%) | |

AC-13 | Normal | Flying test | 4.4 |

Immersion flying test | 5.2 | ||

Addition of GS | Flying test | 7.3 | |

Immersion flying test | 8.8 | ||

Addition of PAI | Flying test | 4.7 | |

Immersion flying test | 6.8 | ||

SMA-13 | Normal | Flying test | 3.8 |

Immersion flying test | 4.5 | ||

Addition of GS | Flying test | 7.9 | |

Immersion flying test | 10.6 | ||

Addition of PAI | Flying test | 4.2 | |

Immersion flying test | 7.6 | ||

Fig. 4Flying specimens of mixed materials immersed in water

It can be seen from Table 5 that the flying loss rate of common mixture specimen increases slightly after immersion in water. The dispersion loss of asphalt mixture is not significantly different from that of ordinary mixtures, but the dispersion loss of immersed asphalt mixtures is significantly higher than that of ordinary asphalt mixtures. After adding GS, the dispersion loss of the mixture increased significantly. The maximum dispersion loss occurs when SMA-13 was mixed with GS. It can be seen that GS has a significant effect on the anti-spalling performance and the dense skeleton of the mixture. PAI has little effect on the anti-stripping performance of the mixture in the early stage, while the precipitation of snowmelt salt has a certain effect on the stripping performance of the mixture.

7. Conclusions

Through indoor experiments, the effects of granular GS and powder PAI on the high-temperature performance, low-temperature performance, water stability, and peel resistance of the mixture are compared, and conclude as follows:

1) The addition of GS has little effect on the high-temperature performance of asphalt mixtures. PAI has a negative effect on the high-temperature performance of asphalt mixtures, but meeting the requirements of technical standards.

2) The low-temperature bending performance of the mixture has little change after the addition of self-melting snow materials. After freeze-thaw cycle, the low-temperature performance of the mixture decreased significantly. It can be seen that snowmelt material has a great influence on the low-temperature durability of asphalt mixture.

3) The freeze-thaw environment and soaking conditions lead to the loss of snowmelt components, which adversely affects the stability of the self-melting asphalt mixture water. Granular GS has the greatest impact on the stability of the mixture water. In severe cases, it may not even comply with the technical standards, and should be used with caution.

4) GS has a great influence on the anti-stripping performance of the mixture, especially for the coarse gradation of the mixture. PAI has little effect on the early spalling resistance of the mixture. However, attention should be paid to the impact of salt loss on the durability and service life of the pavement.

References

-

Z. Z. Liu, “Anti-freezig materials used in asphalt pavement and its application properties,” Chang ’an University, China, 2013.

-

Y. Q. Tan, “Road deicing technology in snow disaster,” (in Chinese), Traffic Construction and Management, Vol. Z1, pp. 86–87, 2008.

-

S. Liu, N. X. Zheng, J. Yang, and F. Y. Meng, “Ice melting performance of deicers and their effect on stripping resistance of asphalt mixture,” Journal of Southeast University (English Edition), Vol. 32, No. 3, pp. 327–332, 2016.

-

M. Y. Shao, “Study on performance and preparation of deicing snowmelt by salt storage asphalt mixture,” Chang ’an University, China, 2015.

-

Y. Q. Tan, R. R. Sun, M. Guo, Y. Zhong, and S. W. Zhou, “Research on deicing performance of asphalt mixture containing salt,” China Journal of Highway and Transport, Vol. 26, No. 1, pp. 23–29, 2013, https://doi.org/10.19721/j.cnki.1001-7372.2013.01.004

-

W. G. Zhang, F. Wang, and L. T. Ding, “Corrosion behavior of melting snow salt on asphalt mixtures,” Journal of Zhengzhou University (Engineering Science), Vol. 42, No. 1, pp. 77–81, 2021, https://doi.org/10.13705/j.issn.1671-6833.2020.02.012

-

C. Wang, “Preparation and performance of composite deicing and snow asphalt mixture,” Chang’an University, China, 2022.

-

R. K. Thakur and S. K. Singh, “Feasibility study for using waste tire rubber in bituminous concrete,” Lecture Notes in Civil Engineering, Vol. 90, pp. 223–236, Sep. 2020, https://doi.org/10.1007/978-3-030-51354-2_20

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.