Abstract

The utilization of reclaimed asphalt pavement (RAP) contributes significantly to reducing resource waste and protecting the environment. However, due to the performance of rejuvenator, fatigue cracking has always been one of the important constraint on the development of the reclaimed asphalt pavements. Based on the studies previously conducted by our group, this paper investigated the fatigue properties of waste rubber/oil (WRO) rejuvenated asphalt and common rejuvenated asphalt by dynamic shear rheometer test (DSR), and analyzed the relationship between fatigue life and rheological properties of rejuvenated asphalt. The results indicated that the fatigue life of WRO rejuvenated asphalt is comparatively better than that of common rejuvenated asphalt. Affected by the of waste tire crumb rubber (WTCR), the increase of the proportion of waste tire crumb rubber (WTCR) can improve the elastic recovery ability of rejuvenated asphalt. The fatigue life of rejuvenated asphalt is susceptible to the rate of phase angle change, and the lower the viscoelasticity change rate, the better the fatigue life. There is no obvious direct relationship between the fatigue life of rejuvenated asphalt and the complex modulus.

Highlights

- WRO rejuvenator exhibits positive fatigue modification capability

- The development of WRO can provide a solution for WTCR and WCO to achieve the reuse of waste resources

- The fatigue performance of rejuvenated asphalt is susceptible to the rate of viscoelastic change

1. Introduction

The use of reclaimed asphalt pavement (RAP) provides a particularly economic alternative to the construction of asphalt (cold regenerative, hot mix asphalt) pavements. As RAP contains both aggregates and binder, the application of RAP is environmentally friendly and economical, saving a substantial amount of natural resources and money [1]. However, rejuvenated asphalt is prone to fatigue cracking due to the poor blending between aged and virgin asphalt and the inferior diffusion capacity of rejuvenators.

The fatigue performance of asphalt binder can be significantly influenced by loading mode, loading level and loading frequency. In addition, the report No. 253 of National Cooperative Highway Research Program (NCHRP) has illustrated that an increase in mixture stiffness leads to a decrease in fatigue life [2]. To settle the properties of the stiffened aged binder, it is essential to rehabilitate its rheological properties by compounding it with a rejuvenator or soft asphalt [3, 4]. Therefore, scholars have been devoted to the research of rejuvenator in order to develop rejuvenated asphalt with excellent performance. Dong [5-8] have found that degradation of waste tire crumb rubber (WCTR) in waste cooking oil (WCO) can make the waste rubber/oil rejuvenator (WRO) obtain higher activity, and adding WRO as a modifier or raw material into the base asphalt or aged asphalt can improve the performance of asphalt. Therefore, the development of WRO rejuvenator can not only provide a direction for solving WTCR and WCO, but also realize the reuse of waste resources and alleviate the resource crisis. In addition, the rheological properties of the rejuvenated asphalt would change accordingly during fatigue loading and react to the fatigue properties of the rejuvenated asphalt.

To evaluate the fatigue performance of rejuvenated asphalt objectively and explore the fatigue performance of WRO rejuvenated asphalt, the fatigue life of rejuvenated asphalt and the relationship with the rheological properties were studied in this paper. First, fatigue loading tests were conducted on the rejuvenated asphalt using a dynamic shear rheometer (DSR) to derive the fatigue life of WRO rejuvenated asphalt compared with that of common rejuvenated asphalt. Secondly, considering the viscoelastic properties of the asphalt, the fatigue life was analyzed as a function of rheology during fatigue loading.

2. Materials and methods

2.1. Materials

2.1.1. Aged asphalt

To obtain aged asphalt with consistent properties, artificially aged asphalt was chosen rather than extracted RAP binder in the study. Therefore, one 70 # base asphalt was aged at 163 °C for 85 min through standard Rolling Thin Film Oven (RTFO) to obtain short-term aging asphalt (70#RT) according to AASHTO T240. Furthermore, according to AASHTO R28, the 70#RT was aged for 20h by pressure aging vessel (PAV) at 100°C and 2.1 MPa to obtain long-term aging asphalt (70#PAV). The primary technical index of base asphalt and aged asphalt is shown in Table 1.

Table 1Test results of base asphalt and aged asphalt

Asphalt | Softening point / ℃ | Penetration at 25 ℃ / (0.1 mm) |

70# | 46.6 | 73.4 |

70#RT | 49.5 | 35.6 |

70#PAV | 57.2 | 24.9 |

2.1.2. Preparation of rejuvenated asphalt

First of all, melted the 70#PAV in a 150°C oven and poured it into the heating device. Then, the rejuvenators (the rejuvenators are two kinds of commercial rejuvenators Evoflex@8182 and Evoflex@ca3, and three kinds of WRO rejuvenators, of which the waste rubber/oil is 5:5, 3:7 and 4:6, respectively.) were added to the 70#PAV separately, and the content of the rejuvenator was 6wt.%, 8 wt.%, and 10 wt.%, respectively. Finally, all blends were heated for 0.5-1 h with a stirring speed of 300~350 rpm at a temperature of 160±5 ℃. The asphalt samples utilized in this research are listed in Table 2 and the basic technical index of rejuvenated asphalt (8 % rejuvenator) is shown in Table 3.

Table 2The asphalt samples utilized in this research

Samples | Attribute | Mix design of asphalt binders |

REVO@8182 | Control group | EVO@8182+70#PAV |

REVO@CA3 | EVO@ca3+70#PAV | |

RWRO@55 | – | EVO@55+70#PAV |

RWRO@37 | EVO@37+70#PAV | |

RWRO@46 | EVO@46+70#PAV |

Table 3Test results of rejuvenated asphalt

Asphalt | Softening point /℃ | Penetration at 25 ℃ / (0.1 mm) |

REVO@8182 | 50.4 | 34.3 |

REVO@CA3 | 44.0 | 80.2 |

RWRO@55 | 51.3 | 32.1 |

RWRO@37 | 47.8 | 58.4 |

RWRO@46 | 49.5 | 35.3 |

2.2. Test methods

2.2.1. Fatigue loading test of rejuvenated asphalt

The fatigue loading tests of rejuvenated asphalt were mainly carried out by Dynamic Shear Rheometer (DSR, AR 1500ex Instrument, TA Co., United States). The tests were carried out under the strain-control at 4.5 %, 5.5 %, 6.5 %, with an 8-mm-diameter parallel plate geometry (2 mm gap). The load frequency was set at 10 Hz, and the test temperature was set at 20 °C. What’s more, the Np20, dissipation energy deviation from the no damage curve by 20 %, is used as the evaluation index in this paper.

3. Results and discussion

3.1. Accuracy of PVA aging

To verify the accuracy of the PAV-aged asphalt, this paper compares the properties of naturally aged asphalt (NA asphalt) with that of PAV aged asphalt, and the results are shown in the Table 4. It was found that the results of PAV aging were more consistent with that of naturally aged asphalt, demonstrating the good accuracy of PAV aging, which supported the applicability of PAV aging.

Table 4Results of PVA aged asphalt and naturally aged asphalt

Asphalt | Softening point / ℃ | Penetration at 25 ℃ / (0.1 mm) |

70#PAV | 57.2 | 24.9 |

70#NA | 56.8 | 26.2 |

3.2. Fatigue life

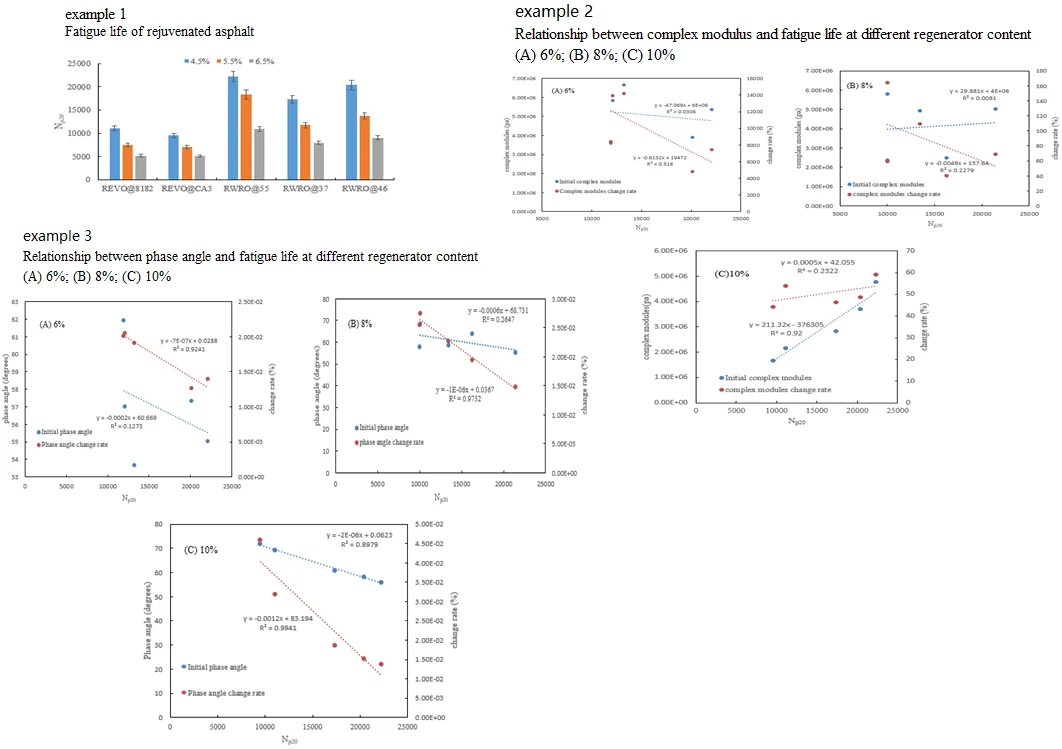

Fig. 1 demonstrates the fatigue life of each rejuvenated asphalt in the strain-control mode. The fatigue life of each rejuvenated asphalt decreases with the increases of loading level under the strain-control mode. However, the response of rejuvenated asphalt to loading level is different due to the performance of rejuvenator. The fatigue life of WRO rejuvenated asphalt under each loading level is higher than that of common rejuvenated asphalt. For WRO rejuvenated asphalt, WRO rejuvenated asphalt with high content of tire crumb rubber (TCR) has better fatigue life under the same loading level.

Fig. 1Fatigue life of rejuvenated asphalt

3.3. Correlation analysis of fatigue life and rheological properties

3.3.1. Sensitivity analysis of the fatigue life to the complex modulus

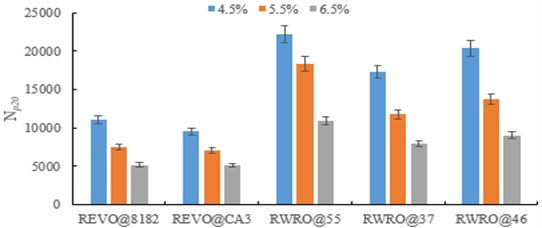

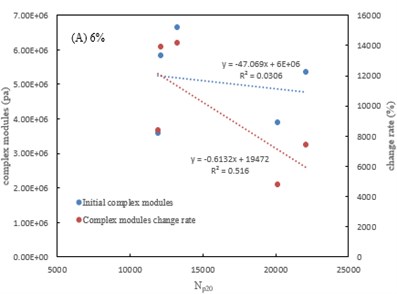

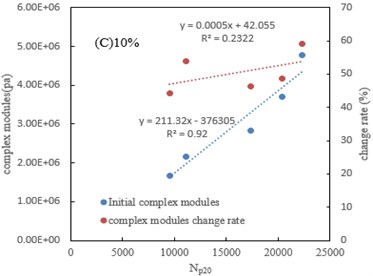

The relationship between the fatigue life of rejuvenated asphalt and the initial complex modulus and the rate of complex modulus change (CR=(G*initial-G*end/Np20) were analyzed at different content of rejuvenator, and the results are shown in Fig. 2. With the increase of the rejuvenator content, the complex modulus of each rejuvenated asphalt significantly decreases, and the rate of complex modulus change also decreases significantly. It shows that the initial deformation resistance of the material gradually decreases and its transient deformation increases with the increase of rejuvenator content, but the fatigue life of the material does not change significantly for the whole fatigue loading process. The initial complex modulus of the rejuvenated asphalt is not a key factor affecting the fatigue life of the rejuvenated asphalt. Moreover, it was proved that there was no obvious linear relationship by fitting the linear relationship between the fatigue life of rejuvenated asphalt and the initial complex modulus. Again, by fitting the relationship between the fatigue life of rejuvenated asphalt and the rate of complex modulus change, it was found that the linear relationship was also not obvious. Therefore, the fatigue life of rejuvenated asphalt cannot be judged qualitatively by the complex modulus of rejuvenated asphalt.

Fig. 2Relationship between complex modulus and fatigue life at different regenerator content: a) 6 %; b) 8 %; c) 10 %

a)

b)

c)

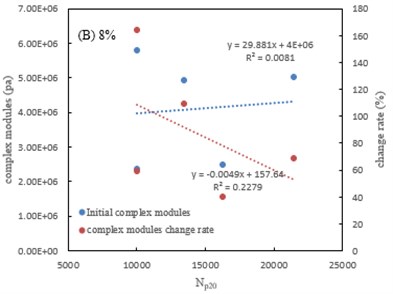

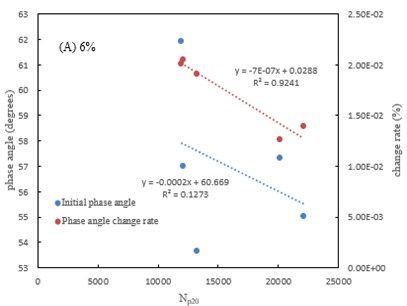

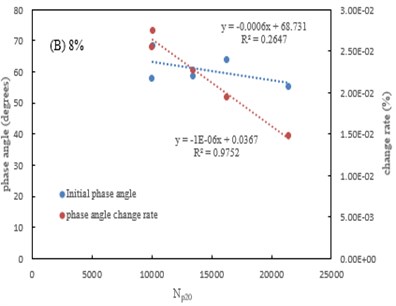

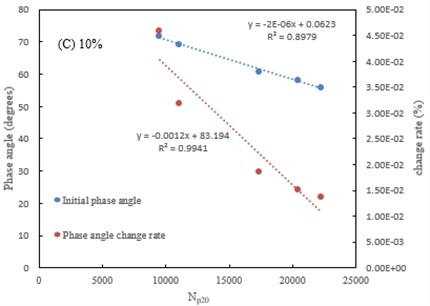

3.3.2. Sensitivity analysis of fatigue life to phase angle

The relationship between the fatigue life of the rejuvenated asphalt and the initial phase angle, phase angle change rate (CR=(δinitial-δend)/Np20) at different rejuvenator content was analyzed, and the results are shown in Fig. 3. With the increase of the rejuvenator content, the phase angle of each rejuvenated asphalt, the rate of change of phase angle increased. It indicates that the elastic proportion and viscous proportion of rejuvenated asphalt decreases. There is a certain change in fluidity and the deformation resistance of the material decreases. By fitting the relationship between the fatigue life of rejuvenated asphalt and the initial phase angle, it was found that the linear relationship between the fatigue life of each rejuvenated asphalt and the initial phase angle was gradually strengthened with the increase of the rejuvenator content. It indicates that the initial phase angle of rejuvenated asphalt will affect the fatigue life of rejuvenated asphalt when the content of rejuvenator is gradually increased. In addition, it is found that the fatigue life of rejuvenated asphalt has an obvious linear relationship with the rate of phase angle change (R2> 0.9) by analyzing the relationship between the fatigue life of rejuvenated asphalt and the rate of phase angle change at each content, and the lower the rate of change of phase angle, the better the fatigue life. The linear relationship is more obvious with the increase of rejuvenator. This indicates that the fatigue life of rejuvenated asphalt is easily affected by the viscoelastic change rate of rejuvenated asphalt, and the fatigue life can be analyzed qualitatively by analyzing the viscoelastic change rate.

Fig. 3Relationship between phase angle and fatigue life at different regenerator content: a) 6 %; b) 8 %; c) 10 %

a)

b)

c)

4. Conclusions

The fatigue loading of rejuvenated asphalt is carried out with the help of DSR, the fatigue properties of WRO rejuvenated asphalt and common rejuvenated asphalt and the relationship between fatigue life and the rheology were analyzed.

1) PAV aging has good accuracy, and it is recommended to use PAV aging to simulate natural aging.

2) WRO rejuvenator has good fatigue modification ability. The fatigue life of rejuvenated asphalt prepared by WRO rejuvenator is better than that of common rejuvenated asphalt.

3) The fatigue life of rejuvenated asphalt is susceptible to the rate of change of phase angle, and the lower the viscoelasticity change rate, the better the fatigue life. There is no obvious direct relationship between the fatigue life of rejuvenated asphalt and the complex modulus.

References

-

F. Moghadas Nejad and H. Fallahi Abandansari, “Evaluating the effects of using recycled asphalt pavements on fatigue properties of warm mix asphalt,” Periodica Polytechnica Civil Engineering, Vol. 61, No. 3, pp. 454–461, Jan. 2017, https://doi.org/10.3311/ppci.8320

-

R. S. Mcdaniel, H. Soleymani, R. M. Anderson, P. Turner, and R. Peterson, “Recommended use of reclaimed asphalt pavement in the superpave mix design method,” NCHRP Project D9-12: Contractor’s Final Report, 2000.

-

M. S. Sondag, B. A. Chadbourn, and A. Drescher, “Investigation of rejuvenated asphalt pavement (RAP) mixtures,” Technical Report, 2002.

-

D. Wang, A. Cannone Falchetto, K. Moon, C. Riccardi, and M. Wistuba, “Experimental investigation of the re-recycling of RAP in asphalt pavement,” in Bituminous Mixtures and Pavements VII, CRC Press, 2019.

-

X. Yi, R. Dong, and N. Tang, “Development of a novel binder rejuvenator composed by waste cooking oil and crumb tire rubber,” Construction and Building Materials, Vol. 236, p. 117621, Mar. 2020, https://doi.org/10.1016/j.conbuildmat.2019.117621

-

Yi Xingyu, “Properties Investigation of a desulfurized rubber rejuvenator contained waste cooking oil,” Chongqing University, 2019.

-

R. Dong and M. Zhao, “Research on the pyrolysis process of crumb tire rubber in waste cooking oil,” Renewable Energy, Vol. 125, pp. 557–567, Sep. 2018, https://doi.org/10.1016/j.renene.2018.02.133

-

M. Zhao, R. Dong, Z. Chi, A. Aljarmouzi, and J. Li, “Effect of process variables on the chemical characteristics of crumb rubber desulfurized by waste cooking oil and its desulfurization mechanism,” Construction and Building Materials, Vol. 311, p. 125361, Dec. 2021, https://doi.org/10.1016/j.conbuildmat.2021.125361