Abstract

In view of the influence of asphalt mixture nonlinearity on the mechanical response of pavement structure, the creep compliance of AC-16 under 0.1, 0.3, 0.5, 0.7 and 0.9 MPa is studied first. The results show that the asphalt mixture is in the linear viscoelastic region, when the load is in the 0.1-0.5 MPa interval. When the load is greater than 0.5 MPa, the creep compliance increases significantly, and asphalt mixture presents a nonlinear property. The Prony series is used to fit the creep compliance data, and the relaxation modulus is calculated based on the convolution relationship between creep compliance and relaxation modulus in viscoelastic mechanics. The relaxation modulus under different loads is introduced into the mechanical calculation of layered viscoelastic system. The calculation results show that the nonlinearity of asphalt mixture significantly affects the permanent deformation of asphalt layer, but has little effect on the fatigue problem of the asphalt base. In the design of pavement structure, attention should be paid to the nonlinearity of asphalt mixture.

1. Introduction

Asphalt mixture is a composite material consisting of asphalt, coarse aggregates, and fine aggregates. It is a typical viscoelastic material, and its performance is closely related to load, temperature, and the duration of load application. Traditional studies have treated asphalt mixtures as linear viscoelastic materials, using linear viscoelastic constitutive equations to study their performance, such as the Huet model [1], 2S2P1D model [2], generalized Kelvin model [3], and others. Similarly, in the study of the mechanical response of asphalt pavement structures, the properties of linear viscoelastic materials are often incorporated into layered viscoelastic systems or finite element viscoelastic analyses [4-6]. However, numerous studies have shown that asphalt mixtures are nonlinear viscoelastic materials [7-9], with material properties exhibiting stress dependency.

Therefore, this paper first conducts research on the creep properties of asphalt mixtures under different loading conditions in the laboratory. Then, by establishing the conversion relationship between viscoelastic creep compliance and relaxation modulus, the conversion of relaxation modulus is accomplished. Finally, the relaxation modulus is applied to the mechanics of layered viscoelastic systems to analyze the influence of asphalt mixture nonlinearity on the mechanical response of asphalt pavement structures, aiming to clarify the significance of asphalt mixture nonlinearity in pavement structure design.

2. Uniaxial creep test

2.1. Specimen preparation

The aggregate and mineral filler used in this study were sourced from Acheng District, Harbin. The technical properties of the coarse aggregates and fine aggregates’ mineral filler are provided in Table 1 and Table 2.

Table 1Technical properties of coarse aggregate

Particle size (mm) | 16-19 | 13.2-16 | 9.5-13.2 | 4.75-9.5 | 2.36-4.75 |

Apparent density | 2.737 | 2.736 | 2.748 | 2.729 | 2.703 |

Water absorption (%) | 0.399 | 0.312 | 0.642 | 0.581 | 2.013 |

Bulk volume density | 2.710 | 2.713 | 2.703 | 2.686 | 2.565 |

Table 2Apparent density of fine aggregate and mineral powder

Particle size (mm) | 1.18-2.36 | 0.6-1.18 | 0.3-0.6 | 0.15-0.3 | 0.075-0.15 | Mineral powder |

Apparent density | 2.732 | 2.723 | 2.723 | 2.723 | 2.681 | 2.722 |

Table 3AC-16 gradation composition

Sieve opening size (mm) | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 |

Aggregate passing rate (%) | 100 | 95 | 84 | 71 | 50 | 37 |

Sieve opening size (mm) | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

Aggregate passing rate (%) | 26.5 | 18.5 | 12.5 | 9.5 | 6.5 |

The asphalt mixture used in the test is AC-16 gradation, and the gradation composition is shown in Table 3. SBS-modified asphalt is used, and the optimum asphalt content of 4.5 % is determined through Marshall testing. Superpave gyratory compactor is employed to make specimens with a diameter of 150 mm and a height of 170 mm and specimens are prepared using the height control method. Then, a core drill is used to take the test piece, and cut 10 mm at both ends of the test piece to prepare the specified size of the test piece.

2.2. Test method

In this experiment, a UTM (Universal Testing Machine) was used to test the viscoelastic parameters of the asphalt mixture. Initially, the specimens were placed in a temperature-controlled chamber at 40 °C for 4 hours. Subsequently, creep compliance tests were conducted under different loading conditions with loads of 0.1, 0.3, 0.5, 0.7, and 0.9 MPa for aduration of 3600 s. After completing the creep compliance tests, the relaxation modulus was calculated based on the relationship between viscoelastic creep compliance and relaxation modulus. This provided material parameters for analyzing the mechanical response of asphalt pavement under different loads.

3. Study of viscoelastic parameters of asphalt mixtures

3.1. Asphalt mixture creep compliance under different loading conditions

Axial displacements of asphalt mixtures under various loads were measured using a UTM (Universal Testing Machine). Subsequently, axial strain values at different time intervals under different loading conditions were obtained using Eq. (1):

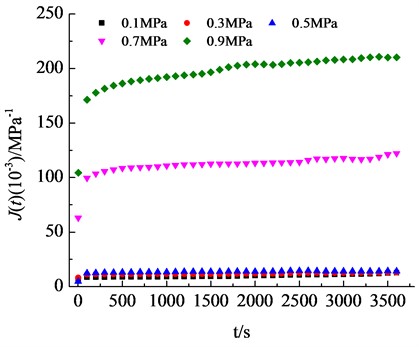

Based on the calculation method for creep compliance, the creep compliance values of asphalt mixtures under different loading conditions were determined, as shown in Fig. 1.

Fig. 1Asphalt mixture creep compliance under different loads

As shown in the figure, the creep compliance of the asphalt mixture gradually increases with an increase in time. However, the creep compliance tends to stabilize at a constant value after a certain time period. When the load is in the range of 0.1 to 0.5 MPa, the creep compliance of the asphalt mixture is approximately consistent, which indicates that the asphalt mixture behaves as a linear viscoelastic material within the load range of 0.1 to 0.5 MPa. However, at load levels of 0.7 MPa and 0.9 MPa, the creep compliance of the asphalt mixture increases significantly, being 5 times and 10 times greater than that at lower loads. This suggests that the asphalt mixture is in a nonlinear phase at these load levels. The Curve Fitting Toolbox in MATLAB was utilized to perform Prony series fitting for creep compliance under different loads. The Prony series is expressed as Eq. (3), and the parameters τi of the Prony series are provided in Table 4, the parameters Ji values of the Prony series are provided in Table 4:

Table 4Parameter τivalues

1 | 2 | 3 | 4 | 5 | 6 | 7 | |

τi | 0.001 | 0.01 | 0.1 | 1 | 10 | 100 | 1000 |

Table 5Parameter values of creep compliance Prony series of asphalt mixtures under different loads

Ji | Loads (MPa) | ||||

0.1 | 0.3 | 0.5 | 0.7 | 0.9 | |

J0 | 0.925 | 1.123 | 1.252 | 1.532 | 1.645 |

J1 | 0.3273 | 1.877 | 2.433 | 13.46 | 23.02 |

J2 | 1.393 | 1.939 | 2.407 | 13.32 | 23.38 |

J3 | 1.278 | 1.564 | 1.92 | 13.2 | 23.37 |

J4 | 1.568 | 1.305 | 0.5098 | 17,27 | 22.2 |

J5 | 1.727 | 2.873 | 3.736 | 35.15 | 74.92 |

J6 | 0 | 0 | 0.0001916 | 7.075 | 0 |

J7 | 3.788 | 1.781 | 2.037 | 16.26 | 40.6 |

*Considering the form of (3), values of Ji less than 10-5 are treated as zero | |||||

3.2. Conversion of creep compliance to relaxation modulus

In the calculations of mechanical responses for asphalt pavement structures, modulus is used as an input parameter. Therefore, it is necessary to convert creep compliance into relaxation modulus. Research on the conversion of viscoelastic parameters for asphalt and asphalt mixtures primarily focuses on the conversion between creep compliance and relaxation modulus. Xue et al. [10] used BBR tests to measure the creep compliance of asphalt, and then discretized the creep compliance in the time domain, and calculated the relaxation modulus using the convolution relationship in the time domain between creep compliance and relaxation modulus, as shown in Eq. (4):

where, E(t0+t12)=2J(0)+J(t1).

Similarly, Yan and Wang [11] also used this method to calculate the relaxation modulus of asphalt mixtures using creep compliance. Andmany countries also used this method for parameter conversion of viscoelastic materials in the early stages [12-13]. However, this method requires the discretization of creep compliance in the time domain, which resulted into some errors in the backcalculation of relaxation modulus. Lvet al. [14] employed the calculation relationship in Eq. (4) to determine the parameter values in the expression for relaxation modulus, and established an expression for the relaxation modulus of asphalt mixtures based on the viscoelastic constitutive equation for asphalt mixtures.

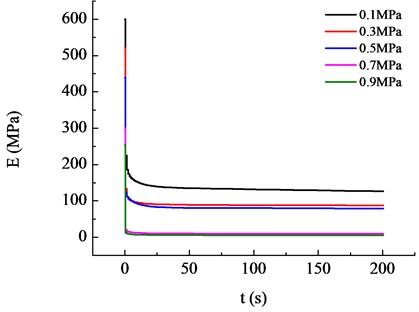

This paper employs the method proposed by Tschoegl [15] to perform the conversion between creep compliance and relaxation modulus. The specific conversion formula is as follows. And the calculating result is shown in Fig. 2.

Fig. 2The relaxation modulus of asphalt mixture under different loads

From Fig. 2, it can be observed that the relaxation modulus decreases continuously with an increase in loading time. Additionally, it is evident that the relaxation modulus values tend to become two-digit numbers under the influence of high temperatures (40 °C) and high loads (0.7 MPa, 0.9 MPa). This phenomenon is also consistent with the findings in the studies of Huang et al. [16] and Lvet al. [14]. Furthermore, it can be noted that the magnitude of the load significantly affects the relaxation modulus of the asphalt mixture.

4. Study of asphalt pavement mechanical response

From the findings in the previous section, it is evident that the magnitude of the load has a significant impact on the relaxation modulus of the asphalt mixture. In the 2017 edition of China’s Asphalt Pavement Structural Design Code, the dynamic modulus of the asphalt mixture is used as a material parameter for analysis in the context of layered elastic systems to study asphalt pavement structural behavior. On one hand, this design approach does not consider the viscoelastic properties of the asphalt mixture, especially during high-temperature seasons. On the other hand, the vertical load decreases gradually in the depth direction of the asphalt pavement under vehicle loads. This implies that the modulus at different positions within the asphalt pavement structure are not equal.

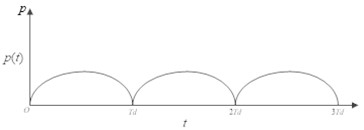

The American Empirical Mechanics Method [17] points out that different driving speeds result in different load frequencies within the pavement structure. Referring to the research findings of Zhao et al. [18-19], a driving frequency of 10 Hz is adopted, which is corresponding to a vehicle time of 0.1 seconds. Thus, the vehicle load is represented as a semi-sinusoidal load, with the load function defined as shown in Eq. (6) and Fig. 3:

The load function is incorporated to multilayered viscoelastic mechanics after undergoing Laplace transformation.

Fig. 3Half sine wave load diagram

To analyze the impact of nonlinear load variations on the mechanical response of asphalt pavement under different conditions, the pavement structure combinations and parameters used are outlined in Table 6. The asphalt layer is divided into three layers, with the modulus values for each layer as specified in Table 7.

Table 6Typical asphalt pavement structure

Structural layer | Material type | Thickness (mm) | Modulus (MPa) | Poisson’s ratio |

Surface layer | AC-13 (SBS Modified Asphalt) | 40 | – | 0.25 |

AC-20 (Grade 90 Road Petroleum Asphalt) | 60 | – | 0.25 | |

AC-20 (Grade 90 Road Petroleum Asphalt) | 60 | – | 0.25 | |

Base layer | Cement-Stabilized Crushed Stone | 300 | 7500 | 0.25 |

Subbase layer | Graded Crushed Stone | 180 | 250 | 0.35 |

Subbase | 81 | 0.40 | ||

Table 7Modulus of asphalt surface layer under different working conditions

Case one | Case two | Case three | |

Upper layer | Relaxation modulus at 0.9 MPa | Relaxation modulus at 0.7 MPa | Relaxation modulus at 0.5 MPa |

Middle layer | Relaxation modulus at 0.9 MPa | Relaxation modulus at 0.5 MPa | Relaxation modulus at 0.3 MPa |

Lower layer | Relaxation modulus at 0.9 MPa | Relaxation modulus at 0.3 MPa | Relaxation modulus at 0.1 MPa |

The analysis focuses on the permanent deformation of the asphalt surface layer at the end of loading and the tensile stresses at the bottom of the semi-rigid base layer during the loading process. The calculation results are presented in Table 8.

From Table 8, it can be observed that the nonlinearity of the asphalt mixture has a relatively minor impact on the tensile stress at the bottom of the semi-rigid base layer, indicating minimal influence on the base layer's fatigue performance. However, it significantly affects the permanent deformation of the asphalt layer [20]. In case one, the permanent deformation of the asphalt layer is five times that of case three, and the permanent deformation of the asphalt layer of case two is twice that of case three.

Table 8Calculation results under different working conditions

Case | Case one | Case two | Case three |

Asphalt layer permanent deformation (0.01 mm) | 368.6 | 165.5 | 67.7 |

Tensile stress at the bottom of the base layer (MPa) | 0.447 | 0.463 | 0.448 |

5. Conclusions

The specific conclusions are as follows:

1) The magnitude of the load significantly affects the creep compliance of asphalt mixtures. For AC-16 mixtures, the creep compliance of asphalt mixtures remains roughly the same under loads ranging from 0.1 to 0.5 MPa, which indicates that the material behaves within the linear viscoelastic region. However, when the load exceeds 0.5 MPa, the creep compliance increases significantly, which indicates the material's entry into the nonlinear viscoelastic region.

2) Through the convolution formula between relaxation modulus and creep compliance, relaxation modulus conversion was accomplished. The relaxation modulus of asphalt mixtures decreased rapidly initially and eventually stabilized under high-temperature and high-load conditions. The calculation results also demonstrated that the magnitude of the load significantly influences the relaxation modulus of asphalt mixtures.

3) The nonlinearity of asphalt mixtures has a minor impact on base layer fatigue cracking but significantly affects the permanent deformation of the asphalt layer. In asphalt pavement structural design, attention should be given to the influence of material nonlinearity caused by vehicle axle loads on pavement permanent deformation.

References

-

K. H. Moon, A. Cannone Falchetto, and M. O. Marasteanu, “Rheological modelling of asphalt materials properties at low temperatures: from time domain to frequency domain,” Road Materials and Pavement Design, Vol. 14, No. 4, pp. 810–830, Dec. 2013, https://doi.org/10.1080/14680629.2013.817351

-

F. Olard and H. Di Benedetto, “General “2S2P1D” Model and relation between the linear viscoelastic behaviours of bituminous binders and mixes,” Road Materials and Pavement Design, Vol. 4, No. 2, pp. 185–224, Jan. 2003, https://doi.org/10.1080/14680629.2003.9689946

-

T. Q. Yang et al., Theory and Application of Viscoelasticity. Beijing: Science Press, 2004.

-

Y. Zhao, Y. Ni, L. Wang, and W. Zeng, “Viscoelastic response solutions of multilayered asphalt pavements,” Journal of Engineering Mechanics, Vol. 140, No. 10, p. 04014, Oct. 2014, https://doi.org/10.1061/(asce)em.1943-7889.0000797

-

Q. Xu and J. A. Prozzi, “A time-domain finite element method for dynamic viscoelastic solution of layered-half-space responses under loading pulses,” Computers and Structures, Vol. 160, pp. 20–39, Nov. 2015, https://doi.org/10.1016/j.compstruc.2015.07.005

-

J. Kim, “General viscoelastic solutions for multilayered systems subjected to static and moving loads,” Journal of Materials in Civil Engineering, Vol. 23, No. 7, pp. 1007–1016, Jul. 2011, https://doi.org/10.1061/(asce)mt.1943-5533.0000270

-

Q. T. Nguyen, H. Di Benedetto, and C. Sauzéat, “Linear and nonlinear viscoelastic behaviour of bituminous mixtures,” Materials and Structures, Vol. 48, No. 7, pp. 2339–2351, Jul. 2015, https://doi.org/10.1617/s11527-014-0316-5

-

D. Gao, P. Wang, M. Li, and W. Luo, “Modelling of nonlinear viscoelastic creep behaviour of hot-mix asphalt,” Construction and Building Materials, Vol. 95, pp. 329–336, Oct. 2015, https://doi.org/10.1016/j.conbuildmat.2015.07.112

-

E. Rahmani, M. K. Darabi, D. N. Little, and E. A. Masad, “Constitutive modeling of coupled aging-viscoelastic response of asphalt concrete,” Construction and Building Materials, Vol. 131, pp. 1–15, Jan. 2017, https://doi.org/10.1016/j.conbuildmat.2016.11.014

-

Z. J. Xue, X. N. Zhang, X. L. Zhan, J. N. Wang, and Y. Zhao, “Calculation of low temperature relaxation modulus of asphalt based on creep test,” Journal of South China University of Technology (Natural Science Edition), No. 2, pp. 64–68, 2007.

-

M. X. Yan and J. C. Wang, “Study on conversion between creep compliance and relaxation modulus of asphalt mixture,” Technology of Highway and Transport, Vol. 32, No. 5, pp. 28–31, 2016, https://doi.org/10.13607/j.cnki.gljt.2016.05.008

-

S. W. Park and Y. R. Kim, “Interconversion between relaxation modulus and creep compliance for viscoelastic solids,” Journal of Materials in Civil Engineering, Vol. 11, No. 1, pp. 76–82, Feb. 1999, https://doi.org/10.1061/(asce)0899-1561(1999)11:1(76)

-

S. Mun, G. R. Chehab, and Y. R. Kim, “Determination of time-domain viscoelastic functions using optimized interconversion techniques,” Road Materials and Pavement Design, Vol. 8, No. 2, pp. 351–365, Jan. 2007, https://doi.org/10.1080/14680629.2007.9690078

-

H. J. Lv, C. Zhang, H. Q. Liu, R. Luo, and H. Chen, “A novel approach for converting creep compliance into relaxation modulus for asphalt mixtures,” Journal of Highway and Transportation Research and Development, Vol. 34, No. 11, pp. 1–7, 2017.

-

N. W. Tschoegl, The Penomenological Theory of Linear Viscoelastic Behaviour. Berlin: Springer-Verlag, 1989.

-

W. K. Huang, L. J. Zhang, X. N. Zhang, and S. S. Shao, “Research on the relaxation modulus converted to creep compliance of asphalt mixture,” Journal of Transport Science and Engineering, Vol. 31, No. 3, pp. 7–12, 2015, https://doi.org/10.16544/j.cnki.cn43-1494/u.2015.03.002

-

M. W. Witczak, D. Andrei, and W. N. Houston, “Guide for the mechanistic-empirical design of new and rehabilitated pavement structures,” Transportation Research Board of the National Research Council, 2004.

-

Y. Q. Zhao, X. Yu, and Y. Q. Tan, “Effects of vehicle speed on mechanical properties ofasphalt mixtures and pavement responses,” Journal of Beijing University of Technology, Vol. 36, No. 9, pp. 1253–1257, 2010.

-

Y. Q. Zhao and Y. Q. Pan, “Study on loading frequency distribution and changes within asphalt pavements,” Journal of Transport Science and Engineering, No. 4, pp. 7–10, 2007.

-

S. Q. Chen, “Theoretical solution and application of layered viscoelastic system under non axisymmetric vertical load,” Harbin Institute of Technology, 2016.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.