Materials Science

Editor's pick

Research Article

Enhancing technical proposal evaluation in consultant selection in Department of Water Resources and Irrigation, Nepal: a fuzzy analytic hierarchy process and fuzzy TOPSIS

By Nischal Silwal, Subash Kumar Bhattarai, Dinesh Sukamani

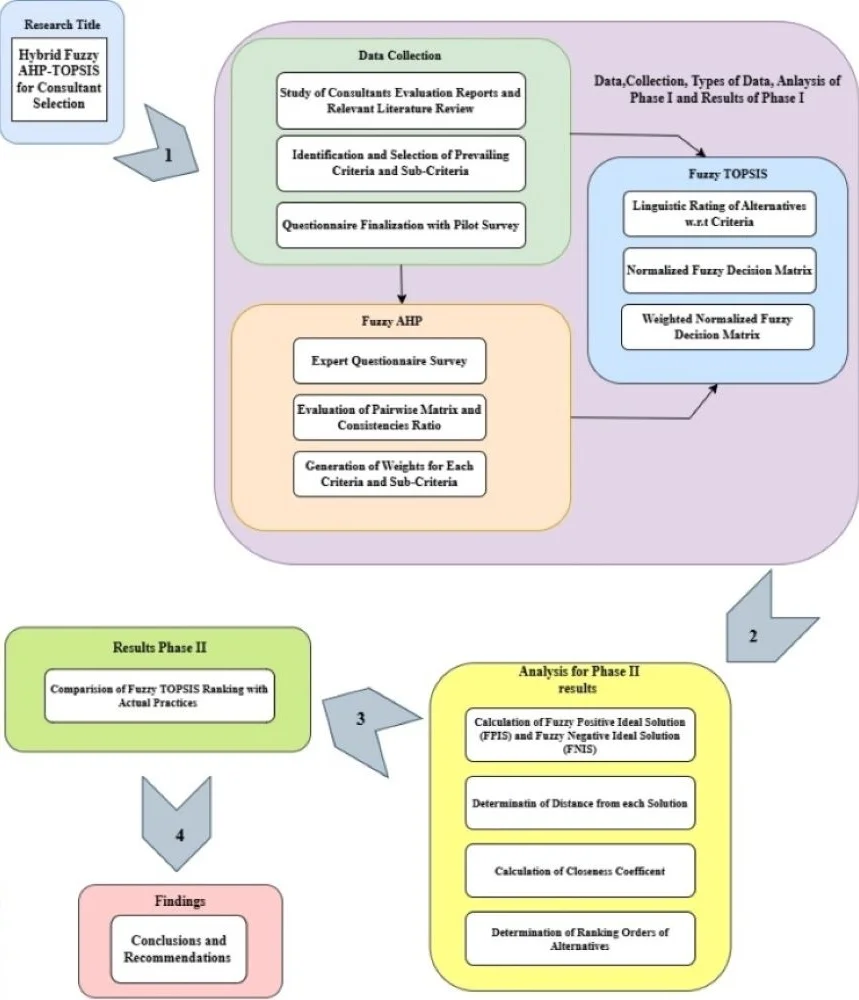

In today's dynamic construction landscape, where challenges like complexity, costs, and uncertainties loom large, the selection of consultants emerges as a pivotal factor for project triumph. Among the array of methods available, Quality and Cost Based Selection (QCBS) stands out for its holistic approach, considering both technical prowess and financial considerations. Yet, amidst its structured framework, the evaluation of technical proposals within QCBS often grapples with subjectivity, despite the presence of well-defined criteria. This study boldly tackles this challenge head-on by delineating common criteria and sub-criteria for consultant selection within the esteemed Department of Water Resources and Irrigation (DWRI). Leveraging the innovative Fuzzy Analytic Hierarchy Process (AHP), our endeavor is to ascertain the relative significance of these criteria and sub-criteria. Through the fusion of Fuzzy AHP and Fuzzy Techniques for Order Preference by Similarity to Ideal Solution (TOPSIS), our study aspires to revolutionize consultant ranking methodologies. The ingenious application of Fuzzy AHP empowers us to derive independent weights for criteria and sub-criteria, thereby embracing the inherent ambiguity and nuances of qualitative factors. Subsequently, employing Fuzzy TOPSIS, we aim to systematically rank consultant alternatives based on their Closeness Coefficients, heralding a paradigm shift in evaluation paradigms. Through this groundbreaking hybrid approach, our study endeavors to elevate the consultant selection process, ensuring an impeccable alignment of chosen consultants with project requisites and benchmarks. By dispelling the shadows of subjective decision-making uncertainties, our research holds the promise of ushering in a new era of excellence in the realm of construction projects under the aegis of the Department of Water Resources and Irrigation.

December 30, 2024

Applied Physics

Most cited

Research Article

A conversion guide: solar irradiance and lux illuminance

By Peter R. Michael, Danvers E. Johnston, Wilfrido Moreno

December 4, 2020

Applied Physics

Most cited

Research Article

Experimental analysis of cutting force during machining difficult to cut materials under dry, mineral oil, and TiO2 nano-lubricant

By I. P. Okokpujie, L. K. Tartibu

December 13, 2021

Applied Physics

Most cited

Research Article

Experimental kinematic analysis of an intermittent motion planetary mechanism with elliptical gears

By Alexander Prikhodko

September 30, 2020

Applied Physics

Most cited

Research Article

Experimental and finite element approach for finding sound absorption coefficient of bio-based foam

By L. Yuvaraj, S. Jeyanthi, Lenin Babu Mailan Chinnapandi

September 30, 2019

Public Health

Liquid and Gaseous Energy Resources

Research Article

Sucker rod pump frequency-elastic drive mode development – from the numerical model to the field test

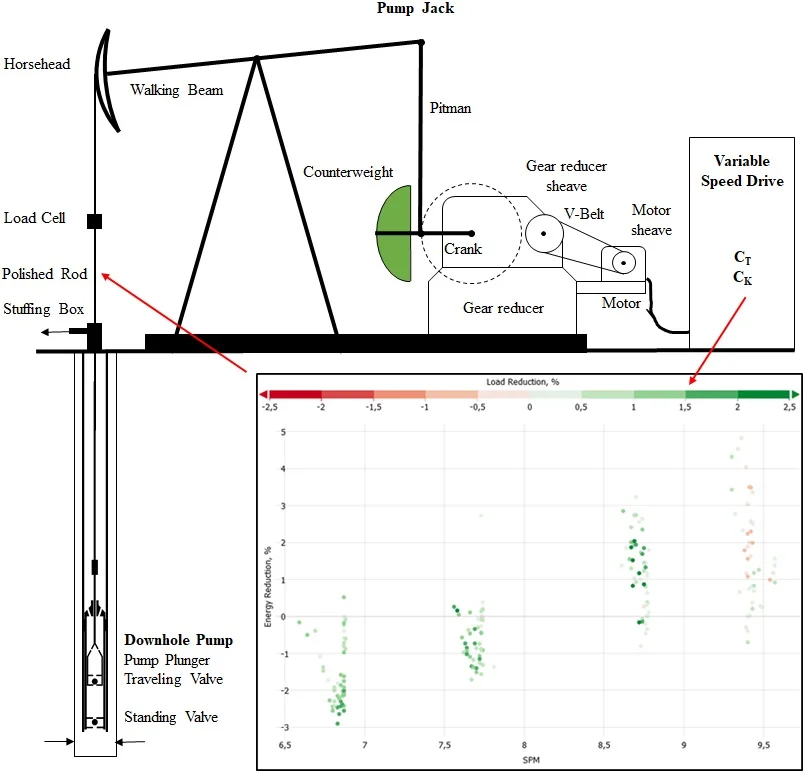

A frequency-elastic drive mode for a sucker rod pumping system is introduced to reduce its polished rod peak loads and the total energy consumption. Numerical modeling and an extensive field test verify the concept. The frequency-elastic drive mode is a software solution for variable speed drive systems, which can be applied in the controller and does not require any hardware adjustments. The novel drive mode adjusts the set frequency, sent by the controller to the frequency converter, depending on the actual power requirements. An increase in power consumption results in a reduction of the set frequency, which is proportional to the power consumption increase. A reduction in power consumption results in the opposite effect to achieve a similar pumping speed as for regular operation. The frequency-elastic drive mode is simulated by a numerical model, which covers the entire pumping system. An extensive field test was performed to verify the concept and the numerical model. The simulation and the field test have confirmed the concept of the frequency-elastic drive mode and quantified its saving potential. The evaluation of the field test has shown that the energy-saving potential can reach five percent. In addition, a peak polished rod load reduction of up to three percent was seen. At the tested pumping system the frequency elastic drive mode under optimized parameters yields the best results in terms of total energy savings in the pumping speed range between 7 to 10 strokes per minute. A downhole system efficiency increase was seen for any pumping speed. The numerical model matches the field test data and allows the performance prediction of the novel drive mode for changed parameters and wellbore configurations without extensive field testing. The novelty of the presented paper is the concept of the frequency-elastic drive mode, which is a pure software solution for variable speed drive sucker rod pumping systems. The holistic model includes the entire pumping system and matches the field test data at remarkable accuracy.

June 21, 2021

Industrial Engineering

Research Article

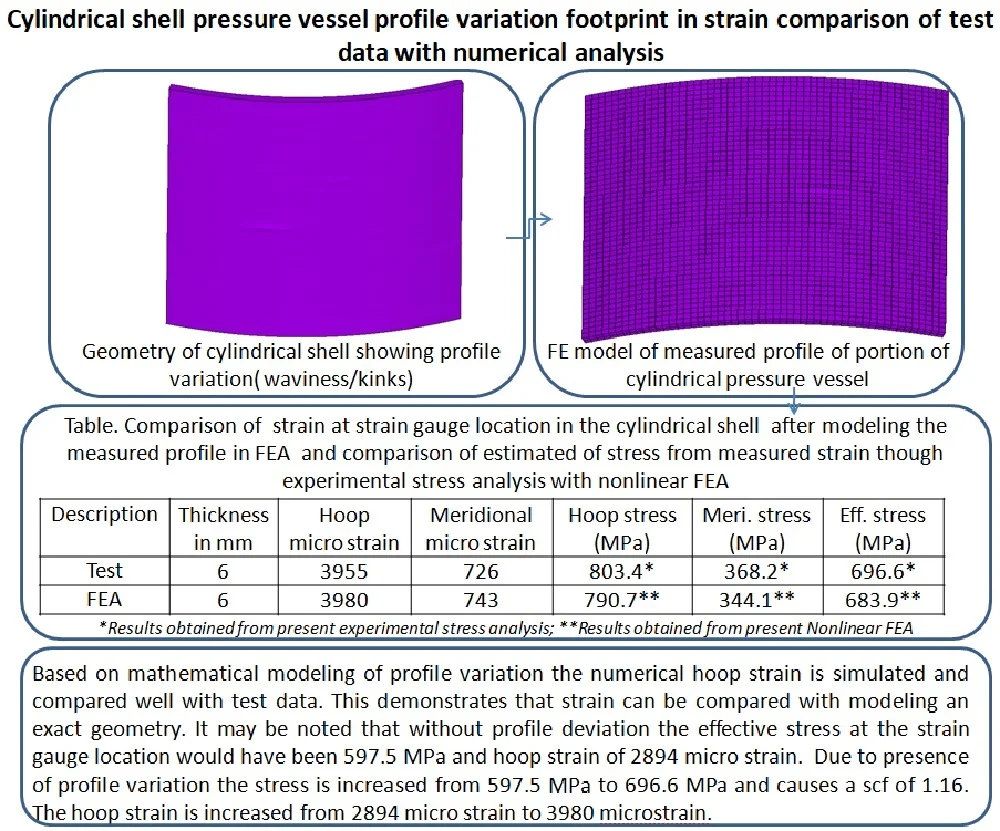

Cylindrical shell pressure vessel profile variation footprint in strain comparison of test data with numerical analysis

The strain comparison of a pressure vessel made of HSLA 15CDV6 in a cylindrical shell membrane region in a pressure test is discussed in this paper. Non-linear finite element analysis (FEA) of thin-walled cylindrical pressure vessels has been carried out using ANSYS. Hoop strain obtained from FEA is not compared well with the pressure test data at the membrane location of the cylindrical shell where the strain gauge is mounted. So to explain the reasons for the difference in strains at the membrane region, the profile of the cylindrical shell at strain gauge region has been measured. The 3D FEA of the cylindrical region with the measured profile is performed. It is found that with measured profile the FEA is giving the strain close to measured strain in the hoop direction. This leads to the increase in strain and stress as having been demonstrated through mathematical modeling in the deviated profiles variations of cylindrical shells. Therefore, the stresses in the deviated region are greater than those that would exist in an undeviated cylindrical shell, which reduces the margin of safety with respect to the yield strength of the material and causes stress concentration. The details of the stress analysis carried out including the effect of measured 3D profile variation are discussed in this paper.

December 23, 2021

Industrial Engineering

Research Article

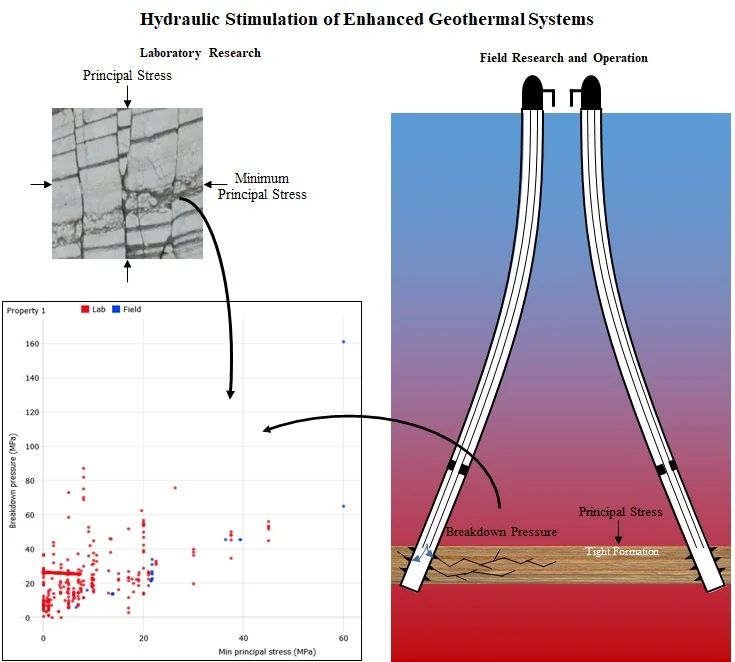

A holistic review on hydraulic fracturing stimulation laboratory experiments and their transition to enhanced geothermal system field research and operations

This paper presents a thorough overview of hydraulic stimulation techniques, conducted in laboratories. It further analyses field experiments and ongoing projects for geothermal energy production to investigate if the findings from the lab can be practically applied to the field. Stimulation techniques have been long used in the oil and gas industry as a means to increasing the rock permeability and consequently the reservoir’s fluid production rate. Among the different stimulation methods, hydraulic fracturing is known to be the most successful in creating new passageways in the formation. Nevertheless, the benefits of fracturing have been hindered by the handful of events in which poor planning had led to severe seismic activities. Therefore, across the globe, many efforts were dedicated to characterizing fracture creation and propagation in different rocks, not only to provide know-how for further and safer developments in the oil and gas front but also to adapt such findings to the ever-emerging field of geothermal energy recovery. In the course of this work, over 100 papers were studied. The papers included laboratory experiments on various rock types encountered in reservoirs, where parameters such as stress regime, fracture initiation pressure, formation breakdown pressure, volume, and types of fluid injected were monitored. To investigate whether or not such practices had been previously applied in geothermal energy production, a thorough study was also conducted on large-scale experimental setups constructed in the field as well as hydraulic fracturing procedures performed in operational projects, going back as far as a decade. The results show an agreement between laboratory experiments and field operations, yet naturally including individual results from cases where either the lab parameters or field characteristics were extraordinarily unique. Multiple cross-correlations were also performed between different key parameters that play a role in a fracturing process, providing trends that could be intra- or extrapolated for further research and planning. The novelty of this work is the comprehensive analysis of numerous research projects done around the world. As a result, this paper will not only be an informative and yet compacted source of information concerning previous projects, but it also points out the main factors and their relationships which need to be understood to guide a future project to success.

June 21, 2021

Industrial Engineering

Research Article

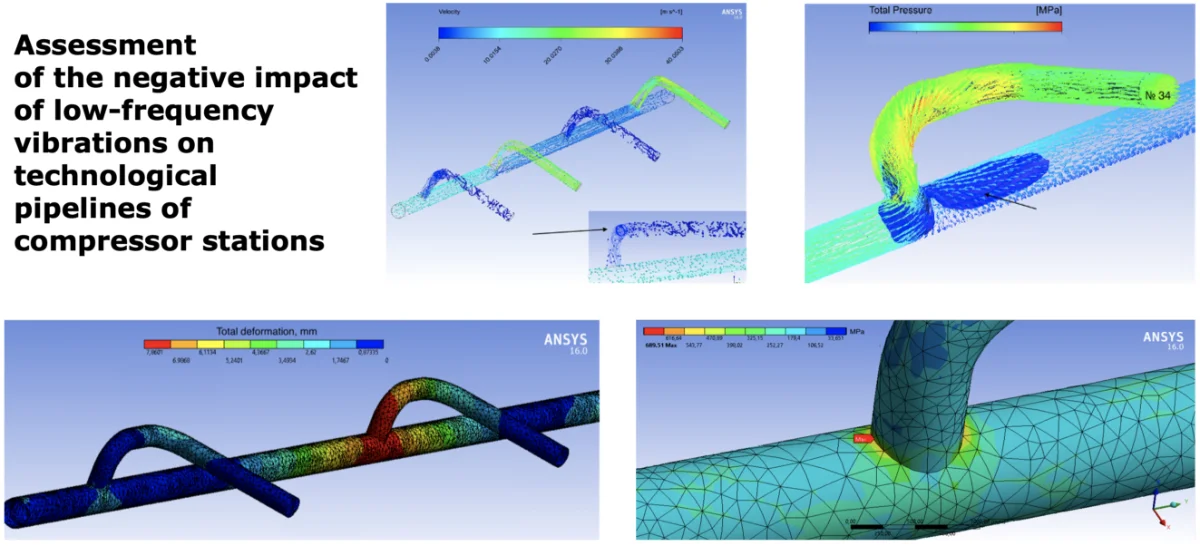

Assessment of the negative impact of low-frequency vibrations on technological pipelines of compressor stations

The intensive development of gas transport and compressor manufacturing aimed at increasing the unit capacities of gas pumping units, creating high-flow centrifugal compressors, increasing the productivity of compressor shops has led to the appearance of fundamentally new problems in the diagnosis of industrial pipelines. The reasons for premature failure of piping manifold of gas pumping stations can be associated with both high static voltage in the pipelines and a high level of vibration. The main reasons for the increased vibration of the technological pipelines of the centrifugal compressor can be significant disturbing forces of the gas flow, coincidence of the natural frequencies of the pipeline system elements with frequencies of the disturbing forces, low dynamic stiffness of the pipeline- support system or a combination of the above conditions. The most effective method for studying problems such as low-frequency vibrations is the combination of engineering means for calculating dynamic processes and the results of measurements of the parameters of these processes in real systems and operating modes of the compressor stations. The hypotheses of the occurrence of low-frequency vibrations in pipelines are considered during the study, the acoustic properties of the process piping, and the resonant vibrations conditions are calculated. A computer model was created in the ANSYS Workbench software in order to consider the loading conditions for process piping. Based on Gazprom company standard 2-2.3-324-2009, an algorithm is proposed that is of practical importance for engineers of plant diagnostics operating gas transmission equipment. It is proposed to combine the performance of vibroacoustic studies and computing modeling with the determination of trends in the technical condition of the system for the analysis of changes in vibro-parameters. As a result of the work, direct measurements of the vibrodiagnostic specialists of the operating compressor station were compared with the obtained modeling data. Some methods were proposed to reduce the impact of operating conditions and design of the process piping on unacceptable low-frequency vibrations.

June 25, 2021

Industrial Engineering

Liquid and Gaseous Energy Resources

Devoted to transportation of liquid and gaseous energy resources: hydrocarbons, crude oil, oils, petroleum, water, hydrogen, biofuel

APC

Free of charge

Best of Theme

Most cited

Research article

January 22, 2021

Design of low-cost wireless noise monitoring sensor unit based on IoT concept

By Maja Anachkova, Simona Domazetovska, Zlatko Petreski, Viktor Gavriloski

Most cited

Research article

May 7, 2021

Modelling and mitigation of drone noise

By John Kennedy, Simone Garruccio, Kai Cussen

Most cited

Research article

June 30, 2022

The vibration of a thermoelastic nanobeam due to thermo-electrical effect of graphene nano-strip under Green-Naghdi type-II model

By Hamdy M. Youssef, Abdullah A. Al Thobaiti

Most cited

Research article

August 25, 2021

Design and development of patient-specific prosthetic socket for lower limb amputation

By Giri Ratnakar Gubbala, Ramu Inala

You might also like

Most downloaded

Research Article

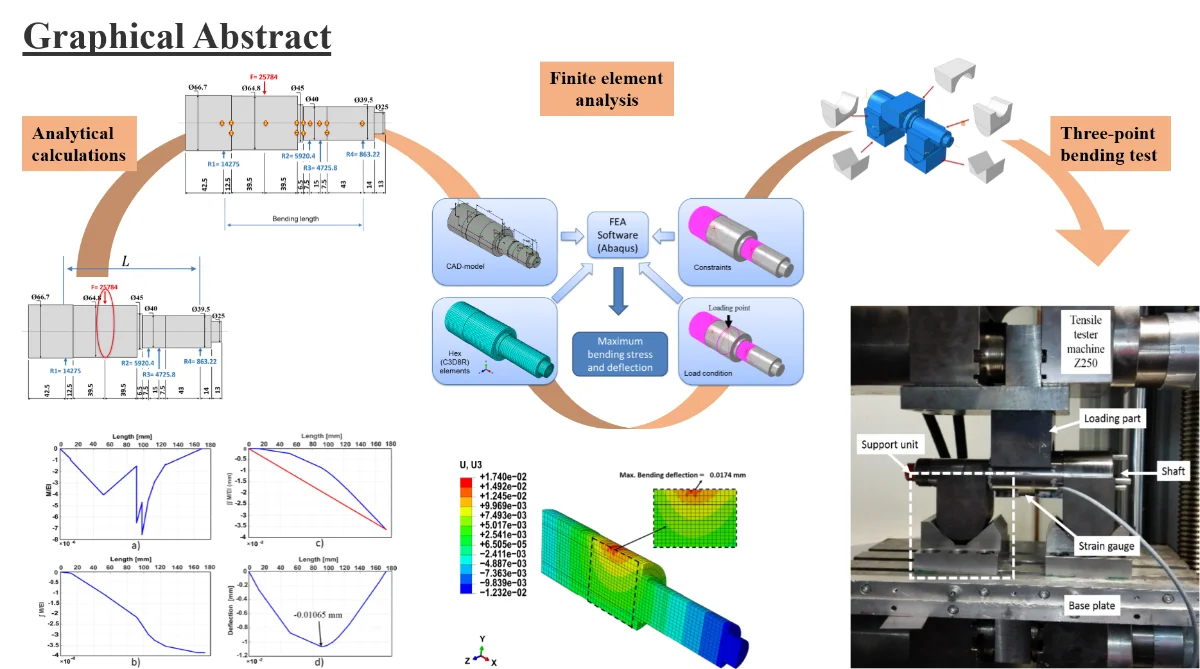

FE analysis and experimental determination of a shaft deflection under three-point loading

By Bernd Engel, Sara Salman Hassan Al-maeeni

Increasing industrial demand for new products including advanced production technology leads to substantial natural resources consumption. Furthermore, huge environmental pollution and emerging environmental legislation motivate the machine tools industry as one of the major resource consumers on a global scale to develop methods for more sustainable use of the Earth's resources. Machine tools re-engineering concerning design and failure analysis is an approach by which outdated machines are upgraded and restored to like-new machines. To evaluate the mechanical failure of the used machine components and to ensure their reliable future performance, it is essential to make material, design, and surface investigations. In this paper, an experimental approach based on the principle of a three-point bending test is presented to evaluate the shaft elastic behavior under loading. Moreover, finite element analysis and numerical integration method are used to determine the maximum linear deflection and bending stress of the shaft. Subsequently, a comparison between the results is made. In conclusion, it was found that the measured bending deflection and stress were well close to the admissible design values. Therefore, the shaft can be used again in the second life cycle. However, based on previous surface tests conducted, the shaft surface needs re-carburizing and refining treatments to ensure the reliable performance of the surface.

September 24, 2018

Applied Physics

Most downloaded

Research Article

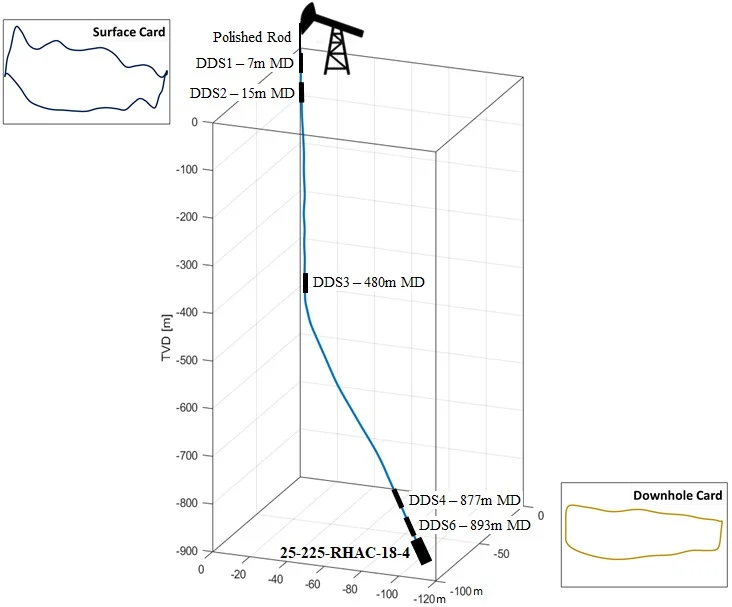

Sucker rod pump downhole dynamometer card determination based on a novel finite element method

By Patrick Eisner, Clemens Langbauer, Rudolf Fruhwirth

An advanced dynamic finite element model is presented that diagnoses the downhole pump performance of sucker rod pumping systems, applicable for any pumping conditions and equipment used. The results are compared to downhole measurements and other evaluation techniques. Buckling is an undesirable phenomenon occurring in sucker rod pumping. It essentially depends on the plunger load, which is a function of time and typically not measured but evaluated by diagnostic tools. Existing diagnostic tools exhibit specific limitations that reduce their applicability and output quality. This paper introduces a diagnostic tool, which can predict the rod string's stress field and its movement not only at the pump plunger but all along the rod string. Moreover, this tool can account for the interaction between rod guides and tubing as well as rod string and tubing. To this end, innovative tube-to-tube contact modeling is applied. The high precision results are accomplished by running a dynamic finite element simulation. The basic principle is to evaluate the plunger load incrementally by consecutively applying restarts of each time step, fully automated and computation time optimized. This publication shows that both the plunger load and the rod string’s dynamic behavior can be determined for any given wellbore as long as the borehole trajectory and surface dynamometer measurements are known. The dynamic finite element model is evaluated for a deviated system and a vertical system equipped with two different downhole pump types. Comparing the simulation results with the available downhole measurements and the analytical solution shows an excellent match, whereas the proposed solution provides a considerable amount of details about the overall system’s behavior. The evaluation has shown that the performance of standard and novel downhole pump types can be successfully diagnosed in detail, which is just possible under limitations with commercial software solutions. This tool can correctly predict whether or not the sucker rod string is subjected to buckling during the downstroke, which has a considerable effect on increasing the mean time between failures of a sucker rod pumping system. From the economic point of view, this means that the economic limit of a wellbore can be postponed. The novelty of the shown technique is the consideration of the full 3D trajectory and the implementation of only physical properties, result in an excellent accuracy of the output.

June 21, 2021

Industrial Engineering

Error correction and uncertainty measurement of short-open-load calibration standards on a new concept of software defined instrumentation for microwave network analysis

Software-Defined Radio (SDR) has appeared as a sufficient framework for the development and testing of the measurement systems such as a signal generator, signal analyzer, and network analysis used in the network analyzer. However, most of researchers or scientists still rely on commercial analyzers were larger benchtop instruments, highly cost investment and minimum software intervention. In this paper, a new concepts measurement revolution called as Software Defined Instrumentation (SDI) on network analysis is presented, which is based on reconfigurable SDR, a low-cost implementation, ability to access RF chain and utilizing open source signal processing framework. As a result, a Vector Network Analyzer (VNA) has been successful implemented by deploying an SDR platform, test sets, and data acquisition from the GNU Radio software in host PC. The known calibration process on SHORT-OPEN-LOAD (SOL) technique is validated to ensure measurement data from this SDI free from systematic error. Two types of SOL calibration standards used for a comparison study to validate the SDI measurement system which is capable of generating the response on the differential of standard quality and accuracy of standards kits. Finally, calibration uncertainty analysis is also presented in this work by utilizing RF open source package without any cost addition.

Joint parameter identification, vibration and noise analysis of gearbox

A certain type of gearbox is investigated for the problem that the stiffness and damping of bearings are difficult to be accurately determined and then affect the analysis of vibration and noise of gearbox. Firstly, a coupled dynamic lumped parameter model of three-stage helical gear system with consideration of bearing stiffness, bearing damping, and transmission error is established. The modal parameters of gear system are obtained by using the experimental modal analysis method with single-input and multiple-output. The equation for joint parameter identification of gearbox is established which is based on the experimental modal analysis theory and the dynamic lumped parameter model, and subsequently the parameters of the joint are obtained by the least square method. Then, a gear-shaft-bearing- housing coupled dynamic finite element model is developed on the basis of the identified parameters, and after that the dynamic response results of gearbox are solved by using the modal superposition method and compared with the vibration test results. Finally, an acoustic boundary element model of gearbox is established by taking the dynamic response results as the acoustic boundary condition, and the surface sound pressure and radiation noise of gearbox are solved by the boundary element method (BEM), and then the results are compared with the noise test. The results show that the simulation laws and test laws are in good agreement, and thus the method of joint parameter identification, vibration and noise analysis of gearbox is feasible.