Abstract

The hazards arising from long-term hand-transmitted vibration operations can cause significant damage to the human body. As China is a populous country, understanding the current situation of vibration exposure among workers in various related fields in China holds significant reference value. To this end, this paper analyzes data from core journal literature in China from the 1980s to the present based on the keywords hand-arm vibration disease, hand-transmitted vibration, and occupational exposure. This paper provides an overview of the current status of hand-transmitted vibration hazards, including the distribution characteristics, hazards, and diagnostic methods of hand-arm vibration disease, as well as the deficiencies in these diagnostic methods. It also integrates data on the vibration intensity, frequency, and prevalence of vibration tools to analyze the relationship between the prevalence of hand-arm vibration disease and the vibration intensity and frequency of vibration tools. The results indicate that the vibration tools causing occupational hand-arm vibration disease are primarily found in the mining and manufacturing industries, with rock drilling jobs and positions being dominant in the mining industry and grinding jobs and positions being dominant in the manufacturing industry. The A(4) values of grinding tools, jobs, or positions are significantly higher than China’s limit value of 5 m/s2 for hand-transmitted vibration. The A(4) distribution of rock drilling tools is more concentrated, while the A(4) distribution of grinding tools is broader. The current diagnostic methods have poor specificity and sensitivity. There is insufficient awareness of the hazards of hand-transmitted vibration. There is no significant correlation between A(4) and the prevalence of vibration white finger (P>0.05), and A(4) alone is insufficient to reflect the extent of harm caused by hand-transmitted vibration operations to the human body. Both low-frequency and high-frequency vibrations may be harmful to the human body, and there may be a positive correlation between the fundamental frequency of vibration tools and the prevalence of disease (r>0,P<0.05).

Highlights

- There is no significant correlation between A(4) and the prevalence of vibration white finger (P>0.05).

- A(4) alone is insufficient to reflect the extent of harm caused by hand-transmitted vibration operations to the human body.

- There may be a positive correlation between the fundamental frequency of vibration tools and the prevalence of disease (r>0,P<0.05).

1. Introduction

With the rapid development of industry, the use of vibration tools or exposure with vibrated workpieces has long been the norm in many occupations. These vibrations often result in whole body vibration and hand-transmitted vibration (HTV). Whole body vibration refers to mechanical vibration that poses a risk to the health and safety of employees, particularly by causing discomfort in the waist area and trauma to the spine when transmitted throughout the body [1]. HTV, also known as hand-arm vibration (HAV) or segmental vibration (SV), often occurs when vibration tools are used or vibrated workpieces are exposed in production [2]. In this paper, we mainly consider the effect of vibration on the hands, i.e., HTV. Whole body vibration is also a direction for further research and generalization in the future. Prolonged exposure to hand-transmitted vibration can cause hand-arm vibration disease (HAVD), including vibration white finger (VWF), muscle cramps, headaches, psychological problems, etc., which seriously affects people's physical and mental health. Therefore, it is very important to reduce the impact of HAVD on the related working population.

Abatement of the impact of HAVD on human beings generally includes early prevention and treatment before the disease and later treatment after the disease. Currently, early prevention and treatment methods mainly include: controlling the source of vibration, reforming the production process, reducing the intensity and frequency of HTV to a harmless level; reducing the time of HTV operations, strengthening personal protection, changing job types; strengthening the occupational monitoring and health of the workers working with HTV [3]. Later treatment mainly includes medication, physiotherapy, such as massage and acupuncture, and surgical treatment. In recent years, some studies have shown that after the onset of HAVD, recovery is more difficult, and some patients may still experience worsening of certain clinical manifestations even after they are removed from vibration operations [4]. Thus, early prevention and treatment of workers exposed to HTV is of significant research value.

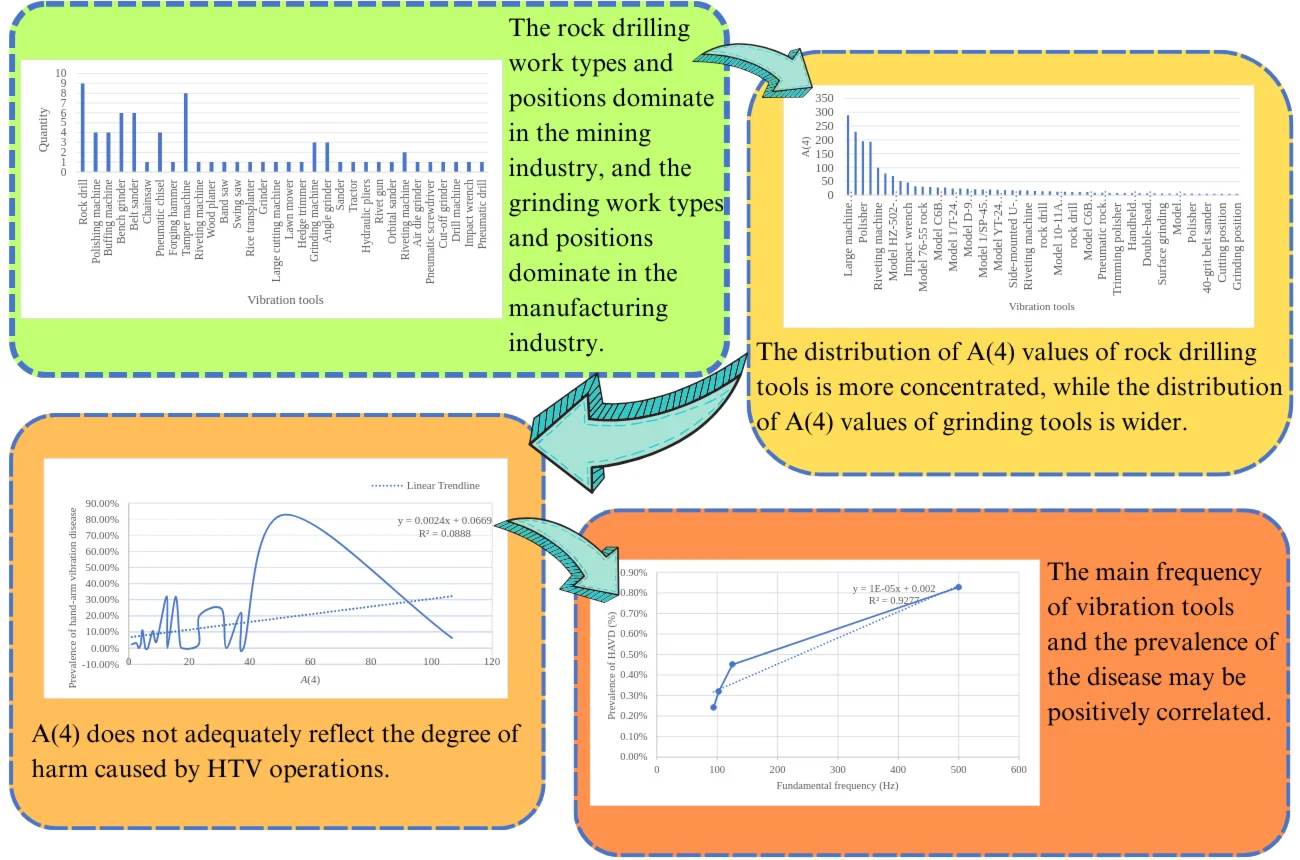

In order to understand the current status of research in the field of HTV, this paper statistically analyzes the literature included in the China National Knowledge Infrastructure (CNKI) from 1983 to 2023 according to the technical terms of HTV, HAVD and other related technical terms. As shown in Fig. 1, the number of relevant literature in the CNKI shows that the research in the field of HTV has been on an upward trend in the past 20 years. So far, many scholars have made significant progress in the field of HTV, and some literature summarizes the existing research. Zhang et al. [5] provided an overview of HAVD clinical symptoms and other aspects of HAVD, serving as a reference for updating treatment techniques and developing norms for prevention and treatment. Wu and Yang [6] outlined the hazards of HTV, introduced a test system for HTV response characterization and the grip posture of the hand, and provided an overview of the vibration response characterization of the hand-arm system and the damping performance of the damping gloves. Bu et al. [7] introduced the functional damage of the nervous system caused by HTV, discussed the influencing factors of vibratory nerve injury, and explored the research prospect related to vibratory nerve injury based on the relevant literature at home and abroad. In order to grasp the latest progress in the field of HTV, outline the hazards of HTV, and analyze the relationship between the prevalence of HAVD and the vibration intensity and frequency of vibration tools, this paper presents a review of the hazards of HAVD and the vibration intensity, frequency, and prevalence of vibration tools. This study helps peers quickly grasp the current state of research on the hazards and pathogenicity of HAVD.

Fig. 1CNKI search results

2. Literature and data processing

2.1. Literature search and selection

To search CNKI for studies on hand-transmitted vibration, HTV, HAVD, and occupational exposure in China. The categories of literature were limited to domestic and foreign standards, domestic core journals, and foreign literature by domestic authors; and the publication time was limited to 1983 to June 2024; the search terms in Chinese were “HTV”, “HAVD”, “occupational exposure”, and then the extensions such as vibration intensity and vibration frequency were selected as needed.

2.2. Correlation analysis

SPSS 27.0 software was used for correlation analysis. Since none of the data conformed to a normal distribution, Spearman correlation analysis was performed to evaluate the relationship between vibration intensity, fundamental frequency of each vibration tool, and prevalence. Statistical significance was defined as P<0.05.

3. Occupational hand-transmitted vibration

3.1. Measurement of occupational hand-transmitted vibration

At present, there are two main evaluation systems for HTV, namely, the absorbed power method and theISO 5349 system, which takes the root mean square of acceleration as the index.ISO 5349-1:2001 clearly specifies the methods for measuring and evaluating HTV [8]. Compared with the absorbed power method, theISO 5349 system is more convenient to calculate and the evaluation system is more complete. Based on this standard, combined with the actual national production situation, China has promulgated the new national standardsGB/T 14790.1-2009 [9] andGB/T 14790.2-2014 [10], which are suitable for our country. According to theISO 5349-1:2001 evaluation system, when evaluating HTV, the evaluation is mainly based on the total vibration value (ahv), which is the root-mean-square (RMS) value of the three-axial frequency-weighted acceleration [8]. The standardISO 2631-1:1997 [1] considers that the human body, when subjected to vibration, has different sensitivities to vibrations of different frequencies;ISO 5349-1:2001 [8] mentions that the response of the human body to vibration depends strongly on the frequency of the vibration, and therefore the calculation of the acceleration during operation needs to be frequency-weighted. The root mean square value of acceleration needs to be calculated within the range of 6.3-1250 Hz specified by 1/3 octave, and the frequency weighting factor (Wh) shall comply with the provisions ofGB/T 23716-2009 [11], as shown in Table 1.

Table 11/3 octave weighting factor

Frequency / Hz | Wh | Frequency / Hz | Wh |

6.3 | 0.727 2 | 100 | 0.160 2 |

8 | 0.873 1 | 125 | 0.127 |

10 | 0.951 4 | 160 | 0.100 7 |

12.5 | 0.957 6 | 200 | 0.079 88 |

16 | 0.895 8 | 250 | 0.063 38 |

20 | 0.782 | 315 | 0.050 26 |

25 | 0.647 1 | 400 | 0.039 8 |

31.5 | 0.519 2 | 500 | 0.031 37 |

40 | 0.411 1 | 630 | 0.024 47 |

50 | 0.324 4 | 800 | 0.018 62 |

63 | 0.256 | 1000 | 0.013 46 |

80 | 0.202 4 | 1250 | 0.008 94 |

Single-axis frequency weighting vibration acceleration root-mean-square value calculation formula shown in Eq. (1):

where Whi is the weighting factor for the ith 1/3-octave band; ahi is the RMS value of acceleration measured in theith 1/3-octave band; and ahw is the RMS value of the weighted acceleration.

Then the frequency-weighted acceleration RMS values in the x-axis, y-axis, and z-axis directions are calculated using Eq. (1), and the total vibration value, i.e., the three-axis total frequency-weighted acceleration RMS value, is calculated based on Eq. (2). If the working day consists of several operations with different vibration states, the total vibration value ahv is calculated according to Eq. (3).ISO 5349-2:2001 [12] mentions that the triaxial weighted acceleration RMS value can be up to 1.7 times the maximum uniaxial weighted acceleration RMS value (generally 1.2 to 1.5 times, the text takes 1.35 times), therefore, in the actual measurement, can only be measured to the uniaxial, can be used to correct for this factor:

where ahwx, ahwy, ahwz are the RMS values of the frequency-weighted acceleration along the x, y, and z axes, respectively, in m/s2:

where T is the daily exposure duration to vibration with respect to ahv, n is the number of vibration states, ahvi is the total vibration value for the ith vibration state, and Ti is the operating time for theith vibration state.

ISO 5349-1:2001 specifies that the daily exposure value is derived from the total vibration value and the daily exposure duration to vibration [8]. Currently, different standards are used both domestically and internationally to express daily exposure value. Internationally, standards such as 2002/44/EC [13],ISO 5349-1:2001 [8], etc., express daily exposure value in terms of the 8 hours energy equivalent frequency-weighted acceleration, denoted as [ahv(8), or A(8)]; while in our country, daily exposure value is expressed in terms of the 4 hours energy equivalent frequency-weighted acceleration, denoted as [ahv(4), or A(4)]. According to ISO 5349-1:2001 [8], if the daily exposure duration to vibration is not 8 hours, it is converted to the A(8) value using Eq. (4). According toGBZ 2.2-2007 [14], if the daily exposure duration to vibration is not4hours, it is converted to the A(4) value using Eq. (5):

where T is the daily exposure duration to vibration relative to ahv, and T0 in Eq. (4) and Eq. (5) represents the reference times of 8 hours and 4 hours, respectively.

Xiao et al. [15] suggested that if the exposure of the vibration worker is not 5 days and 8 hours per week, it should be converted to the daily exposure hours for a 5-day work week. Lin et al. [16] proposed that the daily exposure hours for a 6-day work week can be converted to the daily exposure hours for a 5-day work week using Eq. (6). Accordingly, if the weekly work schedule is not 5 days, the daily exposure can be converted to a 5-day work week daily exposure duration to vibration based on Eq. (7):

where T represents the daily exposure duration to vibration for a 5-day work week, and T0 represents the daily exposure duration to vibration for a 6-day work week:

where T is the daily exposure duration to vibration relative to ahv; T0 in Eq. (4) and Eq. (5) represents the reference times of 8 hours and 4 hours, respectively.

There is no difference in nature between A(4) and A(8), and A(4) can be converted to A(8) by Eq. (8) according toISO 5349-1:2001 [8]. However, when comprehensively evaluating all human exposures in the environment, A(8) can be consistent with the time-weighted averaging method for evaluating other physical factors such as noise and chemical substances [15], [17], so it is recommended to use A(8) for convenience:

where ahv is the total value of vibration used in the calculation of A(4); T0 is the reference time of 8 hours.

GB/T 14790.1-2009 [9] stipulates that the number of years of vibration exposure (Dy) of the vibration-exposed population and the A(8) value of the 10 % VWF prevalence rate of the investigated population are shown in Table 2.

Table 21/3 octave weighting factor

Dy / year | 8 | 4 | 2 | 1 |

A(8) | 3.7 | 7 | 14 | 26 |

Dy for a 10 % prevalence of white finger in the exposure population was calculated according to Eq. (9):

At present, domestic standards primarily follow the requirements ofGBZ/T 189.9-2007 [18] andGBZ 2.2-2007 [14] to record the hand biomechanical coordinate system’s x, y, and z axes vibration acceleration and the daily average exposure time to calculate A(4). The measuring instrument adopted is a specialized HTV vibration meter with a weighting network. It records the weighted acceleration or weighted acceleration level. If the measuring instrument measures the vibration amplitude as a weighted acceleration level (dB), it can be converted to weighted acceleration using Eq. (10):

where Lh is the acceleration level indB;a is the RMS value of the vibration acceleration; a0 is the reference value of vibration acceleration, a0=10-6 m/s2.

3.2. Occupational hand-transmitted vibration limits

The vibration dose is mainly affected by vibration intensity, vibration frequency and duration of vibration exposure. Zhou and Chen [19] calculated the cumulative vibration dose of each worker according to Eq. (11), and then obtained the relationship between the cumulative vibration dose of the worker and the cumulative incidence of white finger, and thus calculated that, at the level of protecting 90 per cent of the workers from the occurrence of white finger for 20 years, the limit value of A(4) should not exceed 5.0 m/s2, and the limit value of the standard of our country was precisely set in accordance with this:

where D represents the cumulative vibration dose when white finger occurs, Y is the number of years of vibration exposure, and d is the number of working days with vibration exposure per year.

Exposure action value refers to the value that requires the control of risks arising from an employee’s exposure to vibration once exceeded; exposure limit value refers to the vibration exposure level that employees should not exceed. Currently, internationally recognized standards for hand-transmitted vibration limits include 2002/44/EC [13],ISO 5349-1:2001 [8], andANSI S2.70:2006 [20]. Most of these standards set A(8) daily exposure values at 2.5 m/s2 as the action level and 5.0 m/s2 as the limit value, which have been widely accepted by many countries. In China, the limit value is specified inGBZ 2.2-2007 [14], where A(4) is considered to exceed the standard when the daily exposure value surpasses 5.0 m/s2. According to Eq. (8), the A(8) value in China exceeds the standard when the daily exposure value surpasses 3.5 m/s2.

4. Occupational hand-transmitted vibration hazards

4.1. Distribution characteristics of hand-arm vibration disease

HAVD is a disease caused by prolonged HTV work, use of hand-held vibrating tools or contact with vibrated workpieces. At least 2 million workers in China are currently exposed to HTV tools, with prevalence rates ranging from 2.5 % to 82.5 % in different occupational groups [21], [22]. With the change of industrial structure in China, the number of occupational HAVD incidence due to HTV is on the rise [23], [24].

In terms of geographic distribution, the study of HAVD was mainly in the northern region in the past, but in recent years, the number of cases suffering from HAVD in subtropical areas in the south of China has also gradually increased [25]-[27]; outbreaks of HAVD have occurred in places such as Guangdong Province, and nearly 60 % of HAVD cases in occupational disease reports in recent years have come from Guangdong Province [2]; unlike the industry distribution characteristics of northern regions where HAVD is mostly found in the mining industry, HAVD in Guangdong Province is mostly found in industries such as sports equipment manufacturing and wooden furniture manufacturing [17], [24], [28], and is more obviously spatially clustered [29], [30]. In terms of industry distribution, HAVD is mainly concentrated in the construction, machining, and furniture manufacturing industries [31]. In terms of the distribution of work types, according to the domestic data, the work types in which HAVD occurs are mainly rock drillers, wind shovellers, tampers, chain sawyers, riveters, etc.

The author reviewed more than 290 pieces of literature related to HTV vibration, in which the relevant literature mentioning vibration tools, job types, positions and their vibration intensity [the text is evaluated by A(4)] is recorded in Table 3.

The vibration intensity in the table is A(4), and A(8) in the literature has been converted to A(4) values according to Eq. (5); MA(4) denotes the median of A(4).

Table 3Vibration tools, job types, positions, and their vibration intensity in the public literature

References | Vibration tools, work types, positions | Vibration intensity (m/s²) | References | Vibration tools, work types, positions | Vibration intensity (m/s²) |

[32] | Coal mining tools | 20.9 | [55] | Model GK-50 forge hammer | 13.8 |

[33] | Pneumatic rock drill | 9.26 | [55] | Gate grinding | 2.78-5.58 |

[34] | Model 1/T-24 rock drill | 25.1 | [55] | Large cutting machine | 2.01-2.05 |

[34] | Model 1/SP-45 rock drill | 21.3 | [55] | Coating grinding machine | 1.10-1.29 |

[35] | Model 76-55 rock drill | 30.76 | [55] | Grinding filler | 1.11-1.31 |

[36] | Aluminum grinding | 194.2 | [55] | Trimming / dressing | 1.92-2.02 |

[36] | Large machine grinding | 289.4 | [37] | Riveting machine | 0.47-33.09 |

[36] | Iron grinding | 220.9~239.5 | [37] | Grinding | 0.012-7.640 |

[36] | Polisher | 195.2 | [37] | Electric tool grinding | 7.64 |

[38] | Model 01-30 pneumatic drill | 4.6 | [37] | Grinding operator | 0.093 |

[38] | Model 07-M28 riveting machine | 4.13 | [37] | Angle grinder | 2.49 |

[38] | Model C6C7 pneumatic chisel | 4.00 | [37] | Grinding in designated area | 0.049 |

[38] | Model 01011 tamper | 2.60 | [37] | Handheld grinding wheel machine | 0.012 |

[38] | Single-sided wood planer | 2.20 | [37] | Grinding wheel pump assembly technician | 0.045 |

[38] | Band saw | 0.62 | [37] | Electric grinding wheel machine | 0.42 |

[38] | Swing saw machine | 0.24 | [37] | Pneumatic grinding (medium size) | 0.67 |

[39] | Impact wrench | 46.72 | [37] | Pneumatic grinding (small size) | 0.046 |

[39] | Drilling machine | 32.29 | [37] | Pneumatic grinding gun | 3 |

[39] | Bench grinder | 9.39 | [37] | Pneumatic angle grinder | 0.16 |

[39] | Grinder | 5.94 | [37] | Pneumatic grinding tool | 0.53 |

[39] | Pneumatic screwdriver | 4.16 | [37] | Metal adhesive cutting and grinding | 1.42 |

[39] | Cutting and grinding machine | 4.95 | [37] | Polishing machine | 2.6 |

[40] | 16-grit belt sander | 5.44 | [37] | Grinding workstation | 3.355 |

[40] | 40-grit belt sander | 5.34 | [37] | Grinding machine | 1.1 |

[40] | 180-grit belt sander | 5.27 | [37] | External grinding | 4.88 |

[40] | 600-grit belt sander | 3.40 | [41] | Riveting machine | Riveter 20.8 |

[40] | 800-grit belt sander | 3.42 | [41] | Holder 176.7 | |

[16] | Grinding station | 4.21 | [17] | Grinding position | 2.38 |

[42] | Walk-behind rice transplanter | 2.442 | [17] | Polishing position | 1.59 |

[21] | Polisher | 5.16~6.57 | [17] | Assembly position | 1.16 |

[21] | Grinding | 5.77~6.30 | [17] | Cutting position | 5.29 |

[21] | Weld seam grinding | 3.97~4.07 | [17] | Sandblasting position | 0.66 |

[21] | Surface grinding | 6.03~6.52 | [17] | Maintenance position | 1.07 |

[21] | Trimming cutter | 8.72~8.76 | [43] | Rock drill | 12.64 |

[21] | Trimming polisher | 8.52~8.62 | [43] | Grinding position | 5.06 |

[21] | Trimming bench grinder | 2.94~3.11 | [44] | Pneumatic rock drill with air legs | 19-24 |

[21] | C/B forming room belt grinding | 0.96~1.01 | [45] | Rock drill | Dominant hand |

[21] | Wire wheel brushing | 3.81~3.86 | [45] | 16.30~19.10 | |

[21] | Buff polishing | 2.09~2.56 | [45] | Non-dominant hand | |

[21] | Sunflower buffing | 4.20~4.81 | [45] | 8.30-14.40 | |

[46] | Model CYD-2B line tamper | 3.35 | [47] | Side-mounted U-type dual-handle gasoline grass trimmer | 5.70-30.21 |

[46] | Model XYD-2B line tamper | 6.39 | [47] | Handheld single-blade gasoline hedge trimmer | 9.66-27.48 |

[46] | Model 5-KM rivet gun | 5.54 | [48] | Motor polishing machine | MA(4) = 3.8 |

[46] | Model 6-KM rivet gun | 23.32 | [48] | Dual-speed polishing machine | MA(4) = 4.4 |

[46] | Model 01-30 rock drill | 16.81 | [48] | Motor polishing machine | MA(4) = 3.2 |

[46] | Model 10-11A foundry tamper | 17.54 | [48] | Double-head polishing machine, single-head polishing machine | MA(4) = 7.6 |

[46] | Model D-9 foundry tamper | 32.24 | [49] | Handheld workpiece grinding | MA(4) = 7.68 |

[46] | Flat wheel | 37.08 | [50] | Pneumatic grinding machine | 7.329 |

[46] | Model C6B pneumatic chisel | 37.93 | [50] | Grinding wheel angle grinder | 3.011 |

[46] | Model HZ-502-11 cement tamper | 94.41 | [50] | Flat sanding machine | 5.329 |

[46] | Model B-15 cement tamper | 106.72 | [51] | Model dongfanghong LX804 wheeled tractor | 6.02 |

[52] | Chainsaw | 15.5 | [53] | Model C6B pneumatic chisel | 8 |

[54] | Model YT45 rock drill | 51.6 | [53] | Model D9 tamper | 12.8 |

[55] | Model YT-24 rock drill | 19.6 | [56] | Model XYQ-3B hydraulic pliers | 3.667 |

[55] | Model D-9 tamper | 24.5 | [57] | Grinding wheel polishing | 29.45 |

[55] | Model C6B pneumatic chisel | 12.1 |

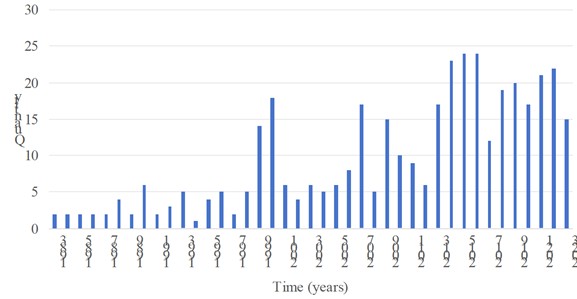

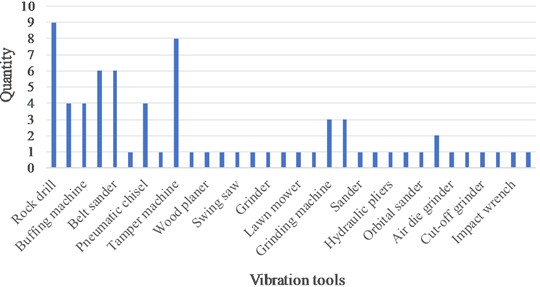

Data collation of Table 3 leads to Fig. 2, which shows that there are more domestic investigations of vibration tools such as rock drills, tamping machines, sanders, belt sanders, grinders, polishers, wind shovels, sanding machines, angle grinders, etc., and the number of literature involving grinding tools is significantly higher than that of the rest of the vibration tools; the number of literature on rock drills and grinding tools accounts for the vast majority of the literature. Among them, Fig. 3 shows the vibration tools, work types or positions with A(4) exceeding the national limit of 5 m/s2, which can be seen in the figure, the tools, work types or positions such as large machine grinding, iron grinding, and grinders have A(4) significantly higher than the limit value of 5 m/s2 for HTV in China; vibrating tools that cause occupational HAVD mostly occur in the mining industry as well as in the manufacturing industry, with rock drilling work types and positions dominating in the mining industry and grinding work types and positions dominating in the manufacturing industry; the distribution of A(4) for rock drilling tools is more concentrated, indicating that there is a high degree of consistency in A(4) for different types or models of rock drilling tools; the A(4) of grinding tools is involved in all value intervals, with a wide distribution of values and a large span, reflecting the diversity of their types or models and functional differences. Fig. 4 shows the vibration tools with a higher number of investigations conducted in China.

Fig. 2The number of times vibration tools recording energy equivalent frequency-weighted acceleration have been mentioned in the literature

Fig. 3Vibration tools with A(4) values greater than 5 m/s2 and their corresponding A(4) values

4.2. The hazards of hand-arm vibration disease

HTV refers to the mechanical vibration or shock that acts directly on or is transmitted to the human arm when vibrating tools are used or vibrated workpieces are touched during the production process [58]. HTV-induced HAVD can cause serious damage to the health of workers, which is a disease that mainly consists of peripheral circulation disorders in the hand, nerve dysfunction in the arm, and bone, joint and muscle injuries, and it can lead to changes in the blood biochemical indexes and electrophysiological indexes reflecting the functioning of the nervous system of the workers [59]-[62]. Clinical symptoms initially include hand symptoms such as hand numbness, hand stiffness, hand swelling, sweaty hands, and neurological symptoms such as headache and memory loss [43], [63]. The main clinical manifestations of HAVD are VWF, also known as occupational Raynaud's phenomenon, caused by microcirculation damage at the end of the fingers, and osteoarticular-muscular injury of the arm, mainly including deformation of the finger joints and ‘eagle-claw hand’ [3].

Fig. 4Vibration tools with a higher number of investigations

a) Rock drill

b) Tamper machine

c) Bench grinder

d) Belt sander

GBZ 7-2014 [59] grades the diagnosis of HAVD, which is categorized as mild, moderate and severe HAVD based on different symptoms. The episodes of HAVD are characterized by transient and temporal phases, i.e., after being exposed to cold, numbness, swelling and pain will appear in the fingers in a short period of time, and will change from gray to pale, with distal to proximal progression and clear boundaries; the duration of the episodes is 5 to 30 min; the more severe the disease the more frequent the episodes are; after the episodes, they gradually change from pale, gray to flushed, and finally change to normal skin color, and the hand’s sensation gradually recovers, and pain may appear, burning, itching and other sensations [3], [64].

At present, the pathogenesis of HAVD has not been clarified, and both treatment and recovery are difficult; once the disease develops, it is difficult to recover, and even if the exposure to HTV operations is stopped, recovery remains difficult and disability is high without effective intervention or treatment, which seriously affects the physical and mental health of the patients and may jeopardize the society [6], [50], [59], [65]-[70].

In addition, HTV vibration often coexists with noise as a synergistic factor in noise-induced hearing damage, while noise can also exacerbate hazards to circulatory and neurological function, and the higher the noise intensity the more synergistic the two are, and the greater the impact on physical health [33], [50], [71].

It is evident that HTV can cause various symptoms. Due to the unclear pathogenic mechanisms and the lack of effective preventive and treatment measures, recovery is difficult. Therefore, early diagnosis of workers exposed to vibration, with the timely detection of pathogenic signs, plays a crucial role in preventing the onset of HAVD.

4.3. Diagnostic methods and limitations of hand-arm vibration disease

Currently, health examination signs are dominated by abnormalities in thresholds of heat and cold, pain, touch, and vibration sensation [3], [31], [45], [72].

According toGBZ 188-2014 [73] andGBZ 7-2014 [59], the examination of HAVD includes symptom inquiry, physical examination, and laboratory and other tests, and the routine physical examination, cold provocation test, nerve electromyography, and other objective examination results are mainly used as diagnostic criteria for health testing. Among them, routine blood test is compulsory, and cold provocation test, nerve electromyography, fingertip vibration sensation and fingertip temperature sensation are optional.

In recent years, in order to further study diagnostic methods with higher sensitivity and specificity, more suitable for the human body and stronger screening ability, many scholars in China have carried out in-depth research on the detection methods of finger systolic blood pressure [74]-[76], fingertip thermotactile perception [31], [66], [77], [78], and fingertip vibrotactile perception [45], [79]-[81], and so on.

Studies have shown that the cold provocation test is affected by factors such as room temperature, water temperature, and immersion time, resulting in low specificity and poor screening power [82]. Even in healthy populations, the abnormality rate of the cold provocation test is relatively high [83]. It is less effective in diagnosing white finger in subtropical regions [84], with poor specificity, difficulty in inducing VWF, poor sensitivity, and a high likelihood of missed diagnosis. Moreover, there is a lack of simple, stable, and effective laboratory diagnostic indicators. Neuromuscular electromyography has the advantages of convenience and high reproducibility, but it is an invasive examination. It cannot be used to detect fibers that conduct fast cold sensation and nociception, or those that conduct slow temperature sensation and nociception. Age and length of service are influencing factors for abnormalities in neuromuscular electromyography among vibration-exposed workers, and it is difficult to reflect early changes in the sensory nerves of the fingertips [2], [77], [85]. Finger systolic blood pressure, fingertip thermotactile perception, and fingertip vibrotactile perception are not clearly defined in terms of testing procedures and standards inGBZ 188-2014 [73], [86].

Therefore, the early identification of health damage among vibration-exposed workers is still challenging [2], [87], which may lead to delayed implementation of preventive and control measures.

4.4. Protective measures for hand-arm vibration disease

The early preventive measures for HAVD mainly include early detection, early diagnosis, and early treatment [88]. Among these, effective prevention and control of HAVD have become a research focus [5], [6]. Treatment methods primarily target peripheral circulatory disorders in the arms, neurological dysfunction, and osteoarticular injuries. Symptomatic treatments involve improving microcirculation, dilating blood vessels, and nourishing nerves through a combination of traditional Chinese and Western medicine, physical therapy, and exercise therapy. Additionally, attention should be paid to keeping both the hands and the body warm [3], [5].

In recent years, progress has been made in the treatment of HAVD, such as acupuncture [89] and warm needling therapy [90]. However, the damaged peripheral circulation and peripheral nerves have not fully recovered after treatment, and the therapeutic effects remain limited [5].

Mitigation measures for HTV in the workplace primarily involve early prevention strategies such as engineering controls and personal protection. Engineering controls include measures like controlling the vibration source, improving power tools and production processes, using elastic pads and supports for vibration reduction, isolating the hand from the tool with elastic components (e.g., effective shock absorbers, rings, handles), and reducing the weight of handheld vibrating tools [3], [91], [92]. Other measures include the mechanization and automation of operations [33]. Personal protective measures involve keeping warm to prevent cold exposure, wearing anti-vibration gloves, and reducing vibration exposure time [21].

Furthermore, different vibration tasks or tools have varying vibration accelerations and frequency spectra, leading to different risks and control measures [17], [93]. When tools wear out or age, issues such as loose screws can alter the amplitude and frequency of the vibration tools, while air or water leaks can increase the risk of hand temperature loss for vibration-exposed workers, making HAVD prevention more challenging. Therefore, another important aspect of preventing HAVD is the regular maintenance and inspection of vibration tools [16], [92].

Additionally, some companies have implemented feasible measures, such as strengthening health management and education, regularly conducting health examinations for vibration-exposed workers, rotating and reassigning workers to reduce exposure time, providing vibration-damping gloves, and taking effective actions for workers with abnormal health reports to protect their well-being [16], [17], [94], [95].

However, many factories and enterprises, due to considerations of cost, risk avoidance, and operational convenience, have not arranged for workers to undergo optional health checks [30]. Literature [96] found that the rate of promotion and education on vibration hazards and protection in most factories was only 28.82 %, with a regular inspection rate of just 15.72 %. Literature [37] surveyed 20 companies with riveting operations, but only2of them had organized and implemented occupational health checks related to HTV. Literature [17] revealed that only a few companies provided dedicated anti-vibration gloves. Literature [50] surveyed10machinery manufacturing companies and found that none of the workers were equipped with anti-vibration gloves, nor had they undergone occupational health checks related to hand-transmitted vibration.

The analysis of the above literature suggests that the HTV industry still lacks sufficient attention to the hazards of HTV, with weak emphasis on the provision and use of personal protective equipment, education and training on vibration hazards, and the regular health examinations of workers.

5. The relationship between the prevalence and the vibration intensity and frequency of vibration tools

The frequency and intensity of vibration, along with the duration of exposure, are the primary factors affecting the health effects of HTV, while environmental factors, work posture, and other variables also play a significant role [97]. Therefore, this paper has compiled data from the literature on A(4), vibration frequency, and the prevalence of VWF to explore their interrelationships.

5.1. The impact of vibration tool intensity on prevalence

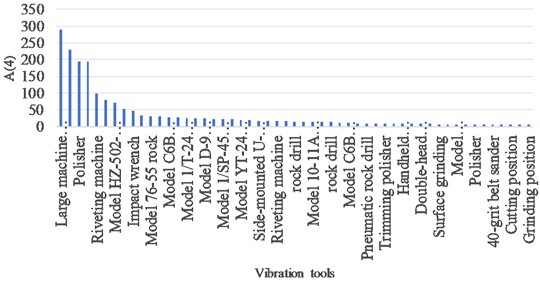

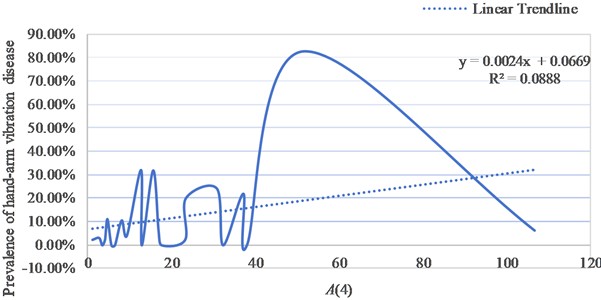

To better analyze the relationship between vibration intensity and the prevalence of VWF, literature mentioning vibration intensity and prevalence has been compiled as shown in Table 4. Based on Table 4, data fitting resulted in the curve shown in Fig. 4. The results of the correlation analysis showed that there was no significant correlation between A(4) and the prevalence of VWF (P>0.05).

Furthermore, it is easy to find that the relationship between vibration intensity and prevalence and the fitted curves of some vibration tools vary widely. This discrepancy is because the prevalence of HAVD is influenced not only by vibration intensity but also by factors such as workers’ years of service, environmental temperature, and the vibration frequency of the tools [25], [67]. For example, under identical production conditions, the prevalence of VWF for the C6B wind shovel is higher than the fitted curve, while the prevalence for the D9 tamper is lower. This is due to differences in the inherent frequencies of these two tools and the hardness of the processed material, resulting in significant differences in frequency distribution, and the frequency-weighted vibration acceleration is more affected by low-frequency and less attenuated mid-frequency components of vibration intensity [53]. The lower prevalence of VWF for the 1/T-24 and 1/SP-45 rock drills compared to the fitted curve may be due to higher temperatures in the southern regions, as low temperatures are an inducing factor for HAVD, resulting in a lower prevalence [34]. Therefore, A(4) alone is insufficient to reflect the extent of the health hazards of hand-transmitted vibration operations, and environmental factors such as temperature should also be considered.

Table 4Statistical results of vibration intensity and pathogenicity in the literature

References | Vibration tools | Vibration intensity (m/s2) | Prevalence (%) | References | Vibration tools | Vibration intensity (m/s2) | Prevalence (%) |

[33] | Pneumatic rock drill | 9.26 | 4.2 | [46] | Model D-9 foundry tamper | 32.24 | 0 |

[34] | Model 1/T-24 rock drill | 25.1 | [46] | Flat wheel | 37.08 | 22 | |

[34] | Model 1/SP-45 rock drill | 21.3 | [46] | Model C6B pneumatic chisel | 37.93 | 0 | |

[34] | AA(4) = 23.2 | 2.4 | [46] | Model B-15 cement tamper | 106.72 | 6.3 | |

[35] | Model 76-55 rock drill | 30.76 | 24.2 | [52] | Chainsaw | 15.5 | 31.9 |

[53] | Model C6B pneumatic chisel | 8 | 10.6 | [54] | Model YT45 rock drill | 51.6 | 82.8 |

[53] | Model D9 tamper | 12.8 | 0 | [38] | Model 01-30 pneumatic drill | 4.6 | 11.11 |

[43] | Rock drill | 12.64 | 32.1 | [38] | Model 07-M28 riveting machine | 4.13 | 4.17 |

[46] | Model CYD-2B line tamper | 3.35 | 0 | [38] | Model C6C7 pneumatic chisel | 4.00 | 2.22 |

[46] | Model XYD-2B line tamper | 6.39 | 0 | [38] | Model 01011 tamper | 2.60 | 3.12 |

[46] | Model 5-KM rivet gun | 5.54 | 0 | [38] | Single-sided wood planer | 2.20 | |

[46] | Model 6-KM rivet gun | 23.32 | 20 | [38] | Band saw | 0.62 | |

[46] | Model 01-30 rock drill | 16.81 | 6.3 | [38] | Swing saw machine | 0.24 | |

[46] | Model 10-11A foundry tamper | 17.54 | 0 | [38] | AA(4) = 1.02 | 2.32 | |

AA(4)represents the average ofA(4) | |||||||

Fig. 5Prevalence of HAVD-A(4) curve

5.2. The effect of the vibration frequency of tools on the prevalence of disease

Vibration frequency, intensity, and exposure duration are the primary factors affecting human health. Therefore, studying the vibration frequency of tools is also highly significant. Some researchers have focused on the handles of rice transplanters and the arms of exposed workers, finding that the palms poorly absorb low-frequency vibrations below 25 Hz in the left-right (x) and front-back (y) directions; in the up-down (z) direction, they poorly absorb mid-frequency vibrations around 100 Hz. As a result, within the 25 Hz and 100 Hz ranges, vibrations transmitted to the palms are prone to resonance; moreover, the primary cause of Raynaud’s phenomenon is the destruction of cells and tissues caused by the dissipation of vibration energy between 100 to 200 Hz acting directly on the subcutaneous tissue [42], [98]. Another study [99], [100] on portable fire extinguishers found that the larger the fundamental frequency among different blower-type extinguishers, the fewer dominant frequencies there are in the 0 to 400 Hz range, leading to a reduced impact of vibration on the human body. Additionally, research [51] on tractor steering wheels showed that high-frequency vibrations above 100 Hz are largely absorbed and dissipated when transmitted from the steering wheel to the back of the hand. Furthermore, low-frequency vibrations below 10 Hz are amplified when transmitted to the back of the hand, possibly due to resonance at around 5 Hz, which is close to the natural frequency of the human arm, leading to an increase in vibration transmission rate. Therefore, as vibrations are transmitted through the arm, high-frequency vibrations decay rapidly, and the vibrations are primarily concentrated in the low-frequency range. The study in [101] found that the vibration frequency spectrum of the handle of a mini-tiller’s handrail is primarily distributed between 20 and 200 Hz; it also noted that the hands, wrists, and elbows tend to amplify vibrations in the low-frequency range of 4 to 20 Hz, while vibrations at frequencies greater than 100 Hz rapidly attenuate, making the human body more sensitive to low-frequency vibrations. Another study [25], [78], [102], discovered that high-frequency vibration exposure is significant in golf club head manufacturing and rock drilling in mining operations, with a high incidence of hand symptoms reported. The research in [43] observed that during rock drilling, the first peak in acceleration occurs at 25 to 40 Hz, with the highest peak between 125 and 160 Hz; in grinding operations, acceleration increases with frequency, peaking between 500 and 800 Hz; consequently, the incidence of hand symptoms in these two vibration-exposed populations is high, correlating with the exposure frequency.

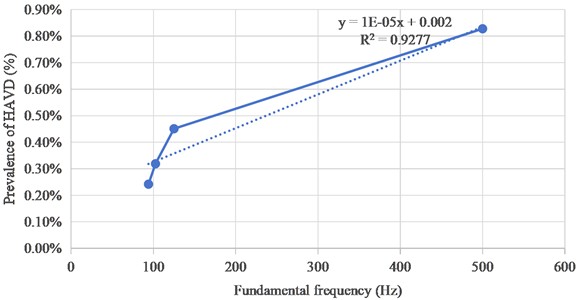

Based on the above analysis, vibrations below 25 Hz are absorbed poorly, and resonance is likely to occur around 25 Hz in the forearm; low-frequency vibrations below 10 Hz may cause resonance in the back of the hand, amplifying the vibration; the hands, wrists, and elbows amplify low-frequency vibrations in the 4 to 20 Hz range. Vibrations in the 100 to 200 Hz range pose significant hazards; high-frequency vibrations above 100 Hz are largely absorbed and dissipated during transmission. The larger the fundamental frequency, the fewer dominant frequencies in the 0 to 400 Hz range, which reduces the impact of vibration on the human body. Therefore, both low-frequency and high-frequency vibrations can potentially harm the human body and contribute to the development of VWF. The fundamental frequency is the most impactful frequency component on the human body. To facilitate the analysis of vibration tools, literature involving the fundamental frequency of vibration tools has been integrated, as shown in Table 5 and Fig. 5. The results of the correlation analysis showed a significant positive correlation between the fundamental frequency of vibration tools and prevalence (r>0,P<0.05). That is, as the fundamental frequency of the vibration tools increases, the prevalence also rises to some extent, which is consistent with the findings of [25], [43], [78], [102], indicating that working under high-frequency vibration is associated with an increased prevalence of hand-related diseases. However, due to the limited data, the relationship between the two cannot be definitively determined. The fundamental frequencies in the third reference data are quite similar. Therefore, for ease of observation, the average value is temporarily used.

Table 5Statistical results of fundamental frequency and prevalence in the literature

References | Vibration tool | fundamental frequency /Hz | Prevalence (%) |

[35] | Model 76-55 rock drill | A1 = 94 | 24.2 |

[103] | Model YT-24 rock drill | 125 | 45.10 |

[52] | Model 051 Chainsaw | 125 | |

[52] | Model GJ-85 Chainsaw | 80 | |

[52] | A2 =102.5 | 31.9 | |

[54] | Model YT45 rock drill | 500 | 82.8 |

A1 represents the average value of the primary frequency band; A2 represents the average value of the fundamental frequency | |||

Fig. 6Prevalence of HAVD-fundamental frequency curve

6. Conclusions

Long-term exposure to HTV operations can easily lead to HAVD, which has already caused significant adverse effects on individuals, society, and the nation. This paper integrates over 290 articles, systematically reviewing research related to HAVD, covering the distribution characteristics, hazards, diagnostic methods, and gaps. It also analyzes the severity of exposure to HTV among workers and examines the relationship between the vibration intensity, frequency, and prevalence of the disease in vibration tools. The following conclusions can be drawn from recent studies.

1) The vibration tools that cause occupational HTV mostly occur in the mining industry and manufacturing industry, with rock drilling work types and positions dominating in the mining industry, and grinding work types and positions dominating in the manufacturing industry, and the A(4) of grinding tools, work types or positions is significantly higher than our country’s limit value of 5 m/s2 for HTV.

2) The distribution of A(4) values of rock drilling tools is more concentrated, suggesting that different types or models of rock drilling tools have a high degree of consistency in A(4); the distribution of A(4) values of grinding tools is wide, spanning a wide range, reflecting the diversity of their types or models, the characteristics of functional differences.

3) Existing diagnostic methods suffer from poor specificity and sensitivity, which may result in early prevention and control measures not being implemented in a timely manner.

4) There are still many HTV-related enterprises and exposure workers who still pay insufficient attention to the hazards of HTV, and pay weak attention to vibration operations and the equipment and use of personal protective equipment, publicity and education, and occupational health checks for workers.

5) There is no significant correlation between A(4) and the prevalence of VWF. A(4) is not enough to reflect the degree of harm caused by HTV operations, and factors such as the ambient temperature and the age of the workers need to be taken into account.

6) Both low-frequency and high-frequency vibration frequencies may be harmful to human beings and promote the occurrence of VWF; the main frequency of vibration tools and the prevalence of the disease may be positively correlated, but more data needs to be collected to further verify this relationship.

References

-

“Mechanical vibration and shock – Evaluation of human exposure to whole-body vibration – Part 1: General requirements,” International Organization for Standardization, ISO Standard 2631-1, 1997.

-

Q. S. Chen, “Focus on prevention and control of noise and hand-arm vibration, and protect workers’ health,” (in Chinese), Journal of Environmental and Occupational Medicine, Vol. 37, No. 4, pp. 334–336, 2020, https://doi.org/10.13213/j.cnki.jeom.2020.20099

-

“Scientific prevention and control of occupational hand-arm vibration disease,” (in Chinese), China Occupational Medicine, Vol. 48, No. 4, p. 421, 2021.

-

L. Lin, Q. Zhang, and C. Z. Zhang, “Some problems in studies on hand-arm vibration disease in China,” (in Chinese), Chinese Journal of Industrial Medicine, No. 2, pp. 107–108, 2004.

-

B. Zhang et al., “Research progress on occupational hand-arm vibration disease,” (in Chinese), Chinese Journal of Industrial Medicine, Vol. 31, No. 6, pp. 434–438, 2018, https://doi.org/10.13631/j.cnki.zggyyx.2018.06.013

-

M. Z. Wu and F. Yang, “Review of hand-transmitted vibrationin hand-arm system,” (in Chinese), Journal of Huaqiao University (Natural Science), Vol. 40, No. 3, pp. 281–290, 2019.

-

Q. Bu et al., “Advances on nervous system impairment induced by hand-transmitted vibration,” (in Chinese), Journal of Environmental and Occupational Medicine, Vol. 39, No. 11, pp. 1237–1241, 2022.

-

“Mechanical vibration-Measurement and evaluation of human exposure to hand-transmitted vibration-Part1: General requirements,” ISO Standard 5349-1, 2001.

-

“Mechanical vibration – Measurement and evaluation of human exposure to hand-transmitted vibration – Part 1: General requirements,” GB/T Standard 14790.1, 2009.

-

“Mechanical vibration – Measurement and evaluation of human exposure to hand-transmitted vibration – Part 2: Practical guidance for measurement at the workplace,” GB/T Standard 14790.2, 2014.

-

“Human response to vibration. Measuring instrumentation,” BSI British Standards, London, GB/T Standard 23716, Apr. 2022.

-

“Mechanical vibration – Measurement and evaluation of human exposure to hand-transmitted vibration – Part 2: Practical guidance for measurement at the workplace,” ISO Standard 5349-2, 2001.

-

“The minimum health and safety requirements regarding the exposure of workers to the risks rising from physical agents (vibration),” EC Standard 44, 2002.

-

“Occupational exposure limits for hazardous agents in the workplace Part 2: Physiscal agents,” GBZ Standard 2.2, 2007.

-

B. Xiao, “Issues and recommendations in the measurement and evaluation of hand-transmitted vibration in the workplace,” (in Chinese), Chinese Journal of Industrial Hygiene and Occupational Diseases, Vol. 32, No. 4, pp. 315–316, 2014.

-

H. S. Lin, “Evaluating the occupational exposure to hand-transmitted vibration in golf ball head grinding positions,” (in Chinese), China Occupational Medicine, Vol. 46, No. 3, pp. 286–291, 2019.

-

M. S. Yan et al., “Investigation on occupational exposure level of workers to hand-transmitted vibration in Guangdong province,” (in Chinese), Chinese Journal of Industrial Medicine, Vol. 34, No. 5, pp. 394–398, 2021, https://doi.org/10.13631/j.cnki.zggyyx.2021.05.003

-

“Measurement of physical agents in workplace part 9: hand-transmitted vibration,” GBZ/T Standard 189.9, 2007.

-

D. L. Zhou and L. Chen, “Study on dose-response relationships and occupational health standards for segmental vibration.,” (in Chinese), Chinese Journal of Preventive Medicine, No. 1, pp. 23–26, 1989.

-

“Guide for the measurement and evaluation of human exposure to vibration transmitted to the hand,” ANSI Standard S2.70, 2006.

-

W. G. Ye, “Investigation and analysis of 53 cases of occupational hand-arm vibration disease in a golf club manufacturing company in Shenzhen,” (in Chinese), Practical Preventive Medicine, Vol. 27, No. 12, pp. 1519–1521, Dec. 2020.

-

Y. Z. Liu, “Diagnostic value of high-frequency ultrasonography in testing carpal canal structure in patients with occupational hand-arm vibration disease,” (in Chinese), China Occupational Medicine, Vol. 43, No. 4, pp. 433–436, Apr. 2016.

-

Y. M. Zheng, “Bibliometric analysis on occupational hand-arm vibration disease in China,” (in Chinese), China Occupational Medicine, Vol. 47, No. 5, pp. 539–542, May 2020.

-

S. Y. Zhou, “Surveillance and occupational health risk assessment for major occupational diseases in Guangdong province,” (in Chinese), Chinese Journal of Public Health, Vol. 35, No. 5, pp. 549–553, May 2019.

-

N. Wei et al., “The hand-arm vibration syndrome associated with the grinding of handheld workpieces in a subtropical environment,” (in Chinese), International Archives of Occupational and Environmental Health, Vol. 94, No. 4, pp. 773–781, Jan. 2021, https://doi.org/10.1007/s00420-020-01615-5

-

Q. Chen et al., “Nailfold capillary morphological characteristics of hand-arm vibration syndrome: a cross-sectional study,” (in Chinese), BMJ Open, Vol. 6, No. 11, p. e012983, Nov. 2016, https://doi.org/10.1136/bmjopen-2016-012983

-

J. Q. Feng, “Analysis on incidence of occupational diseases in Zhongshan city during 2001 to 2017 and its countermeasures,” (in Chinese), Chinese Journal of Industrial Medicine, Vol. 32, No. 1, pp. 53–55, 2019, https://doi.org/10.13631/j.cnki.zggyyx.2019.01.015

-

Y. P. Xiang et al., “Monitoring and analysis of occupational hazards in wood furniture manufacturing industry in Shenzhen city,” (in Chinese), Chinese Journal of Industrial Medicine, Vol. 35, No. 4, pp. 356–359, 2022, https://doi.org/10.13631/j.cnki.zggyyx.2022.04.024

-

Q. Tan et al., “Spatial analysis of the incidence of occupational diseases in Guangdong Province,” (in Chinese), China Preventive Medicine Journal, Vol. 31, No. 2, pp. 119–123, 2019, https://doi.org/10.19485/j.cnki.issn2096-5087.2019.02.003

-

S. Y. Zhou et al., “Epidemiological characteristics and risk assessment of occupational diseases caused by physical factors in Guangdong Province, 2013-2022,” (in Chinese), China Occupational Medicine, Vol. 50, No. 3, pp. 279–284, 2023, https://doi.org/10.20001/j.issn.2095-2619.20230607

-

M. S. Yan et al., “Analysis on influencing factors of fingertip thermotactile perception threshold of hand-transmitted vibration operators,” (in Chinese), Chinese Journal of Industrial Medicine, Vol. 36, No. 2, pp. 131–135, 2023, https://doi.org/10.13631/j.cnki.zggyyx.2023.02.008

-

X. Z. Zhao et al., “Magnetic resonance imaging for the wrist joint of the coal miners in vibration department,” (in Chinese), Chinese Journal of Industrial Hygiene and Occupational Diseases, No. 4, pp. 235–238, 2006.

-

X. R. Xu et al., “A survey on occupational hazards of heading drivers using hand-transmitted vibration tools in a Northern China Coal Mine,” (in Chinese), Industrial Health and Occupational Diseases, Vol. 42, No. 4, pp. 241–244, 2016, https://doi.org/10.13692/j.cnki.gywsyzyb.2016.04.001

-

D. X. Wu, “Study on the local vibration among lead-zinc miners,” (in Chinese), Chinese Journal of Industrial Medicine, No. 2, pp. 118–119, 2002.

-

L. Lin et al., “Investigation and analysis of occupational hazards from localized vibration in rock drilling operations in a gold mine,” (in Chinese), Journal of Jining Medical University, No. 1, pp. 39–41, 1999.

-

Q. L. Zheng et al., “Clinical analysis on the peripheral circulatory disturbances in 84 cases of occupational hand-arm vibration disease,” (in Chinese), China Occupational Medicine, Vol. 37, No. 4, pp. 311–313, 2010.

-

J. Qiao et al., “Status quo of hand-transmitted vibration hazards of riveting and sanding operation in aerospace equipment manufacturing industry,” (in Chinese), Occupation and Health, Vol. 39, No. 23, pp. 3196–3199, 2023, https://doi.org/10.13329/j.cnki.zyyjk.2023.0572

-

G. R. Lei and G. W. Guo, “Investigation of localized vibration hazards in certain areas of the Xi’an railway region,” (in Chinese), Railway Energy Saving and Environmental Protection and Occupational Safety and Health, No. 3, pp. 15–18, 1991, https://doi.org/10.16374/j.cnki.issn2095-1671.1991.03.008

-

Q. S. Chen et al., “Investigation on occupational exposure status of workers exposed to hand-transmitted vibration,” (in Chinese), China Occupational Medicine, Vol. 39, No. 4, pp. 298–299, 2012.

-

Z. Ma et al., “Occupational hazard analysis of hand-arm vibration during abrasive belt metal-grinding operation,” (in Chinese), Chinese Journal of Public Health Engineering, Vol. 10, No. 1, pp. 30–32, 2011, https://doi.org/10.19937/j.issn.1671-4199.2011.01.011

-

J. X. Chen, “Analysis of vibration parameters of aircraft riveting tools,” (in Chinese), Industrial Health and Occupational Diseases, No. 2, pp. 100–101, 2008.

-

S. Liu et al., “Hand vibration transmission evaluation and vibration tansmission characteristics test of hand-held rice transplanter,” (in Chinese), Journal of Huazhong Agricultural University, Vol. 39, No. 1, pp. 151–160, 2020, https://doi.org/10.13300/j.cnki.hnlkxb.2020.01.019

-

H. M. Huang, “Peripheral circulation and peripheral nerve injury in workers exposed to vibration at two different frequencies,” (in Chinese), Journal of Environmental and Occupational Medicine, Vol. 39, No. 11, pp. 1198–1203, 2022.

-

L. Q. Tong, X. T. Wang, and J. Y. Jia, “Analysis on occupational hazards and control countermeasures in a pyrophylite mine in Beijing,” (in Chinese), Occupation and Health, Vol. 36, No. 1, pp. 4–7, 2020, https://doi.org/10.13329/j.cnki.zyyjk.2020.0002

-

Z. M. Liang, “Investigation and analysis on fingertip vibrotactile perception threshold at two frequencies in mine drilling workers,” (in Chinese), China Occupational Medicine, Vol. 46, No. 4, pp. 407–411, 2019.

-

A. Z. Yao et al., “Hygienic investigation and study of localized vibration hazards in industrial enterprises,” (in Chinese), Journal of Hygiene Research, No. 6, pp. 13–16, 1985, https://doi.org/10.19813/j.cnki.weishengyanjiu.1985.06.003

-

M. Z. Wu and F. Yang, “Measurement and evaluation of hand-transmitted vibration in workplace-taking grass trimmer and hedge trimmer as examples,” (in Chinese), Journal of Safety Science and Technology, Vol. 15, No. 6, pp. 168–173, 2019.

-

B. Xiao, “Essential characteristics of hand-arm vibration in hand-held workpiece polishing,” (in Chinese), China Occupational Medicine, Vol. 43, No. 3, pp. 312–315, 2016.

-

M. Y. Peng, “Investigation and analysis on occupational hazard of a golf brassie production enterprise,” (in Chinese), China Occupational Medicine, Vol. 43, No. 4, pp. 478–480, 2016.

-

Z. M. Liang et al., “Investigation of hand-transmitted vibration and noise hazards among workers operating handheld grinding tools in the machining industry,” (in Chinese), China Preventive Medicine Journal, Vol. 32, No. 6, pp. 621–624, 2020, https://doi.org/10.19485/j.cnki.issn2096-5087.2020.06.021

-

Y. J. Shang et al., “Evaluation of hand-transmitted vibration of tractor steering wheel and characteristics of vibration transmission of different percentiles driver arm,” (in Chinese), Journal of Huazhong Agricultural University, Vol. 41, No. 6, pp. 277–285, 2022, https://doi.org/10.13300/j.cnki.hnlkxb.2022.06.033

-

Y. S. Zhang and Z. M. Liu, “Investigation of vibration-induced white finger among forestry workers,” (in Chinese), Chinese Journal of Industrial Medicine, No. 3, pp. 46–47, 1991.

-

H. Q. Ding, R. K. Zhang, and H. Zhang, “The impact of hand-transmitted vibration frequency on the human body,” (in Chinese), Industrial Health and Occupational Diseases, No. 3, pp. 156–157, 1992.

-

K. T. Ha, L. Wang, and G. R. Wu, “Investigation of localized vibration hazards among rock drill operators in a molybdenum-copper mine,” (in Chinese), Chinese Journal of Industrial Medicine, No. 3, p. 173, 1993.

-

J. G. Wu, “Investigation of the four-hour energy-equivalent frequency-weighted acceleration in localized vibration operations,” (in Chinese), China Occupational Medicine, No. 2, pp. 54–55, 1994.

-

C. Y. Cao, “Differential diagnosis between hand-arm vibration disease and carpal tunnel syndrome,” (in Chinese), Industrial Health and Occupational Diseases, No. 3, pp. 171–172, 2007.

-

L. Lin, “Study on relationships between duration of vibration exposure and symptoms in hands and vibration-induced white finger,” (in Chinese), Industrial Health and Occupational Diseases, No. 3, pp. 142–144, 1998.

-

“Termls of occupational health,” GBZ/T Standard 224, 2010.

-

“Diagnosis of occupational hand-arm vibration disease,” GBZ Standard 7, 2014.

-

Y. X. Jia, “Effects of hand-transmitted vibration on upper limbs of workers: A meta-analysis,” (in Chinese), Journal of Environmental and Occupational Medicine, Vol. 39, No. 4, pp. 426–433, 2022.

-

S. L. Xu, “Review Research on the Danger of Vibration to the Nervous System,” (in Chinese), Sports Research and Education, Vol. 27, No. 3, pp. 97–101, 2012, https://doi.org/10.16207/j.cnki.2095-235x.2012.03.001

-

R. Yan, “Application of rat tail model for studying hand-arm vibration disease,” (in Chinese), China Occupational Medicine, Vol. 45, No. 5, pp. 634–637, 2018.

-

G. H. Wang et al., “Differential diagnosis of one case of hand-arm vibration disease and connective tissue disease,” (in Chinese), Chinese Journal of Industrial Medicine, Vol. 34, No. 2, pp. 181–183, 2021, https://doi.org/10.13631/j.cnki.zggyyx.2021.02.033

-

Y. Guo and H. L. Zhu, “An analysis of the characteristics of vibration-induced white finger episodes in 75 cases of hand-arm vibration disease,” (in Chinese), Occupation and Health, No. 6, pp. 413–414, 2006.

-

C. Li, “Changes of hemorheology and blood lipid index in patients with occupational hand-arm vibration disease,” (in Chinese), China Occupational Medicine, Vol. 46, No. 5, pp. 559–563, 2019.

-

D. Y. Zhang et al., “Analysis of influencing factors of fingertip thermotactile perception threshold in healthy young adults,” (in Chinese), China Occupational Medicine, Vol. 48, No. 3, pp. 329–333, 2021.

-

X. H. Zhu et al., “Diagnostic analysis of hand-arm vibration cases in a Zhejiang Province enterprise,” (in Chinese), Industrial Health and Occupational Diseases, Vol. 47, No. 4, pp. 327–329, 2021, https://doi.org/10.13692/j.cnki.gywsyzyb.2021.04.018

-

R. Yan et al., “Correlation between vascular endothelia injury factors and occupational hand-arm vibration disease,” (in Chinese), China Occupational Medicine, Vol. 45, No. 2, pp. 138–143, 2018.

-

L. F. Diao, “Analysis of occupational health examination results of hand-transmitted vibration workers,” (in Chinese), China Occupational Medicine, Vol. 45, No. 6, pp. 782–785, 2018.

-

Y. M. Zheng et al., “Two case reports of occupational hand-arm vibration disease,” (in Chinese), Journal of Environmental and Occupational Medicine, 2018.

-

Y. W. Su et al., “Analysis of the effect of hand-transmitted vibration on hearing loss in male noise-exposed workers,” (in Chinese), China Occupational Medicine, Vol. 50, No. 3, pp. 268–273, 2023, https://doi.org/10.20001/j.issn.2095-2619.20230605

-

S. Z. Mao and W. W. Dong, “Application of quantitative sensory testing in diagnosis of diabetic peripheral neuropathy,” (in Chinese), Chinese Journal of Endocrinology and Metabolism, No. 4, pp. 47–50, 2001.

-

“Technical specifications for occupational health surveillance,” GBZ Standard 188, 2014.

-

M. S. Yan et al., “Measurement and its application of finger systolic blood pressure in diagnosis of hand-arm vibration disease,” (in Chinese), Chinese Journal of Industrial Medicine, Vol. 35, No. 2, pp. 139–143, 2022, https://doi.org/10.13631/j.cnki.zggyyx.2022.02.014

-

H. J. Zheng et al., “Detection efficiency of fingertip systolic blood pressure in diagnosis of hand-arm vibration disease,” (in Chinese), Chinese Journal of Industrial Medicine, Vol. 36, No. 2, pp. 135–138, 2023, https://doi.org/10.13631/j.cnki.zggyyx.2023.02.009

-

B. Xiao, “Application of finger systolic blood pressure in the diagnosis of vibration-induced vascular injury,” (in Chinese), China Occupational Medicine, Vol. 48, No. 4, pp. 392–396, 2021.

-

J. Liu and X. Q. Yang, “The clinical study of quantitative thermal threshold in diagnosis of neuropathic pain,” (in Chinese), Chinese Journal of Pain Medicine, Vol. 25, No. 10, pp. 770–777, 2019.

-

M. S. Yan et al., “Effect of hand-transmitted vibration on fingertip thermotactile perception threshold among mine drilling workers,” (in Chinese), Journal of Environmental and Occupational Medicine, Vol. 37, No. 4, pp. 363–367, 2020, https://doi.org/10.13213/j.cnki.jeom.2020.19557

-

L. R. Huang, “Measure of vibration perception threshold in hand-transmitted vibration workers,” (in Chinese), Chinese Journal of Industrial Medicine, Vol. 26, No. 3, pp. 174–177, 2013.

-

D. Y. Zhang, “Analysis on finger sensory examination among drill workers in a gold mine,” (in Chinese), China Occupational Medicine, Vol. 43, No. 3, pp. 296–300, 2016.

-

Y. X. Jia et al., “Investigation and analysis on fingertip vibrotactile perception threshold of grinding workers working with workpiece in hand,” (in Chinese), Chinese Journal of Industrial Medicine, Vol. 36, No. 2, pp. 138–141, 2023, https://doi.org/10.13631/j.cnki.zggyyx.2023.02.010

-

W. J. Liu, “Clinical application research on cool water loading test among workers exposed to hand-transmitted vibration,” (in Chinese), China Occupational Medicine, Vol. 41, No. 4, pp. 404–407, 2014.

-

B. Xiao, “Characteristic changes of finger skin temperature in cold provocation test in workers with vibration white finger,” (in Chinese), China Occupational Medicine, Vol. 44, No. 6, pp. 716–720, 2017.

-

B. Xiao, “Cold water immersion test (10℃, 10 min) for diagnosing vibration-induced white finger among a group of polishers in a subtropical environment,” (in Chinese), International archives of occupational and environmental health, Vol. 92, pp. 865–872, 2019.

-

B. B. Li and Y. H. Bai, “Advances in the assessment of peripheral nerve injury,” (in Chinese), Chinese Journal of Rehabilitation, Vol. 32, No. 5, pp. 421–424, 2017.

-

J. B. Chen et al., “Revision notes of diagnosis of occupational hand-arm vibration disease,” (in Chinese), China Occupational Medicine, Vol. 42, No. 2, pp. 212–216, 2015.

-

M. S. Yan et al., “Research progress on correlation between lncRNAs and pathogenesis of vascular diseases,” (in Chinese), China Occupational Medicine, Vol. 48, No. 1, pp. 103–106, 2021.

-

M. S. Yan et al., “Application of vibrotactile perception threshold in diagnosis of hand-arm vibration disease,” (in Chinese), Chinese Journal of Industrial Medicine, Vol. 36, No. 2, pp. 127–130, 2023, https://doi.org/10.13631/j.cnki.zggyyx.2023.02.007

-

Q. Liu, Q. Wu, Z. Zeng, L. Xia, and Y. Huang, “Clinical effect and mechanism of acupuncture and moxibustion on occupational hand-arm vibration disease: A retrospective study,” (in Chinese), European Journal of Integrative Medicine, Vol. 23, pp. 109–115, Oct. 2018, https://doi.org/10.1016/j.eujim.2018.10.001

-

Q. F. Liu, “Effect of warm needling therapy on nerve conduction in patients with occupational hand-arm vibration disease,” (in Chinese), China Occupational Medicine, Vol. 48, No. 4, pp. 417–421, 2021.

-

X. Q. Wang, “Investigation on the factors of health damage in staff of a golf grinding workshop,” (in Chinese), China Occupational Medicine, Vol. 37, No. 2, pp. 137–139, 2010.

-

H. Yuan, “The hazards of occupational hand-arm vibration and preventive measures,” (in Chinese), West-China Exploration Engineering, Vol. 23, No. 6, pp. 218–219, 2011.

-

X. S. Xie, “Measurement and analysis of hand-transmitted vibration of vibration tools in workplace for automobile casting and assembly,” (in Chinese), Chinese Journal of Industrial Hygiene and Occupational Diseases, Vol. 34, No. 2, 2016.

-

W. L. He et al., “Analysis and survey of occupational hazards in a railway wagon repairing enterprise,” (in Chinese), Chinese Journal of Public Health Engineering, Vol. 22, No. 4, pp. 444–447, 2023, https://doi.org/10.19937/j.issn.1671-4199.2023.04.004

-

S. Y. Pan et al., “Epidemiological investigation of occupational hand-arm vibration disease caused by handheld workpiece polishing,” (in Chinese), China Occupational Medicine, Vol. 51, No. 1, pp. 65–69, 2024, https://doi.org/10.20001/j.issn.2095-2619.20240211

-

J. X. Li, L. Lin, and J. N. Sun, “Investigation on the ergonomic factors of occupational hand-transmitted vibration in a coastal city,” (in Chinese), Industrial Health and Occupational Diseases, Vol. 48, No. 5, pp. 345–348, 2022, https://doi.org/10.13692/j.cnki.gywsyzyb.2022.05.001

-

Z. B. Zhang, Q. Bu, and L. L. Jia, “Hand-transmitted vibration and occupational health,” (in Chinese), Journal of Environmental and Occupational Medicine, Vol. 39, No. 11, pp. 1193–1197, 2022.

-

W. G. Chen, “Biomechanical model of human arm vibration and vibration-induced disease,” (in Chinese), Noise and Vibration Control, No. 2, pp. 33–39, 1988.

-

Q. H. Zhou et al., “Experimental research on the pneumatic extinguishers based on vibration characteristics and vibration transmission along human arm,” (in Chinese), Journal of Beijing Forestry University, Vol. 37, No. 6, pp. 120–125, 2015, https://doi.org/10.13332/j.1000-1522.20140443

-

W. B. Li and J. X. An, “Mechanical impedance and vibrating energy absorption of human arms,” (in Chinese), Journal of Beijing Forestry University, Vol. 17, No. S2, pp. 1–6, 1995.

-

S. Q. Lu et al., “Hand transmitted vibration characteristics of power tiller under the influence of grip force and engine speed,” (in Chinese), Journal of Chinese Agricultural Mechanization, Vol. 42, No. 9, pp. 37–43, 2021, https://doi.org/10.13733/j.jcam.issn.2095-5553.2021.09.06

-

M. S. Yan, “Effects of hand-transmitted vibration on subjective symptoms in mine drilling workers,” (in Chinese), China Occupational Medicine, Vol. 47, No. 2, pp. 168–171, 2020.

-

J. C. Liu, “Investigation of localized vibration hazards among underground rock drillers in a copper mine in the subtropical region of Guangxi,” (in Chinese), Journal of Environmental and Occupational Medicine, No. 3, pp. 43–46, 1985, https://doi.org/10.13213/j.cnki.jeom.1985.03.020

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Jian Yang: data collection, analysis and drafting the initial manuscript. Mingzhong Wu: the overall planning of the paper, financial support, review and revision.

The authors declare that they have no conflict of interest.