Abstract

Curing concrete is an effective method to ensure concrete’s mechanical and durability performance. This article experimentally investigates the impact of various curing methods (air curing, sprinkler curing, geotextile curing, and composite geotextile curing) on the compressive strength of concrete at 7, 14, and 28 days, as well as the carbonation depth and chloride ion diffusion coefficient at 28, 56, and 90 days. The effects of different curing methods on concrete performance are compared. The experimental results demonstrate that sprinkler, geotextile, and composite geotextile curing at 7 and 14 days effectively enhance concrete’s mechanical and durability performance. Compared to air curing concrete at 28 days, sprinkler, geotextile, and composite geotextile curing reduced by 17.75 %, 25.11 %, and 31.51 %, respectively, but the average absolute deviation is reducing. From 28 to 90 days, air curing concrete’s chloride ion diffusion coefficient decreases by 8.5 %. For concrete specimens under sprinkler curing, geotextile curing, and composite geotextile curing, the chloride ion diffusion coefficient decreases by 20.4 %, 8.3 %, and 6.0 %, respectively. Beyond 28 days, the durability performance of concrete under composite geotextile curing, including carbonation depth and chloride ion diffusion coefficient, tends to stabilize. The optimal curing period of 28 days is determined based on comprehensive mechanical and durability performance. Composite geotextile curing retains moisture on the concrete surface, slows evaporation, reduces watering frequency and labour costs, and promotes long-term concrete performance development. Carbonation tests and durability performance, such as chloride ion diffusion coefficient, are more sensitive to concrete curing effects. Single indicators like mechanical or durability performance cannot comprehensively evaluate concrete’s long-term performance. Concrete quality should be comprehensively evaluated by considering strength, carbonation depth, chloride ion diffusion coefficient, and other indicators.

Highlights

- This article experimentally investigates the impact of various curing methods (air curing, sprinkler curing, geotextile curing, and composite geotextile curing) on the compressive strength of concrete at 7, 14, and 28 days.

- Composite geotextile curing retains moisture on the concrete surface, slows evaporation, reduces watering frequency and labour costs, and promotes long-term concrete performance development.

- Concrete quality should be comprehensively evaluated by considering strength, carbonation depth, chloride ion diffusion coefficient, and other indicators.

1. Introduction

Curing is essential for concrete’s mechanical properties and durability [1-4]. According to the definition of the American Concrete Association (ACI), curing controls the humidity and temperature of newly poured concrete and promotes the hydration reaction of cement to ensure the long-term performance of concrete [3, 5, 6]. In concrete construction, it is essential to maintain appropriate humidity and temperature for concrete's mechanical properties and durability [7]. If the concrete is dried too fast in the early stage, it may lead to cracking and insufficient concrete strength [8, 9]. Meanwhile, appropriate humidity and temperature help promote cement's hydration reaction and improve concrete's strength and durability [10]. To achieve the expected quality, the concrete structure project needs to choose an effective and economical curing method. In theory, the complete hydration of cement in concrete requires a water-cement ratio greater than 0.42. However, for concrete projects of sea-crossing bridges, the water-cement ratio is generally at most 0.42, especially for concrete projects of coastal bridges such as the Hong Kong-Zhuhai-Macao Bridge, Humen Bridge and Huangmaohai Sea-crossing Bridge. The hydration of concrete is affected by its water-cement ratio and the humidity in the capillary pores of concrete. When the humidity in the capillary pores of concrete is reduced to 75 %-80 %, the hydration of cement almost stops. Increasing the water-cement ratio will accelerate the evaporation of water and reduce the humidity in the capillary. Proper curing can keep the humidity in the capillary pores of concrete above 80 %, promote hydration, and is conducive to developing mechanical properties and durability.

Concrete curing methods can be divided into surface curing and internal curing [1, 11]. Surface curing mainly maintains the humidity inside the concrete by continuously replenishing the water on the surface of the concrete [12]. Surface curing is divided into underwater, sprinkler, spray, and coverage curing. Underwater curing is placing a concrete structure or component under water. This method requires a large amount of water and enough space to fill with water, which is obviously inconvenient for on-site concrete engineering. Watering curing mainly replenishes water on concrete surfaces continuously to ensure internal humidity. Spray curing is by increasing the relative humidity of the concrete surface; on the one hand, it can reduce the evaporation rate; on the other hand, it can constantly replenish the water on the surface of the concrete. Sprinkler and spray curing are suitable for the construction environment of 20 °C, average temperature, and low wind speed. Aiming at the concrete structure curing project of a cross-sea bridge in the Huangmaohai coastal area, it has the characteristics of high temperature, high wind speed and fast evaporation speed. The effect of sprinkler and spray curing is not good and is not conducive to construction. Under the conditions of high temperature, low humidity or high wind speed, it is suitable for the way of covering the surface of the geotextile and regularly sprinkling water to ensure the humidity of the surface of the geotextile to slow down the evaporation of water inside the concrete and supplement the water. The curing agent is also a standard curing method, which is usually sprayed on the surface of the concrete to form an impermeable membrane, which is generally carried out after the removal of the template.

The curing method can promote the early hydration of concrete, which is conducive to developing strength and improves its crack and corrosion resistance and durability [13-15]. The quality control of concrete is an essential guarantee for the durable service life of concrete structures. The traditional concrete quality control standard is usually based on the compressive strength of concrete as the basis for structural design. However, the excessive or insufficient compressive strength of concrete will affect the quality of concrete structures. Researchers believe that compressive strength cannot be used as an evaluation index of the curing effect. The durability index can better reflect the curing effect of concrete than compressive strength and propose an evaluation method of curing effect. The oxygen permeability test is used to evaluate the traditional curing method, which has high sensitivity, good consistency of results, and minor variation of test data. The test methods of water absorption and unsteady chloride ion penetration of concrete are not uniform, and the test results of different researchers are different, which affects the evaluation of concrete durability.

Underwater curing, watering curing, spraying curing and covering curing can minimize the water loss on the concrete surface, effectively prevent the concrete surface from drying too early and promote the continuous hydration reaction of concrete [16]. In the process of concrete construction, appropriate curing methods should be selected according to the characteristics of concrete, environmental conditions, and engineering requirements. Before choosing the curing method, it is also necessary to consider factors such as the availability of curing materials, the size and shape of products, economy, environmental conditions, supervision, on-site production and factory production, and aesthetics. Due to the need to invest many resources to choose the appropriate curing method, the construction personnel on the site often only carry out partial curing or complete neglect, which directly affects the quality of concrete. It is challenging to evaluate the effect of concrete curing on site. Therefore, it is urgent to develop an efficient and practical concrete curing method and establish the corresponding evaluation index of the curing effect [17].

Based on the influence of different curing methods on the performance of concrete in the early stage, this paper mainly carried out the experimental study on the influence of different curing methods, such as sprinkler curing, geotextile curing and composite geotextile curing, on the mechanical properties, chloride ion penetration resistance and carbonization of concrete, and analyzed the evaluation indexes of the influence of different curing methods on the performance of concrete.

2. Test procedure

2.1. Materials

Raw materials used in the test process: gravel, limestone, particle size 5-25 mm; cement grade PII42.5, manufacturer is Yingde Conch Cement Co., Ltd.; water reducing agent 3301C-HM03, Xika (Jiangsu) Building Materials Co., Ltd.; first-class fly ash, provided by Zhuhai Yuezhu Environmental Protection Technology Development Co., Ltd.; slag powder is S95 type, provided by Zhuhai Yueyufeng Iron and Steel Co., Ltd.

2.2. Concrete mix proportion

The concrete mix ratio is shown in Table 2. AC, WC, GC, and CGC represent air curing, sprinkler curing, geotextile curing, and composite geotextile curing, respectively. The concrete has a strength grade of C40, and the mixture ratio is represented by PZ40.

Table 1Concrete mix proportion

No. | Quantity | Raw materials (kg/m3) | Slump /mm | ||||||||

(100×100× 100 mm) | (100×100× 400 mm) | Φ100× 50mm | Cement | Slag | Fly ash | Sand | Pebble | Water | Admixture | ||

AC | 9 | 3 | 3 | 160 | 140 | 130 | 712 | 1228 | 115 | 4.3 | 120 |

WC | 9 | 3 | 3 | 160 | 140 | 130 | 712 | 1228 | 115 | 4.3 | 110 |

GC | 9 | 3 | 3 | 160 | 140 | 130 | 712 | 1228 | 115 | 4.3 | 105 |

CGC | 9 | 3 | 3 | 160 | 140 | 130 | 712 | 1228 | 115 | 4.3 | 112 |

2.3. Test methods

Based on previous research, the effects of different curing methods on the strength and durability of concrete were studied using sprinkler curing, geotextile curing and composite geotextile curing [18-21]. The compressive strength test was carried out according to GB/T 50107-2010 “Standard for evaluation of concrete compressive strength”, and the carbonization test was carried out according to GB/T 50082-2009 “Standard for long-term performance and durability test methods of ordinary concrete”. To evaluate the influence of different curing methods on mechanical properties, the average absolute deviation (AAD) is used to represent the dispersion degree of compressive strength:

where is the compressive strength of the th concrete specimen, and is the average strength of the n cubic concrete specimens.

The concrete specimens cured for 28 days were put into the carbonization box for a rapid carbonization test. After reaching the test age, they were taken out for carbonization depth measurement. After the test was completed, the measurement section was sealed and put into the carbonization box to continue the carbonization test at 28 days, 56 days, and 90 days, respectively. The chloride ion erosion test was carried out according to GB/T 50082-2009, and the test ages were 28 days, 56 days and 90 days, respectively.

Each curing method pouring nine 100×100×100 mm cube specimens, three 100×100×400 mm, nine cylindrical specimens with a diameter of Φ100 mm and a height of 50 mm, divided into four curing methods. Firstly, the concrete specimens are placed in the air after mold removal, with no curing measures adopted. Air curing is employed to compare the effects with other curing methods. Secondly, sprinkler curing is conducted in the room, with watering twice a day, every 12 hours. Thirdly, surface paving with geotextile for curing is carried out, with sprinkling water once a day. Fourthly, composite geotextile is laid on the surface, with watering once every three days. Under the condition of an indoor temperature of 20 °C, the influence of the amount of watering, the degree of dryness and wetness on the surface, and other factors on the curing and the effect of curing were discussed. When the surface of the concrete specimen begins to dry, it needs to be sprinkled and cured. According to the humidity of the surface of the concrete specimen and the number of sprinkling times, the influence of different curing methods on the curing effect of the concrete specimen is determined. See Fig. 1. Fig. 1(a) is a commonly used geotextile, and Fig. 1(b) is a schematic diagram of a composite geotextile.

Fig. 1Different types of geotextiles

a) Geotextile

b) Composite geotextile

3. Test results and analysis

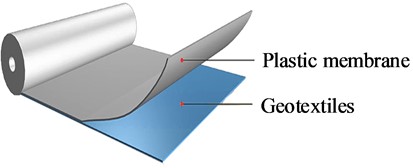

3.1. The influence of curing methods on curing frequency

When the surface of the concrete specimen begins to appear dry, it needs to be sprinkled, as the surface of the concrete specimen is not water-retaining. It is cured once in 18 hours without geotextile. When the concrete surface is cured by the geotextile, 24 hours of sprinkler curing can keep the surface of the concrete specimen wet. When the surface of the concrete specimen is cured with composite geotextile, the geotextile is in contact with the surface of the concrete, and the concrete surface can be kept wet for 72 hours after curing once.

Fig. 2Curing frequency under different curing methods. AC represents the air curing; WC represents the sprinkler curing; GC represents the Geotextile curing; CGC represents the composite geotext curing

Fig. 2 shows the times the concrete needs to be moisturized. When the surface of the concrete specimen is covered with a composite geotextile for curing, the water on the surface of the concrete can be retained, and the rate of water evaporation can be reduced, reducing the number of sprinklers and labour costs.

As shown in Fig. 3, Fig. 3(a) is the time of sprinkler curing, Fig. 3(b) is the specimen cured by geotextile, and Fig. 3(c) is the specimen cured by composite geotextile. After 28 days of curing, the surface of the specimen cured by sprinkler curing is dry and white, the surface of the specimen cured by geotextile is still wet, but there are signs of whitening, while the surface of the specimen cured by composite geotextile is still wet, indicating that the specimen cured by composite geotextile has a specific water retention function.

Fig. 3Different curing effects

a) Sprinkler curing

b) Geotextile curing

c) Composite geotextile curing

3.2. The influence of curing methods on the compressive strength

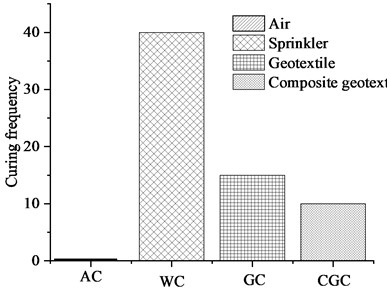

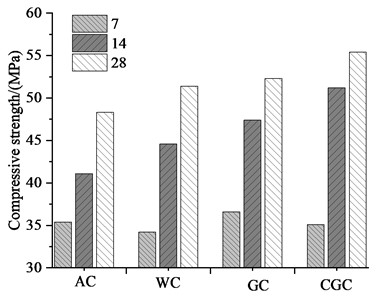

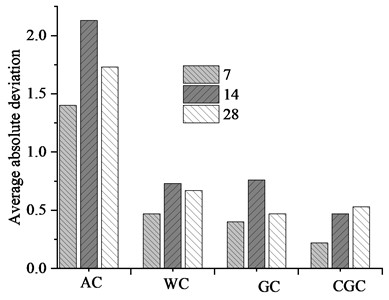

It can be seen from Fig. 4 and the Table 2 that when the concrete specimens are cured for 7 days, the strength of the concrete specimens cured in air, sprinkler water, geotextile and composite geotextile is 35.4 MPa, 34.2 MPa, 36.6 MPa and 35.1 MPa, respectively, and the difference is not large. The average absolute deviation is 1.4, 0.47, 0.4, and 0.22. The dispersion of the data has been reduced, as shown in Fig. 5. The strength of concrete cured in air is higher than that of concrete cured in composite geotextile. The main reason is that the early hydration of concrete will generate heat, and the temperature will increase, which will accelerate the hydration process. However, owing to the regulation of water within geotextiles, the temperature of concrete specimens covered by composite geotextile does not rise significantly, and the hydration rate is lower than that of concrete specimens in air. As a result, the concrete strength of the former is higher than the latter. With the increase of curing age, the water content in concrete specimens cured in air decreases and the hydration rate slows down from the age of 14 days. However, sprinkler curing, geotextile curing and composite geotextile curing still provide water for cement hydration, so that the strength of the latter three increases by 8.5 %, 15.3 % and 24.6 % respectively compared with that of specimens cured in air. When the curing age is 28d, the sequential strength of air curing, sprinkler curing, geotextile curing and composite geotextile curing increases in turn, and the strength is 48.3 MPa, 51.4 MPa, 52.3 MPa and 55.4 MPa respectively. Compared with the concrete specimens cured in air, the strength increases by 6.4 %, 8.3 % and 14.7 % respectively. The surface of concrete specimens cured in air is dry and the internal water is short, which leads to insufficient hydration and insufficient strength development in the process of concrete curing. Moreover, the surface of concrete is easy to shrink and form microcracks after drying, which is also the problem of insufficient durability caused by insufficient concrete curing.

In theory, the compressive strength of concrete specimens cured in sprinkler curing, geotextile curing, and composite geotextile curing is higher than that of concrete specimens cured in air. The strength of concrete specimens cured in air for seven days is higher than that of the latter three, while the strength of concrete for 14 days and 28 days is lower than that of the latter three. However, the test data regarding the strength of cured concrete in air exhibit the highest degree of dispersion. Therefore, the strength of concrete suggests that a more comprehensive approach is necessary to assess the curing effect.

Fig. 4The influence of different curing methods on the strength of concrete

Fig. 5The average absolute deviation of strength with different curing methods

Table 2The test results of the mechanical properties and durability of concrete

No. | Strength / MPa | Carbonation depth / mm | Chloride diffusion coefficient ×(10-12m2/s) | ||||||

7 d | 14 d | 28 d | 28 d | 56 d | 90 d | 28 d | 56 d | 90 d | |

AC | 35.4 | 41.1 | 48.3 | 3.5 | 4.2 | 5.6 | 9.52 | 9.14 | 8.71 |

WC | 34.2 | 44.6 | 51.4 | 3.1 | 3.9 | 5.1 | 7.83 | 6.52 | 6.23 |

GC | 36.6 | 47.4 | 52.3 | 2.8 | 3.7 | 4.7 | 7.13 | 6.92 | 6.54 |

CGC | 35.1 | 51.2 | 55.4 | 2.8 | 3.6 | 4.8 | 6.52 | 6.21 | 6.13 |

3.3. Effects of different curing methods on the carbonation depth

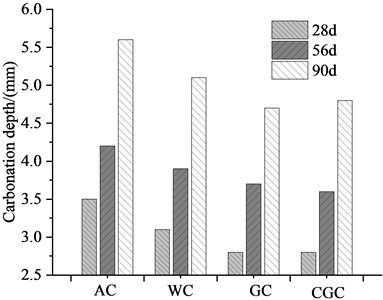

Fig. 6 is the carbonation depth histogram of concrete specimens cured in air, sprinkling water, geotextile and composite geotextile after formwork removal. It can be seen from the diagram that the carbonation depth of concrete is significantly different under different curing conditions. The carbonation depth of concrete cured in the air is the largest, reaching 3.5 mm at 28 d, 4.2 mm at 56 d, and 5.6 mm at 90 d. The carbonation depth of concrete specimens cured by sprinkler, geotextile curing, and composite geotextile curing is smaller than that of concrete cured in air, indicating that maintaining a certain amount of water in the curing process can not only promote hydration but also increase the compactness of concrete. Compared with the curing effect in the air, from 28 days to 56 days, the carbonation depth of concrete specimens cured in the air increased by 0.7 mm, and the carbonation depth of concrete specimens cured by sprinkler, geotextile and composite geotextile increased by 0.8 mm, 0.9 mm and 0.8 mm respectively. From 56 to 90 days, the carbonation depth of concrete specimens cured in the air increased by 1.4 mm, and the carbonation depth of concrete specimens cured by sprinkler, geotextile and composite geotextile increased by 1.2 mm, 1.0 mm and 1.2 mm, respectively. Under the conditions of sprinkler curing, geotextile curing and composite geotextile curing, the carbonation depth also increased significantly with age, but the growth rate slowed down. The results of the carbonation test show that the carbonation depth of concrete can be reduced, and the carbonation rate can be reduced after the implementation of curing measures.

3.4. Effects of different curing methods on chloride diffusion coefficient

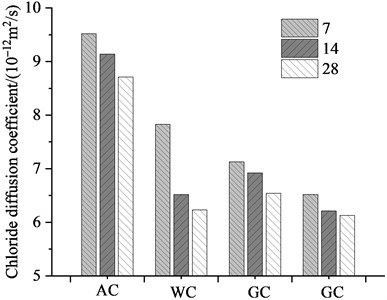

Fig. 7 is the histogram of RCM rapid test results of concrete specimens cured in air, sprinkler, geotextile and composite geotextile. It can be seen from the diagram that the chloride ion diffusion coefficient of concrete is significantly different under different curing conditions. The chloride ion diffusion coefficient under air curing is the largest, which is 9.52×10-12 m2/s at 28 days, 9.14×10-12 m2/s at 56 days, and 8.71×10-12 m2/s at 90 days. The chloride ion diffusion coefficients of concrete specimens cured by sprinkler, geotextile and composite geotextile at 28 days were 17.75 %, 25.11 % and 31.51 % lower than those cured in air. It can also be explained that concrete maintains a certain amount of water during the curing process to promote hydration and increase the compactness of concrete. Compared with the curing effect in air, from 28 days to 56 days, the chloride ion diffusion coefficient of concrete cured in air decreased by 4.0 %, and the carbonation depth of concrete specimens cured by sprinkler, geotextile and composite geotextile decreased by 16.7 %, 2.9 % and 4.8 % respectively. From 28 days to 90 days, the chloride diffusion coefficient of concrete cured in the air decreased by 8.5 %, and the chloride diffusion coefficient of concrete specimens cured by sprinkler, geotextile and composite geotextile decreased by 20.4 %, 8.3 % and 6.0 %, respectively. The chloride ion diffusion coefficient also decreases significantly with age, under sprinkler curing, geotextile curing and composite geotextile curing. The RCM rapid test shows that implementing curing measures can reduce the resistance of concrete to chloride salt erosion, and with the increase of curing age, the chloride ion diffusion coefficient decreases, and the resistance to chloride salt erosion tends to increase.

Fig. 6Effects of different curing methods on the carbonation depth

Fig. 7Effects of different curing methods on chloride diffusion coefficient

4. Analysis

Compressive strength is usually used as an index to evaluate the quality of concrete. However, the test results show that durability-related indicators are more sensitive to the performance of concrete. Different curing methods have a particular influence on the strength of concrete, but the degree of influence is small. The effects of different curing methods on the quality of concrete were evaluated by comparing the 28-day compressive strength, 90-day chloride ion diffusion coefficient, carbonation test and other durability properties. It was found that different curing methods had little effect on the development of compressive strength of concrete at 7 days and 14 days. However, the average absolute deviation of strength is the maximum value in air curing. After the curing measures are applied, the strength dispersion of the concrete becomes smaller, and the mechanical properties are more stable. The use of sprinkler curing, geotextile curing, and composite geotextile curing had a more significant impact on the carbonation depth and chloride ion diffusion coefficient of concrete (see Fig. 6 and Fig. 7). Sprinkler curing, geotextile curing, and composite geotextile curing are more sensitive to chloride ion diffusion coefficient and carbonation depth, which can better reflect the influence of different curing methods on the long-term performance of concrete. Compared with compressive strength. Compared with the compressive strength test, the chloride ion migration coefficient and carbonation test results more directly reflect the external corrosion resistance of concrete.

5. Conclusions

In this study, the effects of different curing methods (including air curing, sprinkler curing, geotextile curing and composite geotextile curing) on the compressive strength and the average absolute deviation of the compressive strength at 7 days, 14 days and 28 days, as well as the carbonation depth and chloride ion diffusion coefficient at 28 days, 56 days and 90 days were discussed. The specific conclusions are as follows:

1) Different curing methods had little effect on the development of compressive strength of concrete at 7 days and 14 days. The average absolute deviation of the compressive strength reduces significantly with the sprinkler curing, geotextile curing and composite geotextile curing, and the mechanical properties become more stable.

2) Concrete durability can be effectively improved by 7 days and 14 days of sprinkler curing, geotextile curing and composite geotextile curing. After 28 days, the concrete’s carbonation depth and chloride ion diffusion coefficient are stable.

3) Comparing with the influence of different curing methods on the performance of concrete, it was found that the composite geotextile has the best curing effect. It can retain the water on the surface of concrete and slow down the evaporation rate of water. It reduces the number of sprinklers and labor costs, which is conducive to the development of long-term concrete performance.

4) Sprinkler curing, geotextile curing, and composite geotextile curing have little effect on the development of compressive strength of concrete at 7 days and 14 days, and the development of strength cannot fully reflect the early curing effect of concrete. In contrast, durability properties such as carbonation test and chloride diffusion coefficient are more sensitive to the curing effect.

5) Single mechanical properties and durability indicators cannot fully evaluate the long-term performance of concrete. The strength, carbonation depth, chloride diffusion coefficient, and other indicators should be comprehensively considered when evaluating the quality of concrete.

References

-

T. Gereziher Atsbha and S. Zhutovsky, “Investigating the effect of hybrid curing on mechanical and durability properties of normal-strength concrete,” Construction and Building Materials, Vol. 369, p. 130536, Mar. 2023, https://doi.org/10.1016/j.conbuildmat.2023.130536

-

D. Shen, C. Liu, M. Wang, X. Jin, and H. Tang, “Prediction model for internal relative humidity in early-age concrete under different curing humidity conditions,” Construction and Building Materials, Vol. 265, p. 119987, Dec. 2020, https://doi.org/10.1016/j.conbuildmat.2020.119987

-

G. Zhang, C. Li, H. Wei, M. Wang, Z. Yang, and Y. Gu, “Influence of humidity on the elastic modulus and axis compressive strength of concrete in a water environment,” Materials, Vol. 13, No. 24, p. 5696, Dec. 2020, https://doi.org/10.3390/ma13245696

-

P. Ge, W. Huang, H. Zhang, W. Quan, and Y. Guo, “Study on calculation model for compressive strength of water saturated recycled aggregate concrete,” KSCE Journal of Civil Engineering, Vol. 26, No. 1, pp. 273–285, Sep. 2021, https://doi.org/10.1007/s12205-021-0286-4

-

L. Liu, S. Zhao, J. Xin, and Z. Wang, “Simplified analysis of thermal cracks in low‐heat Portland cement concrete,” Advances in Civil Engineering, Vol. 2022, No. 1, p. 76305, Apr. 2022, https://doi.org/10.1155/2022/7630568

-

G. H. Guo, Y. F. Bai, and T. Wang, “Analysis of dynamic load level of high-speed heavy vehicle imposed on uneven pavement,” in Applied Mechanics and Materials, Vol. 138-139, pp. 146–152, Nov. 2011, https://doi.org/10.4028/www.scientific.net/amm.138-139.146

-

Z. Shen, H. Zhu, and X. Meng, “The influence of curing methods on the performance of recycled concrete powder artificial aggregates and concrete,” Construction and Building Materials, Vol. 435, p. 136908, Jul. 2024, https://doi.org/10.1016/j.conbuildmat.2024.136908

-

A. Kulkarni, “Effect of curing methods on strength and elastic properties of concrete,” International Journal for Research in Applied Science and Engineering Technology, Vol. 6, No. 4, pp. 2738–2743, Apr. 2018, https://doi.org/10.22214/ijraset.2018.4458

-

M. Ibrahim, M. Shameem, M. Al-Mehthel, and M. Maslehuddin, “Effect of curing methods on strength and durability of concrete under hot weather conditions,” Cement and Concrete Composites, Vol. 41, pp. 60–69, Aug. 2013, https://doi.org/10.1016/j.cemconcomp.2013.04.008

-

A. R. Chougule, M. B. Patil, and K. B. Prakash, “An experimental study of different curing methods on the properties of HVGGBFS concrete,” Journal of Building Pathology and Rehabilitation, Vol. 3, No. 1, pp. 1–9, Oct. 2018, https://doi.org/10.1007/s41024-018-0038-0

-

T. Gereziher Atsbha and S. Zhutovsky, “The effect of external curing methods on the development of mechanical and durability-related properties of normal-strength concrete,” Construction and Building Materials, Vol. 324, p. 126706, Mar. 2022, https://doi.org/10.1016/j.conbuildmat.2022.126706

-

J. Wang, H. Li, C. Ma, C. Cai, and J. Wang, “Effect of surface curing condition on the humidity field and moisture transfer in concrete,” Construction and Building Materials, Vol. 411, p. 134701, Jan. 2024, https://doi.org/10.1016/j.conbuildmat.2023.134701

-

R. He, T. Nantung, J. Olek, and N. Lu, “Field study of the dielectric constant of concrete: A parameter less sensitive to environmental variations than electrical resistivity,” Journal of Building Engineering, Vol. 74, p. 106938, Sep. 2023, https://doi.org/10.1016/j.jobe.2023.106938

-

A. M. Zeyad, H. M. Magbool, M. Amran, M. J. A. Mijarsh, and A. Almalki, “Performance of high-strength green concrete under the influence of curing methods, volcanic pumice dust, and hot weather,” Archives of Civil and Mechanical Engineering, Vol. 22, No. 3, p. 134, May 2022, https://doi.org/10.1007/s43452-022-00445-1

-

M. Z. Rahimi, R. Zhao, S. Sadozai, F. Zhu, N. Ji, and L. Xu, “Research on the influence of curing strategies on the compressive strength and hardening behaviour of concrete prepared with Ordinary Portland Cement,” Case Studies in Construction Materials, Vol. 18, p. e02045, Jul. 2023, https://doi.org/10.1016/j.cscm.2023.e02045

-

B. Liu, G. Luo, and Y. Xie, “Effect of curing conditions on the permeability of concrete with high volume mineral admixtures,” Construction and Building Materials, Vol. 167, pp. 359–371, Apr. 2018, https://doi.org/10.1016/j.conbuildmat.2018.01.190

-

W. Z. Taffese and E. Nigussie, “Automated concrete curing and assessment of strength and durability using IoT system,” Materials Today: Proceedings, Jul. 2023, https://doi.org/10.1016/j.matpr.2023.07.107

-

Y. Shi et al., “Preparation and curing method of red mud-calcium carbide slag synergistically activated fly ash-ground granulated blast furnace slag based eco-friendly geopolymer,” Cement and Concrete Composites, Vol. 139, p. 104999, May 2023, https://doi.org/10.1016/j.cemconcomp.2023.104999

-

P. He, S. Drissi, X. Hu, J. Liu, and C. Shi, “Properties of CO2-cured cement incorporating fly ash and slag subjected to further water curing,” Cement and Concrete Composites, Vol. 152, p. 105633, Sep. 2024, https://doi.org/10.1016/j.cemconcomp.2024.105633

-

T. G. Atsbha and S. Zhutovsky, “Optimising internal curing parameters for autonomous curing of normal-strength concrete,” Magazine of Concrete Research, Vol. 75, No. 17, pp. 888–905, Sep. 2023, https://doi.org/10.1680/jmacr.22.00254

-

L. A. Parsons and S. O. Nwaubani, “Abrasion-wear resistance of precarbonated and water-cured concrete made using ABS plastic derived from waste electrical and electronic equipment,” Cement and Concrete Research, Vol. 179, p. 107470, May 2024, https://doi.org/10.1016/j.cemconres.2024.107470

About this article

The authors wish to express their acknowledgement to the research fund of Road& Bridge South China Engineering Co., Ltd. for their financial support.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Guohe Guo: writing – original draft preparation, methodology, investigation. Shangchuan Zhao: conceptualization, writing – review and editing, writing-original draft preparation. Dongchang Wen: supervision, writing and editing. Ge Zhang: supervision, writing – review and editing. Longlong Liu: conceptualization, formal analysis, investigation, methodology, visualization.

The authors declare that they have no conflict of interest.