Abstract

In order to study the vulnerability of 1,1'-dihydroxy-5,5'-bistetrazole dihydroxylamine salt (HATO) based explosives, a comparative study of the bullet impact vulnerable characteristics of HATO-based explosives and HMX-based explosives were carried out by using the 12.7 mm bullet impact test method of the 700-group of the Military Mixed Explosives Formulation and Performance Test Methods. The results of the study indicate that due to the friction and impact sensitivities of the HATO and the HMX explosives are similar, and the bullet impact response degree and the safety performance of the HATO-based explosives and HMX-based explosives is equivalent too.

1. Introduction

In modern warfare, weapons and equipment put forward higher requirements for charging research. On the one hand, it requires the use of higher energy levels to improve the absolute energy and destructive power of weapons and ammunition; on the other hand, it requires insensitive characteristics to reduce the vulnerability of weapons and ammunition, and meet the safety requirements of high value weapon platforms such as carrier and airborne [1]. At present, the test methods to study the insensitive characteristics of explosives mainly include slow cook-off test, fast cook-off test, bullet impact test, jet impact test, jet impact test, martyr explosion test and fragment impact test. In the whole life cycle of weapons and equipment by the biggest threat mainly comes from the tube weapon bullet impact, so the bullet impact test is one of the ammunition delivery before the military will do the assessment project, bullet impact test is vulnerability assessment way that simulates explosive sample accidentally impacted by bullets or fragments. To study the reaction of explosives caused by the impact and penetration of high-velocity flying bullet can obtain the safety performance of the sample itself, and provide theoretical guidance for the study of ammunition safety [2]. Kimura and Lee et al. [3, 4] studied the bullet impact safety performance of propellant and RDX-based LOVE propellant; Tang et al. studied the bullet impact safety performance of PBX charge by using standard bullet impact test [5]; Yang et al. studied the bullet impact characteristics of RDX with 12.7 mm and ballistic gun, and compared the bullet impact safety with single-based propellant [6].

HATO (1,1′-dihydroxy-5,5′-tetrazole dihydrolamine) is a new type of ionic high energy density compound [7, 8], Has high nitrogen content, density, formation enthalpy and detonation properties; because its crystal contains a large number of hydrogen bond network structure, help to reduce sensitivity and increase thermal stability, so the thermal and mechanical insensitive; HATO also has a low vapor pressure, not volatile, is a good explosive [1]. The Xi’an Institute of Modern Chemistry has a crystal density of 1.879 g/cm3, The thermal decomposition temperature is 249.1 ℃, the thermal stability is better than RDX, the energy is higher than RDX, and the vacuum stability, the characteristic height of 100cm, the impact and friction explosion probability is 16 % and 24 %, respectively [9, 10], The solubility in the water is 0.27 g, placed in the air for 1 month, no obvious hygroscopic phenomenon, good molding [1, 7], The theoretical explosive rate of HATO charge is 9781 m/s [11, 12]. At the same time, it has good thermal stability and low mechanical sensitivity. In conclusion, HATO explosive is an insensitive energy-bearing material with excellent performance [13], however, it is rare to report the insensitive characteristics of HATO-based explosives, so the vulnerability of HATO explosives is of great significance to promote the application of HATO in weapons and equipment, especially in high-value carrier and airborne weapons and equipment.

In this paper, 700 groups of 12.7 mm bullet Impact Test Method of Military Hybrid explosive were used to study the safety performance of HATO base explosives and compare it with HMX base explosives.

2. Test

2.1. Test device

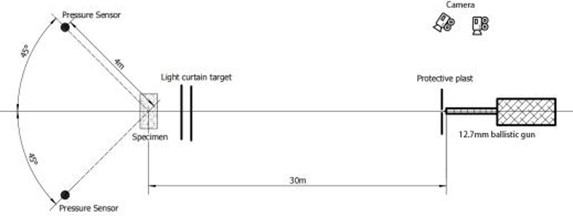

The 12.7 mm bullet impact test uses a 12.7 mm bullet to shoot an explosives specimen in the steel shell. The mechanical energy generated by the high-speed impact and friction of the bullet was rapidly converted into thermal energy, which may cause the specimen to decompose, ignite, combust, or even explode. The test assessed the vulnerability of the explosives specimen through the observation of phenomena such as specimen debris, witness plate, and shockwave overpressure. The test apparatus comprises a 12.7 mm ballistic gun, a firing apparatus, a velocity measurement apparatus, and an overpressure measurement apparatus, as shown in Fig. 1. The 12.7 mm ballistic gun has a caliber of 12.7 mm and can fire the 54 type 12.7 mm armor-piercing bullet, and has a barrel length of 1200 mm. The firing apparatus is a remote electric firing apparatus, which ensures the operator's safety during the test. The velocity measurement apparatus is a 650 nm laser velocity light screen target that can measure the bullet velocity of diameters ranging from 5 mm to 80 mm. The overpressure measurement apparatus comprises two PCB wall pressure sensors, an F482B11 adapter, and a data acquisition, and can measure the shockwave overpressure when the specimen reacts. The two pressure sensors are symmetrically distributed at 45 degrees along both sides of the axis of the ballistic gun, 4m away from the specimen. The technical conditions are as follows:

(1) ballistic guns Calibre is 12.7 mm. (2) The velocity of bullet at 30 m is 850±20 m/s. (3) The velocity measuring apparatus measuring area is 800×1000 mm² with a resolution of less than 5mm, and which velocity measuring range is form 10 to 3000 m/s. Additionally, the overpressure measuring range from o to 0.69 MPa, and sensitivity of 7.25 mV/kPa, and a resolution of 0.007 kPa, and resonance frequency ≥ 500 kHz, and non-linearity ≤ 1 %.

Fig. 112.7 mm bullet impact test schematic

2.2. Test and samples

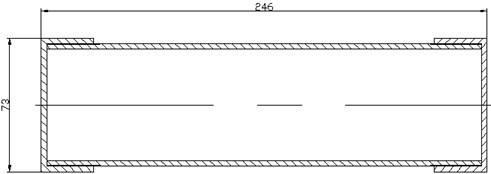

The HATO-based explosive was formulated with 97 % HATO and 3 % wax 68 (mass fraction) [5], which were first made into modelling powder and more compressed into Φ60 mm×60 mm pillars with a density of 1.74 g/cm3 using a hydraulic press, while HMX explosives specimens were formulated with 95 % HMX and 5 % binder (mass fraction), which were also made into modeling powder and then pressed into Φ60 mm×60 mm pillars using a hydraulic press, with a density of 1.73 g/cm3 too. The HATO-based explosive specimens and the HMX-based explosives specimens were loaded into 45# steel tube with internal dimensions of Φ60 mm×240 mm and wall thickness of 3 mm respectively, respectively. The end of the shell is sealed with threaded end caps. The external dimensions of the specimens are shown in Fig. 2, four specimens were prepared for each explosive, both of which were used for radial impact and the other two for axial impact. The two explosive specimens were subjected to 12.7 mm bullet shoot at 30 m from ballistic gun, test schematic show as Fig. 1.

Fig. 2Schematic diagram of the charge shell

Before the start of the test, the velocity of the bullets at a distance of 30 meters from the muzzle were measured 10 times using a laser velocity light screen target to calibrate whether the bullet’s target velocity reached 850±20 m/s technical requirements. The velocity results are shown in Table 1.

The results in Table 1indicate that the bullet target velocity varies from 846.7 m/s to 862.4 m/s, and the average velocity is 856.7 m/sand according with the method.

The specimen is placed 30 m away from the gun muzzle, and two 2-shot tests are conducted in each direction (radial and axial). During the test, a wall pressure transducer and a data acquisition system are used to record the shockwave overpressure generated by the explode.

Table 1Results of bullet target velocity calibration test

No. | Velocity (m/s) | No. | Velocity (m/s) |

1 | 862.4 | 6 | 856.1 |

2 | 859.3 | 7 | 846.7 |

3 | 855.3 | 8 | 851.1 |

4 | 861.4 | 9 | 856.3 |

5 | 860.6 | 10 | 858.1 |

Velocity max(m/s) | 862.4 | Velocity min(m/s) | 846.7 |

Average velocity (m/s) | 856.7 | ||

2.3. Test results

(1) Overpressure results. The data collected by the pressure sensors was processed and averaged to obtain the shockwave overpressure results, shown in Table 2.

Table 2Shockwave overpressure of the two explosive specimens

No. | The HATO-based explosive (kPa) | The HMX-based explosive | ||

Axial impact | Radial impact | Axial impact | Radial impact | |

1 | 53 | 9 | 58 | 10 |

2 | 57 | 9 | 58 | 12 |

Average (kPa) | 55 | 9 | 58 | 11 |

(2) Test phenomena. The status of the witness plate and specimen after the test is shown in Fig. 3 and Fig. 4.

Fig. 3Shell and witness status of HATO based explosive after bullet impact test

a) Radial impact

b) Axial impact

Fig. 4Shell and witness status of HMX based explosive after bullet impact test

a) Radial impact

b) Axial impact

3. Discussion of test results

From Table 1 and Fig. 3 and Fig. 4, it can be indicated that: (1) The HATO-based explosive response is explosion after being radially impacted by the bullet, and the bullet axial impact response of the bullet is partial detonation; (2) The HMX-based explosive response is explosion after being radial impacted by the bullet, and the bullet axial impact response is partial detonation. The results are listed in Table 3.

HATO molecular structure has the following characteristics: (1) HATO is an ionic energetic salt, and its crystal structure has a large number of hydrogen bonding network structures, which helps to reduce the explosives insensitivity and increase the thermal stability; (2) the HATO contains the higher content of nitrogen and hydrogen in its molecular composition and produces higher gas, producing more gas than HMX. (3) HATO-based explosives molecular structure does not include nitro, azide, and other explosive groups [1], these features help to improve the safety of HATO-based explosives. HMX is an eight-element heterocyclic nitramine explosive, its molecular structure includes N-NO2 group. The N-NO2 group is typical explosive group. From the molecular structure of the two explosives feature analysis, HATO-based explosives response intensity seems to be lower than that of the HMX-based explosives, but the test results illustrate the two-response intensity is similar and the safety of the bullet impact is equivalent.

Analysis of the process of the bullet impact illustrates the bullet through the sample is in the form of mechanical stimulation (impact and friction), that is, the bullet impact test is an evaluation of the explosive specimen's response to mechanical stimulation, it can be concluded that the impact and friction sensibility of the specimens to the results of the test plays a decisive role in the course of the impact process. The mechanical sensibility data of HATO and HMX in Table 4, indicates that the impact and friction sensibility of HATO is similar to that of HMX, and it is not difficult to conclude that the results of the bullet impact test of explosives with similar mechanical sensibility are similar, and therefore, the bullet impact responses of HATO and HMX-based explosives are similar in intensity, and the safety of the bullet impacts is equivalent.

Table 3Results of 12.7 mm bullet impact test

Name | Experimental phenomena | Mean of shockwave pressure (kPa) | Results |

HATO-based explosives | The witness plate is deformed, the shell is divided into some large fragments, and there is a little explosive residue | 9 | Explosion (radial) |

The witness plate is torn and the shell is divided into large pieces with a little explosive residue | 55 | Partial detonation (axial) | |

HMX-based explosives | Witness plate deformation, shell-torn, no residue | 11 | Explosion (radial) |

Witness the deformation of the plate, the shell into large fragments, no residue | 58 | Partial detonation (axial) |

Table 4Sensitivity data of HATO and HMX

Name | HATO | HMX |

Impact sensitivity / % | 16 | 21 |

Friction sensitivity / % | 24 | 16 |

4. Conclusions

To assess the bullet impact safety characteristics of HATO-based explosives, we conducted a 12.7 mm bullet impact test of the HATO-based explosive and compared the results with HMX-based explosives. HATO explosive is an ionic energy salt with a crystal structure that has a large number of hydrogen bonding networks, and has a higher content of nitrogen-hydrogen elements and does not contain explosive groups such as the nitro group and the azide group. The impact and friction sensitivity of the two explosives are comparable. Based on the analysis of the molecular structure, it appears that HATO-based explosive should have higher bullet impact safety than HMX-based explosive. Additionally, based on the sensitivity, it appears that the bullet impact characteristics of the two explosives are comparable.

The analysis of the process when bullet shoots the specimen illustrates that the high speed bullet mainly transfers its energy to explosive through mechanical effects such as impact and friction, therefore, the mechanical sensitivity of explosives is crucial in determining the results of the bullet impact test. The test results illustrate that the mechanical sensitivity (impact sensitivity and friction sensitivity) is a crucial factor in the bullet impact safety characteristics. Therefore, it is feasible to study the bullet impact safety performance of the explosives by analyzing mechanical sensitivity.

References

-

Z. X. Ge and F. Q. Bi, “High energy insensitive energetic materials – HATO,” Chinese Journal of Energetic Materials, Vol. 22, No. 4, pp. 434–435, 2014.

-

Z. G. Sun, C. Zhang, J. Q. Li, Y. Z. Dang, Z. K. Wu, and J. B. Chen, “Vulnerabile response of double-base and CMDB propellant by bullet impact test,” Initiators and Pyrotechnics, Vol. 2, pp. 39–42, 2019.

-

E. Kimura and Y. Oyumi, “Sensitivities of azide polymer propellants in fast cook-off, card gap and bullet impact tests,” Journal of Energetic Materials, Vol. 15, No. 2-3, pp. 163–178, Jun. 1997, https://doi.org/10.1080/07370659708216080

-

J. H. Lee and J. C. Lee, “Interior ballistic properties of RDX-based Solid Propallent,” in 36th International Annual Conference of ICT&32nd International Pyrotechnics Semina, 2005.

-

G. F. Tang, X. F. Wang, and W. Li, “Study on low vulnerability of cast PBX,” Chinese Journal of Energetic Materials, Vol. 3, pp. 163–165, 2003.

-

J. Yang, X. Z. Jia, R. Yu, J. J. Yan, P. G. Jin, and X. M. Chen, “Research on the bullet impact characteristic of RDX base propellant,” Initiators and Pyrotechnics, Vol. 5, pp. 14–17, 2011.

-

N. Fischer, D. Fischer, T. M. Klapötke, D. G. Piercey, and J. Stierstorfer, “Pushing the limits of energetic materials – the synthesis and characterization of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate,” Journal of Materials Chemistry, Vol. 22, No. 38, p. 20418, Jan. 2012, https://doi.org/10.1039/c2jm33646d

-

F. Q. Bi et al., “Synthesis and Properties of Dihydroxylammonium 5,5’-bistetrazole-1,1’-diolate,” Chinese Journal of Energetic Materials, 2014.

-

F. Q. Bi et al., “Compatibility of Dihydroxylammonium 5,5′-Bistetrazole-1,1′-diolate with components of CMDB propellant,” Chinese Journal of Energetic Materials, Vol. 22, No. 5, pp. 716–718, 2014.

-

“JGB772A, Explosives test method”.

-

W. P. Zhang et al., “Calculation of theory detonation velocity of dihydroxylammonium 5,5’-bistetrazole-1,1’-diolate,” Chinese Journal of Explosives and Propellants, Vol. 38, No. 6, pp. 67–71, 2015.

-

D. Fischer, T. M. Klapötke, M. Reymann, P. C. Schmid, J. Stierstorfer, and M. Sućeska, “Synthesis of 5-(1 Htetrazolyl)-1-hydroxy-tetrazole and energetically relevant nitrogen-rich ionic derivatives,” Propellants, Explosives, Pyrotechnics, Vol. 39, No. 4, pp. 550–557, Mar. 2014, https://doi.org/10.1002/prep.201300152

-

C. Xu, F. Q. Bi, M. Zhang, Z. X. Ge, Y. Zhu, and Q. Liu, “Synthesis, measurement and correlation of solubility of dihydroxylammonium and alkali metal salts of 5,5′-Bistetrazole-1,1′-diolate,” Chinese Journal of Energetic Materials, Vol. 23, No. 3, pp. 208–212, 2015.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.