Abstract

In this work the physical-chemical properties of asphaltene-resin-paraffin deposits are studied. Their component composition was determined. The results obtained are the basis for the selection of effective solvents and the choice of the method of removing deposits from oil reservoirs. Two hydrocarbon solvents with the brands “TSK А” and “TSK B” were tested. The solvent ability of solvents was tested.

1. Introduction

The problem of removing asphalt, resin, and paraffin deposits (ARPD) during oil production, storage and transportation around the world arose more than 120 years ago. At the moment, heavy oils enriched with a high content of high-molecular components (asphalt-resin-paraffins) are increasingly coming into processing, serious problems can arise during the extraction, transportation and storage of oil due to the accumulation of sediments on the walls and bottom of the reservoir. The resulting solid sediment impedes the movement of oil, there is a decrease in the useful volume of the reservoir, which forces them to be taken out of service for cleaning [1]. The second problem is the occurrence of corrosion damage and the difficulty of inspecting the state of the reservoir. At the same time, all this reduces the operational characteristics of the facility, negatively affects the qualitative and quantitative accounting of oil and oil products.

However, in the absence of systematic studies on the influence of the type of sediment on the selection of conditions and methods of removal, as a rule, it is carried out empirically without taking into account the composition of ARPD. Therefore, studies of the physicochemical composition and properties of deposits, depending on the conditions of their formation, have recently become relevant in order to determine the criteria that allow a rational and effective choice of methods for removing deposits.

In this work, the physicochemical properties and composition of four samples of asphalt, resin and paraffin deposits were studied in order to determine the optimal type of solvent for their removal. In the course of the research, the water content, the content of mechanical impurities, the group chemical composition was determined, and the dissolving power of solvents was tested.

Study of the properties of asphalt, resin and paraffin deposits

At the Gradient-M plant, the quantitative hydrocarbon composition of ARPD was determined by liquid-adsorption chromatography with gradient displacement, divided into seven groups: paraffin-naphthenic hydrocarbons, light, medium, heavy aromatic, resins I, resins II and asphaltenes [2] (Fig. 1(a)).

To determine the group composition of deposits, silica gel ASA was poured through a funnel into a clean and dried chromatographic column and compacted with a vibrator. A portion of the analyzed sample of ARPD with a mass of 0.04 g was dissolved with a mixture of benzene and cyclohexane 1:1 per 7 ml of a mixture of benzene and cyclohexane per 0.04 g of the sample. Then, 2 mcl of the sample solution was injected with a microsyringe into the upper layer of silica gel, which is in the column. Then, with a medical syringe, we introduce 1.5-2 ml of eluent, consisting of a mixture of solvents: isooctane, diisoamyl ether, ethyl acetate, ethyl alcohol. The working pressure was 0.4 MPa.

After all the separated components of the (left meltic part of the column andmaltenic part and six chromatography peaks have been recorded on the chromatogram, we start desorption of the asphaltenes. As a solvent desorption of asphaltenes, an eluent of chlorobenzene and ethanol was used. After the peak of asphaltenes appeared, the column was turned off [2].

The calculation of the chromatograms was carried out by the internal standardization method, by measuring the areas of the peaks recorded on the cartogram. The peak area, approximately taken as the area of a triangle (mm2), is calculated by the Eq. (1):

where is the height of the peak corresponding to the segment of the base line to the top of the peak, mm; – peak width, measured at a distance equal to ½ of its height, mm.

The sum of the areas of all peaks on the cartogram is taken as 100 % and the content of each peak is calculated. To analyze and process the chromatograms, we used the Gradient program, which allows you to automatically calculate the percentage of hydrocarbon groups in the oil product [2].

Thus, the hydrocarbon composition of ARPD was also carried out for the next three samples using this technique.

In Table 1 shows the results obtained after dissolving the precipitates in a mixture of solvents benzene with cyclohexane in a ratio of 1:1.

Table 1Composition of organic part of the sediments

ARPD | Paraffin-naphthenic, % | Aromatic, % | Resins, % | Asphaltenes, % | Asphaltene- resins, % | Resins/asphaltenes, % | |||

Light | Average | Heavy | I | II | |||||

1 | 23.9 | 9.6 | 7.6 | 14.9 | 4.2 | 39.8 | – | 44 | 44 |

2 | 4.8 | 9.9 | 2.2 | 3.2 | 3.9 | 76 | – | 79,9 | 79,9 |

3 | 28.9 | 45.1 | 2.5 | 4.1 | 2.9 | 16.5 | – | 19,4 | 19,4 |

4 | 17.7 | 26.9 | 14.5 | 13.5 | 6.0 | 17.2 | 4,2 | 27,4 | 5,5 |

Fig. 1Installation “Gradient-M” manufactured by JSC “INHP”

a)

b)

As we can see from the data in Table 1, each composition of the organic part of the sediment is characterized by a significant difference in the content of paraffins, resins, and asphaltenes. ARPD is characterized by a high content of aromatic hydrocarbons and a high content of tar-asphaltene substances. The highest content of the sum of resinous substances is observed in sample No. 2, and in ARPD-4 a significant amount of resinous-asphaltene substances is observed.

The high melting point of deposits falls on paraffin-naphthenic hydrocarbons 23.9 % (ARPD-1) and 28.9 % (ARPD-3).

The physical and chemical composition of the deposits is presented in Table 2.

Table 2Physical and chemical composition of inorganic deposits

ARPD sample | Density at 20 °С, kg/m 3 | Water content, % | Content of mechanical impurities, % |

1 | 1390.0 | 17.87 | 50.18 |

2 | 763.9 | 0.65 | 46.60 |

3 | 713.7 | – | 46.8400 |

4 | 822.7 | – | 12.42 |

The density of ARPD, as a rule, exceeds the density of oils, which is associated with a high content of resins and asphaltenes in them compared to oil.

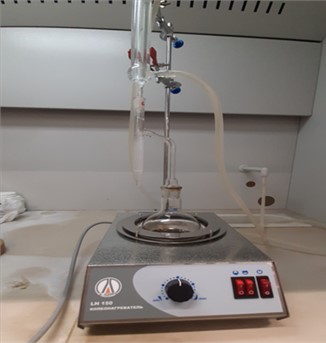

The water content in the composition of ARPD was determined according to GOST 2477-2014 Oil and oil products. Method for determining the water content with the Dean Stark apparatus [3] (Fig. 2).

Fig. 2Determination of the water content in the composition of ARPD: Dean-Stark Apparatus

The essence of the method consists in heating a sample of an oil product with a water-insoluble solvent and measuring the volume of condensed water.

The Dean-Stark method is mainly used for the quantitative determination of water in various substances. 100 ml of solvent is poured into a flask with a sample of ARPD, then heated, during evaporation, water from the deposit through the refrigerator enters the receiver trap. Heating stops after the volume of water in the trap-receiver stops increasing, which indicates the complete extraction of liquid from the sample.

Water contributes to the formation of emulsions stabilized by the polar components of oil (resins and asphaltenes) and is involved in the composition of ARPD. In the presence of water, denser deposits form. As can be seen from Table 2, the water content in all the studied cases is low.

To determine the mechanical impurities in ARPD, GOST 6370-83 Oil and Petroleum product was used. Method for the determination of mechanical impurities [4]. Prepared samples of sludge were placed in a flask and diluted with a heated solvent (toluene), 100 ml in volume.

The essence of the method consists in filtering the test oil with preliminary dissolution in gasoline or toluene, washing the precipitate on the filter with a solvent, hot water (from salts), followed by drying and weighing.

Mechanical impurities in ARPD are sand, corrosion products, clay particles. They can act as nucleation sites that promote structure formation in the oil system and lead to increased deposits.

The contents of the beaker were filtered through a prepared paper filter placed in a glass funnel. Fig. 3 shows the process of filtering a mixture of oil sludge with toluene.

Fig. 3The process of filtering a mixture of oil sludge and toluene

The filter was dried in an oven for 45 minutes until constant weight at 105 °C. Then covered with a lid and cooled for 30 minutes. They were then weighed on an analytical balance. Repeated drying of the filter, as well as subsequent cooling, was carried out for 30 minutes.

The results of determining the content of mechanical impurities in the composition of ARPD are shown in Fig. 4.

The content of insoluble sediment varied in the samples in the range from 12.42-50.18 %, on average, the content was 39 %.

Fig. 4Results of determining the content of mechanical impurities as part of ARPD

The presence of particles of sand, clay and other mechanical impurities in the oil strengthens the paraffin, very often acting as centers of paraffin crystallization. The water contained in oil in the liquid state reduces the solubility of paraffin and increases the temperature at which it begins to deposit.

It is known that with a high content of resins and asphaltenes in ARPD, the efficiency of chemical methods for removing deposits increases.

The solubility of asphalt-resin-paraffin deposits depends on the type and composition of solvents, for example, asphaltenes are highly soluble in aromatic hydrocarbons and poorly soluble in paraffin hydrocarbons, and therefore the ratio of resins and asphaltenes can play an important role in choosing a solvent washing paraffin deposits.

2. Laboratory tests on the selection of wax solvents

The effectiveness of solvents was evaluated by the dissolving and dispersing ability of asphalt, resin and paraffin deposits, determined by the gravimetric method.

Testing of the dissolving power of solvents for asphalt, resin and paraffin deposits was carried out.

An ARPD sample weighing within 1-3 g was formed in the form of a ball and placed in a pre-weighed metal mesh basket with a cell size of 1.5×1.5 mm.

The baskets with the ARPD sample were weighed with an accuracy of ±0.005 g. The initial mass of ARPD () was determined by the difference between the masses of the basket with ARPD and the pure basket.

The basket with ARPD was placed in a sealed glass cell, where the test solvent was poured with a volume of 100 ml. The experiments were carried out at a temperature of 25 °C.

After two hours, the basket with the remaining undestroyed part of the ARPD was taken out and dried to a constant weight at atmospheric pressure at a temperature of 25 °C for at least 24 hours.

The mass of the undissolved part of the ARPD () was determined by the difference between the masses of the basket with the undestroyed mass of the ARPD and the pure basket.

The solvent studied was filtered out of the cell by a prepared paper filter placed in a glass funnel.

After drying the filter and bringing it to a constant weight, the mass of the dispersed part of the ARPD was determined ().

The solvent efficiency was evaluated according to the following parameters:

Undissolved part of ARPD of the container, %:

where is the mass of the initial ARPD sample before dissolution, g; is the mass of the undissolved ARPD residue in the container, g.

Dissolved part of ARPD, %:

where is the mass of the dispersed part, g.

Dispersed part of ARPD (filter sediment), %:

The overall effectiveness of the ARPD solvent (%) is determined by the Eq. (5):

To determine the evaluation of the efficiency of solvents, sediment samples of ARPD-1, ARPD-2, ARPD-3 and ARPD-4 were tested. Solvents with the brands “TSK А” and “TSK В” were chosen as tests. The evaluation of the comparative effectiveness of solvents was carried out in terms of their dissolving, dispersing and general washing ability at a temperature of 25 degrees (Fig. 5).

Fig. 5Testing hydrocarbon solvents

The results of experiments to determine the effective solubility of ARPD in the investigated solvent are given in Table 3.

Table 3Physical and chemical composition of inorganic deposits

Solvent name | TSK А | TSK А | TSK А | TSK А | TSK В | TSK В | TSK В | TSK В |

Name of ARPD | ARPD 1 | ARPD 2 | ARPD 3 | ARPD 4 | ARPD 1 | ARPD 2 | ARPD 3 | ARPD 4 |

Initial weight, ARPD, g () | 1,96 | 1,53 | 1,60 | 1,06 | 2,08 | 1,55 | 1,30 | 1,28 |

Undestroyed mass of ARPD, g () | 1,74 | 1,65 | 1,92 | 1,92 | 1,38 | 1,34 | 1,72 | 1,49 |

Dissolved part of ARPD, % (R.h.) | 88,65 | 0,00 | 0,00 | 0,00 | 66,07 | 86,84 | 0,00 | 0,00 |

Dispersed part of ARPD, % () | 11,20 | 0,00 | 0,00 | 0,00 | 33,16 | 10,96 | 0,00 | 0,00 |

Washing power of the solvent () | 0,15 | 0,16 | 0,18 | 0,10 | 0,77 | 2,20 | 1,50 | 0,87 |

Solvent efficiency, % () | 11,73 | –7,84 | –20 | –12,26 | 33,65 | 13,55 | –32,31 | –16,41 |

The amount of dissolved and dispersed ARPD, g in 1 liter of solvent | 11,35 | 0,00 | 0.00 | 0,00 | 33,93 | 13,16 | 0,00 | 0,00 |

The effectiveness of the ARPD solvent studied was evaluated by dispersing, dissolving abilities and the amount of dissolved and dispersed ARPD in one liter of solvent.

If under the action of the solvent, the ARPD sample swells, then the value of takes on a negative value, and the smaller the value of , the greater the effect of swelling.

If under the action of the solvent there is a dissolution of the ARPD sample, then the value of takes a positive value, and the higher the absolute value of , the greater the effect of dissolution.

The results of the experiments showed that most solvents are ineffective for complex deposits, since the mechanism of their action is based on the complete dissolution of paraffin deposits, and they have a low dispersing ability. Under these conditions, solvents with an increased dispersing effect are most effective.

The obtained data showed that, in general, hydrocarbon solvents retain their washing ability at a temperature of 25 °C.

The best result according to the results of experiments to determine the effective solubility of ARPD in the studied solvents was shown by the solvent brand “TSK А”, which washes the best ARPD-1 (solvent efficiency 33.93 %), which is characterized by the content of the total paraffin-naphthenic hydrocarbons: 23.9 % and resins-asphaltenes: 44 %. At the same time, compared to ARPD-1, this solvent dissolves ARPD-2 worse (efficiency 13.16 %), the content of the total paraffin-naphthenic hydrocarbons is 4.8 % and, which seems important in our opinion, is equal to the relative content of resins and asphaltenes 79.9 %, respectively. Most likely, this is due to the high content of resins – 79,9 %, which is 2 times higher than the percentage in ARPD-1.

The solvent “TSC А” in relation to “TSC В” is inferior in terms of its performance, since the efficiency of dissolving ARPD-1 is 11.35 %.

When washing off ARPD-2, ARPD-3, ARPD-4 with “TSK А” solvent and ARPD-3, ARPD-4 solvent “TSK В”, the deposits swelled.

3. Conclusions

The physicochemical properties of asphalt-resin-paraffin deposits have been studied. It is shown that the group chemical composition, the content of water and mechanical impurities in all the studied samples of ARPD are not the same.

The results obtained are the basis for the selection of effective solvents and the choice of a method for removing deposits from oil reservoirs.

Ratio solvents V ready reagent must be proportionately mass share components ARPD. For example, if ARPD is of paraffin type and on 29 % consists of from paraffin, then the composition of the solvent should contain at least 29 % of light alkane hydrocarbons or an analogue [5].

References

-

E. V. Shchurova, A. O. Krys, and R. A. Khuramshina, “Removal of asphalt, resin and paraffin deposits from oil storage tanks using ultrasonic treatment,” Transport and storage of oil products and hydrocarbon raw materials, pp. 29–33, 2020, https://doi.org/10.24411/0131-4270-2020-6-29-33

-

Kolbin, M. A., Khairutdinov, and I. R., Determination of the group chemical composition of oils and oil products on the Gradient-M chromatograph. Ufa Izd-voBashNII NP, 1977.

-

“GOST 2477-2014 Oil and oil products. Method for determining the water content with the Dean Stark apparatus,” Standartinform, 2018.

-

“GOST 6370-83 Oil and Petroleum product was used. Method for the determination of mechanical Impurities,” Standartinform, 2008.

-

V. P. Tronov, The Mechanism of Formation of Resin-Paraffin Deposits and the Fight Against Them. Nedra, 1970.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.