Abstract

This study explores additive manufacturing's potential in creating tailored assistive technologies, fostering inclusion in education. To design ergonomic solutions for diverse user needs, promoting inclusion and autonomy. A sequential approach involves assessment, 3D modeling, additive manufacturing, and aligning with the Inclusion Support and Accessibility Promotion Program (PIPA). Various assistive technologies were developed, addressing specific needs. The “Ergonomic Pen and Pencil Reamer” improves grip accuracy, and the “Folding Handle for Folding Cup” offers an ergonomic solution. The “Guideline Ruler” supports music education, with accessories like the “Template for Clefs and Musical Notes” and “Thimble with Support Base for Musical Instrument Strings” enhancing versatility. The “Ring with Front Support” aids art education, and the “Support for Scissors” promotes independence. These innovations contribute to inclusion and autonomy. The research underscores the importance of additive manufacturing in crafting personalized solutions, propelling inclusion in education and daily activities. Identified challenges, including material selection and adaptation to diverse needs, signal areas for future research. Continuous collaboration with end-users and professionals remains crucial for enhancing usability and effectiveness, reinforcing the commitment to promoting inclusion and autonomy.

Highlights

- 3D-printed assistive tech fosters personalized learning for students with disabilities, enhancing inclusivity.

- Customized devices adapt to individual needs, promoting inclusive education.

- Ongoing collaboration with users, parents, and professionals ensures tech usability and effectiveness.

- Additive manufacturing revolutionizes assistive tech, empowering autonomy in learning.

- User-centered approach drives inclusive education, shaping a more accessible future.

1. Introduction

Inclusive education is a broad and complex concept that seeks to ensure the inclusion of all students and promote access to quality education with the greatest equity possible. To this end, a school environment with universally adapted rooms, trained professionals, sensory models, didactic-pedagogical resources, and psychological support is necessary [1].

Moreover, it is essential to implement public policies that promote and guarantee that differences and equality be respected and valued, not only focusing on disabled people but also prioritizing other excluded groups. Despite applying the Brazilian inclusion law, Law No. 13.146/2015 [2], which aims to encourage the insertion of people with disabilities into practical activities and fundamental education [3], the challenges of inclusive quality education are diverse.

However, the inclusive education process goes far beyond the classroom. To ensure full functionality, the family, school community, and a multidisciplinary team of health and education professionals should be included, as well as government institutions involved in public policy promotion. Additionally, society should be encompassed, fostering awareness of the topic and encouraging participation in events.

Therefore, inclusive education, based on transformative policies – not only in the lives of people with disabilities but for the entire population – allows for greater social integration, increased opportunities, development of intellectual and social skills, external experiences, the exercise of active citizenship, and social participation [4], besides promoting a high interaction with diversity and the development of respect and empathy.

It is crucial to highlight that the Brazilian inclusion law, Law No. 13.146/2015, commonly known as the “Statute of Persons with Disabilities”, establishes comprehensive guidelines for promoting the inclusion of individuals with disabilities. This legislation emphasizes not only the educational aspects but also the broader societal inclusion of diverse groups. Key components include accessibility, reasonable accommodation, and the acknowledgment of the rights and specificities of individuals with disabilities. Therefore, understanding this legal framework is pivotal in comprehending the concerted efforts to foster inclusive practices within the educational system.

Therefore, it is urgent to implement efficient public policies that guarantee equity to the entire population, providing adequate means and services to the needs of each individual to ensure similar opportunities [5].

Hofmann et al. and Sandy et al. [6, 7] consider that the creation and production of devices or components to satisfy the need for food, hygiene, education, physiotherapy, and individual specificities of people with disabilities are complex, with high time and costs of development and production. In this context, the use of support strategies, such as additive manufacturing – also known as 3D printing – is one of the main tools that has been used to meet the required demand.

In South Africa and Pakistan, education initiatives in additive manufacturing were evaluated in universities [8, 9]. Such initiatives should be applied in the Brazilian context, mainly concerning inclusive education, as in the United States [10]. According to [11], technological development is increasingly present in the reality of students, and its importance should not be ignored.

This technology has been transforming the way of thinking and executing the production of assistive technology (AT) products. When this technique is applied together with clinical practice, it is possible to build highly personalized AT quickly, economically, and locally [6, 7]. The ISO/ASTM 52900/2018 [12] norm explains that additive manufacturing is a making process that, through the successive addition of material in layers, allows the manufacture of physical components based on different principles.

The great advantage of this process, contrasting with other conventional techniques, is the personalization of the piece, meeting the needs and specific conditions of each person [13], without setup and tools [14]. This custom attention produces a better adaptation of a person with disabilities to AT, improving its quality of life and well-being, consequently, a less conflictive rehabilitation stage. Furthermore, the additive manufacturing advantage is its high production speed, regardless of the complexity of the piece [15]. However, the production cost can vary depending on the size and complexity of the part and also on the properties of the filament used to make the piece.

Thus, products are developed quickly, easily accessible, personalized, and easy to handle, reducing the limitations that people with disabilities face every day. For example, didactic materials developed to satisfy particular demands, which can be used in various contexts such as educational, hospitable, professional, and at home [16]. Therefore, this work focused on developing assistive technologies that aid in the learning-teaching process and the autonomy of students with disabilities from the Federal University of Minas Gerais (UFMG).

2. Methods

The development of assistive technology (AT) was based on the following steps: problem assessment, geometry definition, three-dimensional modeling, additive manufacturing, and preparation of parts. Pieces were developed to satisfy the needs observed by university teachers and health professionals, such as pedagogues, physiotherapists, occupational therapists, and psychologists from the Inclusion and Accessibility Center (NAI) of the Federal University of Minas Gerais (UFMG). This development aligns with the approved proposals of the Inclusion Support and Accessibility Promotion Program (PIPA), Notice 001/2020.

2.1. Problem assessment

The problem assessment process was geared towards developing assistive technologies that empowered individuals to carry out activities in an adapted, functional, and independent manner. This phase aimed to comprehend the demand and conceptual design, collecting information to determine the feasibility of ideas, as well as calculating dimensions, selecting materials, manufacturing methods, and mechanical properties of the parts. Virtual meetings were held between March and December 2020 with the project team and students from the institution due to the Covid-19 pandemic period.

2.2. Geometry definition

Anamnesis was conducted to define the specific geometry of parts, and anthropometric information was surveyed following the measurement proceedings applied by Fernandes et al. [17]. The dimensions of the pieces, including height, width, and length, were determined based on specific criteria for each project. These criteria encompassed portability, functionality, flexibility, amount of material used, weight, desired size, strength, and the number of parts, ensuring product optimization.

2.3. Three-dimensional modeling

For three-dimensional modeling of the pieces, Solidworks® 2016 CAD software was utilized, incorporating the defined geometry and other information outlined in Section 2.2.

2.4. 3D printing

For the 3D printing of the piece, an FDM (Fused Deposition Modeling) printer was utilized, specifically the Aip Sethi3D model. This type of printer employs material fusion followed by extrusion through a nozzle to depict the cross-sectional geometry of the piece layer by layer. The manufacturing of the components involved the use of thermoplastic materials, including polylactic acid (PLA) [18, 19] and acrylonitrile butadiene styrene (ABS) [19, 20].

2.5. Preparation and assembly of parts

After the parts were printed, they were removed from the physical printing chamber and cleaned, eliminating burrs, excess materials, or potential supports generated in the process. In certain situations, finishing techniques were applied post-printing. Consequently, some parts underwent sanding to enhance the surface finish and extend the product's useful life. Some of the developed products comprise more than one piece, so they were assembled and adjusted to ensure their perfect functionality.

2.6. Validation and practical testing

Following the preparation and assembly of the components, a crucial stage involves conducting practical tests and validating the developed assistive technologies. This phase will entail direct collaboration with end-users, including individuals with disabilities, educators, physiotherapists, occupational therapists, and psychologists associated with the Inclusion and Accessibility Center (NAI) at the Federal University of Minas Gerais (UFMG).

Throughout the testing process, various aspects will be assessed, such as usability, effectiveness in daily activities, comfort, adaptation to individual user needs, and overall acceptance of the assistive technologies. Qualitative and quantitative feedback will be collected to comprehend the actual performance of the components in practical situations.

Validation and practical testing will significantly contribute to refining the developed solutions, allowing adjustments based on practical experience and the real needs of users. This iterative approach will ensure the effectiveness of the assistive technologies and their relevance and applicability in the context of inclusive education.

3. Results

Assistive technologies, designed to enhance the teaching-learning process and foster autonomy for students with disabilities, have demonstrated effectiveness when produced through additive manufacturing. Positive outcomes were observed as these technologies served as complementary and integrative solutions within inclusive education. In the 3D printing process, two materials, PLA and ABS, were considered, with Santana et al. [21] noting PLA's superior stiffness and mechanical strength compared to ABS in such applications. However, PLA's biodegradability raised concerns about potential degradation when exposed to fluids, leading to the exclusive use of ABS.

ABS, known for its chemical and mechanical resistance, presented challenges in 3D printing due to high thermal contraction, requiring adjustments in printing speed to prevent deformation. While protective measures to control airflow were considered, they were not implemented due to the minimal airflow in the environment.

The study’s additive manufacturing focus led to the creation of assistive technologies, including the “ergonomic pen and pencil reamer”, “folding handle for folding cup”, “guideline ruler or pentagram”, “template for clefs and musical notes”, “thimble with support base for musical instrument strings”, ring with a brush support”, ring with front support”, and “scissors holder”. These technologies were tailored for personalized applications, considering individual characteristics to enhance teaching and learning experiences. The subsequent sections comprehensively explore each assistive technology, elucidating its applications, distinctive features, and significance for diverse types of disabilities.

Ergonomic Pen and Pencil Reamer (see Fig. 1): Meticulously designed to improve grip accuracy in individuals with impaired fine motor coordination. The reamer's oval design with a vertical opening allows adaptation to various writing instruments, facilitating a more precise execution of tasks such as calligraphy and artistic expressions. Its ergonomics and adaptability play a crucial role in optimizing.

Folding Handle for Folding Cup (see Fig. 2): Developed to provide an ergonomic and efficient solution, specially designed for collapsible cups. Aimed at ensuring a comfortable fit in the user's hand, the handle features an articulation that allows for folding, enabling compact transport along with the cup. The design of the folding handle was based on a specific cup with a top diameter of 91 mm. However, the model is adaptable to meet different cup specifications, including both collapsible and traditional types. Additionally, there is an option to design the holder with two foldable handles, further expanding its potential applications.

Fig. 1Ergonomic pen and pencil reamer: a) the 3D modeling is depicted; b) the unfinished piece is showcased; c) the finished piece is displayed; d) the applicability of the device is demonstrated

a)

b)

c)

d)

Fig. 2Folding handle for the folding cup: a) the 3D modeling; b) the handle’s application is demonstrated

a)

b)

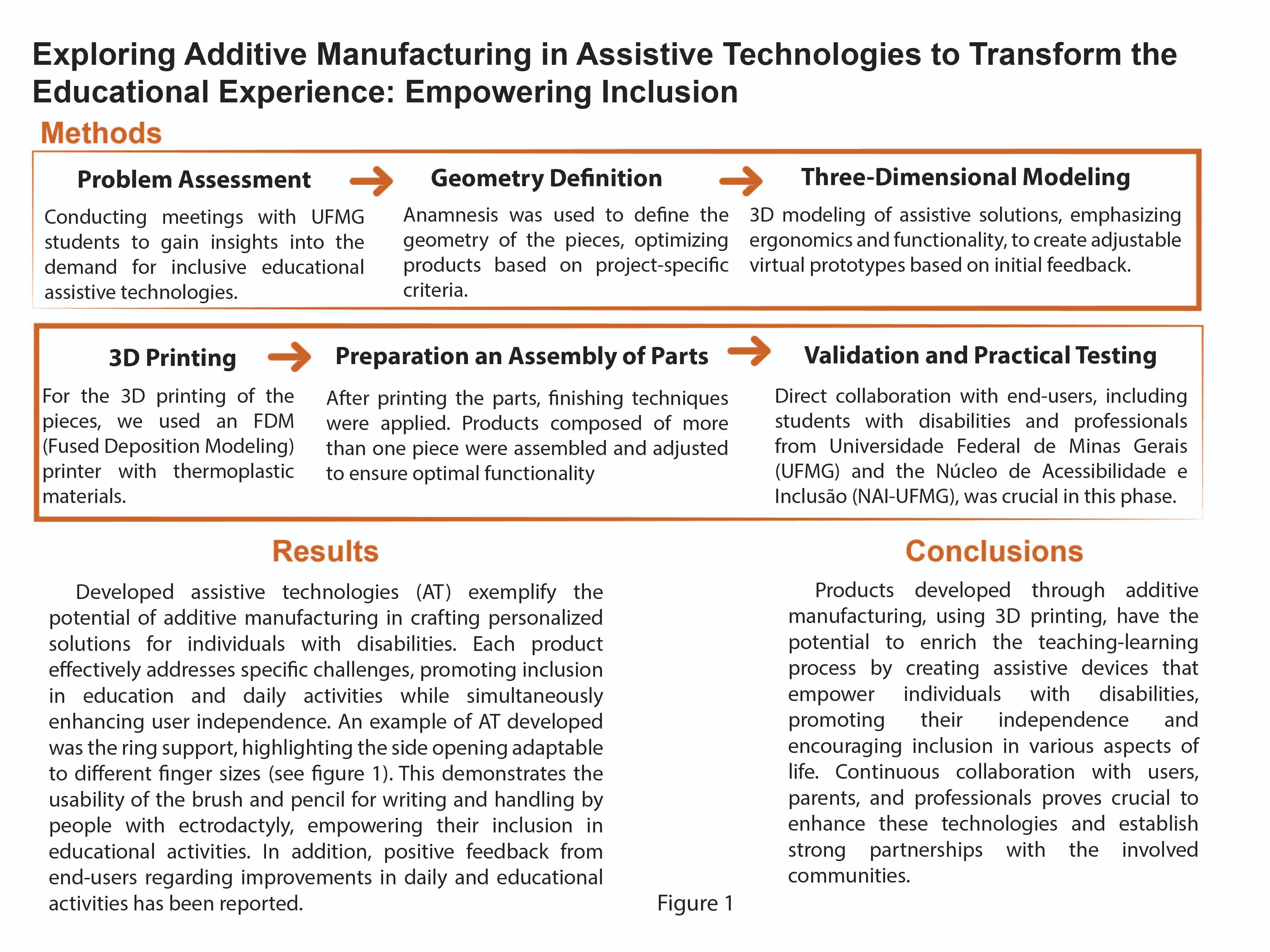

Guideline Ruler or Pentagram (see Fig. 3): Designed for music education, this ruler includes adjustable hand support zones to cater to both right-handed and left-handed individuals. Incorporating these features ensures that the guideline ruler not only assists in the physical act of holding and guiding but also actively contributes to the educational aspect of learning and creating music. The combination of ergonomic design and educational functionality enhances its value as an assistive technology, fostering inclusivity in the realm of music education.

Designed to trace the five parallel lines of the musical stave and the barline on an A4-sized sheet of paper, the guideline ruler enhances usability with low-relief circles added to its sides to prevent slipping from the hand. The ruler consists of two elements: a larger hollow template and a smaller one with five holes for drawing lines and a vertical slot on the left side for the barline of the beat.

Fig. 3Guideline Ruler or Pentagram. The two parts constituting the piece are represented in the upper-left image, and the assembly of the pieces is illustrated on the right side. Below is a demonstration of usability on an A4 paper sheet

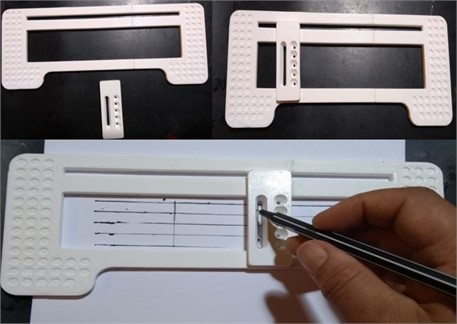

Template for clefs and musical notes (see Fig. 4): Developed as accessories for the Guideline Ruler, the Template for Clefs and Musical Notes enhances the versatility of the ruler in music composition. The template includes clefs and fundamental musical notes, which address individuals with fine motor coordination challenges. The integration of clefs and musical notes provides users with valuable resources for notation and composition, contributing to a more comprehensive and inclusive musical learning experience. Symbols can be created with a fine-point pen or a 0.04 mm point pen.

Thimble with support base for musical instrument strings (see Fig. 5): Developed for individuals with weakness or loss of muscle tone in the fingers, excluding the thumb, the thimble or ring with a support base for a musical instrument string provides enhanced functionality. The designed thimble features a base in the fingertip region to press the musical instrument string with greater firmness, along with a slit at the top. This opening allows different individuals to use it, even if their finger measurements differ from the designed dimensions. Additionally, the piece features a hole in the front designed for individuals with long nails to use. However, this product has been designed with various tips on the base that come into contact with the strings of the musical instrument, resulting in three distinct models.

Fig. 4Template for musical clefs and notes. Designed for musical education, this ruler contains diagonal lines on its surface, added to prevent hand slips. The 3D modeling is depicted in the upper left image, and the finished piece is illustrated on the right side. Below is a demonstration of usability on an A4 paper sheet

Fig. 5The image displays the 3D modeling of the thimble from the front and back, as well as the finished pieces. Three types of thimbles for distal phalanges are presented, along with the practical application of the thimble on a string instrument, mainly a guitar

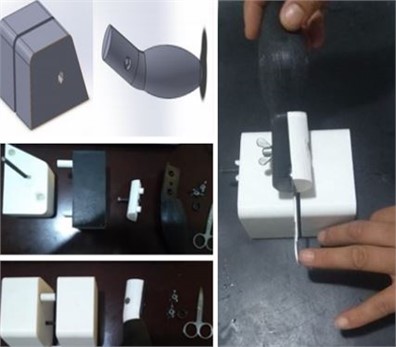

Ring with Holder (see Fig. 6): Developed to handle brushes, pencils, or pens, ensuring greater precision in painting or writing activities. The ring with holder has two cylinders joined together with a side opening for adaptation to different finger sizes and brush, pencil, pen, or touch screen tips. The larger cylinder is for finger fitting, and the smaller cylinder is for fitting the object for the activity. Designed with a focus on versatility, it serves students and individuals interested in fine arts. Its adaptability to various tools enhances accessibility, making it a practical tool for various activities.

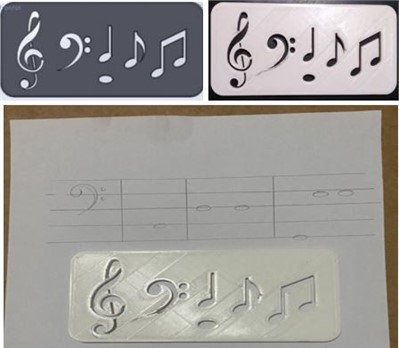

Support for Scissors (see Fig. 7): An assistive device tailored to enhance autonomy in nail cutting and personal care activities for individuals dealing with compromised fine motor coordination. This innovative device comprises a square base and a movable rubber handle, designed to provide stability, adaptability, and ease of use.

The square base is intelligently crafted with a slot accommodating one of the scissor bows, while the other bow is securely fastened to the movable rubber handle. The modular design of both the square base and the movable handle features a split configuration, interconnected through pins on the sides. This allows for easy adjustment and adaptation to different scissor sizes, catering to various user needs.

Fig. 6Photograph of a ring support, highlighting the side opening adaptable to different finger sizes. This demonstrates the usability of the brush and pencil for writing and handling by people with ectrodactyly, empowering their inclusion in educational activities

Fig. 7The image showcases the ring support, emphasizing the side opening adaptable to different finger and brush sizes, as well as tombstones. It demonstrates the usability of the brush and pencil for writing and handling by individuals with ectrodactyly

In the pursuit of inclusive education and improved quality of life for individuals with disabilities, the developed assistive technologies collectively strive to make meaningful contributions. The iterative design process, guided by active collaboration with end-users and healthcare professionals, underscores a commitment to ensuring the effectiveness and customization of the technologies to address a spectrum of user needs. The testing phase concentrated on evaluating usability, effectiveness, comfort, adaptability, and overall acceptance.

Significant challenges encountered during the development phase included the selection of suitable materials, managing printing complexities, and addressing the diverse needs of users. Strategic trade-offs were implemented to balance mechanical strength, printability, and user-friendliness. Future research endeavors should explore advanced materials and manufacturing techniques to enhance overall performance and accessibility. The continued involvement and collaboration with diverse user communities are pivotal for perpetuating ongoing improvements.

4. Discussion

The integration of 3D printing in educational and assistive technology materials is pivotal for inclusive education, dismantling barriers in architecture, instruments, pedagogy, and communication. This technology becomes a cornerstone in education and healthcare, presenting a significant avenue for individuals with disabilities to enhance their learning experience and foster integration into society. Beyond the immediate educational impact, using 3D-printed materials in social contexts becomes a catalyst for developing social and cognitive skills, surpassing the confines imposed by disabilities. The ergonomic extender designed for pens and pencils facilitates their use for individuals with fine motor coordination disabilities and loss of muscle tone in the upper extremities. Embracing Inclusive Education cultivates capable adults and champions their rights, employment opportunities, and social connections, actively contributing to diminishing societal stigmas surrounding disabilities. This assistive technology aims to streamline and improve the writing experience, ensuring greater precision and accuracy, particularly in educational and academic settings. Its ergonomic design not only enhances grip but also increases firmness during use, with a lateral slot for easy adaptation to pencils and pens of slightly larger diameters, adding to its versatility.

Weighing approximately 40 g, the Adaptive for Pen and Pencil is remarkably lightweight due to specific printing settings. Its hollow interior constitutes only about 10 % of the total volume. This aligns with the findings of [22], who developed the Left-handed pinky/thumb-adapted ball pen and Palm-grip pen holder to facilitate writing movements. It also corroborates the analysis presented by Buehler et al. [23], who developed a pen grip system for individuals with limited motor ability to write or use an iPad.

Another device of significant importance is the feeding aid designed for individuals with motor coordination deficits. DA SILVA et al. [24] utilized 3D printing to create spoons with enhanced resistance, finish, and grip stability, which is particularly beneficial for cerebral palsy patients. Similarly, the folding handle, equipped with a folding cup holder, simplifies cup usage for individuals with impaired fine motor coordination or tremors in the upper limbs, minimizing the risk of liquid spillage. Designed for folding cups, this component guarantees efficient and practical usage. Notably, the handle can be adapted for non-folding cups, addressing children’s and seniors’ unique needs. The guideline ruler or pentagram and the template for clefs and musical notes represent complementary tools designed for individuals with impaired fine motor coordination, particularly music students and musicians. These instruments, utilizing a fine-tipped, 0.04 mm pen, facilitate the efficient and independent drawing of horizontal and vertical lines, enabling the creation of the musical staff and notation of musical notes. In addition to fostering inclusive music education, these devices assist students in learning and practicing music theory. The template also serves as a valuable tool for music students with low vision, aiding in tracing clefs and musical notes on sheet music.

In the realm of studies on thimbles or rings, there is a proportionally smaller number of researches exploring solutions for the rehabilitation of the distal phalanx function compared to prosthetics and orthotics. However, an example is the thimble or ring (Fig. 5), specifically designed for music students and musicians experiencing loss of muscle tone in their fingers. This innovation allows for a more secure grip on the instrument strings, providing enhanced support to the base of the distal phalanges, enabling increased pressure on the strings and resulting in cleaner notes on the instrument.

In the realm of studies on thimbles or rings, there is a proportionally smaller number of research exploring solutions for rehabilitating the distal phalanx function compared to prosthetics and orthotics [25]. Other notable contributions include prosthetic studies such as Lee et al. [26] and orthopedic research conducted by Arce & Foggiato [27], Rosenmann [28], Weigert [29], and Poier [30].

In pursuit of a more inclusive and accessible musical environment, three models of base-specific thimbles were crafted. Each is tailored with specific details to offer adequate support to the strings, enabling musicians to select the most suitable option. During testing with a guitar, the thimble with the smallest base area yielded the best results, especially due to the small distance between the strings.

Learning and contact with art in an inclusive way are deemed essential. The study [31] addresses accessibility in museums through pieces made with additive manufacturing, aligning with the inclusive approach of the Ring with Support (Fig. 6). Specially designed for students and others interested in visual arts, the ring is adaptable for use with a pencil, pen, and touch screen, providing a valuable tool for writing and manipulating objects for individuals with ectrodactyly, compromised fine motor coordination, muscle tone loss, or amputation at the fingertips.

The assistive device developed for small scissors targets increased independence for individuals facing challenges in limb movements during daily activities, particularly in self-care and personal hygiene routines. Its rounded design is adaptable, accommodating standard nail scissors for safe cutting.

Essentially, the Support for Scissors promotes autonomy in nail cutting and personal care and provides a versatile solution for individuals with impaired fine motor coordination. Its adaptable design allows customization for different scissor types, expanding its application to serve as an effective teaching tool, especially in educational settings.

Taking into account feedback and experiences from users, future research should prioritize ongoing improvement, customization tailored to user needs, and wider dissemination of these assistive technologies. The ongoing collaboration among researchers, educators, and individuals with disabilities remains paramount in advancing the field of inclusive design and creating innovative solutions that enhance the lives and capabilities of diverse populations.

A significant consideration in deploying these assistive technologies is the diverse range of pathological conditions and disabilities among users. While the developed devices aim to enhance inclusivity, their efficacy may vary based on the specific needs and severity of the user's condition.

Recognizing the heterogeneity within the user population, encompassing different pathologies, impairments, and degrees of disability, is crucial. Tailoring assistive technologies to address the specific requirements of individuals with various pathological conditions becomes a complex task. The effectiveness of the devices in catering to the unique challenges posed by specific pathologies requires careful evaluation.

Factors such as the nature of the condition, its progression, and potential changes in the user’s abilities over time must be considered. Customization and adaptability of assistive technologies become paramount to ensure that individuals with different pathological conditions can benefit optimally from these innovations.

Moreover, involving healthcare professionals and pathology experts is essential for obtaining insights into the specific needs of users, thereby enabling the development of customized and effective assistive solutions.

4.1. Limitations of the developed assistive technologies

The innovative assistive technologies discussed in this study, aimed at enhancing the inclusion and independence of individuals with disabilities, demonstrate commendable characteristics. However, it is crucial to openly acknowledge the limitations associated with these advancements. The following points elucidate the identified limitation:

– Materials Restrictions: The choice of Acrylonitrile Butadiene Styrene (ABS) for its mechanical and chemical resistance presents challenges due to high thermal contraction during printing, potentially impacting device durability.

– Usability Learning Curve: Unique ergonomic designs, such as in the “Ergonomic Pen and Pencil Reamer” and “Ring with Support”, may introduce a learning curve for users, affecting immediate integration into daily activities.

– Specific Scenario Adaptability: Devices like the “Folding Handle for Folding Cup” and “Ring with Support” may function optimally in specific scenarios, raising concerns about adaptability to diverse real-world situations.

– Individual Variability: Recognizing diverse disabilities, the effectiveness of these technologies may vary based on individual needs, emphasizing that the designed solutions may not universally meet all user requirements.

– Long-Term Durability: The impact of long-term use on devices such as the “Thimble with Support Base for Musical Instrument Strings” and “Support for Scissors” requires careful consideration to ensure sustained functionality.

– Environmental Impact: ABS, a non-biodegradable material, raises environmental concerns, prompting inquiries regarding its discardability and recyclability.

– Demographic Testing: Rigorous testing methodologies were employed, but demographic limitations may exist, questioning the generalizability of results to the entire user spectrum.

– Technological Evolution: Rapid technological advancements may impact the relevance and compatibility of these assistive technologies in the future, emphasizing the need to consider the longevity of solutions.

– Cost of Manufacturing and Professional Modeling: Financial challenges may arise from the cost of materials, 3D printing methods, and professional modeling, potentially limiting accessibility. The economic viability and the accessibility of professionals for customization need to be evaluated for widespread implementation. Conducting comprehensive cost-benefit analyses is crucial to evaluate the functional benefits and associated costs.

These considerations are essential for the sustainable and effective adoption of these innovations in the context of educational inclusion and autonomy for people with disabilities.

5. Conclusions

The developed assistive technologies exemplify the potential of additive manufacturing in crafting personalized solutions for individuals with disabilities. Each product effectively addresses specific challenges, promoting inclusion in education and daily activities while simultaneously enhancing user independence.

The iterative design process, informed by collaborative input from end-users and healthcare professionals, ensures the effectiveness and adaptability of these assistive technologies to diverse user needs. Challenges encountered during development underscore the importance of ongoing research and innovation in the field of assistive technology.

Looking ahead, sustained efforts are essential to refine these technologies, explore advanced materials and manufacturing methods, and foster partnerships with user communities. The ultimate goal is to develop assistive devices that empower individuals with disabilities, enhancing their independence and fostering inclusivity across various aspects of life.

References

-

E. P. De Camargo, “Social inclusion, inclusive education, and special education: links and outcomes,” (in Portuguese), Ciência and Educação (Bauru), Vol. 23, No. 1, pp. 1–6, Mar. 2017, https://doi.org/10.1590/1516-731320170010001

-

“Establishes the Brazilian law for the inclusion of persons with disabilities: statute of persons with disabilities,” Brazil, Presidency of the Republic, Deputy Chief for Legal Affairs, 2015.

-

D. L. C. Costa, A. C. D. S. Costa, and A. D. S. Costa, “A look at inclusive education in Brazil through the BDTD,” Research, Society and Development, Vol. 10, No. 10, p. e282101018961, Aug. 2021, https://doi.org/10.33448/rsd-v10i10.18961

-

C. Duk and F. J. Murillo, “The right to education is the right to an inclusive and equitable education,” (in Spanish), Revista Latinoamericana De Educación Inclusiva, Vol. 14, No. 2, pp. 11–13, Dec. 2020, https://doi.org/10.4067/s0718-73782020000200011

-

I. Fedulova, V. Ivanova, O. Atyukova, and V. Nosov., “Inclusive education as a basis for sustainable development of society.,” Journal of Social Studies Education Research, pp. 118–135, 2019.

-

M. Hofmann et al., “Clinical and Maker Perspectives on the Design of Assistive Technology with Rapid Prototyping Technologies,” in ASSETS ’16: The 18th International ACM SIGACCESS Conference on Computers and Accessibility, pp. 251–256, Oct. 2016, https://doi.org/10.1145/2982142.2982181

-

S. Mcdonald et al., “Uncovering challenges and opportunities for 3D printing assistive technology with physical therapists,” in ASSETS ’16: The 18th International ACM SIGACCESS Conference on Computers and Accessibility, pp. 131–139, Oct. 2016, https://doi.org/10.1145/2982142.2982162

-

M. O. Alabi, D. de Beer, and H. Wichers, “Applications of additive manufacturing at selected South African universities: promoting additive manufacturing education,” Rapid Prototyping Journal, Vol. 25, No. 4, pp. 752–764, May 2019, https://doi.org/10.1108/rpj-08-2018-0216

-

K. Waseem, H. A. Kazmi, and O. H. Qureshi, “Innovation in education – inclusion of 3D-printing technology in modern education system of Pakistan: case from Pakistani educational institutes.,” Journal of Education and Practice, Vol. 8, pp. 22–28, 2017.

-

E. Buehler, W. Easley, S. Mcdonald, N. Comrie, and A. Hurst, “Inclusion and education: 3D printing for integrated classrooms,” in the 17th International ACM SIGACCESS Conference, pp. 281–290, Jan. 2015, https://doi.org/10.1145/2700648.2809844

-

M. I. F. Pires and A. J. V. Júnior, “Concrete models in 3D printing as inclusive materials in professional and technological education.,” (in Portuguese), Brazilian Journal of Development, Vol. 6, No. 12, p. 10408, 2020, https://doi.org/10.34117/bjdv6n12-781

-

“Additive manufacturing – General principles – Fundamentals and vocabulary,” ISO/ASTM 52900, 2021.

-

A. C. J. Alves, M. L. G. Emmel, and T. S. Matsukura, “Training and practice of occupational therapists who use assistive technology as a therapeutic resource,” (in Portuguese), Revista de Terapia Ocupacional da Universidade de São Paulo, Vol. 23, No. 1, pp. 24–33, Apr. 2012, https://doi.org/10.11606/issn.2238-6149.v23i1p24-33

-

C. Tuck, R. Hague, and N. Burns, “Rapid manufacturing: impact on supply chain methodologies and practice,” International Journal of Services and Operations Management, Vol. 3, No. 1, pp. 1–22, Jan. 2007, https://doi.org/10.1504/ijsom.2007.011459

-

Y. Zhai, D. A. Lados, and J. L. Lagoy, “Additive manufacturing: making imagination the major limitation,” JOM, Vol. 66, No. 5, pp. 808–816, Mar. 2014, https://doi.org/10.1007/s11837-014-0886-2

-

A. Moriña, “Inclusive education in higher education: challenges and opportunities,” European Journal of Special Needs Education, Vol. 32, No. 1, pp. 3–17, Jan. 2017, https://doi.org/10.1080/08856257.2016.1254964

-

L. F. R. M. Fernandes, D. Bertoncello, N. M. Pinheiro, and L. C. Drumond, “Correlations between grip strength and anthropometric variables of young adults’ hand,” (in Portuguese), Fisioterapia e Pesquisa, Vol. 18, No. 2, pp. 151–156, Jun. 2011, https://doi.org/10.1590/s1809-29502011000200009

-

B. M. Tymrak, M. Kreiger, and J. M. Pearce, “Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions,” Materials and Design, Vol. 58, pp. 242–246, Jun. 2014, https://doi.org/10.1016/j.matdes.2014.02.038

-

R. Melnikova, A. Ehrmann, and K. Finsterbusch, “3D printing of textile-based structures by fused deposition modelling (FDM) with different polymer materials,” in IOP Conference Series: Materials Science and Engineering, Vol. 62, p. 012018, Aug. 2014, https://doi.org/10.1088/1757-899x/62/1/012018

-

K. V. Wong and A. Hernandez, “A review of additive manufacturing,” ISRN Mechanical Engineering, Vol. 2012, pp. 1–10, Aug. 2012, https://doi.org/10.5402/2012/208760

-

L. Santana, J. L. Alves, A. D. C. Sabino Netto, and C. Merlini, “A comparative study between PETG and PLA for 3D Printing through thermal, chemical and mechanical characterization,” (in Portuguese), Matéria (Rio de Janeiro), Vol. 23, No. 4, Dec. 2018, https://doi.org/10.1590/s1517-707620180004.0601

-

A. C. Simpson and A. R. Taliaferro, “Designing inclusion: using 3D printing to maximize adapted physical education participation,” Teaching Exceptional Children, Vol. 54, No. 1, pp. 26–35, Jun. 2021, https://doi.org/10.1177/00400599211010191

-

E. Buehler, S. K. Kane, and A. Hurst, “ABC and 3D: Opportunities and obstacles to 3D printing in special education environments,” in the 16th international ACM SIGACCESS conference, pp. 107–114, Jan. 2014, https://doi.org/10.1145/2661334.2661365

-

E. Froboese Da Silva, L. Menin Da Silva, V. Gonçalves Deon, and M. A. Toso, “Impressão 3D aplicada à tecnologia assistiva,” (in Portuguese), Revista Destaques Acadêmicos, Vol. 12, No. 4, pp. 181–193, Dec. 2020, https://doi.org/10.22410/issn.2176-3070.v12i4a2020.2657

-

A. Goyal and H. Goel, “Prosthetic rehabilitation of a patient with finger amputation using silicone material,” Prosthetics and Orthotics International, Vol. 39, No. 4, pp. 333–337, Aug. 2015, https://doi.org/10.1177/0309364614528203

-

K. H. Lee, S. J. Kim, Y. H. Cha, J. L. Kim, D. K. Kim, and S. J. Kim, “Three-dimensional printed prosthesis demonstrates functional improvement in a patient with an amputated thumb,” Prosthetics and Orthotics International, Vol. 42, No. 1, pp. 107–111, Feb. 2018, https://doi.org/10.1177/0309364616679315

-

R. Pulido Arce and J. Foggiatto, “Orthotics modeling for manufacturing by additive manufacturing,” (in Portuguese), in Congresso Brasileiro de Engenharia de Fabricação, Jan. 2017, https://doi.org/10.26678/abcm.cobef2017.cof2017-1084

-

G. C. Rosenmann, “Evaluation of low-cost 3D scanning systems applied to orthosis development by additive manufacturing,” (in Portuguese), Federal Technological University of Paraná, 2017.

-

M. C. Weigert, “Method for low-cost custom orthosis development aiming additive manufacturing,” Federal Technological University of Paraná, 2017.

-

P. H. Poier, R. P. Arce, G. C. Rosenmann, M. G. R. Carvalho, L. Ulbricht, and J. A. Foggiatto, “Development of modular wrist, hand and finger orthesis by additive manufacturing,” Research, Society and Development, Research, Society and Development, 2021.

-

M. Neumüller, A. Reichinger, F. Rist, and C. Kern, “3D printing for cultural heritage: preservation, accessibility, research and education,” in 3D Research Challenges in Cultural Heritage, Berlin, Heidelberg: Springer Berlin Heidelberg, 2014, pp. 119–134, https://doi.org/10.1007/978-3-662-44630-0_9

About this article

The authors express their gratitude to the Federal University of Minas Gerais (UFMG), the Brazilian National Council for Scientific and Technological Development (CNPQ), and the Coordination for the Improvement of Higher Education Personnel – Brazil (CAPES) – Finance Code 001 for their generous financial support. Additionally, the authors would like to acknowledge the dedicated efforts of the research team in obtaining the results presented in this study. The acknowledgment extends to contributors from the disability community and the Inclusion and Accessibility Center at the Federal University of Minas Gerais. This research aligns with the Inclusion Support and Accessibility Promotion Program (PIPA), Notice 001/2020.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Wellingtânia Domingos Dias, Jefferson Henrique Soares, Lara Corrêa Guimarães and Yaçana Maria da Costa Soares Sousa worked on the concept and design of the study; Wellingtânia Domingos Dias also contributed to the management and coordination of the planning and execution of research activities. Additionally, Wellingtânia Domingos Dias, Jefferson Henrique Soares, Lara Corrêa Guimarães, Natalia Espinosa Martínez, Taciana Ramos Luz, Yaçana Maria da Costa Soares Sousa Lima and Rudolf Huebner contributed to the intellectual content of the manuscript, actively participating in the writing of the article and providing critical review and final approval.

The authors declare that they have no conflict of interest.

Not applicable.