Abstract

Mining and processing enterprises are large consumers of electricity, with a large share of energy costs in the cost of production. Thus, the price of electricity in the cost of production takes higher values for Hydrometallurgical Plant 1. In this regard, the development of energy consumption models that can be used as a basis for managing the energy consumption process is an important component of learning. It is important to analyze the energy consumption to estimate the electricity consumption under different operating conditions of the mining industry. In order to study and plan electricity consumption and develop methods for regulating electricity consumption, it is necessary to determine the place of each technological stage in the energy consumption balance [1]. This article examines the laws of electricity consumption in mining and processing enterprises. The study of such laws helps to determine the level of energy consumption management for the mining and processing plant.

1. Introduction

Electricity consumption of mining and processing enterprises is a random process determined by temporary, mining, technological, production and other factors. In the study of energy consumption, the time factor can be taken into account by discretizing the time periods in which energy consumption occurs, in particular: hour (half hour), shift, day, quarter, year. Geological factors can be taken into account by examining power consumption based on the types of ores processed. Technological factors can be taken into account when studying electricity consumption, differentiating it according to different technological stages. The production factor can be taken into account by studying the power consumption depending on the production load of technological equipment, processing stages and production facilities [1].

Taking into account the probabilistic nature, the analysis of statistical materials on energy consumption modes should be carried out using the rules of probability theory and mathematical statistics;

The following were obtained as preliminary statistical data on the modes of energy consumption in the studied enterprises:

1. Hourly values and volumes of energy consumption modes of gold ore processing combined with energy consumption of technological units of ball mills in the 1st stage of grinding at the 1st hydrometallurgical plant [3].

2. 1-Data on the operational calculation of the daily values of electricity consumption of the hydrometallurgical beneficiation plant and the production indicators of the processing processes (grinding, grinding, flotation, dewatering) combined with them.

3. 1-Statistical report data on monthly values of electricity consumption for hydrometallurgical processing enterprises and production indicators combined with them (volume of processed ores, production of concentrates, granules, briquettes), as well as granule preparation plant and hot melt shop.

Measurement of power consumption modes was carried out using a metrologically approved AR-5 power consumption analyzer.

The initial samples of statistical materials were formed in sufficient size to obtain statistical conclusions with a confidence probability of at least 0.90-0.95.

Experimental studies are planned with the requirement to take into account the effect of different ores on energy consumption modes in the study of energy consumption modes and processing stages of the 1st hydrometallurgical beneficiation plant [2].

2. Study of energy consumption modes of technological devices and processing stages of enrichment production

As studied energy consumers, technological units of grinding mills at the 1st stage of grinding, whose energy consumption is up to 60 % of the capacity of the processing plant, were taken.

Electricity consumption modes are characterized by total energy consumption for ore processing, as well as specific energy consumption per unit of processed ore (tons).

Information on total and relative energy consumption and related ore processing volumes by technological units of mills M0, M2, M3, M4, M5 (the Ml mill is under repair) at the 1st hydrometallurgical plant made it possible to obtain data.

The obtained data made it possible to compile the combined variable series of total and specific energy consumption, as well as the volume of processed ores [3].

Analysis of the obtained statistical material was carried out in accordance with the rules of probability theory and mathematical statistics.

In order to describe the mode of energy consumption of technological units of mills, it is appropriate to consider the dependence of relative power consumption on production efficiency of mills, so-called energy-technological characteristics [6].

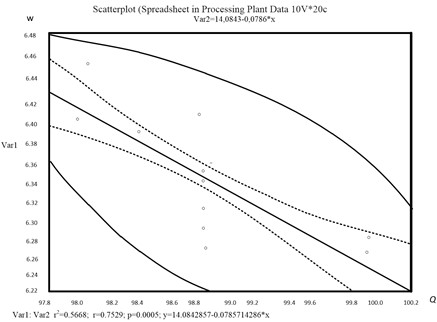

Examples of experimental point distributions of processing volume and specific power consumption for an MO mill are shown in Fig. 1.

Examining the fields of correlation of experimental data on technological units of mills in the coordinates “Hourly volume of ore processing (t) – hourly specific power consumption (kW/t)” shows that the statistics between these indicators the relationship can be described by a function [1]:

with a negative coefficient b.

As a result of statistical data processing, the correlation dependences of the hourly specific electricity consumption on the hourly volume of processed ore of the mill were obtained. For mills M0, M2, MZ, M4, M5: (QP)ω=f(QP).

The obtained electro-technological characteristics of mill technological units have the following expressions for different types of ores:

– Mill M0, Gold ore: ω=14.08-0.08Qp.

– Mill M2, Gold ore: ω=9.02-0.025Qp.

– Mill M3, Gold ore: ω=14.41-0.07Qp.

– Mill M4, Gold ore: ω=23.5-0.2Qp.

– Mill M5, Gold ore: ω=16.93-0.1Qp.

The resulting correlations reflect the energy-technological operating modes of the mills and show the change in the hourly specific power consumption of the mills from the hourly volume of processed ore [7].

The obtained energy technology dependences have a very high correlation between the specific power consumption and the volume of processed ore of the mills, which is confirmed by the correlation coefficient values in the range of 0.75-0.99.

Fig. 1Correlation field and correlation dependence ω=f(QP) for MO Mill (Gold Ore)

3. Energy-technological descriptions of technological stages

In order to distinguish the energy consumption modes of enrichment production, it is appropriate to consider the energy consumption modes of individual processing stages. According to the experimental study, daily values of total and specific energy consumption and statistical samples of relevant production indicators for technological stages – daily volumes of processed ore and resulting concentrate were obtained.

As a result, variation series and correlation fields were obtained to determine the energy-technological characteristics of technological stages as a dependency [9]:

– daily electricity consumption (kWh) from the daily volume of processed ore (t) for crushing and crushing stages W=f(Qm);

– daily electricity consumption (kWh) from the daily volume (t) of the concentrate obtained for flotation and dehydration stages W=f(Qfs);

– relative energy consumption (kW*s/t) from the daily productivity of ore (t) for crushing and crushing stages ω=(Qm);

– relative energy consumption (kW*s/t) from daily productivity (t) for the production of concentrate for flotation and dehydration ω=(Qfs).

A review of the correlation fields of statistical data on the total and comparative consumption of electricity, as well as production volumes, leads to the assumption that the sought relationships can have a linear form (1): for the relationships with positive values of the b coefficient. total electricity consumption, with negative values of β coefficients for dependence on specific electricity consumption [10].

The relationships under consideration were obtained for gold ores. Thus, electrotechnological characteristics - daily electricity consumption to the total daily volume of processed ore (grinding, grinding) and the daily volume of concentrate produced for different types of ores (flotation, dewatering) has the following expression:

– For the technological stage of “grinding”: Wg=36935+0.39338*Qm.

– For the “Mill” technological stage: Wmill=1748E2+1.752*Qm.

– For the technological stage of “flotation”: Wfl=95353+0.8543*Qfl.

– For the “dehydration” technological stage: Wdeh=41691+1.361*Qfl.

For gold ores, the electrotechnological characteristics of the daily specific energy consumption from the daily volume of processed ore (grinding, crushing) and the daily volume of the produced concentrate (flotation, dewatering) have the following expression:

– For the technological stage of “grinding”: ωg=26.321-0.0020*Qm.

– For the “Mill” technological stage: ωmill=127.07-0.0102*Qm.

– For the technological stage of “flotation”: ωfl=251.33-0.0976*Qfl.

– For the “dehydration” technological stage: ωdeh=105.62-0.0411*Qfl.

The obtained energy-technological descriptions of technological processes in the form of correlation equations have a strong enough correlation between the parameters included in them.

It is advisable to use the obtained energy-technological characteristics for planning, operational management and reporting on energy consumption. Modeling of energy consumption of primary energy production of mining and processing enterprises

3.1. Modeling of energy consumption of beneficiation production at a hydrometallurgical plant

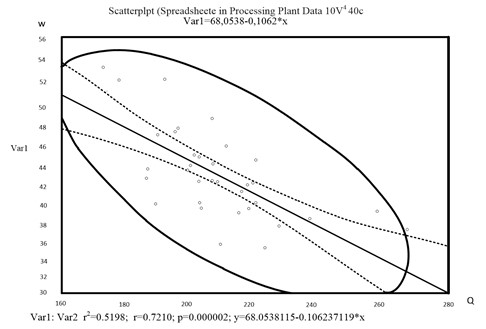

Increasing the level of energy management, incl. In order to increase the level of planning, operational management and reporting of electricity consumption, it is necessary to establish the energy-technological characteristics of the processing plant, which is the dependence of specific electricity consumption on the monthly volume of processed ore – processing energy-technological description of the plant is carried out on the basis of statistical materials on comparative energy consumption and monthly volumes of ore processing.ω=f(Qmv) [8].

As a result of examining the correlation field of these factors (Fig. 2), we can conclude that there is a (1) type linear relationship between them.

Using the rules of the theory of correlation analysis, the processing of statistical data on the exact monthly electricity consumption and the monthly volume of processed ore made it possible to obtain the relationship in the form of an expression, ω=f(Qrm), ωm=68.054-0.1062*Qmv, here: ωm – monthly specific power consumption of the plant, kW/t; Qmv – monthly volume of ore processing by the combine, thousand tons.

As a result, the energy-technological characteristics of the plant are shown in Fig. 2. It is recommended to use this feature to increase the level of control of the power consumption process, including. while increasing the level of planning, operational management and reporting for energy consumption.ω=f(Qmv).

Fig. 2Correlation field and dependence of enrichment ω=f(Qr)

3.2. Modeling of energy consumption by the main energy-consuming production facilities of the 1st hydrometallurgical plant

In order to establish mathematical models of energy consumption regimes, modeling of total and specific energy consumption for the main energy-consuming production facilities of the 1st hydrometallurgical plant was carried out.

Analysis of statistical materials on monthly electricity consumption and related production indicators showed that the sought relationships can have a linear form like (1).

As a result of the correlation analysis, dependences on energy technology with the following expressions were obtained:

1) To crush the plant.

– Full consumption: W=20.17+0.52*Qprod.

– Special consumption: w=1893.8-14.76*Qprod.

2) For concentrator 1 (concentration)

– Full consumption: W=4569E2+11450*Qprod.

– Special consumption: w=1195E2-6221*Qprod.

3) For concentrator No. 2 (enrichment)

– Full consumption: W=2869E2+27899*Qprod.

– Special consumption: w=93413-3670*Qprod.

4) For concentrator No. 2 (filtering)

– Full consumption: W=54065+2576.8*Qprod.

– Special consumption: w=11292-338.5*Qprod.

5) For concentrator No. 3 (concentration)

– Full consumption: W=4763E2+16383*Qprod.

– Special consumption: w=99731-3580*Qprod.

6) For concentrator No. 3 (additional concentrator)

– Full consumption: W=41696+8854.4*Qprod.

– Special consumption: w=22697-1081*Qprod.

7) For granulation plant No. 3 (total for technology)

– Full consumption: W=2699E2+25536*Qprod.

– Special consumption: w=64795-1398*Qprod.

In above expressions – the volume of relevant production products Qprod.

It is recommended to use the obtained energy-technological properties to increase the level of energy consumption management, including. increase the level of planning, operational management and reporting of energy consumption.

4. Conclusions

Management of the energy consumption process should be based on laws that determine the consumption of energy resources (public and private), including for production. Among the mentioned laws, the electrotechnological energy nature of electricity consumption obtained in this chapter shows the dependence of electricity consumption on processed ores.

Energy consumption regimes (electrical-technological characteristics) of the main production of mining and processing enterprises are reliably described by linear functions and depend on the type of production technological schemes and types of processed ores are used with coefficients that differ depending on the type of production.

Taking into account the clear dependence of electricity consumption on the volume of production, it is desirable to increase the level of planning, operational management and reporting of electricity consumption in accordance with the schemes of electricity consumption defined in this article. The use of the main energy-consuming components, technological stages and electrical technological characteristics of the main energy-consuming sectors obtained in this article in planning, operational management and reporting on energy consumption increases the level of adaptation to production conditions and accuracy. and reliability of energy consumption process management.

Technological factors in the production process of mining enterprises affect electricity consumption. Solving the problem of describing energy consumption processes becomes more complicated due to significant changes in technological factors in production that affect electricity consumption. It is recommended to use probability theory and mathematical statistical methods to solve the problem.

References

-

Karshibayev A. I., “Increasing the efficiency of electricity consumption in mining enterprises in Uzbekistan,” Ph.D. Thesis, Moscow, 2011.

-

A. N. Tovbоyev, G. G. Boynazarov, and Z. I. Jumayev, “Analysis of subharmonic oscillations of the third order in three-phase circuits with a separate ferromagnetic element,” International Journal of Advanced Research in Science, Engineering and Technology, Vol. 6, No. 12, pp. 12229–12233, Dec. 2019.

-

A. I. Karshibayev and Z. I. Jumayev, “Expanding the level of forecasting and operational planning of electric consumption at mining enterprise,” E3S Web of Conferences, Vol. 417, p. 03015, Aug. 2023, https://doi.org/10.1051/e3sconf/202341703015

-

A. I. Karshibayev, Z. I. Jumayev, and Sh. Sh. Abdullayev, “Development of modern methods of increasing the efficiency of electricity use in mining enterprises,” Journal of Advances in Engineering Technology, pp. 39–42, 2022.

-

J. S. Olimov, S. S. Fayziyev, F. M. Raximov, A. U. Majidov, and B. Q. Muxammadov, “Controlling power of short circuited induction motor via modern sensors without speed change,” in E3S Web of Conferences, Vol. 417, p. 03007, Aug. 2023, https://doi.org/10.1051/e3sconf/202341703007

-

J. Mavlonov, D. Mardonov, M. Eshmirzayev, and I. Togayev, “Improvement of methods to ensure energy efficiency of ball mills functioning,” in E3S Web of Conferences, Vol. 417, p. 03014, Aug. 2023, https://doi.org/10.1051/e3sconf/202341703014

-

B. S. Narzullayev and M. A. Eshmirzaev, “Causes of the appearance of current waves in high voltage electric arc furnaces, and methods of their reduction,” in E3S Web of Conferences, Vol. 417, p. 03003, Aug. 2023, https://doi.org/10.1051/e3sconf/202341703003

-

A. Tovbaev, G. Boynazarov, and I. Togaev, “Improving the quality of electricity using the application of reactive power sources,” in E3S Web of Conferences, Vol. 390, p. 06032, Jun. 2023, https://doi.org/10.1051/e3sconf/202339006032

-

O. Ishnazarov, J. Mavlonov, and D. Mardonov, “Control of ball mill operation depending on ball load and ore properties,” in E3S Web of Conferences, Vol. 461, p. 01091, Dec. 2023, https://doi.org/10.1051/e3sconf/202346101091

-

A. Taslimov, F. Rakhimov, and F. Rakhimov, “Economic interval analysis of loads for selection of cross-section surfaces of electrical transmission lines,” in E3S Web of Conferences, Vol. 384, p. 01037, Apr. 2023, https://doi.org/10.1051/e3sconf/202338401037

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.