Abstract

Electricity consumption of mining enterprises depends on many factors. The influence of factors on the process of electricity consumption is complex and diverse, and it is impossible to describe it within the framework of deterministic methods, due to the uncertainty of the conditions that determine the influence of factors. These factors include mining geological, mining technological, climate-meteorological, energetic, organizational, operational and others. Energy consumption regimes of mining enterprises depend on many mining technological factors, most of which are insufficiently taken into account in the analysis and planning of electricity consumption.

1. Introduction

In modern conditions, issues of energy resource consumption in mining enterprises are especially important, because one of the main reserves of the country's energy saving potential is located in this field.

Electricity consumption of mining enterprises depends on many factors. The influence of factors on the process of electricity consumption is complex and diverse, and it is impossible to describe it within the framework of deterministic methods, due to the uncertainty of the conditions that determine the influence of factors. These factors include mining geological, mining technological, climate-meteorological, energetic, organizational, operational and others.

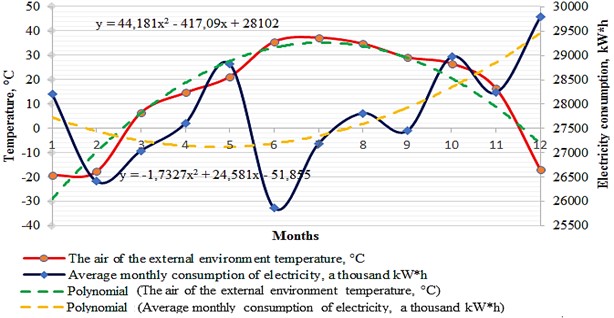

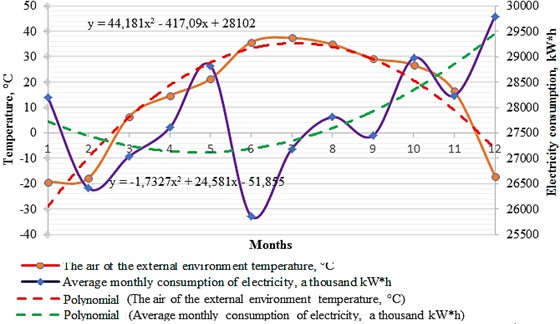

The 7th hydrometallurgical plant belonging to the Central Mining Department is located in the desert regions of the city of Zarafshan in the Navoi region, so the outside temperature changes constantly. Climatic-meteorological factors demand electricity determines the seasonality of goods and forms the internal tendency of its change. The change of external air temperature of the 7th hydrometallurgical plant in 2022-2023 years and the average monthly trend of electricity consumption by the 7th hydrometallurgical plant are presented in Table 1 and Figs. 1-2.

In analysis, we can directly see the effect of air temperature on electricity consumption. The monthly average trend of external temperature variation and electricity consumption at 7th hydrometallurgical plant shows that the influence of electricity consumption is higher when the air temperature drops and rises.

Mountain - the composition of geological and technological factors of the mine, the depth of the mine, the scale of the mine, the temperature of the mountain ridges, the technological appearance, the order of opening and the method of digging, the types of machines and equipment used, strength, piece-piece ore and others, affecting the electrical capacity of the product.

Table 1Monthly average trend of external temperature changes and electricity consumption at the 7th hydrometallurgical plant under the Central Mining Administration for 2022-2023

Months | 2022 year | 2023 year | ||

The air of the external environment temperature, °C | Average monthly consumption of electricity, a thousand kWh | The air of the external environment temperature, °C | Average monthly consumption of electricity, a thousand kWh | |

January | –17,2 | 25755 | –19,3 | 28204 |

February | –16,7 | 24908 | –17,7 | 26412 |

March | 5,8 | 27899 | 6,5 | 27041 |

April | 13,6 | 26844 | 14,7 | 27606 |

May | 19,7 | 27602 | 21,3 | 28824 |

June | 34,9 | 27310 | 35,7 | 25864 |

July | 36,2 | 28069 | 37,4 | 27188 |

August | 33,8 | 27942 | 34,9 | 27814 |

September | 28,1 | 27863 | 29,3 | 27451 |

October | 25,3 | 28867 | 26,7 | 28975 |

November | 15,1 | 28118 | 16,4 | 28235 |

December | –16,9 | 29050 | –17,1 | 29796 |

Fig. 1Monthly average trend of outdoor temperature variation and electricity consumption at 7th hydrometallurgical plant in 2022

Fig. 2Monthly average trend of outdoor temperature variation and electricity consumption at 7th hydrometallurgical plant in 2023

2. Results and discussion

Mining enterprises are large consumers of electricity. In addition, recently they are characterized by an increase in electricity consumption, which is the main source of energy consumption (up to 70-75 % on average for mining enterprises). This is due to changes in the conditions of extraction and processing of minerals, reduction of useful content in ore, use of energy-intensive mechanisms, introduction of environmental protection measures, etc. The most energy-intensive process in mining enterprises is the beneficiation process, which accounts for 55-63 % to 75-82 % of the enterprise’s total electricity consumption. At the same time, a large number of factors affect the consumption of electricity.

Table 2Technological factors of production subject to accounting

No | Designation | A group of factors | The name of the technological factor | Unit of measure |

1 | A1 | The main quantitative indicators of production | Amount of electricity consumption | kW*h |

2 | A2 | Volume of concentrate released | T | |

3 | A3 | Comparative electricity consumption | kW*h/t | |

4 | A4 | Physico-chemical composition of ore | The percentage of total iron in the ore | % |

5 | A5 | Magnetite is the percentage of iron in the ore | % | |

6 | A6 | Technological parameters of used mining equipment | Processed ore volume wet self-crushing mill | (T) |

7 | A7 | The efficiency of the self-extinguishing mill | Ton*hour | |

8 | A8 | The working time of the self-extinguishing mill | Hour | |

9 | A9 | Volume of ore sent for regrinding | Tons | |

10 | A10 | load percentage of a self-extinguishing mill | % | |

11 | A11 | The power of the self-extinguishing mill | kW | |

12 | A12 | RSHT (ore and gravel mill) capacity | kW | |

13 | A13 | The volume of water used in combustion, | m3 | |

14 | A14 | Classifier density at the exit of the mill | gr/liter | |

15 | A15 | Physico-chemical composition of the final concentrate | Percentage of total iron in concentrate | % |

16 | A16 | Percentage of magnetite iron in concentrate | % | |

17 | A17 | Percentage of moisture in the concentrate | % | |

18 | A18 | concentrate class | % | |

19 | A19 | Physico-chemical composition of waste and residue from mineral processing in production | The fraction of total iron in the tailings from mineral processing | % |

20 | A20 | The percentage of magnetite iron in the waste remaining from mineral processing | % |

Determining and taking into account the factors affecting the consumption of electricity in the process of beneficiation of ore in mining enterprises is the main and important task in the study and analysis of electricity consumption. At the same time, it is almost impossible to take into account all factors, because they affect the consumption of electricity under conditions of uncertainty.

In terms of electricity consumption and energy saving in mining enterprises, the following main technological factors determining the level of electricity consumption in the process of ore beneficiation are determined:

1) ore productivity;

2) composition of useful components in ore;

3) strength and moisture content of the ore;

4) release of concentrate;

5) product extraction;

6) ball mill loading.

However, in addition to the listed factors, modern mining enterprises take into account a number of different technological factors affecting the production of finished products. From these technological factors, it is necessary to determine the factors affecting the consumption of electricity. The list of such factors is presented in Table 2. For technological factors, a qualitative division (decomposition) was carried out to determine the first - and second-order factors. First -order factors include factors that directly affect the efficiency of electricity consumption. Factors affecting the efficiency of electricity consumption through first-order factors are called second-order factors. Consequently, second-order factors can be neglected, as their influence on electricity consumption is completely described by first-order factors.

Factor analysis is used to determine the structure of relationships between technological factors of the first level. Factor analysis allows you to gather preliminary information that represents a large number of characteristics under consideration through a smaller number of internal characteristics of the phenomenon (groups of factors) that cannot be directly measured. The number of extracted factor groups, on the one hand, determines the complete repetition of the observed correlations, and on the other hand, a meaningful interpretation of the dependence of technological factors.

In the process of factor analysis of the technological factors of ore beneficiation production in mining enterprises, it was found that the number of groups of factors to be distinguished is 4. This number was determined based on the “Rockfall criterion” using the “Rockfall” graph. The number of factors is plotted along the abscissa axis, and the characteristic values of these factors are plotted along the ordinate axis. The rockfall criterion is to find the point at which the decline in eigenvalues slows down the most. To the right of this point there is only the “spill factor”. Thus, the number of selected factors should not exceed the number of factors to the left of this point.

Table 3Results of factor analysis of first-order technological factors

Factor 1 | Factor 2 | Factor 3 | Factor 4 | ||

A3 | Comparative electricity consumption | 0,1915 | 0,8621 | 0,0699 | 0,0213 |

A4 | Percentage of total iron in ore | –0,2990 | –0,6103 | 0,5911 | 0,0597 |

A5 | Percentage of magnetite iron in ore | –0,2234 | –0,5486 | 0,6967 | 0,1890 |

A15 | Percentage of total iron in concentrate | 0,2012 | 0,3001 | 0,1074 | 0,3102 |

A17 | Percentage of moisture in concentrate | 0,0436 | 0,6426 | 0,4432 | –0,1904 |

A19 | Mineral processing waste, percentage of total iron in the residue | –0,0997 | 0,0810 | –0,4341 | –0,3874 |

A20 | Mineral processing waste, percentage of iron magnetite in the residue | 0,4214 | –0,1623 | –0,0183 | –0,1932 |

A6 | Processed ore volume | –0,7905 | 0,2414 | –0,1987 | 0,2114 |

A7 | Ball mill efficiency | –0,4898 | –0,4504 | –0,4153 | –0,4201 |

A10 | Ball mill loading percentage | –0,2872 | 0,3121 | –0,0796 | 0,4341 |

A11 | Power consumption of ball mill | –0,2283 | –0,5309 | –0,4298 | 0,2565 |

A9 | Ore volume (when sent for re–grinding) | –0,7190 | 0,2174 | 0,1426 | –0,3534 |

A12 | Power consumption of ore and gravel mill | –0,2360 | 0,2071 | 0,3809 | –0,7509 |

A13 | Volume of water used in self-extinguishing mills | –0,7815 | 0,4445 | 0,0203 | 0,3075 |

A14 | Classifier density at the output of self-extinguishing mills | –0,7138 | 0,0370 | 0,0507 | 0,1263 |

Common variance | 3,2238 | 2,8374 | 1,8209 | 1,6578 | |

Percentage of total variance | 0,2043 | 0,1914 | 0,1214 | 0,1103 |

Thus, we can conclude that the relative electricity consumption depends on the following technological factors:

1) A4, iron content in ore (%).

2) A17, moisture in final concentrate (%).

3) A5, magnetite iron content in ore (%).

4) A11, power consumption of ball mills (kW).

If two technological factors have a high level of interaction with each other, one of them can be excluded from the group of influencing factors. A factor with a lower factor loading is dropped.

Table 4Factor analysis

Specific electricity consumption, | Percentage of total iron in the ore, | Percentage of magnetite iron in the ore, | Percentage of moisture in the final concentrate, | Volume of processed ore, | Production efficiency of the ball mill, | Power consumption of the ball mill, | Volume of ore sent for regrinding, | Volume of water used in milling in wet autogenous mill, | The classifier density at the output of wet autogenous mill, | |

Relative electricity consumption | 1,00 | –0,51 | –0,43 | 0,44 | 0,02 | –0,61 | –0,46 | 0,03 | 0,19 | –0,09 |

Percentage of total iron in ore | –0,48 | 1,00 | 0,81 | –0,12 | 0,05 | 0,21 | 0,11 | 0,22 | 0,03 | 0,27 |

Percentage of magnetite iron in ore | –0,43 | 0,80 | 1,00 | –0,04 | -0,02 | 0,00 | 0,14 | 0,06 | –0,02 | 0,15 |

Percentage of moisture in concentrate | 0,46 | –0,11 | –0,04 | 1,00 | -0,02 | –0,26 | –0,31 | 0,19 | 0,14 | 0,02 |

Processed ore volume | 0,02 | 0,04 | –0,02 | –0,03 | 1,00 | 0,32 | 0,16 | 0,32 | 0,85 | 0,47 |

Production efficiency of the self-extinguishing mill | –0,56 | 0,11 | 0,00 | –0,26 | 0,31 | 1,00 | 0,39 | 0,35 | 0,05 | 0,18 |

Power consumption of self-extinguishing mill | –0,46 | 0,10 | 0,10 | –0,31 | 0,15 | 0,39 | 1,00 | 0,04 | -0,08 | 0,20 |

Ore volume when sent for re-grinding | 0,03 | 0,12 | 0,05 | 0,19 | 0,41 | 0,35 | 0,04 | 1,00 | 0,49 | 0,46 |

The volume of water used for grinding in a self-grinding mill | 0,19 | 0,02 | –0,01 | 0,14 | 0,87 | 0,05 | –0,08 | 0,49 | 1,00 | 0,54 |

Classifier density | –0,08 | 0,19 | 0,15 | 0,02 | 0,47 | 0,19 | 0,21 | 0,44 | 0,53 | 1,00 |

The results of the factor analysis of the first-order technological factors for four groups of factors are presented in Table 4.

The threshold value of the factor loadings of the conducted factor analysis is 0.47.

According to the results of the factor analysis, the groups of indicators that make up the groups of factors were determined. The group of factors consists only of indicators whose loading of factors is above the limit. For the first factor, these indicators are: A6, A7, A9, A13 and A14. The second factor group consists of factors: A3, A4, A5, A17 and A11.

3. Conclusions

Taking into account the consumption of electricity in mining enterprises, it is possible to form the following specific characteristics:

1) Electricity consumption depends on many factors. The influence of these factors on electricity consumption is complex and diverse, and it is almost impossible to describe them within the framework of deterministic functions and methods due to the incompleteness of the data and the uncertainty of the conditions reflecting the influence of these factors. In this regard, it can be argued that determining the influence of factors on electricity consumption is one of the complex problems that can be solved using probability theory and mathematical statistical methods.

2) Technological factors in the production process of mining enterprises affect electricity consumption. Solving the problem of describing energy consumption processes becomes more complicated due to significant changes in technological factors in production that affect electricity consumption. It is recommended to use probability theory and mathematical statistical methods to solve the problem.

3) The study of electrical energy consumption takes place in the conditions where there are many production indicators combined with correlations in the experimental material.

The above-mentioned characteristics lead to the need to use mathematical methods that allow to determine the technological factors in production that affect the consumption of electricity. In addition, mathematical methods should provide algorithms that reduce the size of the initial information array and establish production and technological factors that have a significant impact on the energy consumption process.

Based on the above, the following can be identified as the goals of studying electricity consumption in mining enterprises, in particular, in the 7th hydrometallurgical plant:

1) assessment of the state of the energy consumption process at the 7th hydrometallurgical plant;

2) determine the factors affecting the energy consumption process;

3) determining the dependence of energy consumption on technological factors;

4) development of methodical principles for energy resource management and creation of software analytical complex;

5) development of recommendations for improving the energy efficiency of the 7th hydrometallurgical plant.

It is characterized by the demand for electric energy by technological machines, mechanisms, devices, mode of electric loads, consumption of electric energy per product unit. In this regard, when studying the electrical energy consumption of machines, mechanisms, devices, it is appropriate to determine the following: the main probabilistic laws of the formation of one-hour electrical loads, the appearance of energy characteristics, the relationship between energy and technological factors in production.

References

-

Karshibayev A. I., “Increasing the efficiency of electricity consumption in mining enterprises in Uzbekistan,” 2011.

-

Tovbоyev A. N., Boynazarov G. G., and Jumayev Z. I., “Analysis of subharmonic oscillations of the third order in three-phase circuits with a separate ferromagnetic element,” International Journal of Advanced Research in Science, Engineering and Technology, Vol. 6, No. 12, pp. 12229–12233, Dec. 2019.

-

A. I. Karshibayev and Z. I. Jumayev, “Expanding the level of forecasting and operational planning of electric consumption at mining enterprise,” E3S Web of Conferences, Vol. 417, p. 03015, Aug. 2023, https://doi.org/10.1051/e3sconf/202341703015

-

A. I. Karshibayev, Z. I. Jumayev, and Sh. Sh. Abdullayev, “Development of modern methods of increasing the efficiency of electricity use in mining enterprises,” Journal of Advances in Engineering Technology, pp. 39–42, 2022.

-

J. S. Olimov, S. S. Fayziyev, F. M. Raximov, A. U. Majidov, and B. Q. Muxammadov, “Controlling power of short circuited induction motor via modern sensors without speed change,” E3S Web of Conferences, Vol. 417, p. 03007, Aug. 2023, https://doi.org/10.1051/e3sconf/202341703007

-

J. Mavlonov, D. Mardonov, M. Eshmirzayev, and I. Togayev, “Improvement of methods to ensure energy efficiency of ball mills functioning,” E3S Web of Conferences, Vol. 417, p. 03014, Aug. 2023, https://doi.org/10.1051/e3sconf/202341703014

-

B. S. Narzullayev and M. A. Eshmirzaev, “Causes of the appearance of current waves in high voltage electric arc furnaces, and methods of their reduction,” E3S Web of Conferences, Vol. 417, p. 03003, Aug. 2023, https://doi.org/10.1051/e3sconf/202341703003

-

A. Tovbaev, G. Boynazarov, and I. Togaev, “Improving the quality of electricity using the application of reactive power sources,” E3S Web of Conferences, Vol. 390, p. 06032, Jun. 2023, https://doi.org/10.1051/e3sconf/202339006032

-

O. Ishnazarov, J. Mavlonov, and D. Mardonov, “Control of ball mill operation depending on ball load and ore properties,” E3S Web of Conferences, Vol. 461, p. 01091, Dec. 2023, https://doi.org/10.1051/e3sconf/202346101091

-

A. Taslimov, F. Rakhimov, and F. Rakhimov, “Economic interval analysis of loads for selection of cross-section surfaces of electrical transmission lines,” E3S Web of Conferences, Vol. 384, p. 01037, Apr. 2023, https://doi.org/10.1051/e3sconf/202338401037

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.