Abstract

The utilization of aeolian sand resources for road construction is a specific measure to develop green and low-carbon transportation, and also conforms to the concept of green and sustainable development of roads in China. Based on this, the feasibility of using aeolian sand as a substitute for fine aggregate for cement stabilized graded crushed stone was explored, and the effects of different aeolian sand dosages on the unconfined compressive strength, bending and flexural strength, and splitting strength of cement stabilized crushed stone mixtures were studied. The results indicate that the addition of aeolian sand has a significant deterioration effect on the mechanical properties of cement stabilized graded crushed stone mixtures. The larger the amount of aeolian sand added, the more severe its impact on the mixture. Therefore, controlling the amount of aeolian sand within 6 % can meet the mechanical performance requirements. To ensure the large-scale utilization of aeolian sand resources, future research can comprehensively consider the shrinkage characteristics, durability, and water stability of cement stabilized crushed stone mixtures, and further recommend the maximum dosage of aeolian sand.

1. Introduction

The desert area in China is about 3.4×105 km2, and the desert Gobi which is widely distributed in the northwest region of China accounts for nearly 16 % of the national territory. In recent years, with the steady progress of the “the Belt and Road” initiative and the western development strategy, the western region of China has risen rapidly, and the construction of high-grade highways has moved to desert, Gobi and other regions. At that time, China will build a considerable number of desert highways. However, due to the characteristics of loose particles, low cohesion, low natural moisture content, high permeability, poor water retention performance, and poor gradation of aeolian sand [1], it cannot be directly used as a road base construction material. If the stability problem of aeolian sand in desert areas can be solved, and its strength can meet the standard requirements for road base construction, it not only provides the best choice for building road materials in desert areas, but also has significant economic, environmental, and social benefits.

At present, scholars have conducted a large number of experimental studies on aeolian sand filling roadbeds, and the complete set of technology for aeolian sand filling roadbeds has become mature. In terms of the application of aeolian sand as a raw material for concrete, research has found that the slump of concrete shows a trend of first increasing and then decreasing with the increase of aeolian sand content. The optimal content of aeolian sand is between 20 % and 60 % [2]-[4]. Bai et al. [5] studied the mechanism of the influence of aeolian sand content on the pore structure and mechanical properties of concrete. In addition, Yi et al. [6] and Zhang et al. [7] conducted relevant research on the engineering characteristics of aeolian sand and found that aeolian sand can be compacted in both dry and optimal moisture conditions. Song et al. [8] conducted a study on the mechanical and durability properties of cement stabilized aeolian sand graded crushed stone, and found that the addition of aeolian sand has a significant deterioration effect on the mechanical properties, dry shrinkage performance, temperature shrinkage performance, erosion resistance performance, and fatigue performance of cement stabilized crushed stone mixtures. When the aeolian sand content increases to 12 %, this deterioration effect becomes more obvious. Finally, based on engineering practice, it is feasible to use 6 % aeolian sand and other quality substitutes for fine aggregates in cement stabilized graded crushed stone base. Guo et al. [9] found that the more cement content is added, the better the water stability of the aeolian sand gravel base layer, which can meet the construction requirements of different levels of highway base layers. However, the shrinkage and cracking characteristics of the base layer under high cement content are ignored.

Overall, research on cement stabilized aeolian sand and gravel mixtures is still in its early stages, with most studies limited to indoor experiments. There is relatively little research on the mechanical properties, durability, and road performance of cement stabilized aeolian sand and gravel mixtures. Therefore, based on indoor experiments, this article explores the influence of aeolian sand replacing fine aggregates on the mechanical properties of cement stabilized crushed stone mixtures. The research results provide a theoretical basis for the promotion and application of aeolian sand in roadbeds, which is of great significance for the high-quality construction of highways in desert areas.

2. Materials and method

2.1. Materials

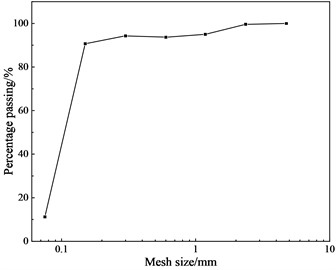

The aeolian sand selected in this article comes from the southern part of the Mu Us Desert, and its mineral composition is mainly quartz, feldspar, and calcite, with a small amount of mineral components such as hornblende, biotite, and muscovite. Its chemical components mainly include SiO2, Al2O3, MgO, Na2O, CaO, and Fe2O3. The grading curve of aeolian sand particles is shown in Fig. 1, with a particle size distribution of 0.075-0.3 mm. According to the formula, the non-uniformity coefficient (Cu), curvature coefficient (Cc), and fineness modulus (Mx) of aeolian sand particles can be calculated to be 2.13, 2.13, and 0.266, respectively, which indicates that aeolian sand belongs to poorly graded sand.

Fig. 1Aeolian sand particle size distribution curve

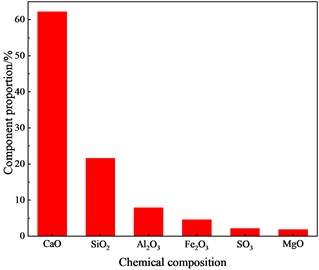

Fig. 2Chemical composition of cement

This article selects limestone crushed stone from Taiyang Mountain in Ningxia, and the coarse aggregate particle sizes were 2.36-4.75 mm, 4.75-9.5 mm, and 9.5-26.5 mm, respectively. Referring to the “Test Code for Aggregates in Highway Engineering” (JTG-E42-2005), the engineering characteristics of the aggregate, such as crushing value, needle like content, water absorption rate, and apparent density, were tested. The results are shown in Table 1. According to Table 1, it is known that the aggregates used meet the relevant requirements of the “Technical Specifications for Construction of Highway Pavement Base” (JTGT F20-2015).

The selected cementitious material in this article is 42.5 ordinary Portland cement (from Jidong of Shaanxi), whose chemical composition is shown in Fig. 2. Its various properties were tested according to the specifications, and the results are shown in Table 2. The test results show that the cement used in this article meets the requirements of the standard “General Portland Cement” (GB 175-2020).

Table 1Test results of aggregate engineering characteristics

Performance index | Particle size / mm | ||

2.36-4.75 | 4.75-9.5 | 9.5-26.5 | |

Crushing value (%) | 19.20 | 17.8 | 20.0 |

Needle like content (%) | 14.20 | 13.5 | 12.0 |

Water absorption rate (%) | 0.78 | 0.38 | 0.22 |

Apparent density (g·cm-3) | 2.64 | 2.71 | 0.22 |

Table 2Main technical performance indicators of cement

Specific surface area / (m2·kg-1) | Loss on ignition / % | Setting time / min | Compressive strength / MPa | Flexural strength / MPa | |||

364 | 3.89 | Initial | Final | 3 d | 28 d | 3 d | 28 d |

202 | 259 | 30.4 | 50.4 | 6.4 | 7.5 | ||

2.2. Experimental design

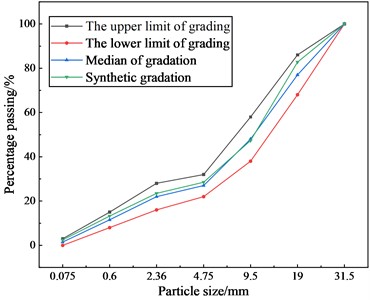

The experiment adopts the same mineral aggregate gradation, and according to the relevant requirements of the “Technical Rules for Construction of Highway Pavement Base” (JTGT F20-2015) and the results of aggregate screening test, a skeleton dense structure is selected. The graded crushed stone adopts C-B-3. Based on the results of the aeolian sand screening test, aeolian sand is used to replace fine aggregates smaller than 0-2.36 mm in the composite gradation, accounting for 0 %, 2 %, 4 %, 6 %, 8 %, and 10 %, respectively. The composite gradation of the mixture is shown in Fig. 3.

Fig. 3Synthetic gradation curve of mixture

During the testing process, in accordance with the requirements of the “Test Code for Stable Materials of Inorganic Binders in Highway Engineering” (JTGE51-2009), all specimens were left to stand for 24±2 hours after molding for demolding, and cured to the specified age under standard conditions of 20±2 ℃ and relative humidity greater than 95 %. Unconfined compressive strength test formed according to the method specified Φ150 mm×150 mm cylindrical specimen in regulation T 0843-2009, bending and flexural strength test formed according to the method specified 550 mm×150 mm×150 mm beam specimen in regulation T 0844-2009, splitting strength test formed according to the method specified Φ150 mm×150 mm cylindrical specimen in regulation T 0843-2009.

3. Result and discussion

3.1. Unconfined compressive strength test results and analysis

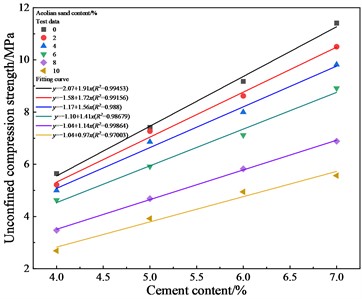

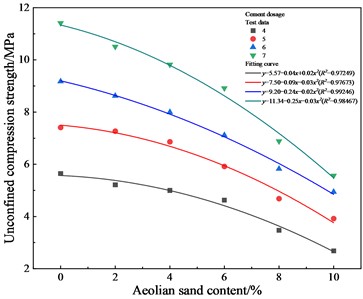

According to the experimental results in Fig. 4, it can be seen that under the same amount of aeolian sand, the 7 d unconfined compressive strength of cement stabilized crushed stone mixture increases in a linear functional relationship with the increase of cement content. The fitting optimization degree R2 is greater than 0.97. When the aeolian sand content is 0 %, 2 %, 4 %, 6 %, 8 %, and 10 %, and the cement content is increased from 4 % to 7 %, the unconfined compressive strength of cement stabilized aeolian sand crushed stone mixture increases by 102.1 %, 101.6 %, 96.5 %, 92.9 %, 98.3 %, and 107.5 %, respectively. Under the same cement content conditions, the unconfined compressive strength of cement stabilized aeolian sand graded crushed stone mixture decreases in a quadratic functional relationship with the increase of aeolian sand content. That is, within the range of 0 %-6 % aeolian sand content, the unconfined compressive strength shows a slow decreasing trend. Within the range of 6 %-10 % aeolian sand content, the unconfined compressive strength rapidly decreases. The fitting optimization degree R2 is all above 0.97, and the cement content is under the conditions of 4 %, 5 %, 6 %, and 7 %, the unconfined compressive strength of cement stabilized aeolian sand graded crushed stone mixture decreased by 52.5 %, 47.1 %, 46.2 %, and 51.2 %, respectively. When the aeolian sand content increased from 0 % to 10 %, indicating that increasing the aeolian sand content has a negative impact on the strength of cement stabilized graded crushed stone mixture. In addition, for the convenience of comparing and studying the flexural strength and splitting strength of cement stabilized graded crushed stone mixtures under different aeolian sand content in the following text, the cement content is taken as 6 %.

Fig. 47 d unconfined compressive strength of cement stabilized graded crushed mixture under different aeolian sand and cement content

3.2. Bending and flexural strength test results and analysis

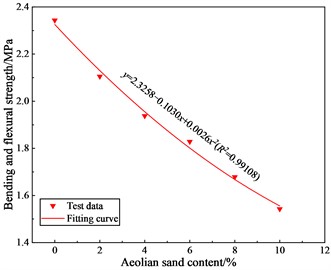

The results of the bending and flexural strength test are shown in Fig. 5. Fig. 5 shows that the bending and flexural strength of cement stabilized crushed stone mixture decreases in a quadratic relationship with the increase of aeolian sand content, and the fitting optimization degree R2 is greater than 0.99. The increase of aeolian sand content from 0 % to 10 % resulted in a decrease of 34.16 % in the bending and flexural strength of cement stabilized crushed stone mixture. This is because the filling effect reaches a threshold with the continuous increase of aeolian sand content. Due to the large amount of fine sand content, faults appear in the fine aggregate gradation, the porosity increases, and the strength decreases [10].

Fig. 57 d bending and flexural strength

Fig. 67 d splitting strength

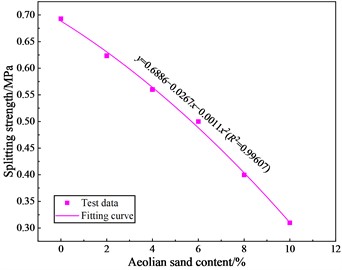

3.3. Splitting strength test results and analysis

The results of the splitting strength test are shown in Fig. 6. Fig. 6 shows that the splitting strength of cement stabilized crushed stone mixture gradually decreases with the increase of aeolian sand content. The fitting curve satisfies a quadratic function relationship, and the fitting optimization degree R2 is greater than 0.99. The aeolian sand content increases from 0 % to 10 %, and the splitting strength decreases by 55.32 %. This is because with the increase of aeolian sand content, it becomes the main aggregate. On the one hand, it causes poor or even missing aggregate gradation, and has little effect on the squeezing of coarse aggregate. On the other hand, aeolian sand has a larger surface area and stronger water absorption than river sand. Excessive addition will cause the system to have a larger surface area and stronger water absorption. The decrease in effective water cement ratio leads to a decrease in the amount of slurry used to fill pores and wrap aggregates, resulting in a decrease in the compactness of cement stone and an increase in harmful pore content [11].

4. Conclusions

1) This research used aeolian sand as a substitute for fine aggregates under different water cement ratios to conduct stability tests on the pavement base layer. The results indicate that the amount of aeolian sand has a negative impact on the mechanical property of cement stabilized crushed stone mixture, and the larger the amount of aeolian sand, the more significant the negative impact.

2) Under the conditions of cement content of 4 %, 5 %, 6 %, and 7 %, the aeolian sand content increased from 0 % to 10 %, and the unconfined compressive strength of the mixture decreased by 52.5 %, 47.1 %, 46.2 %, and 51.2 %, respectively. At a cement content of 6 %, the flexural strength and splitting strength of the mixture decreased by 34.16 % and 55.32 %, respectively.

3) The research results of this article provide theoretical support for the large-scale promotion and application of aeolian sand in road grassroots. At the same time, the development and comprehensive utilization of aeolian sand in desert areas can not only reduce engineering costs and improve construction efficiency, but also have significant social and economic benefits.

References

-

M. G. M. Elipe and S. López-Querol, “Aeolian sands: characterization, options of improvement and possible employment in construction – The State-of-the-art,” Construction and Building Materials, Vol. 73, pp. 728–739, Dec. 2014, https://doi.org/10.1016/j.conbuildmat.2014.10.008

-

C. Lynda Amel, E.-H. Kadri, Y. Sebaibi, and H. Soualhi, “Dune sand and pumice impact on mechanical and thermal lightweight concrete properties,” Construction and Building Materials, Vol. 133, pp. 209–218, Feb. 2017, https://doi.org/10.1016/j.conbuildmat.2016.12.043

-

A. S. Al-Harthy, M. A. Halim, R. Taha, and K. S. Al-Jabri, “The properties of concrete made with fine dune sand,” Construction and Building Materials, Vol. 21, No. 8, pp. 1803–1808, Aug. 2007, https://doi.org/10.1016/j.conbuildmat.2006.05.053

-

Y. Li, H. Zhang, G. Liu, D. Hu, and X. Ma, “Multi-scale study on mechanical property and strength prediction of aeolian sand concrete,” Construction and Building Materials, Vol. 247, p. 118538, Jun. 2020, https://doi.org/10.1016/j.conbuildmat.2020.118538

-

J. Bai, Y. Zhao, J. Shi, and X. He, “Cross-scale study on the mechanical properties and frost resistance durability of aeolian sand concrete,” KSCE Journal of Civil Engineering, Vol. 25, No. 11, pp. 4386–4402, Jul. 2021, https://doi.org/10.1007/s12205-021-0395-0

-

W. H. Yi, X. Wang, J. Z. Zhang, W. Z. Liu, and X. N. Ma, “Experimental study on compaction characteristics and filling methods of subgrade aeolian sand for freeways in desert hinterland,” (in Chinese), Journal of Railway Science and Engineering, Vol. 18, No. 5, pp. 1177–1187, 2021, https://doi.org/10.19713/j.cnki.43-1423/u.t20210049

-

S. H. Zhang, Z. Y. Li, D. Peng, and Z. M. Chen, “Study of static property of aeolian sand used as roadbed,” (in Chinese), Rock and Soil Mechanics, No. 12, pp. 2511–2516, 2007, https://doi.org/10.16285/j.rsm.2007.12.010

-

R. L. Song and B. Y. Li, “Effect of aeolian sand content on mechanical properties and durability of cement stabilized graded macadam,” (in Chinese), Bulletin of the Chinese Ceramic Society, Vol. 39, No. 5, pp. 1421–1429, 2020, https://doi.org/10.16552/j.cnki.issn1001-1625.2020.05.009

-

G. S. Guo, Y. Zhang, S., and M. Du, “Grassroots-level shear strength experimental study of aeolian sand with cement,” (in Chinese), Science Technology and Engineering, Vol. 17, No. 15, pp. 322–326, 2017, https://doi.org/10.1007/s10064-023-03317-x.pdf

-

F. J. Luo, L. He, Z. Pan, W. H. Duan, X. L. Zhao, and F. Collins, “Effect of very fine particles on workability and strength of concrete made with dune sand,” Construction and Building Materials, Vol. 47, pp. 131–137, Oct. 2013, https://doi.org/10.1016/j.conbuildmat.2013.05.005

-

Y. G. Li, H. M. Zhang, G. X. Liu, D. W. Hu, and X. R. Li, “Mechanical properties and influence mechanism of aeolian sand concrete,” Journal of Building Materials, Vol. 23, No. 5, pp. 1212–1221, 2020.

About this article

The research was supported by the Transportation Science and Technology Project in Shaanxi Province (Nos. 21-50K, 23-91K).

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.