Abstract

In this paper, the influence of extreme service environment on the mechanical properties of C/C composites was analyzed. The mechanical tests for ordinary C/C samples and C/C samples with anti-oxidation coating were carried out under various high temperature and oxidation conditions. The properties of C/C composites with anti-oxidation coating were focused on. It was pointed out that the material properties were mainly affected by the coupling factors of high temperature, pre-stress, oxidation environment and duration. The influence laws of these factors for the high temperature strength of C/C composites with anti-oxidation coating were further discussed and summarized.

1. Introduction

In recent years, advanced composite structures, typically represented by C/C composites, have been used more and more in extreme environments [1]. Compared with the high-temperature alloy structure or the traditional heat-resistant layer and metal-bearing structure, C/C composites structure has obvious advantages of high property/weight ratio [2]. However, the structural design characteristics [3] and mechanical properties [4] of C/C composites are strongly dependent on the actual service environment.

Many researches have shown that C/C composites have excellent high-temperature mechanical properties under oxygen-free conditions [5], and their long-term service temperature is higher than 1650 ℃. However, the materials will be oxidized and damaged in high-temperature oxidation environment [6]. Currently the main solution is to adopt anti-oxidation coating [7], but the coating is affected by many factors and thus can only play a limited role [8]. Therefore, the adverse effect of high-temperature oxidation environment on the performance of C/C composites is a prominent problem exposed in engineering applications. Although there have been many academic literatures accumulated in this respect [9-11], due to the great differences in specific test conditions and the complexity of influencing factors, there is still a lack of experimental data for material with specific fabrication parameters and under particular service conditions in those literatures. The general conclusions given in the literature cannot be directly used as input for engineering application. It is still necessary to further carry out the actual performance test and deepen the understanding of theory and law based on the analysis of typical test results.

In order to simulate the practical application environment and obtain the effects of high temperature and oxidation on the mechanical properties of C/C composites, samples of ordinary C/C composites and C/C composites with anti-oxidation coating were prepared and their tensile properties were tested. The results show that the ordinary samples have a strong performance degradation due to oxidation at high temperature, while the samples with anti-oxidant coating are applicable. Therefore, the mechanical properties of C/C composites with anti-oxidation coating were focused in this paper. Based on the test results, expressive methods of material properties under the coupling factors of high temperature, pre-stress, oxidation and duration are put forward, and the effects of these different factors on material properties are summarized. The work in this paper enriches the basic performance data of C/C composites under high temperature oxidation conditions and improve the evaluation ability for the particular anti-oxidant coating, the summarized regular characteristics in which provide an effective reference for practical engineering applications.

2. Overview of experimental and theoretical analysis methods

In this research, different C/C composites specimens were prepared and the relative experiments were carried out. All the C/C composites specimens were made from 3 K carbon fiber orthogonal three-dimensional fabric, and the matrix is prepared by precursor infiltration pyrolysis (PIP) process. The material density is between 1.95 to 2.07 g/cm3. The obtained typical mechanical tensile samples and the used high temperature test equipment are shown in Fig. 1, which was completed in Harbin Institute of Technology. All the test pieces can be divided into two sorts: with surface anti-oxidant coating or ordinary (without anti-oxidant coating). The anti-oxidant coating on the sample surface is continuous SiC phase, which was deposited for many times and finally with an average thickness of about 80 μm. In order to eliminate the influence of error factors and data discreteness in test result, the dimensional accuracy of the specimen and the test conditions should be strictly controlled. In order to ensure the uniformity of high-temperature test time, it is necessary to use instantaneous transfer device during high-temperature test and ensure a stable heating rate of the furnace.

The description of the relevant test process for these samples is omitted in this paper. According to characteristic analysis of the completed test results, the performance evolution of C/C composites under the coupling conditions of high temperature, oxidation and loading pre-stress is put forward here, which should mainly consider oxidation damage and stress damage, as well as the acceleration characteristics of pre-stress on oxidation. As a preliminary result, it can be expressed by the following formula:

where ΔΩ represents the change of target performance, which is mainly characterized by the strength performance of the specimen. T is temperature, σ is pre-stress, χ is content of oxidizing atmosphere, t is action time, and f is some kind of action function. The experimental results show a feature that stress σ and time t exhibit the most obvious influence.

Fig. 1a) C/C composites samples with an anti-oxidation coating obtained by processing, b) ordinary sample and c) corresponding high-temperature test device

a)

b)

c)

3. Effect of pre-stress on mechanical properties of C/C composites with anti-oxidation coating at high temperature

The tensile tests of ordinary C/C composites samples and C/C composites samples with anti-oxidation coating at room temperature and high temperature were completed. All the test results show that the static load tension for the C/C composites has the most significant performance degradation in high temperature and oxidation environment, so the shear and bending moment load conditions can be conservatively referred to the tensile conditions in design. The ordinary C/C composites sample has a strong performance degradation due to oxidation at high temperature, and the results data are discrete strongly. Fig. 3(b) in the next section also shows the damage morphology of the test sample, indicating that this sort of ordinary C/C composites lack applicability in high temperature and oxidation environments. Therefore, in this section we focus on C/C composites with anti-oxidation coating.

According to the academic literature [8] and the experimental phenomena in this work, the influence of stress environment on mechanical properties is mainly realized by changing the microstructure of anti-oxidation coating on the surface of C/C composites, especially the microcrack width. When the crack broadens, more amounts of corrosive gases such as oxygen enter. Oppositely, when the amount of entering corrosive gases is more than the amount of gases consumed in the reaction, the damage mechanism of material changes from diffusion control to reaction control. The crack width has a controlling effect on the mechanical properties and life of the composites.

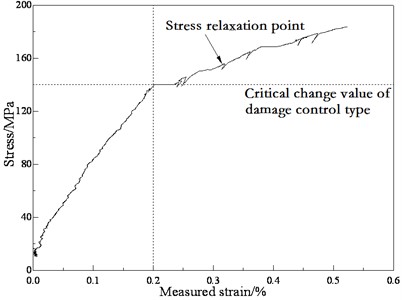

The test results confirmed that with different pre-stress levels the high temperature oxidation damage of C/C composites with anti-oxidation coating shows two types of characteristics: diffusion control and reaction control. In addition, using pre-stress level to characterize the critical transition between diffusion control and reaction control proposed in previous academic literature [12] is not suitable for the results in this paper. It is more reasonable to use the strain of materials to characterize the critical transition, the corresponding value of strain is ε=0.2 %. Fig. 2 shows the stress-strain curve of the high temperature test. It can be seen that when the critical point of strain is reached, the strain would change significantly and increase continuously when the external load (stress level) remains unchanged. This indicates that the load-bearing structure inside the material have changed significantly in nature, and the original part of the load-bearing structure (carbon fibers) lost the load-bearing capacity due to the property degradation after oxidation. With further continuous high temperature loading, the original bearing structure continues to fail, and the remaining fibers play a supplementary role, leading to a redistribution of internal stress. Since this process is randomly coupled, stress relaxation points constantly appear on the curve.

Fig. 2High temperature test stress-strain curve of C/C specimens with anti-oxidation coating

In the initial stage of stress-strain curve, the elastic modulus of the material is higher, and the load-bearing uniformity is obviously better than that in the later stage. In the later stage of reaction control, the residual load on carbon fibers have been significantly reduced, so the tensile modulus of material shows a continuous decline.

The influence of different factors on the mechanical properties of C/C composites with anti-oxidation coating at high temperature are studied. Through statistically analyzing the test results, it is considered that the influence of time t and pre-stress σ can be independent of each other in Eq. (1). Therefore, the engineering calculation formula for C/C composites with anti-oxidation coating based on Eq. (1) is proposed as follow. The available strength under high temperature and oxidation condition is ˉσb, its relationship with the strength under normal temperature σb is:

In the formula, f(t) is the special time term under high temperature environment, which can be decoupled from strain, and can be interpolated by test data under different high temperature duration conditions. It can be deduced from Eq. (2) as follows: under the same calibration time, when the strain ε produced by external load at high temperature satisfied ε≤0.2 %, the high temperature strength level decays to 80 % of strength at normal temperature; when the strain produced by external load at high temperature reaches 0.3 % or 0.5 %, the high temperature strength level decreases to 67 % or 32 % of the normal temperature strength.

4. Effects of anti-oxidant coating on mechanical properties of C/C at high temperature

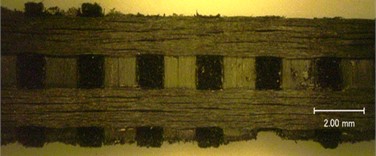

The experimental results show that C/C composites with or without anti-oxidation coating on the surface shows great difference on the high-temperature mechanical properties. In the uncoated state, oxidation damage at high temperature is completely controlled by the reaction. Fig. 3 shows the forms of the damaged samples with and without anti-oxidation coating after high temperature test. The shapes of the former are basically complete and have no obvious ablation thickness loss, while the latter has a serious decrease in ablation thickness. In addition, the mechanical properties degradation caused by high temperature oxidation of C/C composites without anti-oxidation coating is not equal to that caused by the loss of ablative mass or thickness, and the decrease of strength is much heavier than that caused by the loss of ablative thickness.

Fig. 3a) Comparison of morphology between C/C composites samples with anti-oxidation coating and b) ordinary C/C composites sample after failure

a)

b)

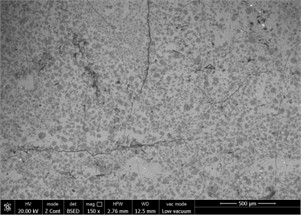

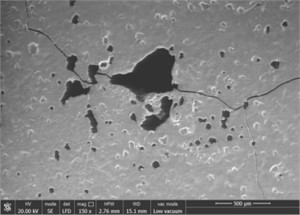

Fig. 4The comparison between the initial state a) of the anti-oxidation coating on the surface of C/C composites and the state b) after high temperature oxidation test

a)

b)

Taking a unified calibration time, the experimental data for C/C composites with and without anti-oxidation coating are compared. When ε, the strain produced by external load at high temperature, is less than or equal to 0.2 %, the available strength of C/C composites without anti-oxidation coating is about 50 % of the strength of C/C composite with anti-oxidation coating. When ε> 0.2 %, for both C/C composites with or without anti-oxidation coating, the oxidation damage is controlled by reaction, and 50 % of properties reduction is conservative.

It is obvious that the oxidation damage of C/C composites is greatly dependent on the active degree of oxidation atmosphere, but the related tests is very difficult. Fig. 4 compares the surface morphologies of anti-oxidation coating before and after high temperature oxidation test with strain ε less than 0.2 %.

5. Effect of high temperature and high temperature holding time on mechanical properties of C/C composites with anti-oxidation coating

As the experimental phenomena in this work shown, the influence mechanism of temperature on C/C composites with anti-oxidation coating is mainly concluded into two kinds. On the one hand, the increase of temperature can gradually heal the cracks and accelerate the formation of oxides on the coating surface, which would seal the cracks and reduce the inward diffusion of oxidizing gases in the external environment, thus reduce the loss of mechanical properties of C/C composites. On the other hand, with temperature increasing, the oxidation activity of carbon inside the composite material is improved, and the oxidation process is accelerated.

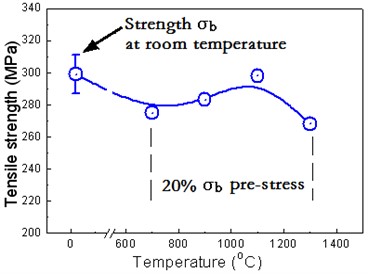

In this paper, the strength properties of C/C composites specimens with anti-oxidation coating after 20 % tensile strength pre-load and heat preservation for 2000 s were obtained at different temperatures. The test results are shown in Fig. 5, which also gives the performance test data at room temperature. There is enough test data only at room temperature, so the corresponding discrete statistics are given in this figure. It can be observed from Fig. 5 that a fluctuation of tensile strength value with temperature, which is comprehensively determined by two kinds of influencing mechanisms. As a consequence, the strength properties of the C/C composites specimens with anti-oxidation coating do not change significantly under different high temperature conditions in a certain range.

It can be considered that although the mechanical properties of C/C composites with anti-oxidation coating have been researched for a long time in the engineering field, above experimental data obtained independently in this paper still have unique regularity, which can provide effective reference for practical applications in similar environments in the future.

Fig. 5Strength of C/C composites specimens with anti-oxidation coating under different test conditions

6. Conclusions

In order to simulate the effect of service environment on the mechanical properties of C/C composites, coupling factors of high temperature, pre-stress, oxidation condition and duration should be considered, which result in a large number of test samples. The discrete characteristics of test results may have obvious influence on the regularity analysis, which should be paid attention to. Under high temperature and oxidation conditions, the mechanical properties of C/C composites decline most significantly under static load and tensile conditions. For the effect of anti-oxidation surface coating, the high temperature mechanical property damage of C/C composites can be concluded into two different mechanisms: diffusion control and reaction control. It is very important to further obtain relevant experimental data and verify the laws obtained in this paper for subsequent practical application.

References

-

S. Y. Du, “Advanced composite materials and aerospace engineering,” Acta Materiae Compositae Sinica, Vol. 24, No. 1, pp. 1–12, 2007, https://doi.org/10.13801/j.cnki.fhclxb.2007.01.001

-

C. Barile, C. Casavola, and F. de Cillis, “Mechanical comparison of new composite materials for aerospace applications,” Composites Part B: Engineering, Vol. 162, No. 4, pp. 122–128, Apr. 2019, https://doi.org/10.1016/j.compositesb.2018.10.101

-

J. H. Zhang, Z. M. Sheng, and J. T. Sun, Composite Material Structure Design Guidelines for Missiles and Rockets. Beijing: China Astronautic Publishing House, 1999.

-

G. L. Shen and G. K. Hu, Mechanics of Composite Materials. Beijing: Tsinghua University Press, 2006.

-

S.-S. Tzeng and W.-C. Lin, “Mechanical behavior of two-dimensional carbon/carbon composites with interfacial carbon layers,” Carbon, Vol. 37, No. 12, pp. 2011–2019, 1999, https://doi.org/10.1016/s0008-6223(99)00074-3

-

K. Fujimoto, T. Shioya, and K. Satoh, “Degradation of carbon-based materials due to impact of high-energy atomic oxygen,” International Journal of Impact Engineering, Vol. 28, No. 1, pp. 1–11, Jan. 2003, https://doi.org/10.1016/s0734-743x(02)00057-x

-

L. M. Manocha, “High performance carbon-carbon composites,” Sadhana, Vol. 28, No. 1-2, pp. 349–358, Feb. 2003, https://doi.org/10.1007/bf02717143

-

Y. N. Zhao, “High-temperature oxidation models and thermo-mechanical-oxygenic coupling behavior studies for advanced thermo-structure materials,” Peking University, Beijing, 2020.

-

L. B. Zhao and J. F. Xu, Advanced Composite Connection Structure Analysis Method. Beijing: Beijing University of Aeronautics and Astronautics Press, 2015.

-

S. D. Green, A. C. Long, B. S. F. El Said, and S. R. Hallett, “Numerical modelling of 3D woven preform deformations,” Composite Structures, Vol. 108, pp. 747–756, Feb. 2014, https://doi.org/10.1016/j.compstruct.2013.10.015

-

J. Liu, T. Kan, J. Lou, L. Xiang, X. Zhu, and Y. Tang, “Localized damage response of carbon fiber reinforced polymer composite sandwich panel after thermal exposure,” Polymer Testing, Vol. 50, pp. 33–40, Apr. 2016, https://doi.org/10.1016/j.polymertesting.2015.12.006

-

X. Dong, X. Fang, X. Feng, and K.-C. Hwang, “Diffusion and stress coupling effect during oxidation at high temperature,” Journal of the American Ceramic Society, Vol. 96, No. 1, pp. 44–46, Jan. 2013, https://doi.org/10.1111/jace.12105

About this article

The present work was supported by National Natural Science Foundation of China (No. U20B2002).

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.