Abstract

The construction of a structure is prohibitively expensive due to high material and labour expenses. Still, the production of cement, which is the most widely used binding substance in construction, results in the emission of a large amount of CO2 into the atmosphere. It has only recently been discovered that Pakistan is short of approximately 9 million residential constructions. Thus, there is a great need for cost-effective and energy-efficient masonry construction because of economic and environmental concerns. Rat-trap masonry bond creates a cavity in the wall, which serves as both thermal insulation and a cost-saving measure. Because of the inherent property of rat-trap masonry bond, a cavity is formed in the wall, which not only serves as thermal insulation for the interior but is also cost-effective It has been observed that approximately 26.11 % of the total construction cost, comprising of labor and material, can be curtailed by adopting the rat-trap bonding technique. Rat-trap bond construction is recognized as a greener and more sustainable alternative to conventional brick bonds. A comparative study of the structural behavior of the rat-trap and conventionally used English bond has been conducted. 72 prisms of rat-trap bond and English bond from three sources of bricks were tested under compression load at the ages of 28 and 56 days. The same number of prisms were tested under diagonal tension load at both ages. 18 triplet prisms from all sources of bricks were tested for shear bond strength without lateral load, whereas 5 triplet prisms from every brick source were tested with a set of lateral pre-compression loading of 29 psi, 87 psi, and 145 psi. The results show that the rat-trap bond has much higher compressive and shear strengths than the English bond.

1. Introduction

Brick masonry structures are as old as civilizations. Masonry has been the most essential and common construction material ever since the beginning of mankind’s history. It has been widely used in a variety of forms in the past few thousand years: from the Tower of Babylon, which should have touched the sky if it had been completed, to the Great Wall of China, which is the only artificial structure visible from the Moon [1]. Today, approximately over half of the world’s population lives in brick masonry houses [2]. However, with the increasing population growth, the necessity of house buildings has become much higher, but at the same rate, their construction is also becoming more challenging due to economic reasons. In developing countries, the rate of population growth is going up by a lot, but most families are in the middle class and earn less than the average [3]. Providing shelter, particularly to the middle and lower-middle classes, has become a major challenge for developing countries [4, 5]. By 2030 [6, 7], an estimated 1 billion people will be homeless. estimated 2.8 billion people would need to be accommodated with a healthy living atmosphere and basic urban facilities. A deficit of approximately 9 million residential buildings has been documented only in Pakistan [8]. The construction of masonry buildings is well known and commonly used in both rural and urban areas globally [9-10]. However, low-cost housing is a novel technique to minimize construction costs and optimize operating costs during building serviceability, providing a reasonable living for the low-income class [11-16].

Low-cost housing is an innovative approach to lower construction costs. It optimizes running costs during the building's life cycle, providing feasible accommodation for low-income groups to buy or rent [14-19]. Optimal construction solutions are implemented for low-cost housing schemes. People in different parts of the world use different masonry techniques to build homes and buildings, and more research is being planned to get there. Several possible combinations developed by nature, geometry, and arrangement in masonry units result in the difference of masonry strength. However, the mechanical behavior of various masonry types typically has a common characteristic of minimum tensile strength [17]. Generally, brick masonry construction involves various kinds of bonds, like English, Flemish, Header, and Stretcher bonds. The type of bond has a significant effect on the volume of mortar. Since the strength of mortar is less than that of brick, the masonry with the more excellent strength bricks and the lower strength mortar results in a lower strength in total if a large amount of mortar is used due to masonry bond type [18]. Overall, the shear and tensile bond strengths of masonry walls are very low. Subsequently, failure occurs across the masonry unit-mortar interface [19]. Regardless of the masonry bond, cement is the most widely used binding material in masonry technology. Whereas cement production causes a significant emission of greenhouse gases, mainly CO2 [20], the production of each tonne of cement emits approximately the same amount of CO2 into the atmosphere [21]. Cement manufacturing releases more than 13 billion tons of CO2 annually and contributes almost 5-7 % of total global CO2. This escalation causes a pronounced threat to the environment because of the enormous CO2 emissions into the atmosphere [22]. When such a large amount of CO2 is released into the air, it could cause serious environmental problems like global warming [23-26].

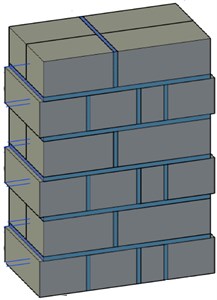

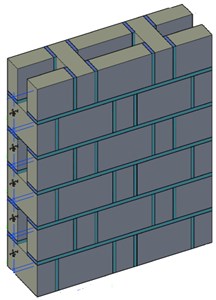

In addition to prohibitive construction, all kinds of bonds, including English bonds, Flemish bonds, Header bonds, Stretcher bonds, etc. are more or less equal contributors to global warming due to the utilization of large amounts of mortar. Hence, for economic and environmental reasons, there is a pressing need for cost-effective and energy-efficient masonry structures. However, putting together these two characteristics unanimously is a significant challenge in the long term. Among all the types of bonds used in brick masonry construction, the rat-trap bond is of recent origin. The rat-trap bond masonry technique was first introduced by Laurie Baker in 1970 [27]. He was commended for his outstanding work on cost-effective and energy-efficient structure designs [28]. The rat-trap bond is the best suitable construction technique for building up to two stories without reinforcement [29]. The rat-trap bond is a special kind of masonry technique that is cost-effective compared to conventional construction. It follows a brick laying pattern so that the width of a brick is made the height and the other way around, like that rowlock and shiner, are visible on the surface of masonry [30]. A typical cross-section of the Rat-trap bond is shown in Figs. 1, 2, and 3. This arrangement of bricklaying produces a cavity inside the wall. In this fashion, for a 9” thick wall, a 3” cavity is built inside. Because of the cavity, a lot of money can be saved on building materials like brick and cement [31].

It is important to get an understanding of heat transfer through the wall. Convection, conduction, and radiation are many heat transfer processes [32, 33], following the principle of heat flow from hot to cold. The heat is conducted inside the room in the daytime and flows back in the evening. But the air medium created in the cavity inside the Red-trap bond wall works as an insulator, decreasing indoor temperature, unlike other masonry bond types. This keeps the interiors cool in the summer and warm in the winter [34]. Therefore, rat-trap bond construction is recognized as a greener and more sustainable alternative to conventional wall masonry. Nilanjan et al. [35] studied ecological and economical construction techniques like compressed stabilized earth block, filler slab, bamboo reinforced concrete, and Rat-trap masonry bond. They found the advantages of the rat-trap bond like good thermal insulation, cost curtailing, plastering not necessary, less material required, and foremost, the strength of the Rat-trap bond matches that of the conventional bond wall. It has been observed that approximately 26 % to 28 % of the total construction cost, comprising labor and material, can be curtailed by adopting the Rat-trap bond technique compared to the conventional construction methods for masonry [36-37]. After conducting an in-depth study of the available literature, it was discovered that the performance of the Rat-trap bond receives relatively little attention in the descriptions that are provided. As a result, the purpose of this study is to conduct an analytical comparison of the mechanical properties of rat-trap bond masonry and the most common type of English bond masonry. Some of the tests that will be conducted include the diagonal tension test, the triple test for shear strength, and the compressive strength test.

2. Materials selection

2.1. Brick

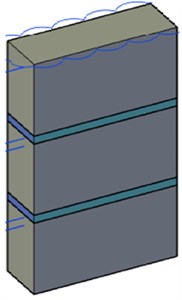

They obtained first-class bricks from three different kilns, and determined their dimensions and compressive strengths. The average size measured from brick samples was 8.9” × 4.5” × 3”. The compressive strength of three representatives from each source was determined under the specifications of ASTM C67 [38], as shown in Figs. 1, 2, and 3. These compressive strengths are reported in Table 1.

Table 1Compressive strength of brick samples from each source

Sr. No. | Source | Trade mark | Compressive strength (psi) |

1. | 1 | F-16 | 520 |

2. | 565 | ||

3. | 533 | ||

4. | 2 | 7-Up | 866 |

5. | 841 | ||

6. | 814 | ||

7. | 3 | MB | 565 |

8. | 551 | ||

9. | 518 | ||

Average | 651.55 | ||

Fig. 1Schematic diagram for English bond

Fig. 2Schematic diagram for Chinese bond

Fig. 3Triplet- test specimen

2.2. Mortar

Cement is used as a binding material in mortar due to its being the most commonly used cementitious material in construction and being easily available. The mixed design of mortar considered was 1:3. Three 50 × 50 × 50 mm3 size cubes from the same mortar were cast and tested after 28 days of water curing under the specifications of ASTM C109 [39], as shown in Fig. 4 and 5. Compressive strengths of all mortar specimens are reported in Table 2.

Table 2Compressive strength of mortar specimens

Sr. No. | Mortar sample | 7 days compressive strength (psi) |

1. | Sample 1 | 3405 |

2. | Sample 2 | 3480 |

3. | Sample 3 | 3440 |

Average | 3441.67 |

Fig. 4Cement blocks ready for compressive strength test

Fig. 5Cement blocks ready for compressive strength test

3. Experimental program

In this paper, English bond masonry is compared with the Rat-trap bond masonry, and for this purpose, a few experiments are performed on both types of masonry and results are compared. Compressive strength and diagonal tension tests were carried out on rat-trap bond masonry prism and conventional English bond masonry prism in accordance with ASTM C 1314-03a [40] and ASTM specification E519 [41], respectively. The Triplet test for shear strength was performed on bricks obtained from all three sources under EN 1052-3:2002 (E) specifications.

3.1. English bond masonry prism

In English bond masonry, header and stretcher courses are laid on an alternate basis just as headers are laid centered on stretchers, and every alternate course is vertically aligned. A total of 72 two-wythes thick English bond masonry prisms with 24 prisms from each brick source were prepared in such a way that three headers with one quoin closer and two stretchers were laid on alternate courses. Among these prism specimens, each half was designated for compression strength testing and diagonal tension testing at 28 days and 56 days after water curing. The curing was done with wet jute bags in an open area at 25 °C.

The purpose of the compressive strength test of masonry prisms is to verify that materials used in masonry construction meet the specified compressive strength. This test provides a means of evaluating the compressive strength of in-place masonry by comparing it with testing of masonry prisms prepared with the same material characteristics as that of in-place masonry. The average dimension of the prisms was 16.63” × 9” × 19.825” with slight variation due to brick layout. The mean height to thickness ratio (h/t) was 2.25. Among 36 prisms nominated for a compressive strength test, 18 prisms were tested at 28 days’ water curing and the rest were tested at 56 days’ curing using UTM. Before installing the prisms in the test machine, proper capping was made on all specimens in accordance with practice C1552. The load was applied on the prism at the rate of specimens as shown in Figure 6 and 7. The correction factor against h/t of each specimen was calculated by linear interpolation between the values given in ASTM C1314 [40].

Fig. 6English bond brick column being tested for compressive strength

Fig. 7Crushed English-bond bricks column after compressive strength test

A diagonal tension test was carried out on 18 prisms at the age of 28 days and the remaining 18 prisms at 56 days water curing using UTM. The objective of this test is to measure the shear strength of a masonry prism. The mean dimension of the prisms was 28.75” × 30” × 9”, with a minor difference due to bricks orientation. Two steel loading shoes were used to apply machine load to the prism in such a way that the upper and lower loading shoes were positioned so as to be centered on the respective bearing surfaces of the machine. The length of the bearing of the shoe was 6”. The prism specimens were installed in a centered and plumb position in a bed of gypsum capping material placed in the lower loading shoe. The load was applied on the prism at the uniform rate of specimens as shown in Fig. 7. The shear strength of all the prisms is calculated from the following Eq. (1), where shear strength , applied load, area of Specimens, , numbers:

Fig. 8Testing scheme overview of English brick-bond column using UTM

Fig. 9Crushed English-bond bricks column after compressive strength test

3.2. Rat-trap bond masonry prism

The Rat-trap bond is a modular type of masonry technique that is cost-effective and environmentally friendly as compared to conventional construction due to less usage of fewer materials. It follows the brick laying pattern in such a way that, rowlock and shiner are visible on the surface of the masonry. In this kind of bond, the thickness of wall can never be less than the length of the stretcher. 72 Rat-trap bond masonry prisms with the same number of bricks from each source were made. Each half of one of these prisms was chosen for a compressive strength test and a diagonal tension test at 28 and 56 days. Rowlock and shiner are alternately placed in this type of bond to create a 3-inch cavity inside the bond. In this kind of bond, rowlocks are laid centered on shiners and every alternate course is vertically aligned. All of the specimens were water cured in a jute bag at a temperature of 25 °C. All the specimens were water cured with the help of jute bag at temperature 25 °C. The average size of the prisms for the compressive strength test was 15.75” × 9” × 24” and the height to thickness ratio was 2.70. Proper capping was done in accordance with practice C1552 before placing the prisms in UTM. The load was applied on specimens at the uniform rate of AAA as shown in Fig. 10. The correction factor against h/t of each specimen was calculated by linear interpolation between the values given in ASTM C1314. A diagonal tension test was conducted on the remaining 36 prisms at the ages of 28 and 56 days using UTM with an average size of 28.5” × 28.5” × 9”. The specimens were placed on the machine in a centered and plumb position.

Fig. 10Diagonal test Sample arrangement in process

Fig. 11Vertical alignment being tested

3.3. Triplet tests for shear strength

A triplet test was performed on the specimens from all brick sources with the purpose of determining the shear bond strength of bed joints in masonry. The test was performed with and without lateral pre-compression load under the specifications of EN 1052-3:2002 [42]. According to the code, three bricks are bonded together with 10 mm mortar. All the specimens were subjected to water curing for 28 days. Before applying load, the end units of each specimen was supported with a 12 mm thick piece of steel to ensure good contact. A total of 15 specimens with uniform representation from all brick sources were tested without pre-compression load under UTM as shown in Fig. 12 and 13. The shear strength of specimens is calculated from the following Eq. (2), Shear strength , applied load , , area of specimens:

whereas, as shown in Fig. 10, 15 specimens from each brick source were tested with lateral pre-compression loads of 0.2, 0.6, and 1.0 MPa under the same machine. Shear strength for lateral pre-compressed specimens was calculated after finding the pre-compressive load from the abovementioned equation 3. Pre-compressive , applied load , , area of specimens:

Fig. 12Pressure application on Triplet test sample

Fig. 13Triplet testing arrangement and load application

4. Results and discussions

4.1. Compressive strength test

As per the brick layout pattern, the mean contact area between bricks is 738 in2 in a 3288 in3 volume of rat-trap bond prism depicting the contact area to volume ratio as 0.22. The mean brick contact area in the English bond is 43 % greater in 23 % less volume than that of rat-trap bond. The average contact area is 1296 in2 in a 2677 in3 prism of English bond, illustrating contact area to volume ratio of 0.48. The comparison of both bonds, with a slightly difference in volumes due to the bricks’ orientation and layout, evidently describes t-effectiveness owing to the lesser utilization of materials and labor in the rat-trap bond.

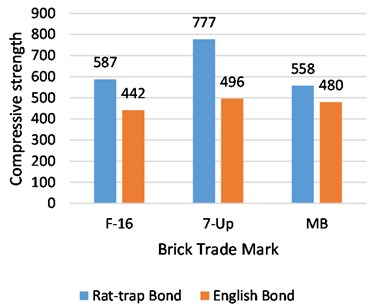

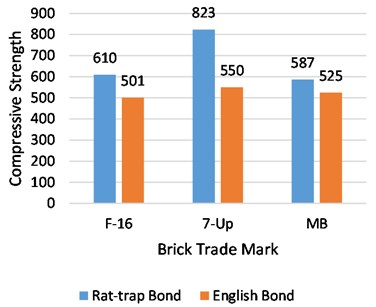

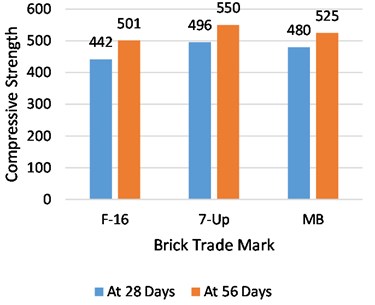

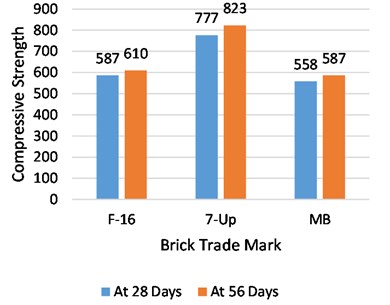

Rat-trap and English bond prisms were tested against compressive strength loads at the ages of 28 and 56 days. From the extensive experimentation, comprising six specimens from each brick source for every test, a tremendous difference was observed between the compressive strengths of both bonds at all ages. At 28 and 56 days, the compressive strength of the F-16 trademark rat-trap bond was found to be 25 % and 18 % higher than that of the English bond, respectively. Similarly, the strength of the rat-trap bond from 7-up bricks was 40 % and 29 % greater than that of other bonds at 28 and 56 days, respectively. In the same way, 14 % and 11 % larger strengths were found in Rat-trap bond prisms than in English bond at the age of 28 and 56 days respectively. The strength gained after 28 days of water curing was very slow in the rat-trap bond and did not put much difference in ultimate strength at the age of 56 days. The strength increase in the rat-trap prisms with F-16, 7-Up, and MB bricks was only 4 %, 6 %, and 5 %, respectively. Whereas English bond prisms showed a greater difference in strength gain after 28 days’ water curing than the other bonds. The strength rises in this type of bond with F-16, 7-Up and MB bricks was observed 13 %, 11 % and 9 % respectively. The leading reason for the higher rate of strength increase in English bond after 28 days is probably the utilization of a larger quantum of mortar in greater contact areas between bricks, which gets more strength with further water curing. A graphical comparison between average compressive strength at the ages of 28 and 56 days and strength increase after 28 days for both types of bonds is drawn in Fig. 14.

The failure of bricks was observed in most of the English bond specimens when subjected to a compressive strength load. Whereas the failure behavior of rat-trap bond prisms was totally different. Due to less contact area between bricks and different bricks layout, most of the failure occurred in mortar rather than bricks in rat-trap specimens.

4.2. Diagonal tension test

Similar to the attributes of prisms for compressive strength, the brick contact area to prism volume ratio for both kinds of bonds differs considerably. The mean brick contact area in the 7179 in 3 volume of Rat-trap bond is 1548 in 2 portraying the contact area to prism volume ratio of 0.21. The contact area in this kind of bond is 120 % less in only 5.4 % greater volume than that of an English bond, in which the mean contact area in 6788 in 3 volume of prism is 3402 in 2 representing a contact area to volume ratio of 0.50. Although, the sizes of specimens prepared for compressive strength and diagonal tension tests are different, the contact area to prism volume ratios are almost the same. From the geometry evaluation of prisms, much less material is used in the rat-trap bond as compared to the conventional bond, making it more economical.

Fig. 14Average compressive strength of English and rat-trap bond at the age of 28 and 56 days

a) Compressive strength at 28 days

b) Compressive strength at 56 days

c) Compressive strength of English bond

d) Compressive strength of Rat-trap Bond

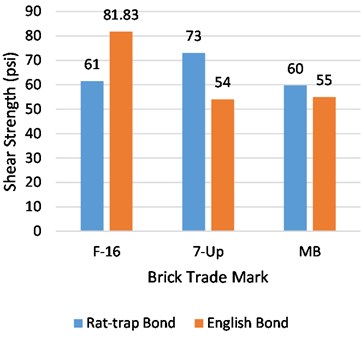

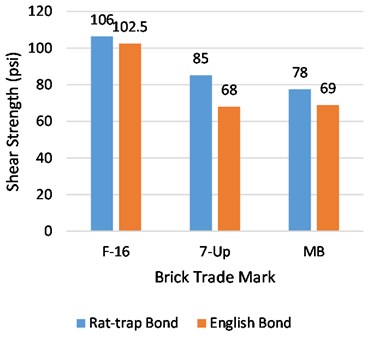

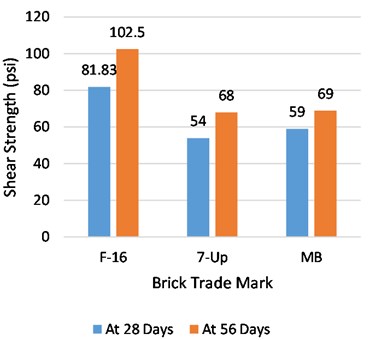

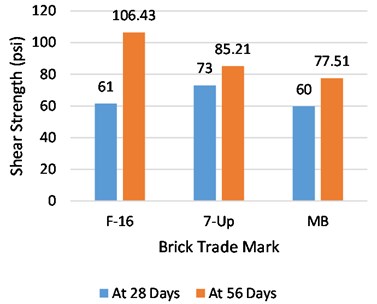

18 specimens were tested against a diagonal tension test for each type of bond at a single age with six specimens from each brick source. There was found to be a considerable difference in the shear strength of both kinds of bonds at the ages of 28 and 56 days. For brick trademark F-16, the shear strength of rat-trap was observed to be 33 % less than that of English bond at the age of 28 days, whereas it showed a 4 % greater value of strength than that of English bond at the age of 56 days. On the other hand, rat-trap prisms made from bricks 7-Up and MB resulted in 26 % and 8 % at the age of 28 days and 20 % and 11 % at the age of 56 days respectively. The increment pattern in strength due to additional water curing after 28 days to 56 days, was not found to be very smooth for both types of bonds. The shear strength increment in Rat-trap bond prisms with F-16, 7-Up and MB bricks was 73 %, 17 %, and 30%, respectively. English bond, on the other hand, produced nearly identical shear strengths for F-16, 7-Up, and MB brick specimens, namely 25 %, 26 %, and 17 %, respectively. A graphical comparison between average shear strength at the ages of 28 and 56 days and strength increment after 28 days for both types of bonds is drawn in Fig. 15.

The failure of bricks was observed in most of the English bond specimens when subjected to diagonal tension load. Whereas, the failure behavior of rat-trap bond prisms was totally different. Due to less contact area between brick layouts and different bricks layout, most of the failure occurred in mortar rather than bricks in rat-trap specimens.

Fig. 15Average shear strength of English and Rat-trap bond at the age of 28 and 56 days

a) Shear strength at 28 days

b) Shear strength at 56 days

c) Shear strength of English bond

d) Shear strength of Rat-trap bond

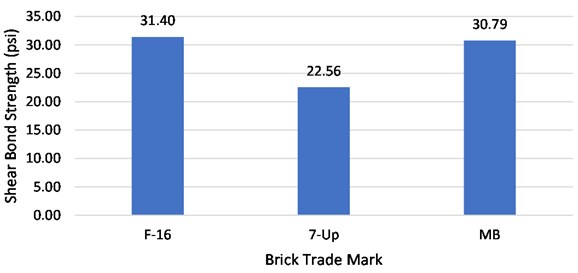

4.3. Triplet test for shear bond strength

Two types of loading arrangements were made for the triplet test of prisms. One arrangement was without lateral pre-compression load, for which 18 prisms with six specimens from each brick source were tested. The average shear bond strength for prisms made of the F-16, 7-Up and MB bricks was 22.56 psi, 31.40 psi, and 30.79 psi, respectively, with an overall mean value of 26.46 psi. For one prism of F-16 brick trademark, shear strength obtained at 78.99 psi was ignored due to being an outlier. The characteristic shear strength based on the mean value is calculated as 21.17 psi, whereas the same strength based on the lowest value is obtained as 11.50 psi. Fig. 16 shows the graphical presentation of the average shear strength of all brick sources.

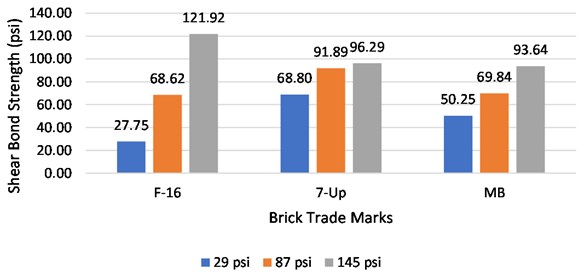

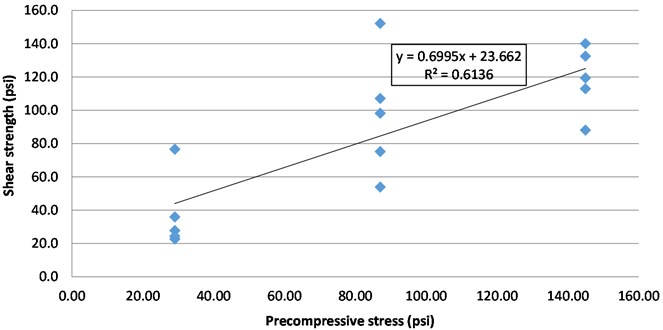

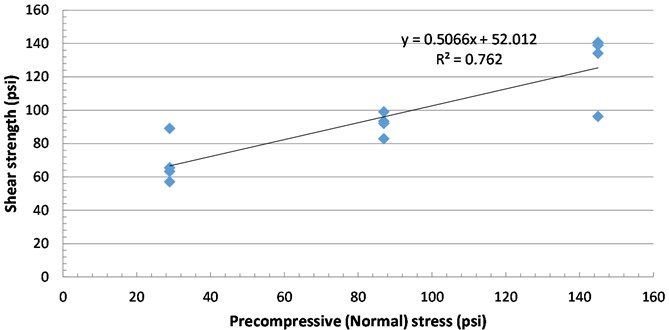

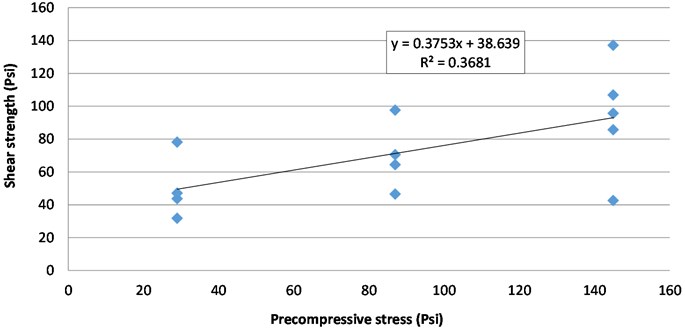

The second arrangement was made by applying 29 psi, 87 psi, and 145 psi, lateral pre-compression loads, with each set of loads for five specimens from every brick source. For F-16 brick prism, the shear strengths obtained against 29 psi, 87 psi and 145 psi lateral pre-compression loads are 27.73 psi, 68.62 psi, and 121.92 psi, respectively. The strength of 76.02 psi obtained for a specimen subjected to 87 psi lateral load, was ignored due to unit splitting failure occurrence. The shear strengths determined against 29 psi, 87 psi, and 145 psi lateral load for the 7-Up brick prism are 68.80 psi, 91.89 psi, and 96.29 psi, respectively. For this also, two values of strengths, 147.76 psi, and 87.91 psi, were ignored because of unit splitting failure. However, for MB brick specimens, the shear strengths found against 29 psi, 87 psi and 145 psi lateral load are 50.25 psi, 69.84 psi, and 90.33 psi, respectively. For this series of tests, the values of strengths of 34.02 psi and 38.40 psi were ignored owing to unit splitting failure. Linear regression analyses between shear strength and lateral pre-compressive strength for all kinds of bricks prisms are carried out and shown in Fig. 17 and 18.

Fig. 16Average shear bond strength of all brick trade marks without precompression load

Fig. 17Average shear bond strength of all brick trade marks with precompression load

Fig. 18Leading characteristics of shear strength for all types of bricks prisms

a) Shear strength vs precompressive stress for F-16 Bricks. = Mean initial Shear strength (psi) = 21.7; = 0.8×= Characteristic initial sh. Strength (psi) = 17.12; Angle of internal friction () = 0.72; Characteristic angle of internal friction = = 0.01

b) Shear strength vs precompressive stress for 7-Up bricks. = Mean initial Shear strength (psi) = 57.16; = 0.8× = Characteristic initial sh. Strength (psi) = 45.73; Angle of internal friction () = 0.4; Characteristic angle of internal friction = = 0.006

c) Shear strength vs precompressive stress for MB-Bricks. = Mean initial Shear strength (psi) = 40.07; = 0.8× = Characteristic initial sh. Strength (psi) = 32.06; Angle of internal friction () = 0.345; Characteristic angle of internal friction = = 0.005

5. Conclusions

In this paper, an attempt has been made to investigate the characteristic strength of the rat-trap masonry bond in comparison with the conventionally used English bond. To study the structural behavior of both types of masonry bonds, each set of 18 prisms, with 6 specimens from all sources of brick, were tested for compressive strength and shear strength at the ages of 28 and 56 days. Furthermore, 18 triplet prisms were tested for shear bond strength without lateral load, and five triplet prisms from every brick source were tested with a set of lateral pre-compression loading of 29 psi, 87 psi, and 145 psi. The key conclusions drawn from the current study are as follows:

1) The mean bricks contact area in the English bond prism prepared for compressive strength was 43 % higher with 23 % lesser volume than that of the rat trap bond, making the rat-trap bond more economical.

2) The compressive and shear strength of rat-trap bond prisms made from all kinds of bricks have been found much higher than those of conventionally used English bond at both the ages 28 and 56 days.

3) The strength gained with additional curing after 28 days was observed to be higher in English bonds as compared to rat-trap bond prisms.

4) Most of the failure happened in the bricks, but most of the failure in rat-trap bond specimens happened in the mortar because there were fewer places where bricks touched each other.

5) The shear bond strength determined from all kinds of brick prisms was near to each other with a mean value of 26.46 psi.

6) The shear bond strength was observed to increase with the increase of lateral pre-compressive load in the case of all types of brick prisms.

References

-

M. Tomaževič, Earthquake-Resistant Design of Masonry Buildings. World Scientific, 1999.

-

H. Guillaud, “Characterization of earthen materials,” Terra Literature Review, 2008.

-

Homi Kharas, “The unprecedented expansion of the global middle class: An update,” 2017.

-

C. Average, “Low income housing problems and low-income housing solutions: opportunities and challenges in Bulawayo,” Journal of Housing and the Built Environment, Vol. 34, No. 3, pp. 927–938, Sep. 2019, https://doi.org/10.1007/s10901-019-09676-w

-

W. Smit, “Urban governance in Africa: an overview,” International Development Policy – Revue Internationale de Politique de Développement, No. 10, pp. 55–77, Sep. 2018.

-

W. A. V. Clark, “Human migration,” Regional Research Institute, West Virginia University, 2020.

-

J. O. Iheme, “Factors for the implementation of affordable federal public housing policies in south-south region of Nigeria,” University of Salford, Oct. 2017.

-

Azra Jabeen, Huang Xi Sheng, and Muhammad Aamir, “Housing crises in Pakistan: review of population growth and deficiencies in housing laws and policies,” International Journal of Sciences: Basic and Applied Research (IJSBAR), Vol. 24, No. 3, pp. 323–347, Oct. 2015.

-

J. Ortega, G. Vasconcelos, H. Rodrigues, and M. Correia, “A vulnerability index formulation for the seismic vulnerability assessment of vernacular architecture,” Engineering Structures, Vol. 197, p. 109381, Oct. 2019, https://doi.org/10.1016/j.engstruct.2019.109381

-

R. Vicente, T. Ferreira, and R. Maio, “Seismic risk at the urban scale: assessment, mapping and planning,” Procedia Economics and Finance, Vol. 18, pp. 71–80, 2014, https://doi.org/10.1016/s2212-5671(14)00915-0

-

C. Cai, Q. Wu, P. Song, H. Zhou, M. Akbar, and S. Ma, “Study on diffusion of oxygen in coral concrete under different preloads,” Construction and Building Materials, Vol. 319, p. 126147, Feb. 2022, https://doi.org/10.1016/j.conbuildmat.2021.126147

-

A. I. Saidu and C. Yeom, “Success criteria evaluation for a sustainable and affordable housing model: a case for improving household welfare in Nigeria Cities,” Sustainability, Vol. 12, No. 2, p. 656, Jan. 2020, https://doi.org/10.3390/su12020656

-

G. Wijburg, M. B. Aalbers, and S. Heeg, “The financialisation of rental housing 2.0: Releasing housing into the privatised mainstream of capital accumulation,” Antipode, Vol. 50, No. 4, pp. 1098–1119, 2018.

-

Q. Zhong, A. Karner, M. Kuby, and A. Golub, “A multiobjective optimization model for locating affordable housing investments while maximizing accessibility to jobs by public transportation,” Environment and Planning B: Urban Analytics and City Science, Vol. 46, No. 3, pp. 490–510, Mar. 2019, https://doi.org/10.1177/2399808317719708

-

R. I. Stone, “The housing challenges of low-income older adults and the role of federal policy,” Journal of Aging and Social Policy, Vol. 30, No. 3-4, pp. 227–243, Aug. 2018, https://doi.org/10.1080/08959420.2018.1462679

-

P. Huali, A.-A. Adedamola, M. Akbar, O. Guoqiang, and A. Amin, “The seismic analysis and performance of steel frame with additional low-yield-point steel dampers,” Journal of Vibroengineering, Vol. 23, No. 3, pp. 647–674, May 2021, https://doi.org/10.21595/jve.2020.21531

-

Z. Pooranian, J. Abawajy, V. P., and M. Conti, “Scheduling distributed energy resource operation and daily power consumption for a smart building to optimize economic and environmental parameters,” Energies, Vol. 11, No. 6, p. 1348, May 2018, https://doi.org/10.3390/en11061348

-

R. Adhikari, P. Jha, D. Gautam, and G. Fabbrocino, “Seismic strengthening of the Bagh Durbar heritage building in Kathmandu following the Gorkha earthquake sequence,” Buildings, Vol. 9, No. 5, p. 128, May 2019, https://doi.org/10.3390/buildings9050128

-

T. Taguchi and C. Cuadra, “Influence of bond types on brick masonry strength,” in 15th World Congress on Advances in Structural Engineering and Mechanics (ASEM15), 2015.

-

D. Gautam, H. Rodrigues, K. K. Bhetwal, P. Neupane, and Y. Sanada, “Common structural and construction deficiencies of Nepalese buildings,” Innovative Infrastructure Solutions, Vol. 1, No. 1, pp. 1–18, Dec. 2016, https://doi.org/10.1007/s41062-016-0001-3

-

P. K. Mehta, “Greening of the concrete industry for sustainable development,” Concrete International, Vol. 24, No. 7, pp. 23–28, Jul. 2002.

-

E. Worrell, L. Price, N. Martin, C. Hendriks, and L. O. Meida, “Carbon dioxide emissions from the global cement industry,” Annual Review of Energy and the Environment, Vol. 26, pp. 303–329, 2001.

-

C. K. Madheswaran, G. Gnanasundar, and N. Gopalakrishnan, “Effect of molarity in geopolymer concrete,” International Journal of Civil Engineering, Vol. 4, No. 2, pp. 106–115, 2013.

-

I. C. Change, The Scientific Basis. Cambridge: Cambridge University Press, 2001.

-

Mohammed Binhussain, “Design, processing and characterization of fly ash-based geopolymers for lightweight concrete application,” Revista de Chimie, Vol. 64, No. 4, pp. 382–387, 2013.

-

E. Worrell, D. Jager, K. Blok, and P. Riemer, “Emission reduction of greenhouse gases from the cement industry,” in Proceedings of the 4th International Conference on Greenhouse Gas Control Technologies, pp. 939–944, 2003.

-

E. Worrell, D. Jager, K. Blok, and P. Riemer, “Emission reduction of greenhouse gases from the cement industry,” Report PH3/7, IEA Greenh, Gas R&D Program, Cheltenham, United Kingdom, 2003.

-

A. Joshi et al., “Rat Trap Bond Masonry,” International Journal of Advanced Research in Science, Engineering and Technology, Vol. 6, No. 2, pp. 467–481, 2017.

-

A. K. Marunmale and A. C. Attar, “Designing, developing and testing of cellular lightweight concrete brick (CLC) wall built in rat-trap bond,” Current Trends in Technology and Sciences, Vol. 3, No. 4, pp. 331–336, 2014.

-

N. Sengupta, “Use of cost-effective construction technologies in India to mitigate climate change,” Current Science, Vol. 94, No. 1, pp. 38–43, 2008.

-

S. Sinha, S. Mishra, P. Kumar, and S. Saurabh, “Sustainable low-cost housing using cost effective construction technology “Rat Trap Bond Masonry” and “Filler Roof Slab” in Bihar,” International Journal of Engineering Research and Technology, Vol. 13, No. 7, p. 1780, Jul. 2020, https://doi.org/10.37624/ijert/13.7.2020.1780-1785

-

C. G. Vikas, “Together to improve housing,” Appropriate Technology, Vol. 30, No. 4, 2021.

-

B. A. Price and T. F. Smith, “Thermal response of composite building envelopes accounting for thermal radiation,” Energy Conversion and Management, Vol. 36, No. 1, pp. 23–33, Jan. 1995, https://doi.org/10.1016/0196-8904(94)00037-z

-

M. Akbar et al., “Seismic analysis of lateral force resisting steel frame with honeycombed steel thin plate shear wall,” Journal of Vibroengineering, Vol. 24, No. 2, pp. 357–368, Mar. 2022, https://doi.org/10.21595/jve.2021.22171

-

Z. Chen, W. Chen, C. Mai, J. Shi, Y. Xie, and H. Hu, “Experimental study on the compressive behaviors of brick masonry strengthened with modified oyster shell ash mortar,” Buildings, Vol. 11, No. 7, p. 266, Jun. 2021, https://doi.org/10.3390/buildings11070266

-

S. Nilanjan, “Study of appropriateness of cost-effective building construction technologies in housing sector in India,” Journal of Architectural Engineering Technology, Vol. 2, No. 2, pp. 1–5, 2013, https://doi.org/10.4172/2168-9717.1000113

-

Tam Vivian W. Y., “Cost effectiveness of using low cost housing technologies in construction,” Procedia Engineering, Vol. 14, pp. 156–160, 2011, https://doi.org/10.1016/j.proeng.2011.07.018

-

H. Bukhari, W. S. Alaloul, M. A. Musarat, S. Akram, I. Tabassum, and M. Altaf, “Materializing low-cost energy-efficient residential utility through effective space design and masonry technique – a practical approach,” Civil Engineering and Architecture, Vol. 9, No. 2, pp. 357–374, Mar. 2021, https://doi.org/10.13189/cea.2021.090209

-

“Standard test methods for sampling and testing brick and structural clay tile,” ASTM C67-07, ASTM Int. West Conshohocken, 2007.

-

Astm C. 109, “Standard test method for compressive strength of hydraulic cement mortars (Using 2-in. or [50 mm] Cube Specimens),” ASTM C109 / C109M – 20b, Annual Book of ASTM Standards, 2020.

-

Astm C. 1314-09, “Standard Test Method for Compressive Strength of Masonry Prisms,” ASTM C1314-09, 2015.

-

“Test Method for Diagonal Tension (Shear) in Masonry Assemblages,” ASTM International, West Conshohocken, PA, ASTM E 519-02, 1900.

-

A. Koksal, British Standard Methods of test for masonry – Part 3: Determination of initial. 2002.

About this article

This paper was supported by the Second Tibetan Plateau Scientific Expedition and Research Program (STEP) (Grant No. 2019QZKK0902), and National Natural Science Foundation of China (Grant No. 42077275). It was also supported by Youth Innovation Promotion Association of the Chinese Academy of Sciences (2018405).

The author acknowledge the work to Institute of Mountain Hazards and Environment, Chinese Academy of Sciences, Chengdu, China.