Abstract

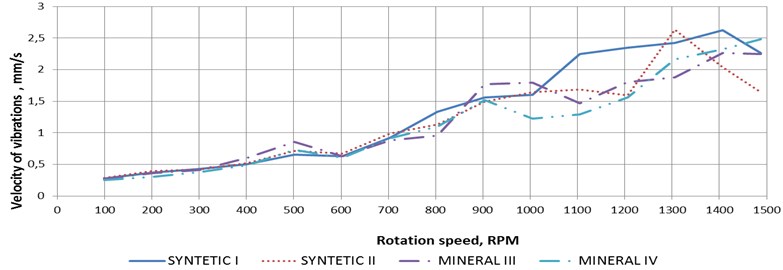

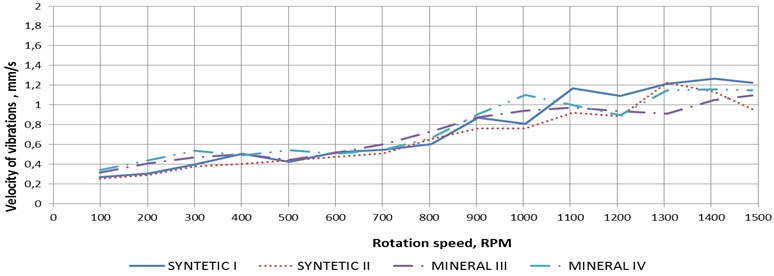

The paper presents the results of experimental studies on the effect of the type of oil on the value of vibrations of gearbox housings. There were analysed 4 types of lubricating oils, including 2 types of mineral oils and two types of synthetic oils. All the oils analysed had the same nominal kinematic viscosity of 320 mm²/s at the temperature of 40 °C. The tests were carried out at a testing station for the constant torque load of 2250 Nm and 15 different values of the rotational speed, which allowed obtaining vibration velocity plots as a function of the rotational speed. Based on these plots, it has been found that the results of the measurements of the vibration velocity were very similar for all the lubricating oils in the rotational speed range up to 800 rpm. Above this value, there was observed an impact of resonance phenomena and the measured values of the vibration parameters were changing significantly for different types of oils – higher values of these parameters were characteristic of the plots obtained for gearboxes lubricated with synthetic oils.

1. Introduction

In the case of gearboxes, gear wheels and bearings are the elements that are particularly responsible for the vibroacoustic condition [1]. These are also elements that should meet high durability requirements, and this fact has a substantial influence on the economic aspect of the use of gearboxes. In the structure of failures of gearboxes, damage to gear wheels has a significant share – up to approx. 40 % [2]. Current trends towards designing smaller drive units cause that modern gearboxes are exposed to higher thermal and mechanical loads [3]. High requirements to be met by gearboxes cause that they are manufactured with the use of materials with increased operational requirements. This also applies to operating fluids, among which oils play an important role. The quality of the transmission oil is a necessary condition for an efficient and long-term operation of gearboxes. Currently, manufacturers of power transmission mechanisms treat transmission oil as an integral part of the powertrain. Proper lubrication of gearboxes, especially those used in highly loaded mining machines and equipment is extremely important due to their operation in very difficult conditions [3-5]. Too little amount or a lack of lubricant, impurities, as well as an incorrect selection can cause permanent damage to gearbox components.

The paper presents the results of experimental studies on the effect of the type of oil on the value of vibrations of gearbox housings. In particular, there were analysed two types of typical mineral oils for use in mining gearboxes and two types of synthetic oils also designed for gearboxes operating in harsh operating conditions (all the oils analysed have the same nominal kinematic viscosity at the temperature of 40 °C).

2. Experimental details and results

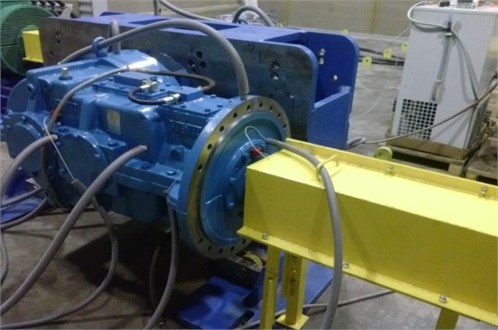

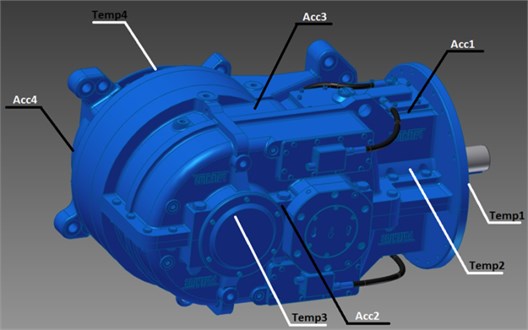

The tests were conducted at a testing station with a maximum power of 630 kW for loading the gearboxes. The test gearboxes (Fig. 1) were mounted to a rack in the same way as in the case of connection to an actual machine. The input part of the gearbox together with the arm was connected to the matching surfaces of the rack with the use of bolts and a key. The gearboxes were connected to the motor with the use of Cardan joints and the hubs of the torque meter. They were connected to each other using a steel connector with splines on both ends. The test gearboxes were rotated by 180 degrees in relation to each other, which reduced the resultant torque acting on the mounting system of the rack. The measurements of vibrations and temperature were performed using a 16-channel measurement system. The parameter characterizing the vibroacoustic condition was the vibration velocity determined according to ISO 10816. Vibroacoustic parameters were determined with the use of piezoelectric sensors (their locations on the gearbox housing are shown in Fig. 2), while the temperature was determined with the use of Pt 100 sensors. In addition, a thermal imaging camera was also used during the tests.

Fig. 1View of the test gearbox during the tests

Four types of oils were used in the tests: two types of synthetic oils (Synthetic I and Synthetic II) and two types of mineral oils (Mineral III and Mineral IV) with a nominal kinematic viscosity of 320 mm²/s at the temperature of 40 °C. These oils are typical transmission oils used in mining gearboxes.

The studies on the effect of the type of oil on vibrations of gearbox housings were carried out for 15 values of the rotational speed and the value of the load torque equal to 2250 Nm. Before the main tests, the gearboxes operated under a load of approx. 90 kW for 1 hour.

Fig. 2The arrangement of Acc1– Acc4 measurement sensors on the gearbox housing

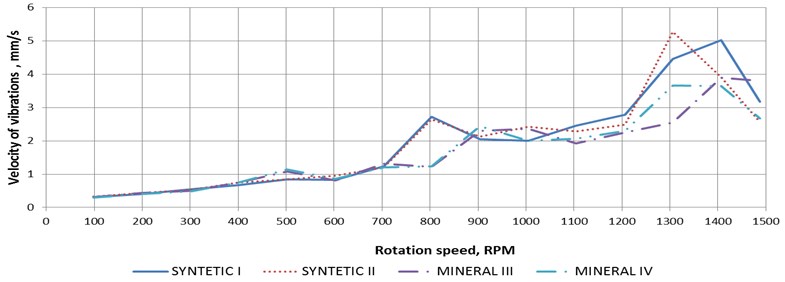

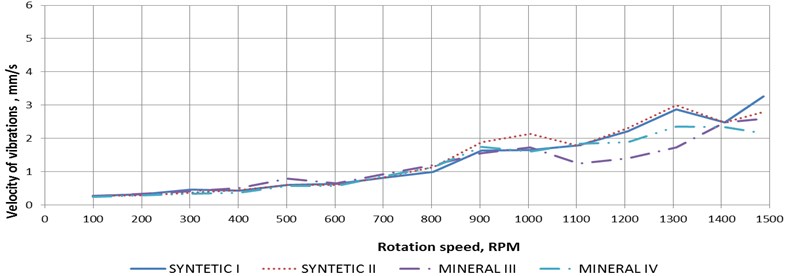

Fig. 3 presents the results of measurements of the vibration velocity as a function of the rotational speed for 4 positions of the sensors measuring the vibration acceleration.

Fig. 3The results of measurements of the velocity of the vibrations of the housing as a function of the rotational speed: a) results obtained with the use of Acc1 sensor, b) results obtained with the use of Acc2 sensor, c) results obtained with the use of Acc3 sensor, d) results obtained with the use of Acc4 sensor

a)

b)

c)

d)

3. Conclusions

The studies on the effect of the type of oil on vibrations of gearboxes were performed at a testing station for the constant torque load of 2250 Nm and 15 different values of the rotational speed, which allowed obtaining vibration velocity plots as a function of the rotational speed. Based on these plots, it has been found that the results of the measurements of the vibration velocity were very similar for all the lubricating oils in the rotational speed range up to 800 rpm. Above this value, there was observed an impact of resonance phenomena and the measured values of the vibration parameters were changing significantly for different types of oils – higher values of these parameters were characteristic of the plots obtained for gearboxes lubricated with synthetic oils.

References

-

Dąbrowski Z., Radkowski S., Wilk A. The Dynamics of Gear. Research and Simulation in the Design of Exploitation-Oriented. Monography, ITEE, Radom, 2000.

-

Ehrlenspiel K. Operating experience with helical and planetary gears – damage prevention measures. Der Maschineneschaden, Vol. 45, 1972.

-

Wieczorek A. The Effect Height of Teeth on the Dynamic Forces in Gearboxes. Dissertation, Gliwice, 2007.

-

Wieczorek A. The effect of construction changes of the teeth of a gear transmission on acoustic properties. International Journal of Occupational Safety, Vol. 18, 4, p. 499-507.

-

Wieczorek A. Reducing the causes of mechanical vibrations of gear transmissions through construction changes in teeth. Machine Dynamics Problems, Vol. 4, 2010.

About this article

The study was carried out as a part of the Project “Development of an Innovative Pro-Ecological Specialized Gear Transmission Integrated with a Diagnostic System” No. POIG.01.04.00-24-094/11.