Abstract

Torsional vibration dampers are an important part of many combustion engines, especially those with high power. Rubber dampers are frequently used as a solution. The paper presents results of research of the influence of changes in hardness of a rubber component on the effectiveness of a damper, e.g. due to the aging of rubber. Using two laser vibrometers of torsional vibrations, the simultaneous measurement of the vibration damper hub was made. The hub is connected with the nose of the crankshaft and vibrations of the inertia ring which is connected to the hub by the means of tested rubber element. There were compared the results for different values of hardness of the rubber damper element.

1. Introduction

In combustion engines with a high number of cylinders, dampers of torsional vibrations of the crankshaft are frequently used. They are used to reduce the amplitudes of torsional vibrations resulting from the extortion by gas and inertial forces connected with the work of engine. The use of dampers results in decreasing the values of angles of shaft torsion (especially with the extortions close to the range of resonance vibrations), which increases the reliability and life cycle of the engine.

One of the problems occurring in combustion engines, is the selection of parameters, which allows for avoiding the work in conditions of resonance, or minimizing the time of its occurrence. However, this is not always possible. Hence, the use of torsional vibration dampers of crankshafts is so important. Their use in combustion engines results in the following advantages:

– reduces fatigue stress of crankshafts;

– increases uniformity of entire drive system;

– increases efficiency of drive system;

– reduces emission of vibroacoustic energy of the engine.

The effectiveness of dampers depends on their condition, which changes during the operation. Evaluation of technical condition is especially important for large combustion engines [1, 2] used in drives of ships or locomotives, however, it can be used in the propulsion systems of small vehicles, e.g. cars, where OBD systems are often not focused on the diagnostics of mechanical elements [3].

2. Research of torsional vibrations of the crankshaft with a damper

Research of torsional vibration of the crankshaft with a rubber damper was conducted during an active experiment on the chassis dynanometer during the engine acceleration from rotational speed of the neutral gear to maximum speed. The basic measuring system consisted of two laser vibrometers POLYTEC RLV 5500 used to measure torsional vibration (Fig. 1).

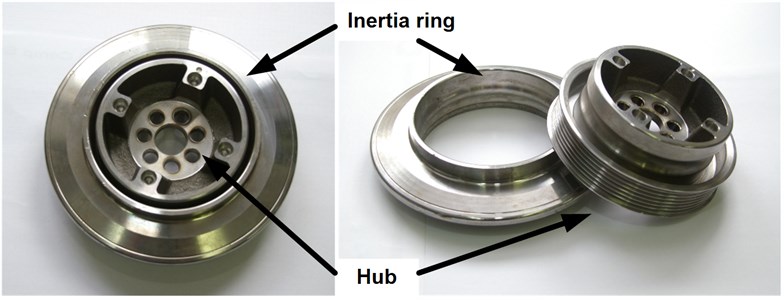

The test dampers consisted of a hub attached to the crankshaft nose and an inertia ring connected with the hub by the means of a rubber ring of a specified hardness. Fig. 2 shows the elements of tested dampers.

Fig. 1Research object with engine and two laser sensors of torsional vibrations

Fig. 2Rubber torsional vibration damper and its basic elements

The aging of rubber changes its hardness and stiffness at the same time. It could significantly affect the effectiveness of a damper. Thus, it was decided to carry out the study with dampers, in which rubber elements have different hardness: 50, 55, 60, 70 and 90°Sh.

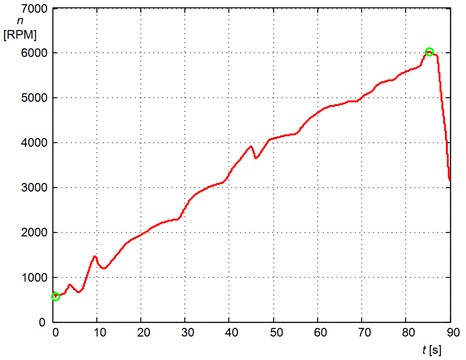

The use of two laser vibrometers allowed for simultaneous recording of torsional vibrations of the hub (nose of the crankshaft) and inertia ring. The comparison of these two values can be used to assess the actual influence of the characteristics of rubber element on vibrations of the crankshaft. The measuring system with the applied laser vibrometer allowed for further registration of change of rotational speed of the engine (Fig. 3).

Fig. 3Sample registration of changes in rotational speed during tests

It allowed to determine the spectral characteristics of torsional vibrations in the function of rotational speed of the engine.

The variety of forms of torsional vibrations of the crankshaft and polyharmonic character of extorting forces derived from thermodynamic phenomena associated with the combustion of fuel-air mixture in cylinders causes that the crankshaft can operate in the resonance zone at various rotational speeds of the engine. In simple cases, it is enough to take into account the first harmonic of rotational frequency of the engine. Small stiffness of modern constructions and the impact of drive system make it necessary to take into account higher harmonics. In multi-cylinder combustion engines each family of harmonics excited by a single cylinder is added to the harmonics excited by the remaining cylinders. There may appear so called “strengthened” harmonics, which are called main harmonics.

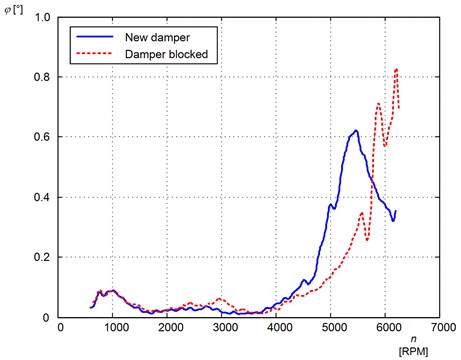

For the six-cylinder four-stroke engine, which was used in the study, one of such components is the third harmonic frequency of rotational frequency of engine. Fig. 4 shows an example of changes in the amplitudes of the third harmonic of torsional vibrations of the crankshaft nose of a new damper and a blocked damper. Presented characteristics were obtained from the spectral characteristics of torsional vibrations in the function of rotational speed of the engine.

Fig. 4Example characteristics of a new damper and a blocked damper

Blocking the damper corresponds to the case where elastic element does not work. Having compared the presented results, it can be concluded that the work of a new damper is effective in relation to a blocked damper, for which there exists an increase of values of torsional vibrations for higher rotational speeds. The change of characteristics of the rubber may influence the effectiveness of working of a damper of rotational vibrations.

3. Conclusions

The results of the research show that the change of characteristics of a rubber ring (elastic part of the damper of torsional vibrations) influences the changes of dynamics of the system with a crankshaft. The results can be useful for modeling this type of mechanical systems [4, 5], and for creating diagnostic systems.

References

-

Desbazeille M., Randall R. B., Guillet F., El Badaoui M., Hoisnard C. Model-based diagnosis of large diesel engines based on angular speed variations of the crankshaft. Mechanical Systems and Signal Processing, Vol. 24, 2010, p. 1529-1541.

-

Charles P., Sinha J. K., Gu F., Lidstone L., Ball A. D. Detecting the crankshaft torsional vibration of diesel engines for combustion related diagnosis. Journal of Sound and Vibration, Vol. 321, 2009, p. 1171-1185.

-

Dabrowski Z., Zawisza M. Investigations of the vibroacoustic signals mechanical defects sensitivity is not recognized by the OBD system in diesel engines. Solid State Phenomena, Vol. 180, 2012, p. 194-199.

-

Deuszkiewicz P., Pankiewicz J., Dziurdź J., Zawisza M. Modeling of powertrain system dynamic behavior with torsional vibration damper. Advanced Materials Research, Vol. 1036, 2014, p. 586-591.

-

Chiliński B. Analysis of disturbance torque influence on critical state in rotational systems. Transportation Problems, Vol. 8, Issue 4, 2013, p. 137-146.

About this article

Scientific work financed by the funds for the study in the years 2012-2015 as a Research Project.