Abstract

Gearboxes are widely applied in power transmission lines, so their health monitoring has a great impact in industrial applications. In the present study, acoustic signals of Pride gearbox in different conditions, namely, healthy, worn first gear and broken second gear are collected by a microphone. Discrete wavelet transform (DWT) is applied to process the signals. Decomposition is made using Daubichies-5 wavelet with five levels. In order to identify the various conditions of the gearbox, artificial neural network (ANN) is used in decision-making stage. The results indicate that this method allow identification at a 90 % level of efficiency. Therefore, the proposed approach can be reliably applied to gearbox fault detection.

1. Introduction

Reliability has always been an important aspect in the assessment of industrial products. By development of technology, cost of time-based preventive maintenance increased thus, new approaches in maintenance such as condition-based maintenance (CBM) developed [1]. Condition monitoring involves the assessment of the condition of a machinery component while it is working. Machine condition monitoring has long been accepted as one of the most effective and costefficient approaches to avoid catastrophic failures of machines [2]. Precise and high accuracy assessment of machinery condition results in fewer stoppages and better product quality and reduces maintenance costs for plants. Thus, they can optimize workforce and implement more efficient operations [3].

In recent years, the rapid development of industry automation has motivated the need of more intelligent and reliable machining systems. To minimize the loss due to the interruption of production and high machine failure cost, it is necessary to monitor machine condition on-line using an effective condition monitoring system to provide timely information for maintenance decision making [4]. Gears are the most efficient and compact devices used to transmit torques and change the angular velocities. They are widely applied in many machines, such as mining machines, automobiles, helicopters, and aircraft turbine engines [5]. Condition monitoring of gear transmission systems in industry has attracted increasing interest in recent years, due to the need to decrease the downtime on production machinery and to reduce the extent of the secondary damage caused by failures [6, 7]. Development of gear failure diagnostic techniques based on the analysis of vibration signals has been an active area of research for more than two decades [8].

Analysis of acoustic and vibration signals of the gearbox gears is the common way of extracting reliable representative of the gearbox condition [9, 10]. In contrast to vibration signals, acoustic signals from a machine can be measured at distances sufficiently far from a vibrating machine surface with help of microphones. This allows the acoustics signal to be measured for machines working at a condition (extreme temperature and humidity) which is not suitable for vibration measuring sensors, like proximity transducers or accelerometers. In [1], ANN and K-nearest neighbor (KNN) were used for intelligent fault detection of gear. In [9], faulted gear recognition was done using the combination of WT and ANN. In [13], a procedure for fault diagnosis of planetary gearbox was presented by using data fusion technique. The difference between current work and [13] is in used case study and signal type. Also, in the present work, the satisfactory results were obtained by a good combination of signal processing and classification techniques.

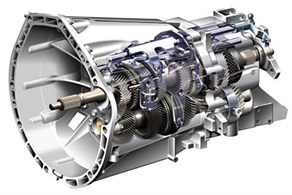

In this research, the gearbox of Pride vehicle, that is one of high production vehicles in Iran, was used as case study. Acoustic signals were used for gearbox fault detection. This gearbox has five front ratio gear and on rear ratio gear. Fig. 1 shows a schematic of gearbox.

Fig. 1Schematic of gearbox

2. Experimental Setup

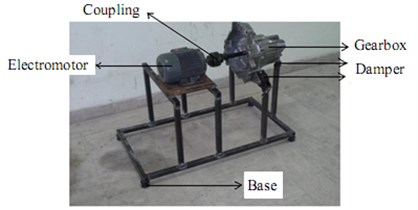

For this work, at first a test bed was built to mount the gearbox and electromotor on it. A 2 KW electromotor was used to drive power to the gearbox using a coupling power transmission. The input shaft of gearbox was drove by the electromotor in 3000 RPM and its speed was controlled by an inverter. The test stand is shown in Fig. 2.

Fig. 2Experimental setup

Fig. 3The positioning of the acoustic sensor

Table 1Specifications of microphone used for this work

Model | AKB-c417 |

Type | Pre-polarized condenser |

Frequency range | 20 Hz-20 KHz |

Sensitivity | 10 Mv/Pa |

Electrical Resistance | 200 |

Signal to noise ratio | 60 Db |

Ability of sound record | 126 Db |

The acoustic signals of the gearbox in each condition were recorded by a capacitive microphone AKG.C417 model (Table 1) which was placed perpendicularly above the surface of the gearbox, as shown in Fig. 3. Three commonly conditions of the gearbox were studied in this research; i) healthy ii) wear in first gear iii) broken first gear. These classes have been shown in Fig. 4.

Fig. 4Different conditions of first gear: a) healthy; b) wear in gear; c) broken gear

a)

b)

c)

3. Signal processing and feature extraction

Several signal processing techniques are developed during recent years to analyze these raw signals in time or frequency domains. Wavelet transform is a conventional time frequency domain signal analyzer that uses oscillating functions as window functions. This series of functions, that usually called mother wavelets, have different frequencies to deal with transient signals in different time intervals [9]. Wavelet is useful for the transient nature of non-stationary signal [10]. Discrete wavelet transform (DWT) decomposes signal in both time domain and frequency domains simultaneously. DWT is expressed as:

where is the complex conjugate of (mother wavelet), and denoted the scale and translation parameters, is the raw signal and represents the decomposition level. Wavelet coefficients could not be used directly as inputs of classifier and a post process stage is needed to prepare data for classifier. Therefore, twenty nine features were extracted from the wavelet coefficients using different parameters. For more information about the used features see [11, 12].

4. Artificial neural network (ANN)

Artificial intelligent systems are widely used for classification and fault detection based on learning pattern from examples or empirical dataset modeling. These techniques such as Artificial Neural Networks (ANN) are developed in decision-making and recognition [13].

Fault diagnosis in current study is done using two layers feed forward back-propagation. Outputs layer of all networks consist of four neurons, this is due to defining output in data set as two columns matrix having 0-1 digits to define desired class. This means 0-1-0-0 output is related to second class. Using this output method turns classification to a pattern recognition problem.

Input layer neurons are defined by features count. The most important layer of networks is middle layer (hidden layer) that should be defined by settings. In current research, a three layers neural network with 9 neurons (N) in hidden layer used to gain the best classification results. This set of nine networks generated by training with train set and simultaneously simulated by test sets. Using test sets has the advantage of preparing a real decision condition for generated classifier to perform a performance exam with new arrival data. ANN was trained and implemented using Matlab neural network toolbox with back-propagation, the performance function of mean square error (mse) and the training algorithm of Levenberg-Marquardt (LM).

5. Results and discussion

The purpose of the present work is the fault detection of the automotive gearbox. To carry out this aim, the fault diagnosis system which consists of a combination of signal processing and classification techniques was used. The classification of the gear based on its situation was done using the features extracted from the wavelet coefficients.

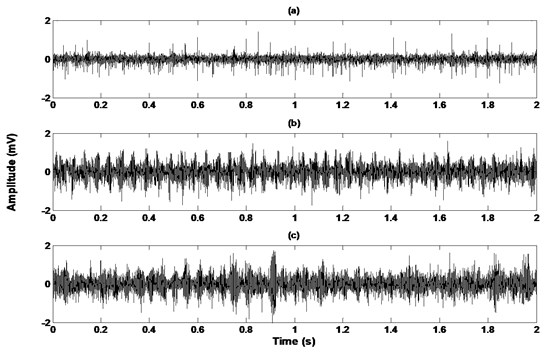

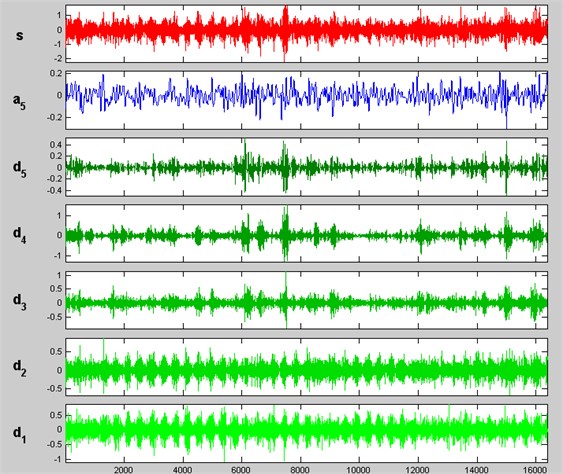

Fig. 5 shows the acoustic signals in time domain for each class. It can be seen that it is difficult to discriminate different conditions of gearbox from time domain, so it is necessary to use the proposed intelligent procedure for gearbox fault diagnosis. Acoustic signals for each class were processed by Daubichies-5 wavelet with 5 decomposition levels. Fig. 6 shows the wavelet decomposition of the acoustic signals in broken first gear condition.

Fig. 5Acoustic signals of each gearbox condition: a) healthy, b) wear in gear, c) broken gear

Fig. 6DWT of acoustic signal in broken first gear situation

Then, different feature parameters were used in feature extraction stage. Each class consisted of adequate samples that divided in two parts: training samples for training ANN and other samples for checking the efficiency of the proposed method. Ten values of neuron (N) in hidden layer between 1 and 10 were used for the training stage of ANN. The results showed that the best performance was belonged to 9 neurons in hidden layer ( 9). The best total classification accuracy of ANN was 92.7 % and 89.3 % for training and test dataset, respectively. Therefore, it is found that the DWT and ANN are appropriate techniques for signal processing and classification respectively and the combination of DWT and ANN can be effectively applied to gearbox fault diagnosis.

6. Conclusions

In this research, we performed the detection of gear fault by using the wavelet technique and ANN classifier. Wavelet transform technique was used for processing the acoustic signals. Then twentynine features were extracted from time-frequency domain signals. These features were used as input to ANN. The accuracy rate of the classifier was 92.7 % and 89.3 % on training and testing dataset. The results indicate that the wavelet analysis is a fast and effective method in signal processing for the detection of different faults. Likewise, the ability of ANN in classification can be seen. The experimental results above demonstrate that the proposed approach is successful in fault diagnosis of gearboxes.

References

-

Bagheri B., Ahmadi H., Labbafi R. Application of data mining and feature extraction on intelligent fault diagnosis by artificial neural network and K-nearest neighbor. ICEM Conference, Rome, Italy, 2010, p. 7.

-

Ahmadi H., Mollazade K. A practical approach to electromotor fault diagnosis of Imam Khomaynei silo by vibration condition monitoring. African Journal of Agricultural Research, Vol. 4, 2008, p. 383-388.

-

Zhan Y., Mechefske C. Robust detection of gearbox deterioration using compromised autoregressive modeling and Kolmogorov–Smirnov test statistic. Part II: experiment and application. Mechanical Systems and Signal Processing, 21, 2007, p. 1983-2011.

-

Miao Q., Makis V. Condition monitoring and classification of rotating machinery using wavelets and hidden Markov models. Mechanical Systems and Signal Processing, 21, 2007, p. 840-855.

-

Yang M., Makis V. ARX model-based gearbox fault detection and localization under varying load conditions. Journal of Sound and Vibration, 329, 2010, p. 5209-5221.

-

Zhan Y., Makis V. A robust diagnostic model for gearboxes subject to vibration monitoring. Journal of Sound and Vibration, 290, 2006, p. 928-955.

-

Wang X., Makis V., Yang M. A wavelet approach to fault diagnosis of a gearbox under varying load conditions. Journal of Sound and Vibration, 329, 2010, p. 1570-1585.

-

Endo H., Randall R. B. Enhancement of autoregressive model based gear tooth fault detection technique by the use of minimum entropy convolution filter. Mechanical Systems and Signal Processing, 21, 2007, p. 906-919.

-

Wu J., Chan J. Faulted gear identification of a rotating machinery based on wavelet transform and artificial neural network. Expert Systems with Applications, 36, 2009, p. 8862-8875.

-

Widodo A., Yang B. S. Wavelet support vector machine for induction machine fault diagnosis based on transient current signal. Expert Systems with Applications, 35(2), 2008.

-

Moosavian A., Ahmadi H., Tabatabaeefar A. Fault diagnosis of main engine journal bearing based on vibration analysis using Fisher linear discriminant, K-nearest neighbor and support vector machine. Journal of Vibroengineering, Vol. 14, Issue 2, 2012, p. 894-906.

-

Lei Y., He Z., Zi Y. A new approach to intelligent fault diagnosis of rotating machinery. Expert Systems with Applications, 35, 2008, p. 1593-1600.

-

Khazaee M., Ahmadi H., Omid M., Moosavian A., Khazaee M. Vibration condition monitoring of planetary gears based on decision level data fusion using Dempster-Shafer theory of evidence. Journal of Vibroengineering, Vol. 14, Issue 2, 2012, p. 838-851.