Abstract

The laboratory testing of the influence of the mechanical vibration on the materials is very important for every applied research. By acting on the materials and construction of static and dynamic forces in laboratory conditions we can predict what will be their probable behaviour in reality. Always we are needed parallel verifications of results of computer simulations with the real or laboratory experiment. The laboratory equipment is also important to research the validity of the required standards and implementing the long-term tests which would be very expensive in reality. Our laboratory passed of series of mechanical innovations, and today we can test as the specimens as the whole structures. In this paper we present our possibilities and some tests of materials to product automobile seats.

1. Introduction

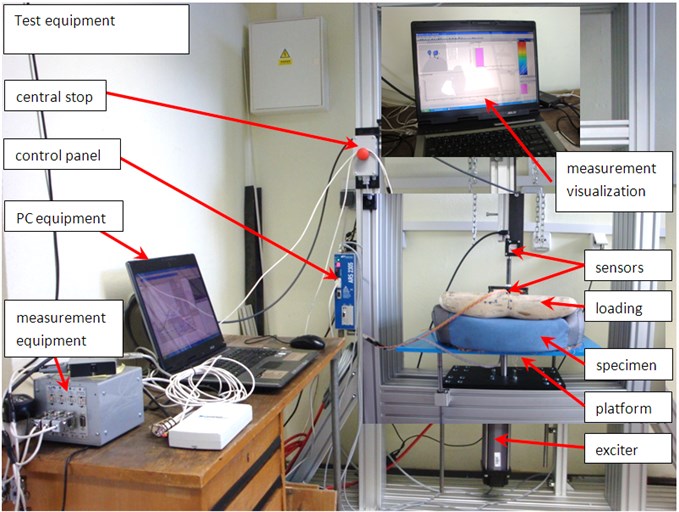

Our applied research has been focused in research the effect of mechanical vibration on the human and material. In this article we want to introduce to new developments in our laboratory and the direction of our research at present. Hydrodynamic laboratory has been completed with electrodynamics laboratory. Currently we have two new workplaces for static and dynamic vibration diagnostics. In the paper we present a dynamics workplace and monitoring of vibrations Fig. 1. The workplace is equipped with the source of mechanical vibrations (linear servo actuator GSM40-1008 series, stroke 254 mm, maximum velocity of 953 mm/sec, max static load 17642 N and 0.001977 kgm2 armature inertia) and its control system. The control system is realized on basis of electronic control servo drive series ARS. Used digital servo amplifier presents a new of generation of high dynamic digital amplifiers for three-phase synchronous motors. Universal interface position sensor (universal encoder interface) makes possible to connect a wide range of sensors position from most major producers. With an optional input for external incremental encoder or encoder output simulating signals the servo amplifier can be easily synchronized with various transmit ratios, or simply connect to the PLC. The automatic drive detection greatly simplifies and accelerates initial setting of servo amplifier. Servo amplifier meets the requirements of EN 61000-3-2 respecting higher harmonic and reach better utilization of the motor steadier of intermediate voltage. Recently we also added a measuring system. We can simultaneously measure the forces, movements, vibration, acceleration, etc.

Monitoring and diagnostics are controlled by the computers, while data is stored on hard disk for next processing. Our work is focused on car seats. The device makes possible to measure both an individual components and the whole seats. In terms of laboratory measurements we can measure everything. The main goal of our research is the contemporary search for new materials, particularly in the field of biomaterials applicable to produce car seats. In keeping functionality and comfort of the main criterion is reduction of the weight, price, and replacement of materials from crude oil. Also, re-usage of recycled materials is the subject of our investigation. The main goal of this research is decreasing of energy consumption, renewable, easy recyclability of used materials. Above all, we must know the properties of ancient materials, so that we could verify with the new one. Without laboratory equipment that is not possible.

Fig. 1Vibratory monitoring and diagnostics techniques

2. The results of some measurements

Our applied research is in the area rather Materials Engineering (ME), and subsequent laboratory tests or long-term lifetime tests. With regard to the use of new materials continues a new structure. In this paper we want to introduce to new materials that we discover, measure and find their new applications.

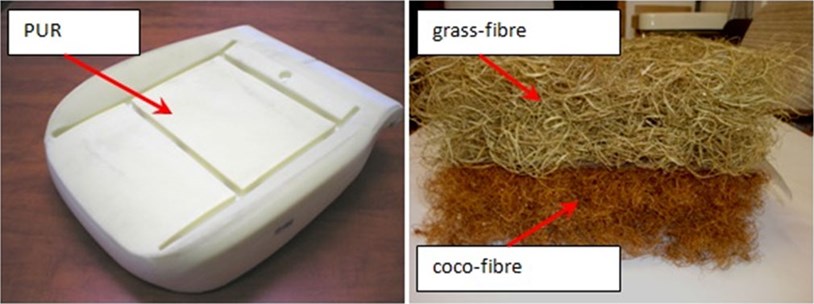

At present, for example we engaged intensively in finding material that would replace the PU foam, material which is used in the automotive industry (Fig. 2) for the production of polyurethane foams used for poly-addition with di-isocyanates. Environmental considerations and the effects on the health of polyurethane insulating material are the most complex and energy demanding production process. The pollution and the risk of toxins to the environment in the production PU foam are occurring. Polyurethane is a typical product of the hard chemicals. Feedstock for the production of polyurethanes is derived from crude oil. In terms of sustainable development are also desirable in engineering efforts on the use of renewable raw materials. Isocyanates include compounds classified as potential human carcinogens and are known to cause cancer in animals. The main effects of hazardous exposures are occupational asthma other lung problems, as well as irritation of the eyes, nose, throat and skin. Toxic substances are occurring in the manufacturing process, including poly-isocyanates (MDI), phosgene and propylene oxide. Directly or indirectly, is widely used by the chlorine, as expansive gases used pentane or CO2 (chemically prepared by adding water to the reaction mixture). There are also procedures for chemical stuff recycling of PU foam, but their application is very problematic. PU foams are now relatively expensive. For all these deficiencies it is necessary to look for their replacement. We believe that within 10 years will be the full substitution in the automotive as well as furniture industry.

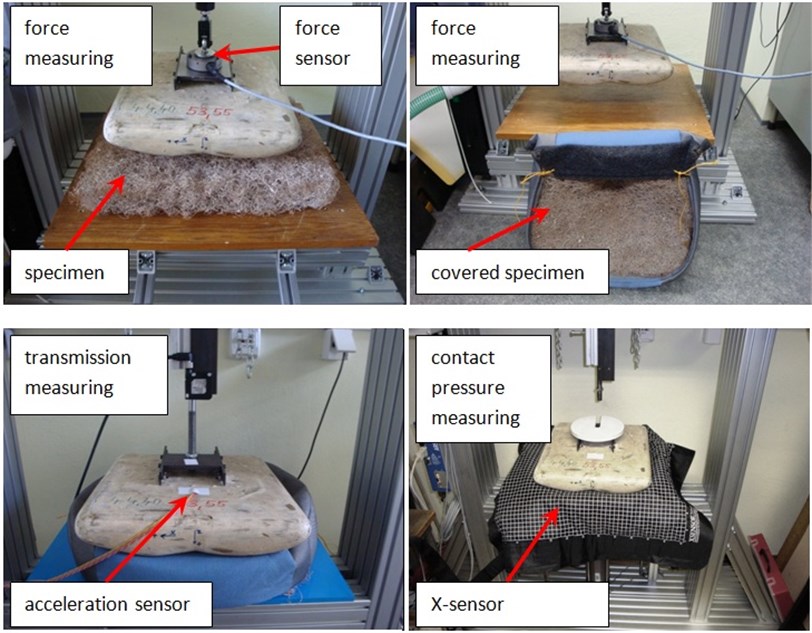

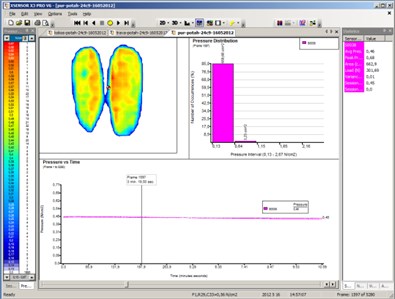

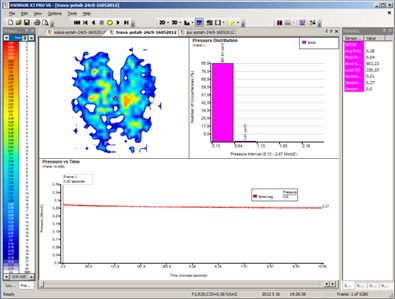

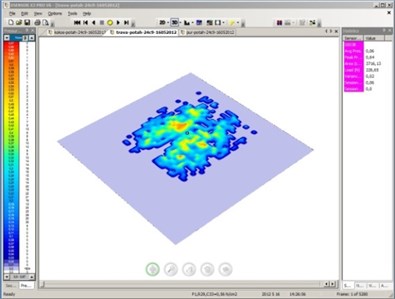

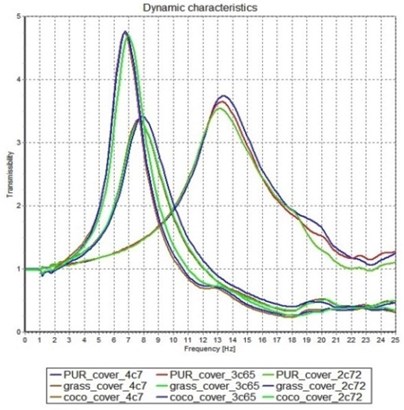

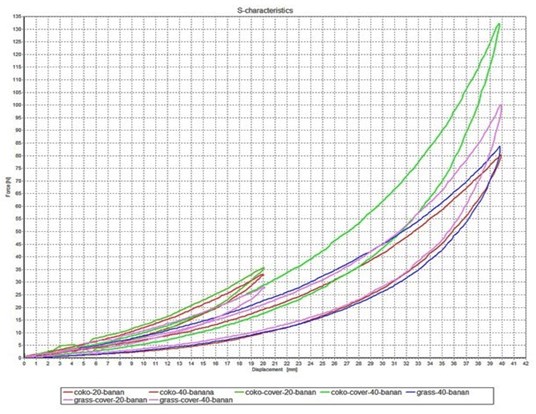

On Fig. 2 are presented two possible substitutions of grass fibers TV-LAT01 and coconut fibers KV-LAT01. These two materials are traditionally used in furniture production, but also more recently in the automotive industry, so well-forgotten materials. Today we are trying to find a consensus of properties of polyurethane foams with these "new" materials. The final processing into the finished product is still a long way from determining the mode of production, processing technology, preparation semi-finished product and forming to finished product. We are beginning to produce at first specimen which we test in our laboratory. We measure their static and dynamic properties in Fig. 3, for example, resistance to compression, transmission characteristics, the distribution of contact pressure under load.

Fig. 2Testing of materials

Fig. 3Type of measurement

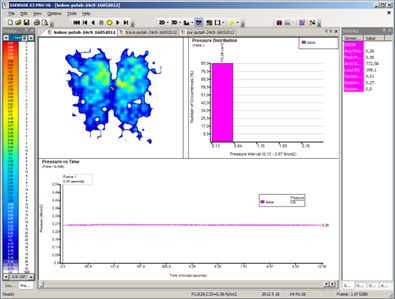

Some from the measurement results are presented in Fig. 4 and Fig. 5. Because all tested materials are visco-elastic at first we were interested in their elasticity and damping. By measuring the transmission characteristics, we can obtain information about the resonant frequency and of the damping rate. By measuring it was found that the resonant frequency of the coconut fiber is between 6.5 to 7.0 Hz, of the grass fiber between 7.5 to 8.0 Hz, of the fibers and PUR between 13.0 to 13.5, and transmissions are 4.7 to 4.8 and 3.3 to 3.7 and 3.5 to 3.7. We do conclude that natural fibers have twice elasticity than the PUR, damping is similar by grass fibers and polyurethane fibers, coconut fibers show a lower damping. We have also measured the hysteresis curves. For example, measurements show that coconut fibers reach higher force at the same deformation of 40 mm than the grass fibers, high force polyurethane. Hysteresis is the same for all samples. A comparison of contact pressure map follows the unique conclusion, the highest resistance has PUR, coconut and grass fibers have a lower resistance, but the same. It also corresponds with the measured size of the contact surfaces for coconut fibers 773 cm2, for grass fibers 794 cm2 and 634 cm2 for PUR, mean pressures are measured for 0.26 N/cm2 coconut fibers, grass fibers for 0.28 N/cm2 and PUR 0.46 N/cm2. Therefore the worst distribution of contact pressures has polyurethane. We can make the general conclusion: in samples of grass fibers and coir TR-LAT01-KV-LAT01 we need to increase density, produce new produce samples and measure again before we reach the optimum consistency.

It is necessary to realize that the product innovation process can be completed with computer simulations, computer testing, but without knowing of actual physical properties that can be converted into virtual models, you cannot use these methods. Also for verification of mathematical models it is necessary to make experiments. That is why today the key equipment of laboratories and their continuous improvement not only for academic research is important.

Fig. 4Measurement results

Fig. 5Measurement results

3. Conclusions

These measurements are part of a comprehensive research of the properties of polyurethane foams (PU) and substitute materials (SM). By testing materials we can determine their properties and eliminate the required new materials. From the measured results for many years we are creating a knowledge database that allows you to keep the innovation process in the right direction. Substitution materials made from crude oil is one of the priorities of the current applied research. We must look for new materials and forms of their useful properties. Then we can make up the structure.

References

-

EN ISO 3386-1. Polymeric Materials. Cellular Flexible – Determination of Stress-Strain Characteristic in Compression – Part 1: Low-Density Materials.

-

Jevremovic Z., Peulic A., Jordovic B. Trends in the Development of Machinery and Associated Technology. 15th International Research/Expert Conference, Prague, Czech Republic, 2011.