Abstract

In CCUS ZEN project one of value chains considered includes emission sources located in the region of northern Poland. The value chain is intertwined with the scope of ECO2CEE Project of Common Interest on CO2 terminal in Port of Gdańsk. The ECO2CEE project in its first stage is to include railway transport of CO2 captured in two of the installations of the studied value chain. Carbon dioxide delivered to the terminal is to be transported by ship and stored under North Sea. However, within the region and its immediate vicinity there is notable storage potential. About 120 km north of Gdańsk, offshore, there is saline aquifer in Cambrian sandstones of storage capacity likely sufficient to store emissions of all selected 16 emitters of the region. The main barrier to such approach is the interpretation of Article 11 of Helsinki Convention suggesting ban of CO2 storage under the Baltic Sea. In southern part of the region where also ECO2CEE emitters are located there are several saline aquifer structures in Lower Jurassic and Lower Cretaceous of estimated storage capacity significantly exceeding the possible demand of emitters of the local cluster. Hence, the work is to propose the further development of the PCI value chain in northern Poland, beyond the original concept.

Highlights

- In CCUS ZEN project one of value chains considered includes emission sources located in the region of northern Poland.

- In the same area the ECO2CEE Project of Common Interest on CO2 terminal in Port of Gdańsk is proposed (the sixth EU PCI&PMI list, 2023). In the first stage (by 2030) CO2 captured in two installations is to be transported by rail then by ship and stored under North Sea.

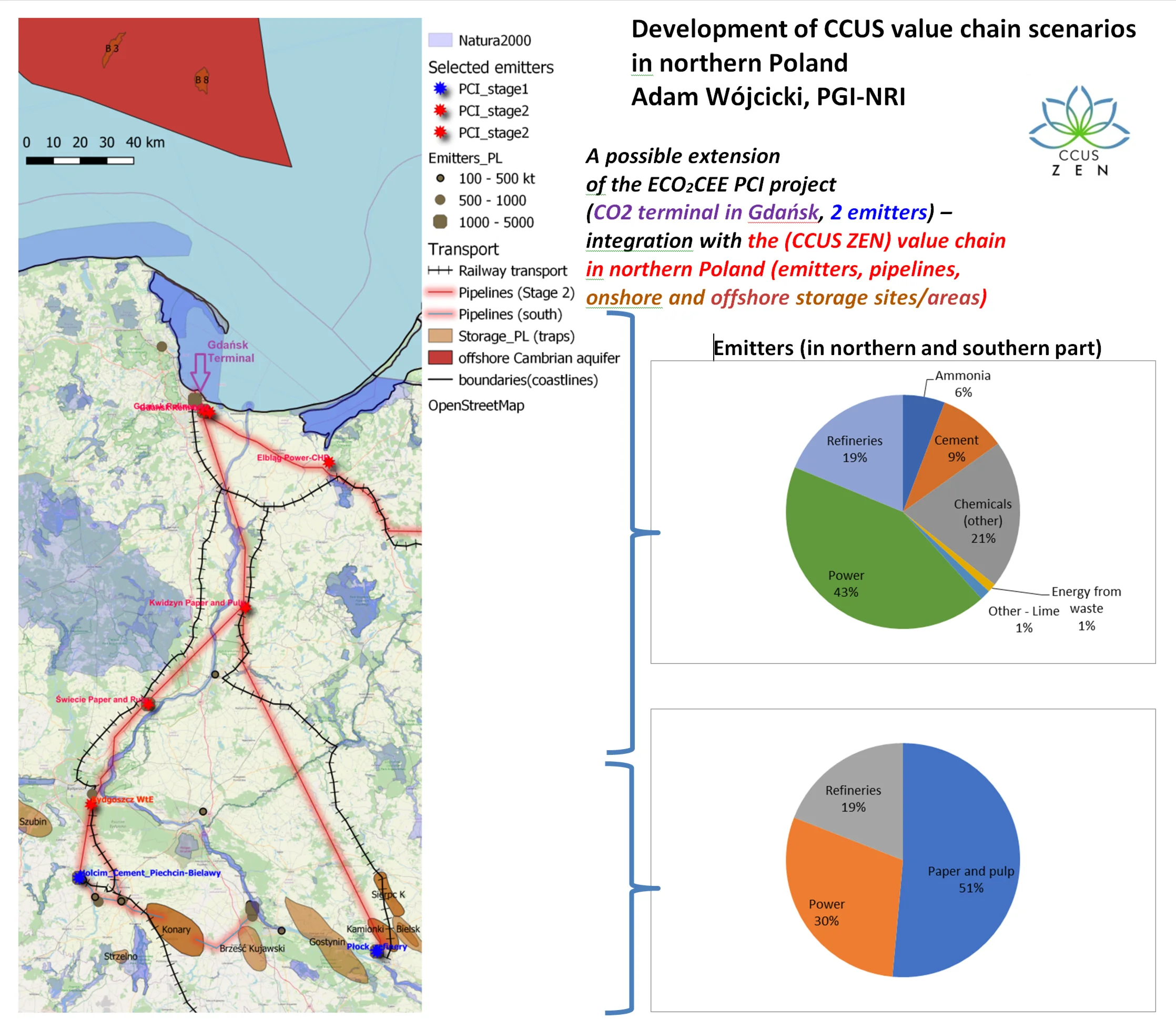

- In the study a possible extension of the ECO2CEE PCI concept is proposed (beyond 2030). It consists in integration with the (CCUS ZEN) value chain in northern Poland.

- The value chain encloses various industrial sources (18 > 100 kt CO2 in total, 11 excluding old fossil fuel fired energy installations)): refineries, chemical, paper and pulp, cement and lime plants, and energy installations. In some installations biogenic CO2 is produced.

- Significant offshore and particularly onshore storage potential exists in the region but some legal issues are to be resolved yet. Various transport options could be considered, some of these include the CO2 terminal in Gdańsk as a part of the chain.

- Hence, onshore and/or offshore storage options in the region together with proposed transport infrastructure could supplement and enhance the original concept of the PCI based on CO2 terminal in Port of Gdańsk. There is even a possibility to expand the value chain/PCI, including more emitters.

1. Introduction

CCUS ZEN project is a Pan-European Coordinated and Support Action project of HORIZON EUROPE EU programme [1], carried out by international consortium led by SINTEF (Norway) and cooperating with numerous networking partners, financed by the European Climate, Infrastructure and Environment Executive Agency (CINEA). The project principal objectives are as follows:

1) Enabling faster development of CCUS projects in industrial clusters across Europe, particularly in the Baltic and Mediterranean regions.

2) Developing specific and actionable plans for the development of CCUS value chains in the Baltic and Mediterranean regions.

3) Identifying potential new Projects of Common Interest (PCI) for transport and storage in the Baltic and Mediterranean regions.

4) Contributing to knowledge sharing on key issues relevant to industrial deployment of CCUS.

One of the value chains in the Baltic region studied in the CCUS ZEN project (including emission clusters, storage and transport options) covers the area of northern Poland, shown in Fig. 1. The area encompasses most of Gdańsk Pomerania and parts of Kuyavia and Masovia together with a small part of Warmia-Masuria [2]. Within the area, refinery, chemical, paper and pulp, cement and lime as well as energy industry installations are present – 27 emittants of at least 0.1 Mtpa, in total about 22.7 Mtpa. In case old coal fired energy installations are excluded (i.e. only CCS ready gas fired power plants as well as energy from waste plants are considered) 16 installations of total 14.8 Mtpa remain [3]. As storage options onshore saline aquifer structures as well as offshore saline aquifer including mature hydrocarbon fields are considered. Transport options include, depending on timeframe and volume of captured carbon dioxide, railway, pipelines and/or ship delivery [2].

Fig. 1The value chain area, encompassing emission clusters (in gray) prospective storage sites and areas (in brown and brown-orange) and Natura 2000 areas (in light blue), based on [2], the background is OpenStreetMap

![The value chain area, encompassing emission clusters (in gray) prospective storage sites and areas (in brown and brown-orange) and Natura 2000 areas (in light blue), based on [2], the background is OpenStreetMap](https://static-01.extrica.com/articles/24676/24676-img1.jpg)

Fig. 2The ECO2CEE PCI project in a nutshell, after [4]

![The ECO2CEE PCI project in a nutshell, after [4]](https://static-01.extrica.com/articles/24676/24676-img2.jpg)

The value chain is intertwined with the scope of the ECO2CEE PCI on CO2 terminal in Port of Gdańsk (Fig. 2). The PCI project was first adopted by the EC in the fifth PCI list in 2021 then upgraded as a fully cross-border proposal adopted in the sixth PCI&PMI list [4]-[5]. The ECO2CEE project is led by Polish fuel company Orlen. In first stage (by 2030), the PCI is to include railway transport of CO2 captured in Holcim cement plant in Piechcin-Bielawy (Kujawy Go4EcoPlanet industrial scale capture project) as well as in Orlen refinery in Płock to the terminal in Gdańsk. These two installations are considered as well in the value chain in question, and are located in the southern part of the studied area (Fig. 3). Carbon dioxide delivered to the terminal is to be transported by ship and stored under North Sea (Fig. 2).

It is proposed to include in the next stage of the PCI project more CO2 emitters of the studied value chain (Figs. 3-4). Simultaneously, it is proposed to supplement and enhance the original concept of the PCI (Fig. 2) with additional transport and storage options in northern Poland.

2. The value chain

Fig. 3The southern part of the value chain area, based on [2] – see Fig. 1; the labelled emitters are preferred components of the value chain

![The southern part of the value chain area, based on [2] – see Fig. 1; the labelled emitters are preferred components of the value chain](https://static-01.extrica.com/articles/24676/24676-img3.jpg)

3. The CO2 emission sources

The value chain area, presented in Fig. 1, is divided into two clusters of CO2 emission sources: Kuyavia-Masovia (South – Fig. 3 and Fig. 5) and Gdańsk-Pomerania (North – Fig. 4 and Fig. 6). According to the inventory of emitters larger than 0.1 Mtpa done in [3], in these clusters there are 9 emitters of total 9.1 Mtpa and 18 emitters of total 13.6 Mtpa respectively.

These emitters belong to various industry sectors (Figs. 5-6). Most of them (15) belong to energy production sector, or provide energy to other industry installations. In bigger installations predominantly fossil fuels are used with a very minor or unspecified share of biomass co-firing. Smaller energy installations utilize biomass or waste of both biogenic and fossil origin. Two of bigger energy installations are modern gas fired (NGCC) CCS ready power plants, the others are older and predominantly hard coal fired – rather unlikely to be retrofitted with capture units.

In one cement plant waste co-firing together with hard coal is used. There are four installations of chemical sector (two at the same location), two paper and pulp plants – one of these mostly biomass fired and particularly large, three oil refineries (two at the same location), one ammonia plant and one small lime plant.

If old, predominantly hard coal fired energy installations are excluded then 16 emitters remain. There are 11 emitters in southern part of 8.2 Mtpa in total (Fig. 3) and 5 in northern part of 6.6 Mtpa in total (Fig. 4).

Fig. 4The northern part of the value chain area, based on [2] – see Fig. 1; the labelled emitters are preferred components of the value chain

![The northern part of the value chain area, based on [2] – see Fig. 1; the labelled emitters are preferred components of the value chain](https://static-01.extrica.com/articles/24676/24676-img4.jpg)

Fig. 5Pie chart of the emitters in the southern cluster, of total emission 13.6 Mtpa (after [2])

![Pie chart of the emitters in the southern cluster, of total emission 13.6 Mtpa (after [2])](https://static-01.extrica.com/articles/24676/24676-img5.jpg)

Fig. 6Pie chart of the emitters in the northern cluster, of total emission 9.1 Mtpa (after [2])

![Pie chart of the emitters in the northern cluster, of total emission 9.1 Mtpa (after [2])](https://static-01.extrica.com/articles/24676/24676-img6.jpg)

4. The storage and transport options

The CO2 storage potential, prospective formations and structures in Poland have been studied in the national project [7] where results of previous research have been verified, updated and integrated (e.g. [6]) and storage capacities assessed. Volumetric storage capacities of prospective storage sites have been recalculated in [3] using CSLF methodology.

Within the value chain area there are several onshore saline aquifer structures located in southernmost part of the said area (Fig. 1 and Fig. 3). Among those, two Mesozoic saline aquifer structures (Konary and Kamionki) are proposed as storage sites (Figs. 7-8) because they are located nearby emitter subclusters and there is no environment protected areas and major settlements above these structures (Fig. 3, Figs. 9-10). The Konary and Kamionki structures are within multi-reservoir Jurassic (Konary) and Lower Cretaceous & Jurassic (Kamionki) aquifers (Figs. 7-8) of quite good reservoir properties (Table 1). The storage complexes of each structure have been drilled by 2-3 legacy wells (of 1960-80s) and explored by 2D seismic of 1970-90s (Figs. 7-10).

Fig. 7Generalized geological cross-section through Konary saline aquifer structure (after [6])

![Generalized geological cross-section through Konary saline aquifer structure (after [6])](https://static-01.extrica.com/articles/24676/24676-img7.jpg)

Fig. 8Generalized geological cross-section through Kamionki saline aquifer structure (after [6])

![Generalized geological cross-section through Kamionki saline aquifer structure (after [6])](https://static-01.extrica.com/articles/24676/24676-img8.jpg)

The main challenge is current Polish geological and mining law [10]. The current legal framework allows applying for permits for CO2 storage in certain areas defined by a regulation issued by the Ministry of Climate and Environment. The onshore storage is not covered by the regulation currently in force [11], but a relevant revision of the regulation is in progress. Another challenge is acceptance of onshore underground storage by local communities.

Regarding transport options onshore pipelines are preferred, but the relevant regulations are still in progress [10]. Railway transport (as scheduled in the first stage of ECO2CEE project [4]) or road transport might be an option in case of the pilot injection or at preliminary stage but not at fully industrial stage.

In the scenario proposed for the southern part of the value chain area (Table 2; Fig. 3) CO2 could be delivered by pipelines of length 4.2-38.2 km, depending on subcluster, connecting the emission subclusters and storage sites. The Konary structure in multi-reservoir Jurassic saline aquifer is proposed as a storage site of three subclusters located to the west (Piechcin-Janikowo-Inowrocław), north-west (Bydgoszcz) and to the east (Włocławek) of the structure. The double-reservoir saline aquifer structure Kamionki (of Lower Cretaceous as a primary reservoir and Jurassic as a possible backup) located very close to Płock emitter subcluster is proposed as a storage site of the subcluster (Fig. 3; Table 2).

Table 1Storage options – after [2]-[3] and [7]

Site/structure/area | Konary | Kamionki | Cambrian offshore PL | |

Reservoir(s) | Age & lithology | Jurassic (Lower Aalenian-Upper Toarcian, Pliensbachian and Synemurian) sandstones | Lower Cretaceous sandstones, Jurassic (Lower Aalenian-Upper Toarcian) sandstones as a backup | Middle Cambrian sandstone |

Representative cumulative thickness [m] | 250 | 140 | 34 | |

Representative porosity [%] | 15-20 | 20 | 8-13 | |

Representative permeability [mD] | 200-400 | 400 | 30-70 | |

Caprock(s) | Age & lithology | Jurassic (Bajocian and Upper Aalenian) claystones & mudstones | Upper Cretaceous marls & marly limestones | Silurian to Upper Cambrian claystones & shales |

Representative cumulative thickness [m] | 143 | 200 | 300 | |

Secondary caprock | Jurassic (Bathonian) claystones | Jurassic (Bajocian and Upper Aalenian) claystones over the backup reservoir | – | |

Estimated CO2 storage capacity [Mt] | 282 | 99 (+149) | 188 | |

Fig. 9Data availability in the area of Konary saline aquifer structure – the structure extent after [7]

![Data availability in the area of Konary saline aquifer structure – the structure extent after [7]](https://static-01.extrica.com/articles/24676/24676-img9.jpg)

Near northernmost part of the studied area there is offshore saline aquifer in Middle Cambrian sandstone formation. The aquifer is a part or an extension of mid-Baltic Dalders monocline extending from Swedish to Latvian sector which according to Bastor 2 project could have a substantial storage capacity, up to 1.9 Gt [8]. In CCUS ZEN project previous studies on the aquifer have been reviewed ([2]-[3]) and the prospective area in Polish sector [7] has been reassessed (Fig. 11; [2]). Several hydrocarbon fields occur within the aquifer in structural traps. The Cambrian offshore aquifer (Fig. 11) is well explored in areas where hydrocarbon fields were discovered and developed.

Fig. 10Data availability in the area of Kamionki saline aquifer structure – the structure extent after [7]

![Data availability in the area of Kamionki saline aquifer structure – the structure extent after [7]](https://static-01.extrica.com/articles/24676/24676-img10.jpg)

Table 2The proposed storage and transport options for the value chain subclusters – based on [2]-[3] and [9]

Emitter subcluster (emissions: total; selected) | Emission sources (emission [Mtpa]) | Storage site (capacity [Mt]) | Transport option (approx. distance [km]) | Remarks |

Bydgoszcz (0.893; 0.164) | Bydgoszcz WtE Energy from waste (0.164) | Konary (282) | Pipeline (38.2) | Bio-CCS possible; pipeline distance till Inowrocław hub (Fig. 3) |

Bydgoszcz Power – CHP (0.729) | Not recommended (old, hard coal fired plant) | |||

Piechcin-Janikowo-Inowrocław (3.442; 1.882) | Holcim Cement Piechcin-Bielawy (1.266) | Konary (282) | Pipeline to Piechcin (1.5) | Kujawy Go4EcoPlanet project (capture, railway transport of ~1 Mtpa to CO2 terminal in Gdańsk after 2027) |

Piechcin lime (0.196) | Pipeline to Janikowo (7.7) | |||

Janikowo chemicals (0.179) | Pipeline to Inowrocław hub (9.9) | |||

Inowrocław chemicals (0.241) | Pipeline to Konary site (16.7) | Total pipeline length of the subcluster is 35.8 km | ||

Janikowo Power – CHP (0.723) | Not recommended (old, hard coal fired plant) | |||

Inowrocław Power – CHP (0.837) | Not recommended (old, hard coal fired plant) | |||

Toruń (0.268; 0.0) | Toruń Power – CHP (0.269) | Not recommended (small gas and fuel oil fired plant, located opposite side of Vistula river) | ||

Włocławek (2.048; 1.813) | Włocławek NGCC (1.022) | Konary (282) | Pipeline to ammonia plant (2.8) | Orlen CCS ready CHP plant |

Włocławek ammonia (0.791) | Pipeline to Konary site (27.0) | Orlen hydrogen hub in development; Total pipeline length of the subcluster is 35.8 km | ||

Włocławek Power – Heating (0.119) | Nor recommended (small, hard coal and gas fired) | |||

Włocławek Oil & Gas Processing (0.116) | Not recommended (small, gas fired plant) | |||

Płock (6.975; 4.328) | Płock refinery (2.557) | Kamionki (99) | Pipeline to remaining plants in Płock complex (0.7) | Orlen hydrogen hub development, CO2 use products |

Płock NGCC (0.947) | Pipeline to Kamionki site (3.5) | Orlen CCS ready CHP plant | ||

Płock chemicals1 (0.721) | ||||

Płock chemicals2 (0.103) | Total pipeline length of the subcluster is 4.2 km | |||

Płock Power – CHP (2.647) | Not recommended (old, fuel oil fired plant) | |||

Świecie (3.973; 3.973) | Świecie Paper and pulp (3.973) | Cambrian offshore (188) | Onshore pipeline and/or barges floating Vistula river to Gdańsk terminal, ship from the terminal to the site (~245) | Largest biomass-fired installation in Poland (fossil fuel share negligible) |

Grudziądz (0.146; 0.0) | Grudziądz Power – CHP (0.146) | Not recommended (old, small, hard coal fired); located near Vistula river | ||

Kwidzyn (0.687; 0.687) | Kwidzyn Paper and pulp (0.687) | Cambrian offshore PL (188) | Onshore pipeline and/or barges floating Vistula river to Gdańsk terminal, ship from the terminal to the site (~195) | Fossil fuel (hard coal) is gradually replaced with biomass (poplar) |

Elbląg (0.223; 0.223) | Elbląg Power – CHP (0.223) | Cambrian offshore PL (188) | Onshore pipeline and/or barge to Gdańsk terminal, ship from the terminal to the site (~200) | The emitter is small but is in process of replacing fossil fuels with biomass |

Gdańsk (3.359; 1.727) | Gdańsk Refinery1 (1.516) | Cambrian offshore PL (188) | A short pipeline to Gdańsk terminal, ship from the terminal to the site (~7+113) | The larger refinery is a quite old and fuel oil fired but unlikely to be closed because of strategic reasons |

Gdańsk Refinery2 (0.211) | ||||

Gdańsk Power – CHP1 (1.340) | Not recommended (old, hard coal fired plant) | |||

Gdańsk Power – CHP2 (0.292) | Decommissioned recently | |||

Gdynia (0.670; 0.0) | Gdynia Power – CHP (0.670) | Not recommended (old, hard coal and fuel oil fired plant) |

In current legal framework in Poland offshore CO2 storage is allowed [11], but Article 11 of the Helsinki Convention is currently deemed to prohibit storage under the Baltic Sea seabed [12].

The northern part of the value chain (Fig. 4) includes a number of emission sources located mostly near Vistula river. Hence, one scenario in this case might employ barges floating Vistula to future CO2 terminal in the port of Gdańsk. Another scenario includes onshore pipelines or a combination of pipelines and barges transporting carbon dioxide to the terminal (Table 2). Then collected CO2 could be transported to the prospective aquifer under Baltic Sea by ship or undersea pipeline, or by ship to a storage site under North Sea as planned in the ECO2CEE project ([3]-[4]). In case the Cambrian offshore aquifer in the Polish sector is utilized as the storage site, necessary offshore collecting and injection infrastructure is to be developed there. It should be noted the offshore aquifer is also connected to the same aquifer in Swedish sector – Fig. 4, Fig. 11).

Fig. 11The offshore prospective Cambrian saline aquifer area including hydrocarbon fields – based on [2] and [7]

![The offshore prospective Cambrian saline aquifer area including hydrocarbon fields – based on [2] and [7]](https://static-01.extrica.com/articles/24676/24676-img11.jpg)

As mentioned above, the concept on first stage of the ECO2CEE PCI in northern Poland includes the multimodal CO2 ship terminal in Port of Gdańsk and two emission sources: Kujawy cement plant of Holcim and Płock refinery of Orlen [4]-[5]. Railway transport of liquid CO2 is planned at that stage. The distance by rail from the emitter to the terminal is about 200 km in case of each emitter [9]. It is proposed to include in the second stage of the PCI a number of emission sources located between the Gdańsk terminal and the Holcim cement plant (Fig. 12). Total CO2 emission of these installations slightly exceeds the CO2 terminal capacity as planned in the PCI second stage (9 Mtpa; Fig. 2). However, most likely no more than 80-90 % of these emissions will be captured and a small part of captured emissions might be utilized in CO2 use products [9]. The preferred transport option in the second stage is onshore pipeline and the estimated length of such pipeline between Kujawy cement plant of Holcim and the Gdańsk terminal is about 200 km. On the other hand, it is proposed to connect the cement plant to transport and storage infrastructure around the Konary site (Fig. 12).

Fig. 12The possible integration of the value chain into the second stage of the PCI project – based on [9] and [2]

![The possible integration of the value chain into the second stage of the PCI project – based on [9] and [2]](https://static-01.extrica.com/articles/24676/24676-img12.jpg)

5. Conclusions

In CCUS ZEN project one of value chains considered includes emission sources located in northern Poland. Some of these emission sources are considered in the ECO2CEE PCI on CO2 terminal in the Port of Gdańsk.

A scenario in the Kujavia-Masovia cluster takes into consideration storage in onshore saline aquifer structures of likely large capacity located very close to the emitters. The cluster includes two of the ECO2CEE PCI emitters: Orlen Płock refinery and Holcim cement plant. In the cement plant the industrial scale capture project Go4ECOPlanet is ongoing. Storage and transport infrastructure (pipeline network) development could be relatively inexpensive there, provided relevant regulations on onshore storage and transport are adopted and public acceptance gained. Because of a significant CO2 storage potential there, further expansion of the value chain could be possible, i.e. more emitters could be added eventually to the cluster.

Emitters located between the terminal in Gdańsk and Orlen Płock refinery and Holcim cement plant could be proposed as a possible direct extension of the PCI in Poland after 2030. In such case pipeline network construction is suggested eventually, as a more permanent solution than railway transport.

Hence, another storage option could be offshore storage of carbon dioxide in the Cambrian aquifer in Polish sector of the Baltic Sea, but the Article 11 of the Helsinki Convention could be an obstacle. The offshore storage potential in Polish sector is not as big as in the onshore scenario, and the option is rather not recommended in case of emitters located deep inland.

Putting all together, onshore and/or offshore storage options in the region together with proposed transport infrastructure could supplement and enhance the original concept of the PCI based on CO2 terminal in Port of Gdańsk.

References

-

CCUS ZEN, https://ccuszen.eu/

-

I. Gravaud et al., “D1.2 Identification of promising CCUS value chains in the two ZEN regions for further analyses in WP3,” EU Horizon Europe CCUS ZEN, Project 101075693, 2023.

-

C. Ringstad et al., “D1.1 High-level regional mapping of CO2 emission sources, utilization industry and infrastructure in the Baltic Sea and Mediterranean Sea regions,” EU Horizon Europe CCUS ZEN, Project 101075693, 2023.

-

Orlen, “Project ECO2CEE (prev. EU CCS Interconnector),” in Carbon Sequestration Leadership Forum 2023, Technical Group Mid-Year Meeting and Workshop on CCUS in Central and Eastern Europe, 2023.

-

Orlen, “ORLEN S.A. – implementing CCS through ECO2CEE Project,” in Baltic Carbon Forum, 2024.

-

L. Dziewińska, S. Marek S., R. Tarkowski, and B. Uliasz-Misiak, “Potential geological structures to CO2 storage in the Mesozoic Polish Lowlands (characteristics and ranking),” (in Polish) in Studia Rozprawy i Monografie IGSMiE PAN, Vol. 164, 2010, pp. 1–138.

-

A. Wójcicki, S. Nagy, J. Lubaś, J. Chećko, and R. Tarkowski, “Assessment of formations and structurescsuitable for safe CO2 storage (in Poland) including the monitoring plans),” (English summary), (in Polish), PGI-NRI, Warsaw, 2014.

-

P. A. Nilsson, “CCS in the Baltic Sea region – Bastor 2,” Elforsk report 14:50, 2014.

-

L.-H. Sousa et al., “D3.2 Identification of potential PCI,” EU Horizon Europe CCUS ZEN, Project 101075693, 2024.

-

“Polish Geological and Mining law,” (in Polish), Dziennik Ustaw 2024 poz. 1290, 2024.

-

“Ordinance of the Minister of the Environment of September 3, 2014 on areas where the location of an underground carbon dioxide storage complex is allowed,” (in Polish), Dziennik Ustaw 2014 poz. 1272, 2014.

-

L. Wammer Østgaard, “CCS under the London Protocol and the Helsinki Convention: status,” in Baltic Carbon Forum, 2024.

About this article

The research is supported by (Coordinated and Support Action) CCUS ZEN project of Horizon Europe programme (Grant No. 101075693, coordinator SINTEF, Norway) financed by CINEA.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.