Abstract

Solar energy is a non-conventional source of energy. Solar panels generate electrical output by absorbing solar radiation. The performance of photovoltaic (PV) module often depends on environmental factors like dust, humidity, hail and temperature. Installation elements like altitude, installation site, tilt angle also affects the efficiency of solar energy output. The objective of this research work is to clean the dust deposited on PV panels using the minimum amount of water and energy. To regularly clean the dust, a semi-automatic self-cleaning mechanism has been designed and fabricated, which cleans the deposited dust on the solar panel automatically. Therefore, the process turns out to be reliable and faster and it leads to increased power output of the solar panels. An experimental investigation has been done at Bennett University, Greater Noida dated 15 October to 21st October 2019. An increase in efficiency by 1.2 % to 3 % was reported in this experimental study.

1. Introduction

The world is conscious about energy crisis problem and it’s time to implement other alternative mechanisms for obtaining safe and efficient energy. Jacbson et al. [1] One option is to use of renewable resources energy especially solar energy that plays a key role in society. This sustainable energy resource can help to reduce worldwide energy insecurity.

Deepak et al. [2] Solar photovoltaic panels have the ability to absorb the sunlight as a source of energy to generate electricity or heat. And it is designed in such a way that maximum output has to be obtained whether it is used to generate electricity or any other purpose. Paudyal et al. [3] The energy generated by solar photovoltaic modules is related to the solar irradiance and sun’s spectral content, as well as other factors like environmental, climatic, component performance and inherent system.

One of the factors affecting the output of PV modules is the accumulation of dust on the top of it. The accumulation of dust particles and debris on the surface of photovoltaic (PV) panels negatively affects the performance.

Chen et al. [4] proposed an alternative approach to evaluate the cleaning efficiency of dust particles. Brush on disk apparatus was used with polymetric tip made of polyoxymethylene sweeping on a glass substrate. applied loads and the relative humidity affected cleaning efficiency considerably. Kawamoto H. [5] found a novel method of dust removal from soiled solar panels using electrostatic cleaning equipment. High AC voltage applied on a solar panel forces the dust particles downwards due to gravitational force. the limitation of the system is that it’s not fully automatic and needs a robotic system. Parrott et al. [6] improved the cleaning efficiency of PV system by 0.25 % per day by using robotic cleaning method. The robotic system consisting of silicone rubber foam brush minimized the effect of dust on the PV panels and increased the power output. This method was cheap and did not damage the solar panels. Vasiljev et al. [7] developed the system for ultrasonic cleaning action method is used to infiltrate the small cracks and hard-to-reach surfaces; penetrating areas normally inaccessible to other cleaning methods. Lu et al. [8] in this method linear piezoelectric actuator are used to clean the PV modules with the help of wipers attached to the actuator. This system was compact sized and light weight. Du et al. [9] designed a special nozzle to remove dust on the PV module. A multi-stage expansion nozzle used in different climatic conditions was designed. Chesnutt et al. [10] designed an electrodynamic dust shield (EDS) to lift and transport dust particles via electrodynamic waves generated by electrodes on the panel surface. Deb et al. [11] developed an automated water free cleaning system to remove dust over the solar panels and also compared the energy captured. Assi et al. [12] developed wide availability of air conditioners, using air flow from the fan of air-conditioners to force the flow the dust on solar panels and also implemented this technique in various countries and widely applied in United Arab Emirates (UAE). Park et al. [13] developed a passive method of cleaning the PV module. A superhydrophobic panel was designed in such a way that Rain and water accumulated due to atmospheric condensation settle in the micro depressions present in the glass surface where they attract particulate matter. The water quickly evaporates, leaving residues that need to be removed. Nano-hydrophobic layer fills in the micro-depressions and provide a smooth glass surface that prevents the holding of water. Demenkova et al. [14] proposed a control system with sun tracing algorithms. Algorithms us tested on moving solar panels and also finds the effectiveness of the PV module. Moharram et al. [15] in this method compared using non-pressurized water and surfactants and finds surfactants is more useful and efficient. Pan et al. [16] proved that difference between the bare glass and nano-micro structured coating on the PV module and shows how nano micro structured coating glass achieves the highest transmittance rate after dust deposition. Saidan et al. [17] study found that in desert area due dust accumulation shows negative impact on PV modules and decreases the efficiency. Sivan et al. [18] proposed automatic self-cleaning mechanism using elements like light dependent resister (LDR) sensors, sprayers and wipers unit works depending upon solar output.

In this research paper an effort has been done to increase the maximum electrical energy of PV module. To address this need for a cleaning mechanism a semi-automatic self-cleaning mechanism has been developed for solar panels. This device will boost the efficiency by increasing the energy output of solar panels quickly and it is cost-effective.

2. Description of proposed photovoltaic (PV) system integrated with solar panel cleaning system

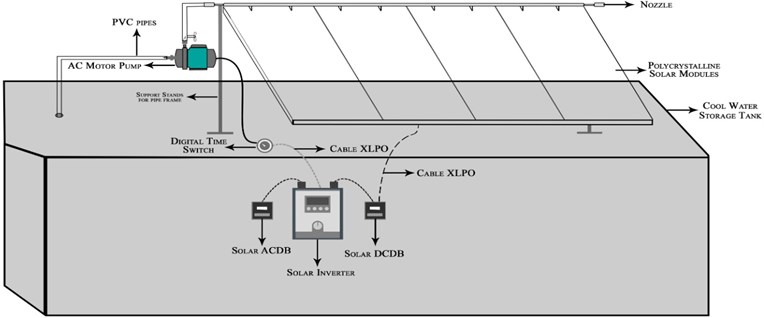

An experimental set up proposed “PV system integrated with solar panel cleaning system” has been installed at the rooftop of Block A, Bennett university. The schematic diagram of the whole experimental set up has been shown in Fig. 1.

Fig. 1Experimental setup of PV system added with solar panel cleaning system

The four photovoltaic (PV) modules have been mounted size (196 × 99 × 3.5 cm each PV module has 72 solar cells) on the cast-iron frame. Further, nozzles of diameter 6 mm and 12 in number have been attached at the top of PV modules. And material of nozzle made up of brass metal. The photographs of the experimental setup are presented in Fig. 2(a). And time switch is attached to the solar inverter Fig. 2(b), triggers as per time set (Generally 2 hrs), and turns on the AC motor pump of 0.5 HP is also attached to the system and it lifts the water from the water tank and water enters into nozzles. From the nozzles water is sprayed on the PV module glass as of its water flows on the glass then dust and dirt particles are removed and it helps to increase in electrical efficiency of the PV module drops. Said et al. [19]. The specification of various equipment's is specified in Table 1.

Fig. 2a) Actual photograph of the experimental setup showing PV module and nozzles; b) actual photograph showing various equipment used to measure the power output

a)

b)

Table 1Specifications of PV system added with solar panel cleaning system

S.no | Item | Quantity | Description |

1. | Solar panels | 4 | Each panel consist of 72 cells and connected in series |

2. | Water tank | 1 | Capacity of 2000 litres Made of concrete and bricks |

3. | Pipe | 4 | Material PVC, diameter of is 3/4 inch and total length is 12 meters |

4. | AC motor | 1 | 0.5 horse power |

5. | Elbow joints | 4 | Material PVC ¾ inch diameter |

6. | T-joints | 14 | Material PVC ¾ inch diameter |

7. | Nozzle | 12 | Material brass and diameter 6 mm |

8. | Time switch | 1 | Model frontier TM619H2 |

9. | Solar inverter | 1 | Solex invertor 3 kw |

10. | Support stand | 2 | Made up of cast iron and length 153 cm each |

11. | Solarimeter | 1 | Digital solar power meter Model: KM-SPM-11 |

3. Analysis of the photovoltaic module system

The expression of electrical efficiency of PV system is as follows:

Power input (Pm) = Solar irradiance × surface area of the panels, where, Pm (W) is the maximum power generated from the PV panels, A (m2) is the surface area of the panels and I (W/m2) is the solar irradiance incident on the panels. The maximum power generated is estimated using solarimeter.

The expression to calculate Fill Factor is as follows:

where Ioc – short circuit current, Voc – cut-off voltage.

An efficiency increase can be calculated by subtracting average efficiency without dust and without dust:

Increased efficiency = (average efficiency without dust) – (average efficiency with dust).

4. Results and discussions

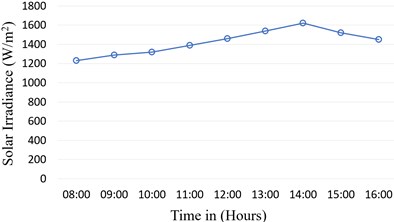

This study has been carried out at roof top, Block A, Bennett University, Greater Noida, India from 15-10-2019 to 21-10-2019. The equipment solarimeter has been used to measure the solar irradiance (Fig. 3). The solar irradiances have been noted to be maximum at around 2 pm and its value has been found to be 1620 W/m2. Shows the average solar irradiance over the study period.

Table 2 exhibits the solar radiation in W/m2. It can be seen that total solar radiation increases from 8:00 am to 14:00 pm and further it decreases.

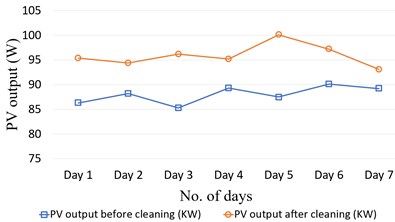

The experimental reading for PV module output from 15-10-2019 to 21-10-2019 have been reported in Table 3.

Table 2Average values of solar irradiance

Time | Solar irradiance (W/m2) |

08:00 | 1230 |

09:00 | 1290 |

10:00 | 1320 |

11:00 | 1390 |

12:00 | 1460 |

13:00 | 1540 |

14:00 | 1620 |

15:00 | 1520 |

16:00 | 1450 |

Table 3Variation in PV module output

Days | PV output before cleaning (KW) | PV output after cleaning (KW) |

Day 1 | 86.3 | 95.4 |

Day 2 | 88.2 | 94.4 |

Day 3 | 85.3 | 96.2 |

Day 4 | 89.3 | 95.2 |

Day 5 | 87.5 | 100.1 |

Day 6 | 90.1 | 97.2 |

Day 7 | 89.2 | 93.1 |

Fig. 3Variation of solar irradiance

Fig. 4Variation in PV modules output

The plot shows variation in PV module output (Fig. 4) and it describes the trends of efficiency. It shows the variation in PV module output with dust and without dust with respect to change in time and date for the PV module. The calculated average efficiency increases by 1.2 % to 3 % after cleaning the panel. Inferred from the graph that the efficiency increases with the regular cleaning.

The efficiency of the solar panel is seen to be varying in accordance with the fluctuating rate of dust deposition. The study period coincided with the immediate variables like solar irradiance and dust deposition have considerably low values. Dust deposition has an adverse effect on the efficiency of solar panels. As the dust accumulation on panels increases, unless any cleaning effect applied to it, the power generation efficiency of solar panels starts to decrease.

5. Conclusions

In this research work an experimental set up has been set up to study the effects of cleaning glass of PV module in order to improve the performance of PV panels. The following conclusions have been made from this investigation:

1) This mechanism requires less time for cleaning of solar panels in comparison with manual cleaning. It ultimately reduces the total time required for cleaning of all solar panels.

2) It was reported that total solar radiation increases from morning to afternoon and further it drops.

3) This cleaning mechanism increases power generation gives a cleaned surface after operation in an easy way and in less time and effort. the efficiency of PV panels was found to increase from 1.2 % to 3 %.

References

-

Jacobson M. Z., Delucchi M. A. Providing all global energy with wind, water, and solar power, Part I: technologies, energy resources, quantities and areas of infrastructure. Energy Policy, Vol. 39, Issue 3, 2011, p. 1154-1169.

-

Deepak Tiwari, Ahmad Faizan Sherwani, Deepali Atheaya, Anil Kumar, Nishant Kumar Thermodynamic analysis of Organic Rankine cycle driven by reversed absorber hybrid photovoltaic thermal compound parabolic concentrator system. Renewable Energy, Vol. 147, Issue 1, 2020, p. 2118-2127.

-

Paudyal B. R., Shakya S. R. Dust accumulation effects on efficiency of solar PV modules for off grid purpose: a case study of Kathmandu. Solar Energy, Vol. 135, 2016, p. 103-110.

-

Eugene Yu-Ta Chen, Lian M, Yuan Yue, Bing Guo, Hong Liang Measurement of dust sweeping force for cleaning solar panels. Solar Energy Materials and solar Cells, Vol. 179, 2018, p. 247-253.

-

Kawamoto Hiroyuki Electrostatic cleaning equipment for dust removal from soiled solar panels. Journal of Electrostatics, Vol. 98, 2019, p. 11-16.

-

Parrott Brian, Zanini Pablo Carrasco, Shehri Ali, Kotsovos Konstantinos, Gereige Issam Automated, robotic dry-cleaning of solar panels in Thuwal, Saudi Arabia using a silicone rubber brush. Solar Energy, Vol. 171, 2018, p. 526-533.

-

Vasiljev Piotr, Borodinas Sergejus, Bareikis Regimantas, Struckas Arunas Ultrasonic system for solar panel cleaning. Sensors and Actuators A: Physical, Vol. 200, 2013, p. 74-78.

-

Lu Xiaolong, Zhang Qi, Hu Junhui A linear piezoelectric actuator based solar panel cleaning system. Energy, Vol. 60, Issue 1, 2013, p. 401-406.

-

Du Xiaoqiang, Jiang Feng, Liu Enxiao, Wu Chuanyu, Fathi H. Ghorbel Turbulent airflow dust particle removal from solar panel surface: Analysis and experiment. Journal of Aerosol Science, Vol. 130, 2019, p. 32-44.

-

Chesnutt Jennifer K. W., Ashkanani Husain, Guo Bing, Wu Chang-Yu Simulation of microscale particle interactions for optimization of an electrodynamic dust shield to clean desert dust from solar panels. Solar Energy, Vol. 155, 2017, p. 1197-1207.

-

Deb Dipankar, Brahmbhatt Nisarg L. Review of yield increase of solar panels through soiling prevention, and a proposed water-free automated cleaning solution. Renewable and Sustainable Energy Reviews, Vol. 82, Issue 3, 2018, p. 3306-3313.

-

Assi A., Hassan A., Al-Shamisi M., Hejase H. Removal of air blown dust from photovoltaic arrays using forced air flow of return air from air conditioning systems. International Conference on Renew Energies for Developing Countries (REDEC), 2012.

-

Park Y., Im H., Im M., Choi Y. Self-cleaning effect of highly water-repellent micro shell structures for solar cell applications. Journal of Materials Chemistry, Vol. 21, Issue 3, 2011, p. 633-636.

-

Demenkovaa T. A., Korzhova O. A., Phinenko A. A. Modelling of algorithms for solar panels control systems. Procedia Computer Science, Vol. 103, 2017, p. 589-596.

-

Moharram K. A., Abd-Elhady M.-S., Kandil H. A., El-Sherif H. Influence of cleaning using water and surfactants on the performance of photovoltaic panels. Energy Conversion and Management, Vol. 68, 2013, p. 266-272.

-

Pan Anjian, Lu Hao, Zhang Li Zhi Experimental investigation of dust deposition reduction on solar cell covering glass by different self-cleaning coatings. Energy, Vol. 181, 2019, p. 645-653.

-

Saidan Motasem, Albaali Abdul Ghani, Alasis Emil, Kaldellis John K. Experimental study on the effect of dust deposition on solar photovoltaic panels in desert environment. Renewable Energy, Vol. 92, 2016, p. 499-503.

-

Athira Sivan, Athira Sivan, Lakshmi Priya G. S., Sera Mathew Automatic self -cleaning solar panel. International Research Journal of Engineering and Technology (IRJET), Vol. 4, Issue 5, 2017, p. 2035-2037.

-

Said S. A. M., Walwil H. M. Fundamental studies on dust fouling effects on PV module performance. Solar Energy, Vol. 107, 2014, p. 328-337.