Abstract

In this work, for the first time, criterion dependencies of the speed of movement of the melt in the bath of an ore-thermal furnace during electric arc melting of oxide refractory materials under external electromagnetic influence were obtained. The initial quantitative characteristics for generalization in the form of the dependence of the speed in the zone of intense movement of the melt on the currents in the electrodes and the electromagnetic device were taken on the electrolyte and mercury physical models of an ore-smelting furnace with an electromagnetic device. Physical modeling was carried out while maintaining the invariance of the derived similarity criteria: the electrovortex flow parameter πμ and the external magnetic field parameter πl. In order to extend the experimental results obtained to a whole group of similar phenomena, the dependences of the dimensionless speed of melt movement (Reynolds criterion) on the dimensionless parameters of the external magnetic field and electric vortex flow were obtained and constructed. Since for all similar processes the similarity criteria retain the same values, then the criterion dependencies for them will be the same, and the results obtained can be extended to all similar cases.

Highlights

- For the first time similarity criteria were derived: the electric vortex flow parameter - and the external magnetic field parameter - to simulate the physical processes of melt movement in the bath of an ore-thermal furnace during electric arc melting of oxide refractory materials under external electromagnetic influence.

- For the first time, experimental studies were carried out on electrolyte and mercury physical models of the dependence of the speed of movement of model liquids on the currents in the bath and the electromagnetic device.

- For the first time, criterion dependences of the speed of movement of the melt of oxide refractory materials in the bath of an ore-smelting furnace under external electromagnetic influence were obtained and constructed, allowing the research results to be extended to all similar cases.

1. Introduction

During the process of electric arc melting of materials under external electromagnetic influence, a complex structural movement of the melt occurs in the bath of an ore-thermal furnace. As a result, the melting process is intensified, energy consumption is reduced, and the chemical and temperature homogeneity of the melt increases, which helps improve the quality of the final product. In this case, the effectiveness of the electromagnetic effect depends on both the structure and the speed of the resulting movement of the melt in the bath of the electric arc furnace [1-3].

The implementation of experimental work related to the study of heat and mass transfer phenomena in the bath of an ore-thermal furnace is complicated by the emerging powerful electromagnetic fields and high temperatures of more than 2000 °C. A serious reason limiting research on existing industrial units is the creation of interference with the production process, loss of production time and safety requirements. Due to the complexity of direct research and the lack of sufficiently reliable and reliable theoretical methods of study, when analyzing such complex phenomena it is convenient to use the method of physical modeling. Physical modeling is widely used to study magnetohydrodynamic processes occurring during melting of various materials in electric arc furnaces [4-10].

The experimental dependences of the speeds of movement of model liquids on the current of the electromagnetic device and the current strength in the liquid obtained using physical models are of limited value, since they are applicable only to this particular case. To extend the experimental results obtained to a whole group of similar phenomena, it is necessary to generalize them by presenting the dependencies between individual quantities in the form of a connection between similarity criteria, i.e. in the form of criterion dependencies characterizing these processes. Since for all similar processes or phenomena the similarity criteria retain the same meaning, then the criterion dependencies for them will be the same, and can be extended to all similar phenomena [11-14].

Thus, it is necessary to study the dependence of the movement of the melt on the parameters of the ore-thermal furnace and the external electromagnetic field using the method of physical modeling with generalization of the research results to a whole group of similar phenomena, which is the goal of this work.

2. Research methods

The research consisted of two stages:

Stage 1. The study of the dependence of the speed of movement of the melt of oxide refractory material during their electric arc melting with electromagnetic influence was carried out by the method of physical modeling on electrolyte and mercury physical models of an ore-smelting furnace with an electromagnetic device.

Stage 2. As a result of processing data on the speed of movement of model liquids at various currents in the electrodes and in the electromagnetic device, the dependences of the dimensionless speed of liquid movement (Reynolds criterion) on the dimensionless external magnetic field and the dimensionless electric current force were obtained as universal quantitative characteristics.

Experimental studies were carried out on a physical model of an OKB-2126A ore-thermal furnace with an electromagnetic device specially developed for these purposes (Fig. 1), the parameters of which are given in Table 1 [3], [15].

Fig. 1Physical model of ore-thermal furnace OKB-2126A with electromagnetic device

Table 1Parameters of the ore-thermal furnace of type OKB-2126A and its physical model

Parameter | Ore-thermal furnace OKB-2126A | Electromagnetic device | ||

Original | Physical model | |||

1. Bath diameter 2. Bath depth, m 3. Electrode decay diameter, m 4. Electrode diameter, m 5. Rated linear voltage, V 6. Rated current, A 7. Total power, kVA | 1,8 0,4 0,8 0,25 123-244 4300 1800 | 0,18 0,04 0,08 0,025 0-380 250 (10*) 160 (5*) | Parameter | Value |

Length x width, m 2. Phase voltage, V 3. Phase current, A 4. Total power, kA | 0,22 х 0,095 220 20 13,27 | |||

* – for electrolyte physical model | ||||

Similarity criteria for physical modeling of processes occurring during electric arc smelting in an ore-thermal furnace of oxide refractory materials with electromagnetic mixing were derived by analyzing of equations the magnetic hydrodynamics that describe the processes.

The resulting four defining criteria πμ, πσ, πω, πl have the form:

When modeling turbulent motion, viscous forces and, together with them, complexes πσ, πω are insignificant and can be neglected. Thus, there remain two similarity criteria, the invariance of which must be observed:

– parameter of electric vortex flow – πμ=μ0I2/ρ-1η2 = idem;

– external magnetic field parameter – πl=BIl/ρ-1η2 = idem, where B – is magnetic induction; I – current strength in the melt; μ0 – magnetic constant;

– ρ melt density; η – dynamic viscosity; l – characteristic linear size.

Based on the obtained similarity criteria and based on convenience, an electrolyte in the form of a 25 % NaCl solution and mercury were used as model liquids, a physical model was selected on a scale of 1:10 for the OKB-2126 A ore thermal furnace and in relation to forsterite-chromite and corundum materials.

The study of the flows and structure of fluid movement was carried out using video and photography at various currents in the electrodes and an electromagnetic device. Due to the boiling of the 25 % NaCl solution, the current value in the bath was limited to I=10 A. Moreover, in the considered range I=1-10 A, the values of the defining criteria are πμ = 6,2×102-6,2×103, πl = 1,4×106-5,9×107. On the mercury physical model, the currents in the electrodes varied in a wide range I=50-500 A. In this case, the considered range of defining similarity criteria was πμ = 1,8×107-1,8×109 and πl = 3,4×108-3,4×109. The upper limit of currents is limited by the fact that when the currents in the electrodes increase more than I= 500 A, i.e. When the criterion value of electric vortex flow is πμ≥ 2×109, electric vortex flows excited as a result of the interaction of currents in the bath with their own magnetic fields become significant.

3. Research results

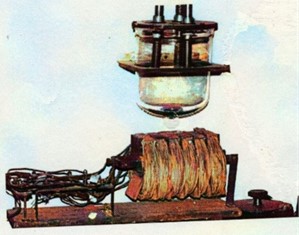

The motion structures on the surface of a bath of 25 % NaCl and mercury solution that arise when the electrodes and electromagnetic device are turned on are shown in Fig. 2.

The dependences of the speed in the zone of intense movement of model liquids at different values of currents in the electrodes and electromagnetic device are given in Table 2.

Table 2Speed of movement of the electrolyte NaCl (in the numerator) and mercury (in the denominator) at various currents in the electrodes and electromagnetic device

Electromagnetic device current, A | Current in electrodes, A | |||

1/100 | 3/200 | 5/300 | 7/500 | |

5/3 | 1.1/1.2 | 1.5/2.0 | 2.5/3.0 | 3.4/4.0 |

10/5 | 1.3/1.5 | 2.1/3.1 | 3.2/4.4 | 4.2/6.0 |

15/7 | 1.7/2.2 | 2.9/4.2 | 4.2/6.0 | 5.3/8.0 |

20/8 | 2.4/2.5 | 4.0.4.6 | 5.7/6.7 | 6.7/9.1 |

As can be seen from Table 2, when the current of the electromagnetic device increases from 5 to 20 A and the currents in the electrodes from 1 to 7 A, the speed of movement of the electrolyte increases from 1.1⋅10-3 to 6.7⋅10-3 m/s. The speed of movement of mercury in the zone of intense mixing with currents of the electromagnetic device I= 3-8 A and electrodes I= 100-500 A varies within the range of 1.2×10-2-9.1×10-2 m/s.

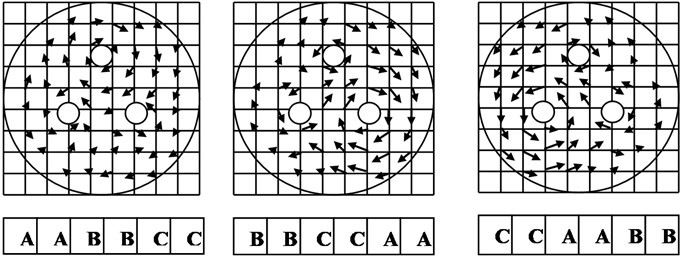

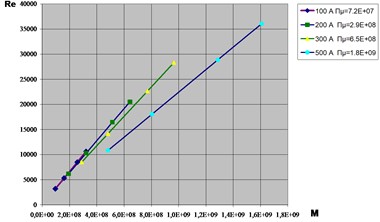

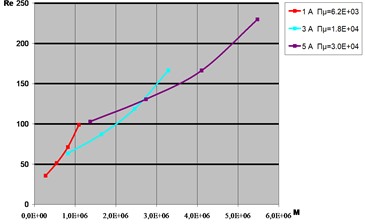

As a result of processing data on the speed of movement of model liquids at various currents in the electrodes and in the electromagnetic device, the dependences of the dimensionless speed of liquid movement (Reynolds criterion) on the dimensionless external magnetic field and the dimensionless electric current strength, presented in Fig. 3, were obtained as universal quantitative characteristics.

Fig. 2a) Movement patterns on the bath surface of 25 % NaCl and b), c) mercury solution, occurring when the electrodes and electromagnetic device

a)

b)

c)

Fig. 3Dependencies of Reynolds motion criteria 25 % solution of NaCl a) and mercury b) from external criteria magnetic field and electric vortex flow

a)

b)

With an increase in the criteria of the external magnetic field and electric vortex flow in the πμ= 6.2×102-6.2×103, πl= 1.4×106-5.9×107, the dimensionless speed of movement (Reynolds number) of a 25 % NaCl solution increases from 36 up to 230, and mercury in the range πμ = 1.8×107-1.8×109 and πl= 3.4×108-3.4×109 from 3190 to 36100. Thus, in studies on the electrolyte physical model, the Stokes regime takes place electromagnetic mixing, and on the mercury physical model – a developed turbulent regime.

Comparison of traces of movement on the free surface of the mercury bath with the structure of movement of the electrolyte NaCl, as well as the melt on the operating plants shows their identity and confirms the reliability and validity of the obtained results of physical modeling.

Since generalized dependencies are purely experimental, they are applicable only within the limits of changes in the argument confirmed by experiments, extrapolation of them both towards large and smaller values of the argument requires additional research.

4. Conclusions

As a result of processing data on the speed of movement of model liquids at various currents in the electrodes and in an electromagnetic device, the dependences of the dimensionless speed of liquid movement (Reynolds criterion) on the dimensionless external magnetic field πВand the dimensionless electric current force πI were obtained for the first time as universal quantitative characteristics.

With an increase in the criteria of the external magnetic field and electric vortex flow in the range πμ = 6.2×102-6.2×103, πl = 1.4×106-5.9×107, the dimensionless speed of movement (Reynols number) of a 25 % NaCl solution increases from 36 up to 230, and mercury in the range πμ = 1.8×107-1.8×109 and πl= 3.4×108-3.4×109 from 3190 to 36100. Thus, the electrolyte physical model allows us to simulate the Stokes mode of electromagnetic mixing, and the regime studied on the mercury physical model is a developed turbulent one.

Since the generalized dependencies are purely experimental, they are applicable only within the limits of changes in the argument, confirmed by experiments, extrapolating them both towards larger and smaller values of the argument for additional research.

References

-

Y. Abdrakhmanov and G. Kalimbetov, “Influence of an external alternating electromagnetic field on convective flows in the bath of an ore-thermal furnace during the melting of oxide refractory materials,” Vibroengineering Procedia, Vol. 49, pp. 147–152, May 2023, https://doi.org/10.21595/vp.2023.23187

-

Y. Chernikhov, “Electromagnetic mixing of metal: a new step in the evolution of arc furnaces,” Science and technology. Materials and technologies, 2019.

-

Y. Abdrakhmanov, A. Yegzekova, and Z. Kaliyev, “To the mechanism of influence of an alternating electromagnetic field on crystallization process of oxide refractory melts,” Vibroengineering Procedia, Vol. 49, pp. 153–159, May 2023, https://doi.org/10.21595/vp.2023.23172

-

N. Wei, L. Lida, C. Xiaojun, and W. Qingwei, “Criterion relaxation in physical simulation for electric melting glass furnace,” Research Journal of Applied Sciences, Engineering and Technology, Vol. 6, No. 8, pp. 1386–1388, Jul. 2013, https://doi.org/10.19026/rjaset.6.3960

-

S. D. Mandrykin, “Currents of liquid metals in closed cavities under the influence of electromagnetic and buoyancy forces,” (in Russian), 2021.

-

I. M. Yachikov, I. V. Portnova, and T. P. Larina, “Stady of the behavior of current-carrying liquid in the bath of DC arc furnace by an external vertical magnetic field on a physical model,” (in Russian), Izvestiya Visshikh Uchebnykh Zavedenii. Chernaya Metallurgiya = Izvestiya. Ferrous Metallurgy, Vol. 61, No. 1, pp. 28–34, Feb. 2018, https://doi.org/10.17073/0368-0797-2018-1-28-34

-

X. Xi, S. Yang, J. Li, J. Wu, M. Zhao, and M. Ye, “Physical model experiment and theoretical analysis of scrap melting process in electric arc furnace combined blowing system,” Ironmaking and Steelmaking Processes, Products and Applications, Vol. 47, No. 7, pp. 748–756, Aug. 2020, https://doi.org/10.1080/03019233.2019.1594549

-

I. M. Yachikov and I. V. Portnova, “Modeling of magnetic field behavior in dc arc furnace bath for different designs of current lead of bottom electrode,” Sciences of Europe. Technical Science, Vol. 2, No. 2, pp. 67–72, 2016.

-

Y. A. Tesfahunegn, M. Tangstad, G. Sævarsdottir, and H. Haraldsson, “Modelling of electric arcs for industrial applications, a review,” in Proceedings of the 16th International Ferro-Alloys Congress (INFACON XVI), pp. 1–15, Jun. 2021.

-

P. Hrma, “Criteria for physical modeling of electric glassmelting furnaces,” Journal of the American Ceramic Society, Vol. 66, No. 7, pp. 519–523, Jun. 2006, https://doi.org/10.1111/j.1151-2916.1983.tb10594.x

-

V. N. Belozertsev, Heat Exchange Intensification. Samara: Publishing House of Samara University, 2018.

-

K. Karalis, N. Karkalos, G. S. E. Antipas, and A. Xenidis, “Pragmatic analysis of the electric submerged arc furnace continuum,” Royal Society Open Science, Vol. 4, No. 9, p. 170313, Sep. 2017, https://doi.org/10.1098/rsos.170313

-

A. L. Kukharev and V. V. Miroshnikov, “Similarity criteria in modeling arc furnaces,” Bulletin of Lugansk State University named after V. Dal, Vol. 8, No. 38, pp. 93–97, 2020.

-

F. V. Nedopekin, O. V. Kazak, and A. N. Semko, Simulation of Hydrodynamic and Thermophysical Processes in Direct Current Steelmaking Furnaces. Donetsk: DonNU, 2014.

-

I. D. Kashcheev and K. G. Zemlyanoy, Production of Refractories: Textbook. St. Petersburg: Publishing House Lan, 2018.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.