Abstract

Approaches are presented for calculating carbon dioxide (CO2) emissions generated by the use of exhaust gas purification technology based on urea catalysts. To reduce harmful substances in the exhaust gases for diesel-fueled automobile engines, the need for SCR technology is justified. It is shown that the main source of emissions is diesel freight transport, while it is advisable to carry out calculations from 2010, and not from 2005, as a number of foreign experts insist. The working scheme of the integrated cleaning system of diesel engines of passenger cars has been developed. An integrated cleaning system for automotive engines has been developed. Additional emissions are very small and account for less than one percent of the CO2 emissions generated from the operation of all road transport. According to the results of the calculations, it was obtained that the share of emissions from the use of urea additives is very small to the emissions of СО2 formed during direct combustion of fuel.

Highlights

- A scheme of Selective Catalytic Reduction) technology has been developed to reduce the content of hazardous nitrogen oxides in the exhaust gases of diesel engines and reduce the carbon black content.

- The analysis of cars equipped with an integrated exhaust gas purification system (SCR and EGR) and trucks and buses equipped with a type of carbamide catalyst system (SCR) in Kazakhstan since 2009 has been carried out.

- Experimental and calculated results of CO2 emissions resulting from the operation of carbamide catalysts have been obtained, compared with total CO2 emissions from road transport.

- To the results of tests carried out in both the Russian Federation and Europe, it is confirmed that it is impossible to reduce the toxicity of exhaust gases by improving the quality of motor fuel alone while maintaining the old technology.

1. Introduction

The accounting of additives (urea-based catalysts) for the automotive sector in Kazakhstan is made for the first time. This task, within the framework of the National Inventory of Greenhouse Gases (GHG), has not been carried out until recently, since it was believed that the car fleet of the Republic of Kazakhstan (RK) is quite old, while the need for such calculations makes sense for relatively “new” cars [1]. However, after the recommendations of the review experts made during the 2019 review, this became one of the mandatory items. Accordingly, several sub-tasks had to be solved:

– Determination of the time period for which it makes sense to consider the use of catalytic converters.

– Assessment of the total age of the country's fleet.

– Estimate of the number of vehicles using different types of fuels.

– Evaluation of the number of vehicles using catalytic converter technologies.

– Assessment of the amount of fuel used in vehicles equipped with catalytic converters.

– Estimation of the number of additives used.

– Calculation of emissions СО2 from the use of urea additives.

– Summation of emissions СО2 from all types of cars using urea additive technology.

2. Define a time period

Although the greenhouse gas inventory has been calculated since 1990, which is the base for the country, the use of urea-based catalytic converters has started much later. By 1990, the technologies of forced fuel injection using nozzles into the intake manifold - (injection injection) and flexible control of the air mixture, which already significantly affected the amount of pollutant emissions, were quite widely used [2].

However, if we touch on the reduction of GHG emissions, then as already mentioned above, the technology did this only by reducing fuel consumption. There is a direct dependence: less fuel is burned, less total emissions of all gases, both polluting and having a greenhouse effect.

The use of technologies with catalytic converters came with the need for large-scale control of harmful substances and stricter environmental standards. They were implemented, as you know, in a series of EURO standards. An important feature of the implementation of standards was their phasing (Table 1), stimulating research in the field of improving the quality of combustion, the need to improve the quality and purification of fuel at factories, preparing the fuel mixture in engines before combustion, and adding additional devices (cellular converters, etc.) to carry out additional gas purification after fuel combustion.

In fact, because of this, two systems for reducing air pollution were developed: SCR for diesel (due to the use of urea solution) and EGR for gasoline cars (due to the partial return of exhaust gases to the general combustion system).

Table 1Timing of Euro standards for trucks and buses in Europe

Vehicle type | EURO 1 | EURO 2 | EURO 3 | EURO 4 | EURO 5 | EURO 6 |

Trucks weighing up to 3.5 tons | 10.1994 | 01.1996 | 01.2000 | 01.2005 | 09.2010 | September 2015 |

Heavy goods vehicles full weight from 3.5 to 12 tons | 10.1994 | 01.1998 | 01.2001 | 01.2005 | 09.2010 | September 2015 |

Heavy goods vehicles GVW over 12 tons and buses | 1992 | 1995 | 1999 | 2005 | 2008 | 2013 |

3. SCR technology

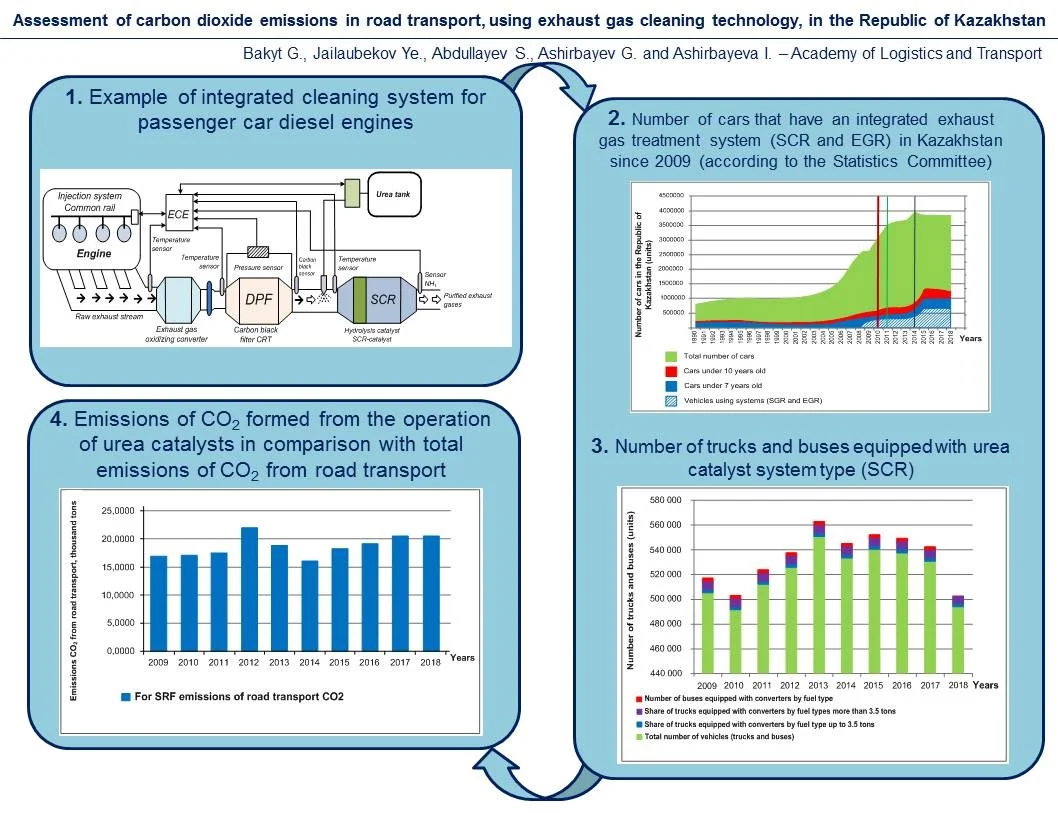

SCR (Selective Catalytic Reduction) technology (Fig. 1) – is designed to reduce hazardous nitrogen oxides in exhaust gases for diesel engines and reduce carbon black (for which CRT technology is used) [3]. To date, the method presented is the best between practical efficiency and economic feasibility.

Fig. 1Example of integrated cleaning system for passenger car diesel engines

The principle of operation of the technology is based on the use of a urea solution to carry out an emission reduction reaction. Urea is injected into the chamber of the outlet manifold installed before the catalyst through the nozzle into the exhaust gases, which are formed from the combustion of fuel. The urea solution forces to intensify the process of decomposition of nitrogen oxides into components: water and nitrogen, which can easily interact with wildlife. As mentioned in the beginning, this technology is most effective for diesel engines and is implemented using Ad blue solution as a technical component. The solution consists of demineralized water –67.5 %, urea solution –32.5 % and is located on modern cars in an additional tank, which is installed next to the fuel tank [4]. One of the disadvantages of the system is its freezing at negative temperatures (about minus 11*S), which prevents the entire system from working when starting and warming up the car, even if there is a heating element.

Let us list the main chemical transformations that will be carried out for the presented system.

Oxidizing catalyst:

2 NO + O 2 —» 2 NO2

2 CO + O 2 —» 2 СО2

CmHn + (m + n / 4) O 2 —» m СО2 + n/2 Н2O

Diesel particulate filter CRT:

С + 2 NO2 —» СО2 + 2 NO CО + O2 —» CО2

Hydrolysis catalyst:

CO (NH2) 2 + H2 O => 2NH 3 + CO2

SCR catalyst:

4NO + 4NH 3 + O 2 => 4N 2 + 6H 2 O NO + NO 2 + 2NH 3 => 2N 2 + 3H 2O

Of all available exhaust gas purification systems, only the SCR system installed on diesel engines must be taken into account to account for additional emissions of SG from vehicles. Thus, when calculating emissions, it is necessary to allocate first of all a new diesel vehicle, in part of which the exhaust gas removal technology should be integrated. This is determined by the Kazakhstan requirements to specific standards for emissions of motor vehicles, according to the technical regulations, which are put into effect in the following terms [5]: the environmental stage EURO-2 from July 15, 2009; environmental phase EURO-3 from 1 January 2011; Environmental phase EURO-4 from 1 January 2014.

The specifics of the Kazakhstan fleet are such that cars with an age of more than seven years do not use this cleaning technology, since it fails, and it is not very advisable to restore it, because of which the system simply emulates its work so that the on-board computer does not prevent the start and operation of the engine.

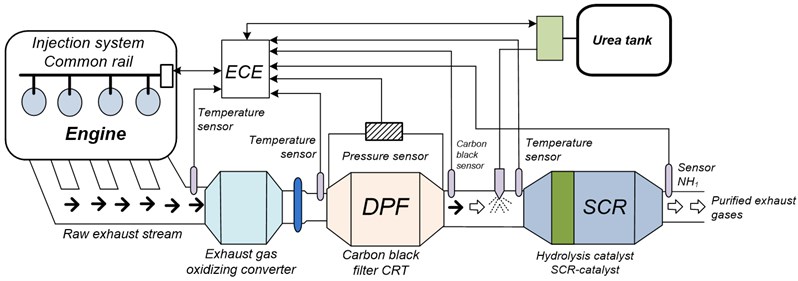

4. Estimation of the age of the country’s car fleet

Assessment of the age of the country’s fleet. Accounting for the age of the car fleet is the most important, as mentioned above, SCR technologies themselves were introduced with the introduction of EURO 4 and 5, that is, on all European machines, starting in 2005. For cars imported from neighboring countries, China, Korea, the Arab Emirates, Japan and the USA, which at the time of delivery to the country were already seven years old and no longer applies this rule. It is believed that if they were equipped with exhaust gas treatment technology, then by the time it was imported into the country it had already fully developed itself.

An important condition is the fact that when importing foreign cars to Kazakhstan until 2008, most of them were 7 years old or more. Only a very small percentage of cars sold in the country was completely new, with zero mileage. Since 2008, cars have been imported into the country much newer, but not always completely new. Although it is worth recognizing that at that time the park is currently being updated, it is not yet necessary to talk about a significant change in its internal age structure [6]. Today, cars are massively operated, which were imported back in the period of two thousandths. As already said, by the time of import, their age was at least 7-10 years. Thus, in the mass fraction, the average car today, is at least 25 years old (Fig. 2).

Unfortunately, the statistics agency in the reporting does not reflect this fact.

According to the presented diagram (Fig. 1), most of the Kazakh passenger fleet falls into the category of more than 10 years and “others”.

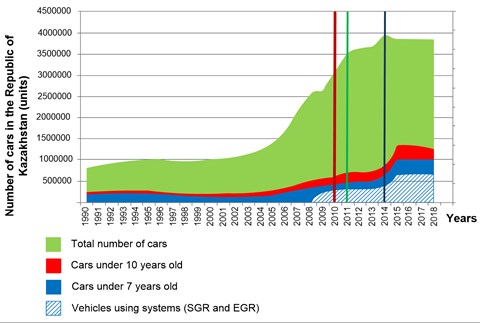

For trucks and buses, the Committee of Statistics does not reflect the age of the units in operation, which significantly complicates the calculations. Therefore, for an objective assessment, the annual difference in the existing fleet of cars was calculated, and it was accepted that this difference is new cars that already have a cleaning system. From the difference received, cars and buses that use gasoline and gas as fuel were excluded [7]. This was especially important for a fleet of trucks up to 3.5 tons, since it is these cars that can use gasoline engines, which can later be modified to be able to operate on gas. For trucks over 3.5 tons, this separation was not necessary, since they all run on diesel fuel (Fig. 3).

Fig. 2Number of cars that have an integrated exhaust gas treatment system (SCR and EGR) in Kazakhstan since 2009 (according to the Statistics Committee)

Fig. 3Number of trucks and buses equipped with urea catalyst system type (SCR)

Certain difficulties arose when dividing the bus fleet, by type of fuel. It is known that with the implementation of sustainable development policies, gas-powered buses began to operate in the urban environment. For this reason, it was necessary to exclude the share of such buses from the total number, and leave only diesel units.

Mobile fuel combustion, to calculate the SO2 of urea-based catalysts, the equation is used: Emissions = Activity × × Cleanliness ×, where: emissions - emissions СО2 from the use of urea-based additives in catalytic converters (Gg СО2); activity - number of urea-based additives used in catalytic converters (Gg); purity - urea weight fraction (%/100) in urea-based additives according to the Manual is recommended to be 32.5% by default if no more accurate data is available.

The coefficient 12/60 takes into account the stoichiometric conversion from urea (CO (NH2) 2) to carbon, in the equations presented by us it is reflected in the work of the hydrolysis catalyst, by the equation: CO (NH2) 2 + N2O = > 2NH3 + CO2.

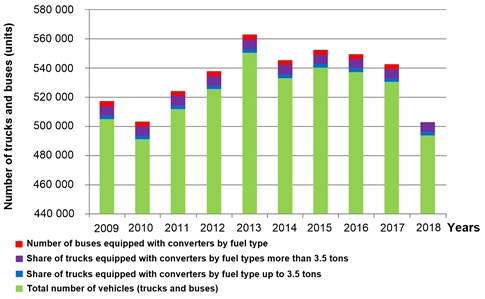

Coefficient converts carbon to CO. For the calculations, it was assumed that for the assessment of “Activities”, which actually reflect the amount of additive consumption, in our case 7 % of the amount of fuel used for trucks and 5 % for cars were used. This is due to the fact that according to all the sources that we studied before the calculations, it was precisely such volumes of fuel additive consumption that were indicated in accordance with the technical regulations [8]. Note that according to the Manual, the level of “Activity” is proposed to be estimated in the range from 1 to 3 % of the fuel consumed. Thus, the results obtained will be slightly more, but more precisely. The “Frequency” value of urea was used by default (32.5 %), since the value proposed by the Manual fit into the mass share of additives used in the domestic market of Kazakhstan (Fig. 4 and Table 2).

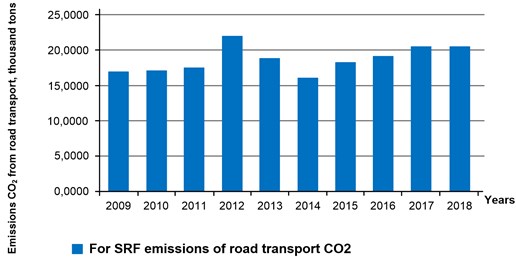

Fig. 4Emissions of СО2 formed from the operation of urea catalysts in comparison with total emissions of СО2 from road transport

Table 2Emissions CO2 urea catalysts in Kazakhstan by vehicle type (tons)

Years | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 |

Buses | 7711 | 7861 | 9122 | 11470 | 8780 | 4238 | 8130 | 8717 | 7621 | 8507 |

Freight up to 3.5 tons | 39159 | 37674 | 41111 | 49236 | 41224 | 20818 | 41286 | 46743 | 41563 | 33 |

Freight heavier than 3.5 tons | 89396 | 86891 | 96702 | 120674 | 98249 | 48434 | 96365 | 105936 | 97,802 | 104837 |

Cars | 26840 | 26784 | 32029 | 39663 | 35111 | 19844 | 69181 | 69196 | 67130 | 26840 |

Total | 136293 | 132453 | 146966 | 181420 | 148288 | 73509 | 145850 | 161465 | 147054 | 159344 |

The calculations made allow us to say that the share of emissions from the use of urea additives is quite small and on average equal to about 0.24 % of the emissions of CO2 formed from direct combustion of fuel in the category “Road transport”. Recall that according to the Decision of the ICEC 24/CP19 paragraph 37 [9], these emissions could not be taken into account. However, taking into account the time spent and the work done in the next report, they will need to be shown how to eliminate one of the comments of the compliance team. Whether these emissions will be taken into account in the future is difficult to say, practice shows that if calculations were made and despite the fact that their share is small in subsequent reports, these data are displayed, although they do not have a significant impact on the overall balance.

5. Conclusions

We also add that despite the strict technical regulations on imported and manufactured cars, Kazakhstan oil refineries lag behind the requirements for the production of appropriate fuel. It should be noted that according to the results of tests carried out in both the Russian Federation and Europe, it is confirmed that it is impossible to reduce the toxicity of exhaust gases by improving the quality of motor fuel alone while maintaining the old technology [7]. Thus, the use of fuel currently produced (not to mention in previous years) does not allow to fully take advantage of the technologies for cleaning up new cars, not to mention the number of outdated cars. The phased introduction of EURO-3, 4 and 5 in the country’s refineries will take a long time, and by the time we implement EURO-5, more improved standards will appear.

“The use of urea catalysts” to control general pollution, which by default is understood as a reduction. There is a possibility that annoying inaccuracies will be taken into account in the next edition of the Guide in order to eliminate the resulting uncertainties and misunderstandings.

To reduce the share of uncertainty in calculations, it is also necessary to revise the system of generating statistical reporting in Kazakhstan in the category of vehicles. Today, the submitted data are formed in the database of the Ministry of Internal Affairs of the Republic through an annual sample, which adds up the category of reporting on the number of total fleet of cars and its age. At the same time, the calculations presented should not change significantly after taking into account all uncertainties, and there is no doubt about their objectivity, with certain tolerances of accuracy.

References

-

J. Pielecha and K. Skobiej, “Evaluation of ecological extremes of vehicles in road emission tests,” Archives of Transport, Vol. 56, No. 4, pp. 33–46, Dec. 2020, https://doi.org/10.5604/01.3001.0014.5516

-

H. S. Chong, Y. Park, S. Kwon, and Y. Hong, “Analysis of real driving gaseous emissions from light-duty diesel vehicles,” Transportation Research Part D: Transport and Environment, Vol. 65, No. 65, pp. 485–499, Dec. 2018, https://doi.org/10.1016/j.trd.2018.09.015

-

M. Gis, “Assessment of exhaust emissions from vehicles in real traffic conditions,” in IOP Conference Series: Earth and Environmental Science, Vol. 214, p. 012035, Jan. 2019, https://doi.org/10.1088/1755-1315/214/1/012035

-

G. Bakyt, S. Abdullayev, N. Suleyeva, A. Yelshibekov, Z. Seidemetova, and Z. Sadvakassova, “Simulation of dynamic processes of interaction of car and railway track during train passage of curved sections of the track,” Transport Problems, Vol. 15, No. 2, pp. 59–70, 2020, https://doi.org/10.21307/tp-2020-020

-

J. Pielecha and M. Gis, “The use of the mild hybrid system in vehicles with regard to exhaust emissions and their environmental impact,” Archives of Transport, Vol. 55, No. 3, pp. 41–50, Sep. 2020, https://doi.org/10.5604/01.3001.0014.4229

-

J. H. Lim et al., “Emission factor of hazardous air pollutants in gas-phase from light commersial vehicle using PEMS on real-road driving,” Journal of Korean Society for Atmospheric Environment, Vol. 34, No. 2, pp. 191–206, Apr. 2018, https://doi.org/10.5572/kosae.2018.34.2.191

-

R. Varella, B. Giechaskiel, L. Sousa, and G. Duarte, “Comparison of portable emissions measurement systems (PEMS) with laboratory grade equipment,” Applied Sciences, Vol. 8, No. 9, p. 1633, Sep. 2018, https://doi.org/10.3390/app8091633

-

N. S. Sifat and Y. Haseli, “A critical review of CO2 capture technologies and prospects for clean power generation,” Energies, Vol. 12, No. 21, p. 4143, Oct. 2019, https://doi.org/10.3390/en12214143

-

I. A. Reşitoğlu, K. Altinişik, and A. Keskin, “The pollutant emissions from diesel-engine vehicles and exhaust aftertreatment systems,” Clean Technologies and Environmental Policy, Vol. 17, No. 1, pp. 15–27, Jan. 2015, https://doi.org/10.1007/s10098-014-0793-9

Cited by

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.