Abstract

In order to research the evolution of microstructures and properties of SCM435 wire rod after annealing with different initial structures, two kinds of initial microstructure (B+M and F+P) SCM435 wire rods were used to simulate spheroidizing annealing, softening annealing and stress relief annealing processes respectively. The results show that under the same process conditions, the spheroidization grade of B+M was 1-2 higher than that of F+P, while the hardness does not decrease with the increase of spheroidization grade. The analysis indicated that precipitation strengthening occurs not only in the micro alloy composition system, but also in carbon steel. By control the size and amount of cementite precipitation particles, obvious strengthening effect can also be produced. Besides, after high-temperature annealing, low spheroidization grade sample has more massive ferrite and concentrated cementite, causing the hardness decreasing. In addition, the differences between the simulation process and the industrial production process are analyzed to provide guidance for formulating annealing process of different enterprises and equipment.

1. Introduction

SCM435 wire rod is a JIS steel with good toughness, high tempering resistance and excellent resistance to delayed fracture, which could be used to produce class 10.9 and 12.9 fasteners and automotive parts. According to ISO898-1:2009, the mechanical properties of class 10.9 and 12.9 fasteners and automotive parts were shown in Table 1.

Table 1Mechanical properties of class 10.9 and 12.9 fasteners according to ISO 898-1:2009

Class | Tensile strength | Yield strength | Elongation rate | Section reduction | Rockwell hardness |

10.9 | ≥ 1000 MPa | ≥ 900 MPa | ≥ 9 | ≥ 48 | 32-39 HRC |

12.9 | ≥ 1200 MPa | ≥ 1080 MPa | ≥ 8 | ≥ 44 | 39-44 HRC |

However, high hardenability due to its high alloying elements (Cr: 0.90-1.20 %, Mn: 0.60-0.90 %, Mo: 0.15-0.30 %, according to JIS G4053), martensite and bainite quenched microstructure are susceptible formed in the production process of wire rod [1].

Therefore, in the manufacturing process of high-strength bolts in industrial production, spheroidizing annealing (SPA) treatment must be carried out first. The microstructure of the hot-rolled wire rod is improved by holding at high temperature for a long time, in order to form a spheroidized microstructure in which spheroidal carbides are uniformly distributed on the ferrite matrix. The deformation resistance and uniform deformation ability of the wire rod can be improved.

Lots of researches on spheroidizing microstructure grade and mechanical properties based on the original structure and annealing process were carried out [2-3]. It is generally believed that the hardness decreases with the increase of spheroidization grade. In this paper, Simulation experiments on SCM435 wire rod with different initial microstructure show that the increase of spheroidization grade does not correspond to the decrease of hardness, no matter by stress relief annealing (SRA), softening annealing (SOA) or spheroidization annealing process, and the mechanism analysis is conducted.

2. Test materials and process

2.1. Materials

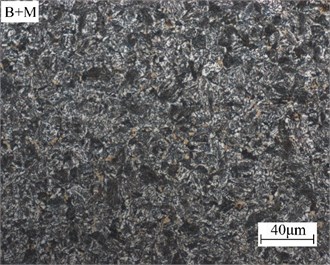

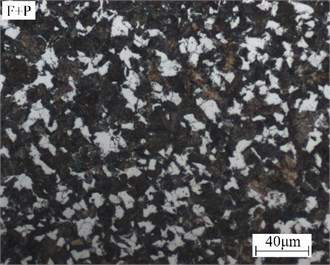

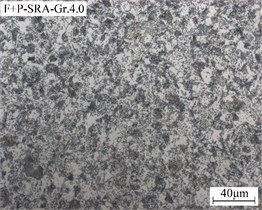

The SCM435 wire rod with 12 mm diameter produced by industrial 180 mm × 240 mm casting billet was used for the test. The chemical composition was shown in Table 2. Two different microstructures were obtained by different rolling processes: massive ferrite and pearlite (F+P), martensite and bainite (M+B), the initial microstructure was shown in Fig. 1.

Table 2Chemical composition of the test steel (wt.%)

C | Si | Mn | P | S | Cr | Mo |

0.33-0.38 | 0.15-0.35 | 0.60-0.90 | ≤0.025 | ≤0.025 | 0.90-1.20 | 0.15-0.30 |

Fig. 1Metallographic photos of two different initial microstructures (B+M and F+P)

2.2. Process

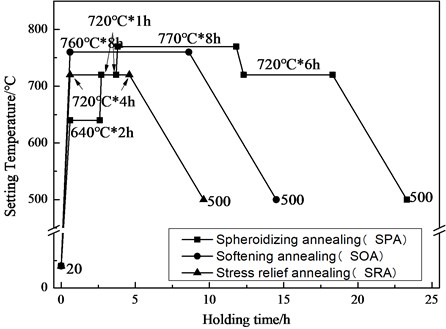

According to the spheroidizing annealing, softening annealing and stress relief annealing processes commonly used by users, the laboratory simulation process was developed as shown in Fig. 2. First, the sample is raised to a predetermined temperature (640, 720, 760 ℃) at a temperature rise rate of 15 ℃/min, SPA process requires to keep the temperature at 720 and 770 in different stages before cooling to 500 ℃, while SOA and SRA process demand 760×5 h and 720×4 h respectively, then furnace cooling to 500 ℃. In order to save the test time, cooling in the air is adopted during the subsequent cooling to room temperature.

After simulated annealing in high-temperature box resistance furnace, the samples are subjected to microstructure observation and hardness testing.

3. Results and discussion analysis

3.1. Microstructure Observation

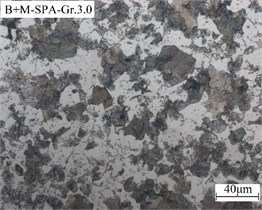

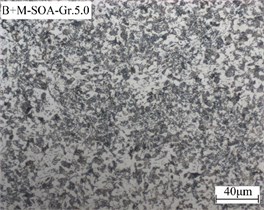

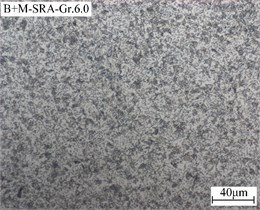

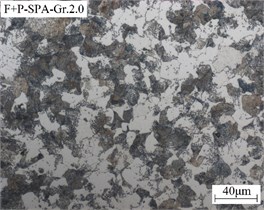

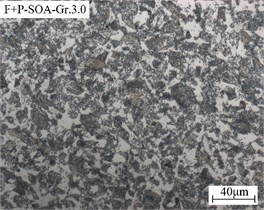

The microstructures and spheroidization grades of the two initial microstructures sample after different annealing were shown in Fig. 3. To avoid the influence of decarburization and central segregation, the middle position between surface and center of the cross section is detected.

Under the same annealing conditions, the spheroidization grade of B+M samples is higher than that of F+P samples. The spheroidization grade of SPA process (with 770 ℃) and SOA process (with 760 ℃) is lower, and the spheroidization grade of stress relief annealing at 720 ℃ is the highest, which is inconsistent with conventional cognition.

Fig. 2Schematic diagram of simulation SPA\SOA\SRA

Fig. 3Microstructures and spheroidization grade of B+M\F+P initial microstructures after simulation SPA\SOA\SRA

From the microstructures and spheroidization grade of two different initial samples, the B+M sample spheroidization grade was 1-2 higher than that of F+P sample, which is consistent with the results of literature review. It indicates that bainite is easier to spheroidize than massive ferrite and pearlite.

This is because during high-temperature annealing process, part of the initial microstructure transformed to austenite in the critical region, and then the carbide dissolves. Combining with the Gibbs free energy of the system as shown Eq. (1) [4]:

where – change of Gibbs free energy of the system, – chemical energy change, – elastic free energy change, – effect of new phase formation on surface free energy, –deformation energy storage driving force. When the temperature is high, the change of elastic free energy and deformation energy storage can be ignored. Therefore, the driving force of austenite decomposition is mainly chemical energy.

Bainite and martensite are metastable microstructure with more chemical energy than that of polygonal ferrite and pearlite, therefore, when the initial microstructure is polygonal ferrite and pearlite, the carbide spheroidization needs more energy due to the aggregation of carbides and the small spacing of cementite lamellae. As for metastable bainite and martensite, carbides are evenly distributed in the matrix, and it is easy to form spheroids spontaneously when the temperature rises.

3.2. Different annealing process effect on microstructure

Compared with the spheroidizing annealing process (with the highest temperature of 770 ℃) and softening annealing process (with the highest temperature of 760 ℃), the stress relief annealing process (with the highest temperature of 720 ℃) has the highest spheroidizing level, which is inconsistent with the expectation. Preliminary analysis shows that the wire rod temperature is closer to the furnace temperature under the laboratory simulation conditions, and there is a certain difference between the wire rod temperature and the furnace temperature in the industrial production line.

The phase change temperature was measured by thermal expansion instrument, results showed that the phase transition temperature of SCM435 wire rod: A1 = 728 ℃, A3 = 780 ℃, when the laboratory simulated 770 ℃ and 760 ℃ annealing temperature, almost all microstructure of wire rod samples were transformation to austenite, and a large amount of cementite is dissolved and the spheroidized core is reduced after a long time keeping at high temperature. Spheroidization occurs only in the subsequent slow cooling process, resulting in the spheroidization grade of SPA and SOA was lower than that of SRA with annealing temperature of 720 ℃.

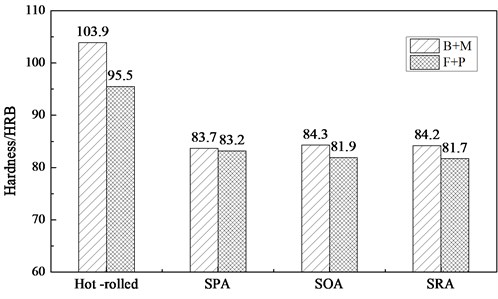

3.3. Hardness test

Hardness HRB test were carried out on the annealed samples with different initial microstructure. To avoid the influence of decarburization and central segregation, the middle position between surface and center of the cross section is detected as the microstructure observation. The test results are shown in Fig. 4. The hardness of initial microstructure sample were tested for comparison, the average hardness B+M unannealed sample is 103.9 HRB while 95.5 HRB for F+P sample.

Fig. 4Hardness test results of B+M\F+P initial microstructures after simulation SPA\SOA\SRA

The spheroidization grade of B+M samples varies greatly (3.0-6.0). The SOA and SRA processed samples grades of F+P were 3.0 and 4.0 respectively, but there is no obvious difference in hardness test results, which showed that there was no obvious correspondence between the spheroidization grade and the hardness.

3.4. Hardness and cementite precipitation

The spheroidization grade is evaluated according to the degree of carbide uniform distribution, the finer, dispersing and uniformly distributed carbide could be evaluated higher spheroidization grade, improving microstructure uniformity and coordinate deformation ability.

But according to the precipitation strengthening mechanism [5], the strengthening effect of micro alloyed carbon and nitride particles is produced by pinning grain boundaries. It is generally believed that precipitation strengthening occurs in the micro alloy composition system [6], but the research [7-8] shows that in carbon steel, by controlling the precipitation size of cementite particles, obvious strengthening effect can also be produced. Nano cementite particles in lower carbon steel can be formed in the microstructure through ultra-rapid cooling process. With the increase of carbon content, the volume fraction of preeutectoid ferrite gradually decreases, the precipitation amount of nano cementite is larger. The volume fraction of proeutectoid ferrite changed, while the microstructure is basically the same.

With the initial microstructures of massive F+P, carbon content in massive ferrite is very low and almost no cementite precipitation. As for the overall structure, uniform strengthening cannot be achieved when nano cementite is precipitated. When hot rolling followed by ultra-fast cooling process is adopted, a large number of dislocations generated by high-temperature deformation, the existence of these dislocations will promote the nucleation and dispersion distribution of the nano cementite, which is beneficial to form uniform cementite strengthening effect. So, by a certain process promoting fine dispersed cementite precipitated particles could play a precipitation strengthening effect.

Generally speaking, the precipitation strengthening effect increases with the increase of precipitated particles number and the decrease of particle size. Therefore, lower spheroidization grade means larger carbide particle size and inferior precipitation strengthening effect, and an amount of massive ferrite exist simultaneously, so these two functions coexist leads to reduction of hardness.

4. Conclusions

The spheroidization grade of B+M initial Microstructure wire rod is 1-2 higher than that of massive F+P wire rod, indicating that metastable quenched microstructure is easier to spheroidize because its higher chemical energy.

Difference between the actual temperature and the set temperature was observed, which of laboratory simulation was less than that of industrial production, this is very important for spheroidizing effect, and the influence factor should be considered in subsequent experiments. The analysis in this paper can provide guidance for formulating annealing process of different enterprises and equipment.

There is no obvious correspondence between the spheroidization grade and the hardness, the finer, dispersing and uniformly distributed carbide could be evaluated higher spheroidization grade, but causing higher precipitation strengthening effect. Lower spheroidization grade means larger carbide particle size and inferior precipitation strengthening effect, and an amount of massive ferrite exist simultaneously, these two functions coexist leads to reduction of hardness.

References

-

S. Dhara, S. M. C. van Bohemen, and M. J. Santofimia, “Isothermal decomposition of austenite in presence of martensite in advanced high strength steels: A review,” Materials Today Communications, Vol. 33, p. 104567, Dec. 2022, https://doi.org/10.1016/j.mtcomm.2022.104567

-

A. Grajcar, A. Skowronek, and K. Radwański, “Mechanical behavior and stability of dispersed retained austenite in thermomechanically rolled and isothermally-treated TRIP-aided multiphase steel,” Materials Science and Engineering: A, Vol. 830, p. 142300, Jan. 2022, https://doi.org/10.1016/j.msea.2021.142300

-

M. Bordone, A. Monsalve, and J. Perez Ipiña, “Fracture toughness of High-Manganese steels with TWIP/TRIP effects,” Engineering Fracture Mechanics, Vol. 275, p. 108837, Nov. 2022, https://doi.org/10.1016/j.engfracmech.2022.108837

-

H. L. Xiao and H. J. Zhang, “High temperature phase transformation behavior of SCM435 steel,” (in Chinese), Heat Treatment of Metals, Vol. 42, No. 3, pp. 147–150, 2017, https://doi.org/10.13251/j.issn.0254-6051.2017.03.032

-

Y. Zheng et al., “Microstructure evolution and carbide precipitation behavior of microalloyed TS800TB steel during hot rolling and coiling processes,” Materials Science and Engineering: A, Vol. 840, p. 142902, Apr. 2022, https://doi.org/10.1016/j.msea.2022.142902

-

J. Moon et al., “Strengthening mechanisms of solid solution and precipitation at elevated temperature in fire-resistant steels and the effects of Mo and Nb addition,” Journal of Materials Research and Technology, Vol. 15, pp. 5095–5105, Nov. 2021, https://doi.org/10.1016/j.jmrt.2021.10.132

-

B. Wang, Z. Liu, X. Zhou, and G. Wang, “Calculation of transformation driving force for the precipitation of nano-scaled cementites in the hypoeutectoid steels through ultra fast cooling,” (in Chinese), Acta Metallurgica Sinica, Vol. 49, No. 1, p. 26, 2013, https://doi.org/10.3724/sp.j.1037.2012.00372

-

B. Wang et al., “Precipitation behavior and precipitation strengthening of nonacale cementite in carbon steels during ultra fast cooling,” (in Chinese), Acta Metalluraica Sinica, Vol. 50, No. 6, pp. 652–658, 2014, https://doi.org/10.3724/sp.j.1037.2013.00584

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.