Abstract

Supply chain is a seamless network of activities and stakeholders involved in any business. It ensures a smooth flow of goods, products and services. In the modern global setting, supply chains have become more complex and inclusion of technology is providing great benefits. Robust technology is needed for identification, tracking and monitoring of the various goods and assets during the supply chain. One such emerging technology for this is RFID sensors. RFID is a popular wireless technology capable of collecting, storing and transmitting data and thus identifying, tracking and communicating. The two main components of RFID systems are tags and readers each of which perform a crucial and specific function. Tags are basically the memory, storing data received by the reader. Readers retrieve the data and transmit it to tags using an antenna. RFID technology has greatly replaced its counterpart and competitive technology- barcodes, in supply chains. It provides various benefits as compared to barcodes due to which it has got increased attention in various fields such as supply chains, healthcare, agriculture, food industry, manufacturing, libraries, security etc. Supply chain management deals with the flow of activities or processes included in any business, production activities. During this entire journey from raw material procurement to final dispatch a number of smaller supply chains are included each of which are critical. RFID technology has been largely deployed in supply chain management in order to identify, track and store information. These RFID systems enable real time monitoring of the supply chain and gives an upper-hand as compared to barcodes. RFID systems are not only used for storing and retrieving product data but also to monitor and track the flow of the entire supply chain. In the case of cold chains, RFID systems are used for maintaining the environment needed for ensuring quality of food products. Various such applications of these sensors in supply chains have been identified and deployed, However, still this technology remains to be dormant to some extent in supply chain industry. This review paper is aimed at doing a thorough literature review of RFID technology, its deployment in the supply chain domain, and challenges faced.

1. Introduction

Globalization has made supply chain management and development of robust supply chains crucial in almost every industry and business. SCM deals with the entire chain of process involved in any activity, production or business. In the current wake of industry 4.0 and ever-increasing globalization, competition has witnessed a surge in the business market. Due to this companies are expanding their operations with the help of more robust supply networks. E-commerce websites are a great example of how supply chain networking and management is changing the scenario people lead their lives. A good supply chain significantly improves the efficiency and competitiveness of an organization. SCM will incorporate largely all the aspects of operations, supply and demand planning, administering, control of processes etc. Supply chains are also prevalent in various industries that deal with management of flow of perishable products or commodities having a limited shelf life such as agriculture and food industry.

Traditionally, barcodes have been popularly used in supply chains. These barcodes required a physical contact, clear line of sight to be read or detected. Due to increasing competitiveness around the world, everyone is trying to cut down on cost and time involved in the entire supply chain. RFID has emerged as an alternative to barcodes and a great solution to reduce overall time and cost involved in supply chains. RFID is basically a wireless technology that, as the name suggests, transmits information through radio waves. RFID stands for ‘Radio Frequency Identification.’ These RFID systems have great advantages over traditional barcode systems such as it does not require a physical connection or line of sight.

RFID is a relatively new concept introduced into SCM in the past decades. However, RFID as a technology has been prevalent since World War II, back then it was primarily used for basic identification applications [1]. In supply chains RFID can play a major role in identification, inventory management, manufacturing, shipping and distribution, managing operations etc. A great rise in deployment of RFID systems can be witnessed in SCM which can be attributed to its many advantages when compared to conventional systems.

This paper is focused on detailed literature review concerning the deployment of RFID systems into supply chains and SCM. The paper studies the RFID technology in required detail and provides a summary regarding the technology, its components and classifications. Further on, the paper focuses on reviewing the various application RFID systems have been deployed in SCM. It also provides a merit-demerit analysis of the technology. The main aim of the paper is to provide a holistic review of the RFID systems and its deployment in SCM.

2. RFID systems

RFID technology has been around for a long time now. However, it has gained recent attention in the past few decades for various applications in a variety of sectors, especially sectors such as supply chain management that are subjected to harsh environments and often deal with products which are perishable in nature. RFID systems are often compared and denoted superior to the conventional barcode systems. RFID has various advantages over barcodes such as it does require a line of sight of physical connection, it has better range etc. Most importantly barcode systems are ineffective in functioning in harsh environments which are subjected to dirt, hazardous contamination, low or high temperatures etc. [1]. RFID systems do share similarities to its competitor technology, which is barcodes. Bothe these technologies rely on scanning, reading information and then relating the information to the stored data. However, there are major differences which come across as RFID being advantageous over barcodes. Firstly, no line of sight is needed in case of RFID which makes the entire process very fast and less prone to human errors. In the barcode system, workers will have to manually scan each of the barcodes but with RFID scanning can be done in bulk instantaneously enabling multiple parallel reading. RFID is also capable of manipulating data without a need to alter the database corresponding to the tag [3].

RFID sensors have 3 main components that govern the entire functioning. These are tags, reader and software. A tag is essentially a memory storage device. Tag consists of small chips which store data and are embedded with an antenna, which is used for transmitting signals between tag and reader. A reader is nothing but a decoder which reads the data stored in the tags. The communication between tag and reader is established via radio waves. Readers have an appreciable range of centimeters to meters. The range also depends upon the type of tag and operating frequency. All this data collected is then processed using a software/computer similar to barcode systems [1].

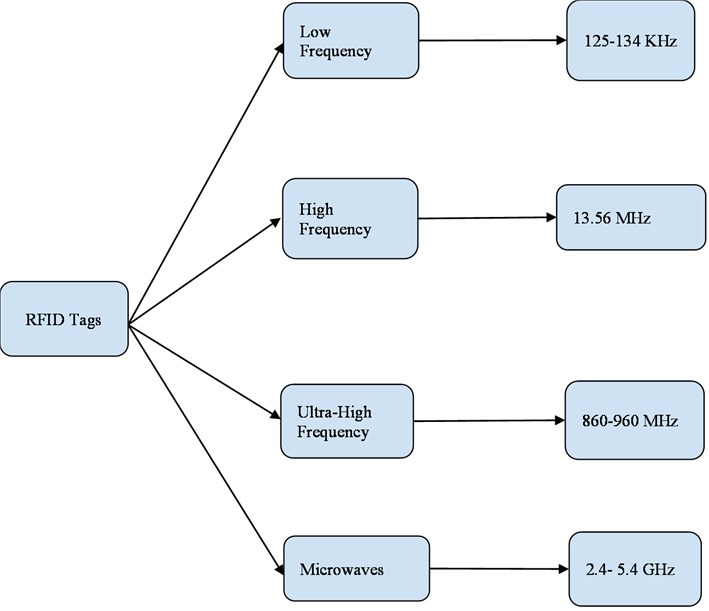

RFID tags can be classified based on operating frequency range and based on the activity. Tags can be classified as active, passive and semi-passive. Passive tags are more popular in terms of applications and deployment and less costly as compared to active tags. The difference between the two is that active tags have a battery embedded and they remain active throughout their own power-supply. On the contrary, passive tags do not have any battery and they are activated by the trigger received from readers [1]. RFID tags operate in different frequency ranges namely, low frequency, high frequency, ultra-high frequency and microwave range. The classification based on operating frequencies is shown in Fig. 1. These ranges are to be selected based on a particular application. In applications involving SCM, usually tags operating in high and ultra-high frequency are used [3].

Fig. 1Classification of RFID tags based on operating frequency

3. Applications in SCM

RFID systems can be effectively deployed for various applications such as retail, warehousing, asset tracking, assembly, configuration manufacturing, logistics, transportation etc. In nutshell, RFID systems can be used at various phases in different supply chains. Table 1 presents a detailed literature review of applications of RFID sensors in supply chains.

Table 1Deployment of RFID in various SCM applications

Sr No. | Research area | Description | Reference number |

1. | Food industry | Deployment of RFID Sensors in smart packaging for the food industry. Monitoring the environment of food products for maintaining quality of products and improved traceability. RFID sensors have proved to of great importance when employed in cold chains and food industry which requires monitoring of environment to ensure good quality of products. This paper highlights the necessity of deploying RFID in such industries and their supply chains | [4] |

2. | Advances in SCM | Various advanced concepts such as IoT, Big Data, blockchain etc. Thorough review of SCM and advances in the field. This paper gives an in-depth analysis of the new technologies that are being employed in SCM and how efficiently they are working | [5] |

3. | Challenges posed to traditional data warehouse (DW) technologies by RFID | With implementation of RFID technology, a ginormous amount of data is created by RFID tags. Although there are several researches indicating the evident importance of the role of RFID sensing management systems, this paper specifically presents methodological steps which can provide powerful solutions to build a system for traceability, exploiting RFID technology | [6] |

4. | RFID in the health care and supply chain | It presents a thorough comparison study of the portions of the healthcare supply chain in which RFID can be implemented, provide specific examples of RFID implementation and discuss how they will add to the effectiveness of the healthcare supply chain, and simultaneously describe the current state of RFID technology. Furthermore, give practical information for managers in the healthcare sector to make optimized decisions about the possible implementation of RFID | [7] |

5. | Potential to increase efficiency of supply chain management with RFID | With the increase in variety of short shelf-life goods, the need for tracking and monitoring each and every product variant creates great complexity of supply chain control and hence generates the need for an information control system that actively optimizes the overall management and track channel inventory. In effect, reducing the mismanagement of resources | [8] |

6. | Critical analysis of RFID systems in various industries | Delves into the power and potential it possesses and the infantile state it is currently in which gives it greater scope for growth and refinement. Also critiques the cost and effectiveness of the RFID implementation in the supply chain management systems | [1] |

7. | Exchange of information using RFID and IoT | Focuses on a method in supply chain to successfully achieve a supply chain information transmission network that can help businesses to develop a global supply chain management strategy | [9] |

8. | Advantages and disadvantages of RFID in supply chain management | Discusses the existing advantages businesses derive by using RFID implementations in their supply management system. Along with this, it also discusses the shortcomings of these implementations and issues which are generated | [10] |

9. | Overview of the applications of RFID implementations in the supply chain management | Consists of an international overview of the global supply chain management system and how various corporations are affected by RFID applications | [11] |

10. | Theoretical versus practical implementations of the RFID technologies under supply management chain systems | Broadly looks into the potential areas of research and methodologies used in research on application of RFID in manufacturing and supply chain management | [12] |

11. | Literature overview of RFID literature from 2000 to 2015 | Provides a systematic review of categorized literatures all largely focused on RFID research and applications with the analysis of its immense potential | [13] |

12. | Literature overview of RFID in supply chain management systems | Research the potential of RFID technologies, approaches to monitor and evaluate their benefits in supply management systems, and the Return on Investment with respect to these systems | [14] |

13. | DWMS in tobacco industry: a case study | This paper proposes a digital warehouse management system (DWMS) in the tobacco industry based on radio frequency identification (RFID) technology. The DWMS helps warehouse managers to achieve better inventory control, as well as to improve the operation efficiency | [15] |

14. | RFID-enabled warehouse management in the steel supply chain: a case study | This paper enriches existing theory by introducing the useful and comprehensive warehouse management optimization methods based on dynamic SKU (storage keeping unit) management in the design and development of a RFID-enabled warehouse. Based on the dynamic SKU management method proposed, cost optimization methods are employed in the development of RFID-enabled warehouses | [16] |

15. | RFID implementation on cost structure in networked manufacturing | This literature aims to explore influences of RFID technology implementation on cost and profit efficiencies. Hence a mathematical model of supply chain cost structure and functions was created to analyze the impact with which the model, which has also been verified through a case study approach, is aimed to examine the economic impact of RFID implementation at an automotive original equipment manufacturer and its suppliers. To analyze the impact of the traceability system using RFID technology, a cost reduction parameter is used | [17] |

17. | RFID technologies: supply-chain applications and implementation issues | As a mobile technology, RFID can enable “process freedoms” and real-time visibility into supply chains. This article provides an introduction to the technology, several case examples, and implementation guidelines for managers based on published reports | [18] |

18. | Evaluating RFID investment on a supply chain using tagging cost sharing factor | A simulation model is used to calculate the net present value (NPV) of an RFID investment on a three-echelon supply chain and to examine the effects of sharing the tagging cost between supply chain members on the NPV at the echelon level. In the proposed model, NPVs for the retailer, distributor, and manufacturer are calculated for two cases | [19] |

19. | An on-line inventory feedback data in RFID-enabled supply chain | Discusses in depth an on-line neural network controller that optimizes a three-stage supply chain. With the inventory data feedback from an RFID system, the neural network controller minimizes the total cost of the supply chain rapidly while satisfying a target order fulfillment ratio. As a test bed of the neural network controller, we develop the beer game model of the supply chain. We demonstrate through simulation-based experiments that the neural network controller shows the highest performance when the inventory data is secured from item-level RFID data | [20] |

19. | A case studying for RFID for handling trade off | This literature quantitatively analyses the trade-off between improved flow and tardiness metrics versus the undesirable increase in material handling when lot splitting in a job shop. Flexible automated material handling equipment may be necessary with some operating conditions and policies because of a dramatic increase in material movements between work centers | [21] |

20. | RFID technology deployment in a supply chain with manufacturer encroachment | Investigates the strategic interaction between manufacturer encroachment and RFID deployment decisions in a supply chain consisting of a manufacturer and a reseller. | [22] |

21. | Profitable RFID strategies under wholesale and buy-back contracts | Investigate RFID adoption strategies under wholesale price and buy-back contracts in a supply chain with one manufacturer and one retailer who faces inventory misplacement and demand forecast error | [23] |

22. | RFID adoption beyond mandate, a retailer’s perspective case study | It analyzes how a retailer firm can stimulate its vendor to adopt this emerging innovation of supply chain management by using an incentive contract rather than a mandate. Such a contract should motivate the vendor to make costly efforts to adopt RFID, truthfully report the information of adoption cost, and execute RFID’s adoption at the retailer’s preferred timing | [24] |

23. | Empirical study of factors affecting RFID's adoption in Taiwan: a case study | Explores the factor affecting radio frequency identification adoption applications in Taiwan. Its objective is to summarize the ways in which organizations are thinking about their possible uses in a wide variety of companies and industries. An empirical investigation found seven factors affecting RFID adoption within Taiwan | [25] |

24. | Determinants of RFID adoption in supply chain among manufacturing companies in China: a discriminant analysis | Studies the determinant factors of the RFID adoption by manufacturing companies in China. The population of this study is manufacturing companies in China that are registered under the Federation of China Manufacturers. A questionnaire survey is conducted to study the adoption of RFID by China's manufacturing industry. This study reveals that the environment, organization, technology and product have the impact on the adoption of RFID in China. Organization should be given strategic attention to improve employee participation in adopting RFID as a strategic tool | [26] |

25. | An empirical study of the effect of applying RFID in supply chain management | The effort of this paper was to determine the effects of applying radio frequency identification (RFID) to identify items in the supply chain of manufacturing enterprises. At first, a comprehensive literature review and experts’ judgments are employed to identify possible influential factors, and then a questionnaire is conducted for evaluating these factors | [27] |

26. | RFID in the warehouse: a literature analysis (1995-2010) | To investigate how RFID technology has had an impact in warehousing, a comprehensive analysis of research findings available from articles through leading scientific article databases has been conducted. Articles from 1995 to 2010 have been reviewed and analyzed with respect to warehouse operations, RFID application domains, benefits achieved and obstacles encountered. Four discussion topics are presented covering RFID in warehousing focusing on its applications, perceived benefits, obstacles to its adoption and future trends | [28] |

27. | Empirical study for RFID adoption in SMEs in Taiwanese information technology industry | Through this review the authors attempt to explore in detail the factors that affect SMEs' RFID adoption in the Taiwan Information Technology (IT) manufacturing industry. Employing Exploratory Factor Analysis (EFA) techniques and utilizing a questionnaire survey in order to collect and analyze our data. After classifying the responding SMEs into three different adopters: – categories named ready adopter, initiator adopter and unprepared adopter using EFA –technique our results show that each category has some specific adoption factors related –to their unique situation | [29] |

28. | RFID implementation in supply chains and its impact on organizational competitive advantage | This literature seeks to address this gap in the literature through a systematic literature review. Based on a rigorous screening of the literature (2006–2018), the study develops a comprehensive understanding of the various corporate-driven and customer-driven benefit-drivers from RFID implementation. The “2 C” categorization of benefit-drivers is novel and should provide more impetus for practitioners to leverage from RFID implementation | [30] |

29. | Improving RFID traceability systems with verifiable quality | Aimed to develop an efficient tool to ensure traceability data entry based on RFID and improve the detection of fakes inside the supply chain. Design /methodology/approach | [31] |

30. | Traceability in textile and clothing supply chain | It describes the process for manufacturing, encoding and validating an innovative two-factor secured tag based on particle randomness that is printed on the surface of textile. Being micro-sized, the particles are easy to read and validate with pattern recognition. Further, as achieved through an uncontrolled manufacturing process, the randomness is unclonable to produce counterfeit tags. A secured tag can be a low-cost and durable substitute for detachable, unsecured identifiers commercially available in the market. And proposes a system approach to introduce an item-centric secured traceability concept to monitor and control manufacturing processes and supply chain activities | [32] |

31. | A cross-national case study on the effects of using RFID technology on its businesses and SCM systems | RFID brings incredible advantages for many aspects of business including supply chain management (SCM). The global implications of RFID necessitate cross‐national studies of the technology. This literature aims to conjecture that the way RFID is perceived and implemented and the extent to which RFID impacts business performance will vary from country to country | [33] |

32. | RFID applications and security review | Radio frequency identification (RFID) is widely used in several contexts, such as logistics, supply chains, asset tracking, and health, among others, therefore drawing the attention of many researchers. This paper presents a review of the most cited topics regarding RFID focused on applications, security, and privacy with Supply chain management effects as well | [34] |

33. | Sustainable Supply Chains with Blockchain, IoT and RFID: a simulation study | The goal this article has is to highlight how order and disruption events processes can be improved with the adoption of emerging technologies and how this reflects on the improvement of sustainability aspects. The study is based on the comparison of two simulation scenarios between three actors in the cheese supply chain | [35] |

34. | Traceability in Fishery SCMs using RFID | The review focuses on RFID-based traceability systems in fisheries’ SCM, which have been employed globally to ensure fish quality and security, and summarizes their advantages in real-time applications. Furthermore, it aims to provide guidelines and solutions for enhancing the reliability of RFID-based traceability in food SCM systems so as to ensure the integrity and transparency of product information | [36] |

35. | Agri-food supply chain traceability with help of RFID technology | Aims to analyze the current developments in RFID technology in the agri-food sector, through an operative framework which organizes the literature and facilitates a quick content analysis identifying future research direction. Along with this, it helps to provide an updated analysis on the current developments of RFID technology for different product typologies within the agri-food industry, discussing at the same time its potential in technological and logistical development regarding different sectors of the production/distribution chain. | [37] |

36. | RFID-enabled traceability in the food supply chain | Studies the main requirements of traceability and examine how the radio frequency identification technology can address these requirements. It further seeks to outline both an information data model and a system architecture that will make traceability feasible and easily deployable across a supply chain | [38] |

37. | A preventive assessment of RFID deployment for efficient SCM in short lived products | A prescriptive framework aimed at addressing radio frequency identification (RFID) deployment and implementation by clearly identifying the practical steps that need to be undertaken in order to carry out a comprehensive preventive risk assessment from both a business and a technical perspective | [39] |

38. | RFID-based manufacture process control and supply chain management in the semiconductor industry | Proposes an RFID management information system that integrated three common areas in the semiconductor testing industry including inventory flows management, location control in warehouse, and handcar localisation. The main core of this research focused on cassette management in the semiconductor test industry. The entire management flow enters the warehouse management from a semiconductor manufacturing company to the semiconductor testing company | [40] |

39. | RFID applications in perishable inventory management | Presents an overview of RFID technology and its applications to perishable inventory management. | [41] |

40. | Strategic value of RFID in supply chain management | This paper provides insight into the strategic value of RFID by building a theory on how RFID used in supply chain management may create and sustain a competitive advantage. Four propositions are developed based on a theory of organizational learning and the theory of first-mover advantages | [42] |

41. | RFID investment on a supply chain using tagging cost sharing factor | A simulation model is used to calculate the net present value (NPV) of an RFID investment on a three-echelon supply chain and to examine the effects of sharing the tagging cost between supply chain members on the NPV at the echelon level | [19] |

42. | Impact of implementing RFID technology in South Korea | This resource investigates South Korean retailers to identify key organizational characteristics that positively drive the evaluation of RFID. Further, this study assesses the impact one's evaluation has on the adoption and integration of RFID within their respective firm | [43] |

43. | A comparative case study between factors affecting RFID implementation in Australian and Chinese supply chains | Investigates and compares enabling factors of RFID implementation in Australian and Chinese supply chains. Employing the analytic hierarchy process (AHP) approach, this study suggests that managers in Chinese firms have a very different view concerning the importance of factors for RFID implementation | [44] |

44. | With integration of SCM due RFID, the case of emerging intelligent B-to-B e-commerce processes in a living laboratory | Purpose of this paper, therefore, is to be an initial effort towards bridging the existing knowledge gap in the literature. Design/methodology/approach - This exploratory research was conducted in one retail supply chain | [45] |

45. | Integrating the supply chain with RFID: A technical and business analysis | Presents in-depth analysis of the technical and business implications of adopting Radio Frequency Identification (RFID) in organizational settings. The year 2004 marked a significant shift toward adopting RFID because of mandates by large retailers and government organizations. The use of RFID technology is expected to increase rapidly in the next few years | [46] |

46. | An RFID adoption framework: a container supply chain analysis | A qualitative study in the South African port community refines and extends an RFID adoption framework and provides insight into the factors potentially affecting the adoption of this new technology as well as the probability of adoption in that community | [47] |

47. | Determinants of RFID adoption in the logistics industry with a perspective of SCM | In this investigation it was found that competition in the marketplace, pressure of transaction partners, suppliers’ industry environment, cost, integration of supply chain strategy, complexity of RFID, and mutual standard were among the critical factors. This research anticipates these factors as crucial and beneficial for the initial introduction phase of RFID adoption | [48] |

48. | Factors affecting RFID adoption different between public and private organizations: a case study | The study suggests two objectives for RFID research: (1) To show that factors (technological, organizational, and environmental factors) affecting RFID adoption are different between public and private organizations in Korea. (2) To apply a balanced score approach (BSC) to assess the organizational performance after RFID adoption and show differences in the performance of RFID adoption between public and private organizations | [49] |

49. | Optimizing RFID technology | RFID can be applied to a variety of tasks, structures, work systems and contexts along the value chain, including business-to-business logistics, internal operations, business-to-consumer marketing, and after-sales service applications. As industry adoption of RFID increases there is an emerging interest by academic researchers to engage in scholarly investigation to understand how RFID relates to mobility, organizational and systems technologies (MOST) | [50] |

50. | RFID implementation in the footwear supply chain | aims to fill this gap by investigating, by means of action research, and the solutions implemented in a footwear supply chain. The results of the study present the approaches developed to address six RFID implementation challenges, namely: forming the implementation team, selecting the RFID technology, and defining the RFID system infrastructure, overcoming technical problems, redesigning supply chain processes, integrating the RFID system with existent information systems, and measuring the RFID implementation performance | [51] |

51. | Implementing an RFID-based manufacturing process management system | This in-depth case study details the organization's experience and identifies the challenges it faces and important issues in the development and implementation of the system. Implications for academics and practitioners are discussed | [52] |

52. | RFID technologies to improve decision-making in apparel supply chains | It aims to illustrate how an RFID system can be implemented in the fashion industry through a case study. We observe that RFID systems are commonly used for shop floor management, logistics, and distribution management, and customer relationship management | [53] |

53. | RFID critical success factors and system deployment outcomes | This study investigates how information technology (IT) infrastructure integration and supply chain process integration moderate the relationships between RFID critical success factors, and operational efficiency and market knowledge creation. Using the online survey method, members of the Council of Supply Chain Management Professionals (CSCMP) were contacted and invited to participate in the study | [54] |

54. | RFID technology in manufacturing and supply chain | Provides an insight to the application of RFID technology in the management of manufacturing and supply chain | [55] |

55. | RFID‐derived benefits in the retail supply chain review | A report on research that examined the recent scholarly literature to identify the information quality attributes associated with radio frequency identification (RFID)‐based benefits across sectors of the retail supply chain. Moreover, the paper uncouples RFID‐focused technology findings that are a feature of many previous publications and reports on the decision‐making attributes associated with the perceived benefits of adopting the technology | [56] |

56. | RFID and buyer‐seller relationships in the retail supply chain | Looks for understanding on why a collaborative innovation, such as radio‐frequency identification (RFID) technology, engenders seemingly opposite buyer‐seller relationship reactions among members of a supply chain | [57] |

57. | Strategic value of RFID for inter-firm supply chain networks | This study broadens the discussion scope of RFID to the implementation stage at the inter-firm level beyond the internal adoption level, hence improving the delay of RFID diffusion among transaction partners. Also, the study describes strategic points that can be used to maximize the RFID value in supply chain networks | [58] |

4. Critical analysis of deployment of RFID in Supply Chains

When compared to conventional barcode systems, RFID technology proves to be far more promising in terms of what it has to offer. RFID tags are capable of continuously collecting data when products transit from shelves to checkout. Thus, this technology helps in minimizing labor, its associated costs and practices such as shoplifting. The tags have significantly helped in reordering, stocking, and keeping track of purchases. Smart-shelves are introduced in the retail sector which are based on RFID systems which prevent situations such as out-of-stock.

RFID systems are also prevalent in shipping and distribution applications. Traceability is improved using RFID as it enables tracking of the pallets and allows real time decision implementation. A fleet of 2600 trucks equipped with RFID tags at a particular logistics provider company enables automatic monitoring of docking and undocking activities.

Supply chain activities such as manufacturing and assembly lines are also potential areas of RFID deployment. Identification of products can be done using these systems. RFID ensures the entire quality of process by providing real time checks during assembly. It also promotes lesser labor and thus optimizes the process cost-wise. A great example of this is the case of Ford Motors that have been using RFID tags. An RFID tag is attached to each car’s chassis skid. This tag is instrumental in indicating which parts and components are to be installed on the chassis, communicating via the serial number to the reader. As the chassis transits from one assembly station to the following one, readers read the chassis’ assembly needs automatically so that the appropriate components can be installed thus eliminating error prone manual barcode scanning [3]. Intelligent components in ETO management have also been studied. RFID technology is capable of identifying, tracing location and establishing communication. RFID sensors operating in the UHF range are proven to be capable of creating intelligent components [59].

RFID systems have proved to optimize logistics, warehousing and transportation activities. Conventionally, all these activities involved a certain amount of time in inspection, identification and documentation which was carried out by human force. All this causes a hindrance into the flow of goods and services in terms of time. RFID can greatly eliminate these hindrances by automating the entire manual process involved. It provides benefits such as reduced time and labor involvement and increased visibility. Thus, goods and services move faster through the SC’s and at a comparatively lower cost. RFID also works efficiently in inventory management by improving the inventory accuracy, which is the difference between physical inventory and logical inventory. In the most ideal case, both these inventories are equal. However, due to a series of reasons such as loss of goods, errors in input etc. both the inventories could differ. Logical inventory is basically recorded in computers using ERP, WMS etc. RFID can automate the entire scanning process and thus improve the records [3]. Throughout the supply chain, RFID can be incorporated at various checkpoints for a plethora of service exchange. RFID will not only ensure identification, monitoring and tracking but also aid manufacturing, warehousing and inventory, retail, logistics and distribution, as shown in Fig. 2. Basically, RFID can be said to be a very versatile technology that will continue to function effectively throughout the supply chain right from inbound material to delivery.

Fig. 2Various RFID transactions during a Supply Chain [60]

![Various RFID transactions during a Supply Chain [60]](https://static-01.extrica.com/articles/22565/22565-img2.jpg)

RFID sensors are enabled with GPS sensors in order to perform the tasks of tracing, tracking and identification. Another important inclusion is the temperature and environment sensors which enable them to be deployed effectively in cold chain monitoring. Cold chain refers to the flow of temperature sensitive and environment sensitive products. A certain temperature and environmental conditions such as humidity, moisture etc. is to be maintained in order to ensure their quality and shelf life is maintained. RFID enabled with temperature sensors can give real time data of the environment and enable human operators to adjust it according to the changes. These RFID sensors are installed in the boxes or pallets and are believed to improve the efficiency of cold chains.

The applications of RFID in retail have been used to encourage intelligent business-to-business e-commerce supply chain management with the aid of the EPC network [45]. The EPC network is a unique feature and a standard for all RFID infrastructure composing essentially of several components such as the EPC code, which when incorporated into the chip and attached to an item, provides the details of it for e.g., Temperature, product size, expiry date, etc. The next component is the RFID reader which identifies any EPC tag/ RFID chip and forwards the information to the next component i.e., SAVANT. Analogous to the middleman in the entire operation, this component communicates between the readers and the application systems. It can be further modified to filter the data according to the specific needs of the organization with the help of the EPC-IS i.e., the fourth component. It is an information service that provides a gateway between any requester of information and the organization’s application systems and data. The last component of the EPC network is the local Object Name Service which is an authoritative directory of information sources available in order to clarify the details including the EPC tags used in the supply chain. Therefore creating ‘smarter products that are able to interact with correct stimuli is helping to enable and facilitate the smoother logging of data in registries within an organization saving time and effort. With this, many large-scale retailers are investing more in information management which has helped them to expand business within a shorter amount of time. It has also enabled retail giants to cross-check their product qualities and customer service.

Considering the role of the deployment of RFIDs in Supply Chain management when it comes to a buyer-seller relationship [57], it has generated an open network of the flow of information and monitoring has been easier than ever. It has generated a healthy, competitive yet knowledgeable environment where suppliers and buyers maintain their connections. Its integration is more visible when we look at EPC global [46]. It is one of the two primary RFID standards. In essence it is an internet-based supply chain model aimed at improving supply chain end to end visibility. One of its key components is the EPC, which is discussed earlier as well. RFID deployment in the supply chain management has been broadened in perspective with authentication applications as well. Automatic data acquisition, location, identification etc. all are products of RFID’s integration with the supply chain Deployment of RFID in supply chain management provides greater power when it is combined with GPS and Bluetooth which help in creating a closed loop in monitoring the products. RFIDs have the largest application in supply chain management. One of the biggest problems a system faces is shrinkage [42]. Various factors contribute to shrinkage and it is one of the main problems that have been reduced significantly. Material handling requirements have reduced phenomenally due to the deployment of RFIDs and respective supply chain networks generated with the help of RFID tags. The usage of these systems has made is much easier to create accurate databases without much human intervention thereby saving time and capital. Quicker exception management has enabled impressive applications, especially in the health-care supply chain management system. Quality control and production tracking, as explained earlier, are incredible feats achieved due to this system.

5. Advantages and limitations

RFID has its advantages and disadvantages as any modern technology does. As a technique heavily dependent on the deployment of radiofrequency waves its accuracy is largely dependent on the accuracy of the transmission and receiver devices involved in the entire process. The entire process depends on the whether the tags used are active or passive. Advantages of using active tags in cases of applications where regular data monitoring takes place can generate large amounts of data and help improve the supply chain therefore fulfilling its purpose in its deployment in the sector. They can be used and implemented over much larger distances/ ranges making them a lot more efficient in terms of enabling distant communication between management systems in the SCM chain. As compared to barcodes, RFID readers and tags do not need line of sight communication and can be worked from fairly distant areas. Even though the distance will vary according to the type and configuration of the readers and tags, it encourages the warehouses to effectively save time. In comparison to other monitoring devices or tagging devices RFID can be read and overwritten. They can be reused and are much durable thus removing the hassle of replacement or loss related to monitoring in the SCM system much less. In a SCM the deployment of safe and secure tagging methods is super important. Thus, RFIDs provide the service of an encrypted service which remains secure throughout the life cycle of the chain. This makes it difficult to easily replace a tag already registered into the system. Another advantage of the RFID’s tags deployed is the fact that they are easily readable once in the system.

In essence, RFIDs have made it so much easier for an organization to manage the entire supply chain management. It has reduced several instances of reduction of human errors due to its automatic logging into the system and in turn increased the lifecycle of certain aspects of the products. The introduction of RFIDs significantly improved the operations over various range of bandwidths and not just over wavelengths.

In addition to simple active and passive RFIDs, the other types of RFIDs used are Near-field and Far-field RFIDs. All of which make use of EM spectrum in addition to radiofrequencies. Although we have seen considerable number of advantages, we do observe several limitations that come along with its deployment in the SCM systems. Ideally any corporation aiming to set up its RFID infrastructure will have to incur initial costs that tend to be large. The amount of money required to set it up might not make the operations for the organization profitable. Even though these systems once deployed are highly accurate they are prone to collision dude to usage of waves for emission of signals. This could result in superposition and hence generate inaccurate readings. The infrastructure of the system is also dependent on the frequency The systems across organizations and countries vary as s result of lack of standardization. As mentioned in the challenges of deployment of RFIDs in SCM systems, lack of standardization makes it much harder for universal systems to be deployed and ever specification followed region-wise makes it much more difficult to encourage uniformity across various outlets of the same organization. Although these systems once deployed tend to be secure it does not mean they are completely fool proof and free of risk. They can be hacked from the connected data base management systems from the SQL serves to which they SCM system is connected to. Unauthorized devices which read radiofrequencies may be able to hack or read into the system.

6. Challenges

One of the major difficulties faced by RFIDs and their deployment is that the effectiveness will largely be dependent on the type of tag itself. Some tag can offer longer reading ranges but fail to hold data for enough time whereas others can hold larger amounts of data and cost less. RFID is still not feasible for businesses that are not financially, technically and operationally sound [46]. The initial cost and maintenance of setting up a system for a business can create generate complications. There is an upfront expense of RFID readers and tracking software as well as the continuing cost of the different types of RFIDs.

RFID isn’t ideal for all situations. Especially when it comes to monitoring different types of materials and substances. Liquids can absorb some of the radio signals and while others can bounce off the material if it is a metal. There is a huge amount of scope for the improvement of accuracy and precision in this technology when it comes to its deployment in the supply chain as well. In the case of too many readers, there is a possibility of collisions and over-reading in the line of monitoring. Moreover, there are a lot of costs involved when it comes to training and implementation of the processes. It is also defined by the level of tagging involved. If the tagging level is at an item level, the number of tags increases significantly, and hence cost of investment increases. Pallet level tagging, although cheap, does not provide the benefits of large data storage. Another concern is the lack of standardization. Many parameters when thoroughly considered do not necessarily yield results due to a lack of standards and normalization. Data warehousing and enterprise integration also play a crucial role in the cost of investment and integration of the RFIDs in the supply chain of any business. In order to manage the vast amounts of data generated in a single day, the organization must be prepared to handle it and be able to use it to its advantage which is, obviously, a very time-consuming and costly process.

Considering the advantages of RFID systems in supply chains, new developments in the technology to overcome these challenges is needed. With new developments, RFID technology can monopolize all the supply chains and significantly improve the entire the market of supply chain management. It will be advantageous for all the stakeholders and give the supply chains a totally new dimension in terms of its operations and efficiency.

7. Conclusions

RFID sensors-based technology is transforming the supply chain industry for the better. RFID comes along with various advantages such as providing real time data, tracking, identification, tracing, automating manual processes etc. All these have proved to be of significant importance in the supply chain industry. This paper has provided a thorough literature review of the deployment of RFID in SCM and their performance. It categorizes various application areas of RFID in SCM through Table 1. The paper also gives brief insights into the technology and it’s functioning thus enabling a complete understanding of the technology and how it is being deployed for various applications. Even though RFID has been there for decades, its popularity is quite new in the field of SCM. It is transforming the entire SC with its capabilities due to embedded GPS and Temperature monitoring systems. RFID systems are providing optimized results in time, money and resources utilized as compared to conventional methods. The paper also draws frequent comparison between RFID systems and the much prevalent conventionally used barcodes systems and how RFID surpasses it. Thorough in-depth analysis of the deployment of RFID sensors in supply chains have shown better productivity and improved efficiency of the supply chain. RFID has great potential in this industry, it can revolutionize and transform every possible supply chain. However, sufficient further development is needed in order to make it viable for all kinds of supply chains. In challenges, we have seen how certain barriers with the technology is limiting its application in certain cases. But with increased attention towards this advantageous technology, better results can surely be expected. Changing the external design of the sensors and tags to make it robust to handle different conditions is needed. At the same time, the loss in transmission in some cases due to liquids can eliminated by providing alternative means of installations and amplifiers. Even though a lot of applications have been actively found installed with RFID, there is a certain scope of research and development. RFID has the potential to bring in more sound changes in the SCM industry thus making the system even more advanced and technologically equipped.

References

-

Mohsen Attaran, “RFID: an enabler of supply chain operations,” Supply Chain Management: An International Journal, Vol. 12, No. 4, pp. 249–257, Jun. 2007, https://doi.org/10.1108/13598540710759763

-

V. Agarwal, S. Jawade, S. Atre, and O. Kulkarni, “The role of mechanical testing in additive manufacturing: review,” Material Science, Engineering and Applications, Vol. 1, No. 2, pp. 21–31, Dec. 2021, https://doi.org/10.21595/msea.2021.22258

-

G. M. Gaukler and R. W. Seifert, “Applications of RFID in supply chains,” in Trends in Supply Chain Design and Management. Springer Series in Advanced Manufacturing, London: Springer, 2007, https://doi.org/10.1007/978-1-84628-607-0_2

-

K. B. Biji, C. N. Ravishankar, C. O. Mohan, and T. K. Srinivasa Gopal, “Smart packaging systems for food applications: a review,” Journal of Food Science and Technology, Vol. 52, No. 10, pp. 6125–6135, Oct. 2015, https://doi.org/10.1007/s13197-015-1766-7

-

Venkesh Agarwal, Shaunak Shiralkar, Shruti Aaher, and Samidha Jawade, “The supply chain management revolution,” INTERNATIONAL JOURNAL of ENGINEERING RESEARCH and TECHNOLOGY (IJERT), Vol. 10, No. 10, 2021, https://doi.org/10.17577/ijertv10is100052

-

D. Lee and J. Park, “RFID‐based traceability in the supply chain,” Industrial Management and Data Systems, Vol. 108, No. 6, pp. 713–725, Jun. 2008, https://doi.org/10.1108/02635570810883978

-

S. Kumar, E. Swanson, and T. Tran, “RFID in the healthcare supply chain: usage and application,” International Journal of Health Care Quality Assurance, Vol. 22, No. 1, pp. 67–81, Feb. 2009, https://doi.org/10.1108/09526860910927961

-

M. Kärkkäinen, “Increasing efficiency in the supply chain for short shelf life goods using RFID tagging,” International Journal of Retail and Distribution Management, Vol. 31, No. 10, pp. 529–536, Oct. 2003, https://doi.org/10.1108/09590550310497058

-

B. Yan and G. Huang, “Supply chain information transmission based on RFID and internet of things,” in 2009 ISECS International Colloquium on Computing, Communication, Control, and Management (CCCM), pp. 166–169, Aug. 2009, https://doi.org/10.1109/cccm.2009.5267755

-

K. Michael and L. Mccathie, “The pros and cons of RFID in supply chain management,” in 4th Annual International Conference on Mobile Business, 2005, https://doi.org/10.1109/icmb.2005.103

-

N. Cerpa, “Editorial,” Journal of Theoretical and Applied Electronic Commerce Research, Vol. 2, No. 3, 2007.

-

A. Gotmare, S. Bokade, Z. Inamdar, and S. Bhirud, “A systematic literature review on RFID application in manufacturing and supply chain management,” Industrial Engineering Journal, Vol. 12, No. 10, Oct. 2019, https://doi.org/10.26488/iej.12.10.1203

-

A. Musa and A.-A. A. Dabo, “A review of RFID in supply chain management: 2000–2015,” Global Journal of Flexible Systems Management, Vol. 17, No. 2, pp. 189–228, Jun. 2016, https://doi.org/10.1007/s40171-016-0136-2

-

A. Sarac, N. Absi, and S. Dauzère-Pérès, “A literature review on the impact of RFID technologies on supply chain management,” International Journal of Production Economics, Vol. 128, No. 1, pp. 77–95, Nov. 2010, https://doi.org/10.1016/j.ijpe.2010.07.039

-

H. Wang, S. Chen, and Y. Xie, “An RFID-based digital warehouse management system in the tobacco industry: a case study,” International Journal of Production Research, Vol. 48, No. 9, pp. 2513–2548, May 2010, https://doi.org/10.1080/00207540903564918

-

Z. Xu, X. G. Ming, J. Zhou, W. Song, L. He, and M. Li, “Management optimisation based on dynamic SKU for RFID-enabled warehouse management in the steel supply chain,” International Journal of Production Research, Vol. 51, No. 10, pp. 2981–2996, May 2013, https://doi.org/10.1080/00207543.2012.751513

-

V. Modrák and V. Moskvich, “Impacts of RFID implementation on cost structure in networked manufacturing,” International Journal of Production Research, Vol. 50, No. 14, pp. 3847–3859, Jul. 2012, https://doi.org/10.1080/00207543.2011.594968

-

R. Angeles, “RFID technologies: supply-chain applications and implementation issues,” Information Systems Management, Vol. 22, No. 1, pp. 51–65, Dec. 2005, https://doi.org/10.1201/1078/44912.22.1.20051201/85739.7

-

A. Ustundag, “Evaluating RFID investment on a supply chain using tagging cost sharing factor,” International Journal of Production Research, Vol. 48, No. 9, pp. 2549–2562, May 2010, https://doi.org/10.1080/00207540903564926

-

S. R. Hong, S. T. Kim, and C. O. Kim, “Neural network controller with on-line inventory feedback data in RFID-enabled supply chain,” International Journal of Production Research, Vol. 48, No. 9, pp. 2613–2632, May 2010, https://doi.org/10.1080/00207540903564967

-

K. Hozak and J. A. Hill, “The material handling trade-off when lot splitting with RFID in a job shop,” International Journal of Production Research, Vol. 48, No. 9, pp. 2723–2743, May 2010, https://doi.org/10.1080/00207540903527386

-

L.-H. Zhang, L. Tian, and L.-Y. Chang, “Equilibrium strategies of channel structure and RFID technology deployment in a supply chain with manufacturer encroachment,” International Journal of Production Research, Vol. 60, No. 6, pp. 1890–1912, Mar. 2022, https://doi.org/10.1080/00207543.2021.1876943

-

L.-H. Zhang, T. Li, and T.-J. Fan, “Inventory misplacement and demand forecast error in the supply chain: profitable RFID strategies under wholesale and buy-back contracts,” International Journal of Production Research, Vol. 56, No. 15, pp. 5188–5205, Aug. 2018, https://doi.org/10.1080/00207543.2018.1463110

-

B. Feng, T. Yao, B. Jiang, and S. Talluri, “How to motivate vendor’s RFID adoption beyond mandate? A retailer’s perspective,” International Journal of Production Research, Vol. 52, No. 7, pp. 2173–2193, Apr. 2014, https://doi.org/10.1080/00207543.2013.860493

-

D.-H. Shih, Y.-W. Chiu, S.-I. Chang, and D. C. Yen, “An empirical study of factors affecting RFID’s adoption in Taiwan,” Journal of Global Information Management, Vol. 16, No. 2, pp. 58–80, Apr. 2008, https://doi.org/10.4018/jgim.2008040104

-

L. Wen, S. Zailani, and Y. Fernando, “Determinants of RFID adoption in supply chain among manufacturing companies in China: a discriminant analysis,” Journal of technology management and innovation, Vol. 4, No. 1, pp. 22–32, 2009, https://doi.org/10.4067/s0718-27242009000100003

-

S. P. Afsharian, A. Alizadeh, and M. Chehrehpak, “Effects of applying radio frequency identification in supply chain management,” International Journal of Business Information Systems, Vol. 23, No. 1, p. 97, 2016, https://doi.org/10.1504/ijbis.2016.078026

-

M. K. Lim, W. Bahr, and S. C. H. Leung, “RFID in the warehouse: a literature analysis (1995-2010) of its applications, benefits, challenges and future trends,” International Journal of Production Economics, Vol. 145, No. 1, pp. 409–430, Sep. 2013, https://doi.org/10.1016/j.ijpe.2013.05.006

-

H. Chen and A. Papazafeiropoulou, “An empirical study for radio frequency identification (RFID) adoption by SMEs in the Taiwanese information technology (IT) industry,” Asian Academy of Management Journal, Vol. 17, No. 2, pp. 39–58, 2012.

-

J. Chanchaichujit, S. Balasubramanian, and N. S. M. Charmaine, “A systematic literature review on the benefit-drivers of RFID implementation in supply chains and its impact on organizational competitive advantage,” Cogent Business and Management, Vol. 7, No. 1, p. 1818408, Jan. 2020, https://doi.org/10.1080/23311975.2020.1818408

-

G. Azuara, J. Luis Tornos, and J. Luis Salazar, “Improving RFID traceability systems with verifiable quality,” Industrial Management and Data Systems, Vol. 112, No. 3, pp. 340–359, Mar. 2012, https://doi.org/10.1108/02635571211210022

-

T. K. Agrawal, L. Koehl, and C. Campagne, “A secured tag for implementation of traceability in textile and clothing supply chain,” The International Journal of Advanced Manufacturing Technology, Vol. 99, No. 9, pp. 2563–2577, 2018, https://doi.org/10.1007/s00170-018-2638-x

-

K. So Park, C. E. Koh, and K. “Ted” Nam, “Perceptions of RFID technology: a cross‐national study,” Industrial Management and Data Systems, Vol. 110, No. 5, pp. 682–700, May 2010, https://doi.org/10.1108/02635571011044722

-

C. Munoz-Ausecha, J. Ruiz-Rosero, and G. Ramirez-Gonzalez, “RFID applications and security review,” Computation, Vol. 9, No. 6, p. 69, Jun. 2021, https://doi.org/10.3390/computation9060069

-

V. Varriale, A. Cammarano, F. Michelino, and M. Caputo, “Sustainable Supply Chains with Blockchain, IoT and RFID: A Simulation on Order Management,” Sustainability, Vol. 13, No. 11, p. 6372, Jun. 2021, https://doi.org/10.3390/su13116372

-

Labonnah Farzana Rahman, Lubna Alam, Mohammad Marufuzzaman, and Ussif Rashid Sumaila, “Traceability of sustainability and safety in fishery supply chain management systems using radio frequency identification technology,” Foods, Vol. 10, No. 10, Oct. 2021, https://doi.org/10.3390/foods10102265

-

C. Costa, F. Antonucci, F. Pallottino, J. Aguzzi, D. Sarriá, and P. Menesatti, “A review on agri-food supply chain traceability by means of RFID technology,” Food and Bioprocess Technology, Vol. 6, No. 2, pp. 353–366, Feb. 2013, https://doi.org/10.1007/s11947-012-0958-7

-

T. Kelepouris, K. Pramatari, and G. Doukidis, “RFID‐enabled traceability in the food supply chain,” Industrial Management and Data Systems, Vol. 107, No. 2, pp. 183–200, Mar. 2007, https://doi.org/10.1108/02635570710723804

-

A. Vecchi and L. Brennan, “Supply chain innovation for short life products: A preventive assessment of RFID deployment and implementation,” International Journal of Business Innovation and Research, Vol. 3, pp. 535–554, 2009.

-

Tsai, Yung-Shun, Ruey-Shun Chen, Yeh-Cheng Chen, and Chun-Ping Yeh., “An RFID-based manufacture process control and supply chain management in the semiconductor industry,” International Journal of Information Technology and Management, pp. 85–105, Jan. 2013, https://doi.org/10.1504/ijitm.2013.051633

-

L. N. K. Duong, L. C. Wood, and X. Wang, “Review of RFID applications in perishable inventory management,” in Handbook of Research on Global Supply Chain Management, IGI Global, 2016, pp. 139–146, https://doi.org/10.4018/978-1-4666-9639-6.ch008

-

M. Tajima, “Strategic value of RFID in supply chain management,” Journal of Purchasing and Supply Management, Vol. 13, No. 4, pp. 261–273, Dec. 2007, https://doi.org/10.1016/j.pursup.2007.11.001

-

S. Kim and G. Garrison, “Understanding users’ behaviors regarding supply chain technology: Determinants impacting the adoption and implementation of RFID technology in South Korea,” International Journal of Information Management, Vol. 30, No. 5, pp. 388–398, Oct. 2010, https://doi.org/10.1016/j.ijinfomgt.2010.02.008

-

Rahman, Shams, Shahadat Khan, Stephen Waters, and Laura Yang., “Factors affecting radio frequency identification technology implementation: a comparative study of Australian and Chinese supply chains.,” in Information Systems: Transforming The Future: Proceedings Of The 24Th Australasian Conference On Information Systems, 2013.

-

S. Fosso Wamba, “Achieving supply chain integration using RFID technology: The case of emerging intelligent B‐to‐B e‐commerce processes in a living laboratory,” Business Process Management Journal, Vol. 18, No. 1, pp. 58–81, Feb. 2012, https://doi.org/10.1108/14637151211215019

-

Zaheeruddin Asif and Munir Mandviwalla, “Integrating the supply chain with RFID: a technical and business analysis,” Communications of the Association for Information Systems, Vol. 15, pp. 393–427, 2005.

-

L. F. Seymour, E. Lambert-Porter, and L. Willuweit, “An RFID adoption framework: a container supply chain analysis,” in IFIP World Computer Congress, TC 8, pp. 175–188, 2008, https://doi.org/10.1007/978-0-387-09682-7-9_15

-

S.-I. Chang, S.-Y. Hung, D. C. Yen, and Y.-J. Chen, “The Determinants of RFID Adoption in the Logistics Industry – A Supply Chain Management Perspective,” Communications of the Association for Information Systems, Vol. 23, pp. 197–218, 2008, https://doi.org/10.17705/1cais.02312

-

Lee, Sangjae, Yong-Jae Park, Myung-Hwan Rim, and Byung Gon Kim., “Are factors affecting RFID adoption different between public and private organizations,” International Journal of Mobile Communications, Vol. 15, pp. 437–465, 2017.

-

Curtin, John P., Robert J. Kauffman, and Frederick J. Riggins, “Making the ‘MOST’ out of RFID technology: a research agenda for the study of the adoption, usage and impact of RFID.,” Information Technology and Management, Vol. 8, pp. 87–110, 2007.

-

A. C. Barros et al., “RFID implementation in the footwear supply chain: from production line to retail store and back,” in Advances in Sustainable and Competitive Manufacturing Systems, Springer, Heidelberg, 2013, pp. 1035–1047, https://doi.org/10.1007/978-3-319-00557-7_85

-

E. W. T. Ngai, D. C. K. Chau, J. K. L. Poon, A. Y. M. Chan, B. C. M. Chan, and W. W. S. Wu, “Implementing an RFID-based manufacturing process management system: Lessons learned and success factors,” Journal of Engineering and Technology Management, Vol. 29, No. 1, pp. 112–130, Jan. 2012, https://doi.org/10.1016/j.jengtecman.2011.09.009

-

H.-L. Chan, “Using radiofrequency identification (RFID) technologies to improve decision-making in apparel supply chains,” Information Systems for the Fashion and Apparel Industry, pp. 41–62, 2016, https://doi.org/10.1016/b978-0-08-100571-2.00003-8

-

R. Angeles, “RFID critical success factors and system deployment outcomes as mitigated by IT infrastructure integration and supply chain process integration,” International Journal of Value Chain Management, Vol. 6, No. 3, p. 240, 2012, https://doi.org/10.1504/ijvcm.2012.050864

-

M. Liukkonen, “RFID technology in manufacturing and supply chain,” International Journal of Computer Integrated Manufacturing, Vol. 28, No. 8, pp. 861–880, Aug. 2015, https://doi.org/10.1080/0951192x.2014.941406

-

C. Sellitto, S. Burgess, and P. Hawking, “Information quality attributes associated with RFID‐derived benefits in the retail supply chain,” International Journal of Retail and Distribution Management, Vol. 35, No. 1, pp. 69–87, Feb. 2007, https://doi.org/10.1108/09590550710722350

-

Harold Boeck and Samuel Fosso Wamba, “RFID and buyer‐seller relationships in the retail supply chain,” International Journal of Retail and Distribution Management, Vol. 36, No. 6, pp. 433–460, May 2008, https://doi.org/10.1108/09590550810873929

-

Hwang, Yoonmin, and Jae Jeung Rho., “Strategic value of RFID for inter-firm supply chain networks,” Information Development, Vol. 32, pp. 509–526, 2016.

-

E. Ergen, B. Akinci, and R. Sacks, “Life-cycle data management of engineered-to-order components using radio frequency identification,” Advanced Engineering Informatics, Vol. 21, No. 4, pp. 356–366, Oct. 2007, https://doi.org/10.1016/j.aei.2006.09.004

-

J. Sounderpandian, R. V. Boppana, S. Chalasani, and A. M. Madni, “Models for cost-benefit analysis of RFID implementations in retail stores,” IEEE Systems Journal, Vol. 1, No. 2, pp. 105–114, Dec. 2007, https://doi.org/10.1109/jsyst.2007.909788