Abstract

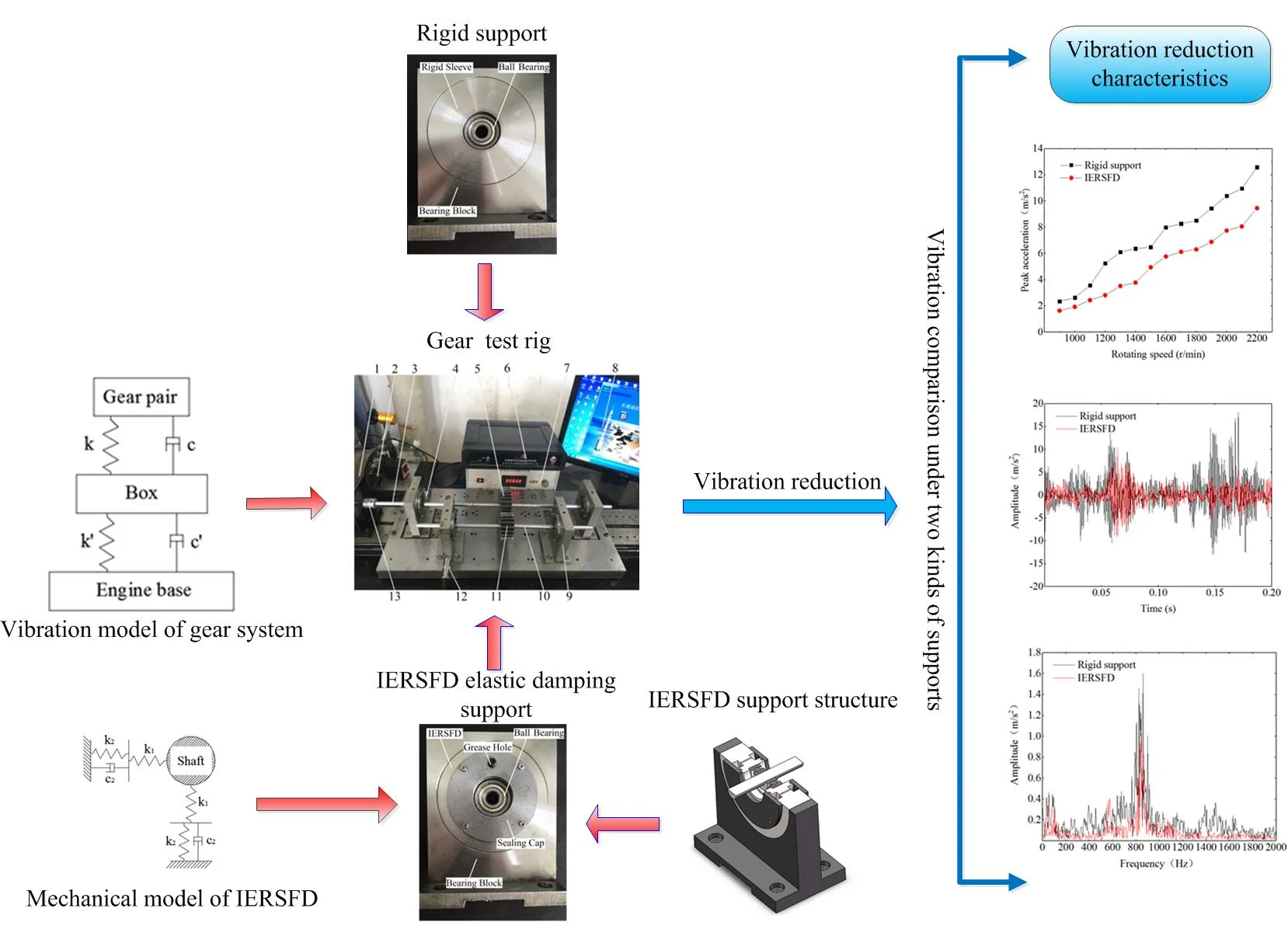

Integral elastic ring squeeze film damper (IERSFD) is proposed to reduce and isolate the vibration of the gear transmissions. IERSFD offers the performance of a low radial stiffness and high squeeze film damping. This paper presents a mechanical model of an IERSFD elastic damping support and a single-degree-of-freedom vibration isolation system for the gear system. An open single-stage spur gear system was built to experimentally study the vibration characteristics of gear transmissions with rigid supports and with IERSFD elastic damping supports filled with damping fluids of different viscosities. The experimental results show that the IERSFD can effectively reduce the peak vibration acceleration of the gear shafts and can guarantee the smooth operation of the gear assembly over a range of speeds. This work shows that an IERSFD can reduce the shock and vibration of the gears’ meshing. It effectively attenuates vibration for most of the gears’ frequency components. Within a limited viscosity range, the vibration reduction is more effective with the higher-viscosity IERSFD damping fluids tested.

1. Introduction

Geared transmissions are one of the most widely used power transmission methods in mechanical engineering. Because of the internal excitations caused by time-varying meshing stiffness and gear errors, gear systems are prone to significant vibration and noise problems, especially when there are manufacturing and installation errors. Significant vibrations can cause damages to the equipment. Noise caused by vibration can also affect the health of operation staff. Therefore, it is of great engineering value to study the technology to reduce vibration and noise in gear transmissions [1]. The vibration characteristics of gear system are rather complicated, because it is composed of multiple components such as the meshing frequency with its high harmonics and the rotating frequency with its low harmonics [2].

Scholars have done a great deal of research on vibration reduction methods for gear transmissions. Their developed gearbox vibration reduction methods can be divided into vibration source reduction, and passive vibration reduction through vibration absorption. Vibration source reduction reduces the source of gears’ vibration by optimizing the parameters and modifying the gear teeth during the gear design process [3-5]. The process of vibration source reduction is complicated by its high manufacturing cost and large computational effort [6, 7]. Passive vibration reduction for a gear transmission uses energy-consuming devices to dissipate vibration energy. For example, a damping ring and viscoelastic damping layer in the gear can absorb the vibration energy of the gear [8-10]. However, it is necessary to add the damping material over a large area, increasing the weight and size of a gearbox. Sutton et al. [11] used hysteresis regulators to control the vibration of the gear and achieved a decrease of 30-40 dB for the 250 to 1250 Hz frequency range, but the damping effect was inadequate in the 500 to 800 Hz frequency range. Guan et al. [12] used piezoelectric actuators to counteract the vibration and noise of the gearbox. By improving the control algorithm, the vibrations were reduced by 8-13 dB, and the noise at the meshing frequency was reduced by 5-8 dB. However, the range for which the vibration frequencies had been reduced was very limited, and the control algorithm was complex. Huang et al. [13] obtained a certain damping effect by installing a viscous damper on the gear shaft, but their damper required a large amount of space and was unsuitable for a gearbox requiring compact shaft structure.

Squeeze film dampers (SFD) are often used to reduce the rotor vibration as it passes through its critical speed. However, the traditional squirrel cage-SFD has many problems such as large space occupation, difficult assembly, and vulnerability to fatigue. In addition, the oil film force of a SFD is nonlinear. If the damper design is unreasonable, the rotor vibration will increase instead of decrease. To overcome these shortcomings, an integral elastic ring squeeze film damper (IERSFD) was designed and used to reduce and isolate vibrations generated by gear mesh excitation.

Unlike the unbalanced excitation of the rotor, the vibration of the gear system is mainly caused by gears’ meshing process. The dynamic excitation of the gear system is transmitted to the box mainly through the bearing. Measures taken at the bearing position can effectively attenuate the vibration transmission [14]. The IERSFD described in this paper is designed to control the vibration of gear shafts and isolate the vibration excitation through the bearings to the supporting structure. IERSFD has both the performance of a low radial stiffness and high squeeze film damping, which can provide viscous damping to reduce the lateral vibration amplitude of the gear system and to isolate vibration transmitted to other structural parts. IERSFD has segmented squeeze film regions that can inhibit the generation of nonlinear oil film stiffness. Its system-level advantages include its simple structure and straightforward assembly. Dimethyl silicone oil is a kind of silicon-based liquid with high viscosity and good thermal stability, and it is often used as a damping fluid for vibration absorption structures. In this study, dimethyl silicone oil is used as the IERSFD damping fluid.

For the experimental work described in this paper, four sets of IERSFD elastic damping support structures were designed and manufactured, and a single-stage involute spur gear transmission system was built. The vibration reduction characteristics of gear shafts with IERSFD were studied by comparing the vibrations of the gear system with the IERSFD elastic damping support filled with different viscosity damping fluids, to the vibrations of a gear system fabricated with the same layout and the same gear ratio and gear meshing characteristics, but a solid structure and without the damping structures. This latter case serves as a base case.

2. Integral elastic ring squeeze film dampers

2.1. The structure of an IERSFD

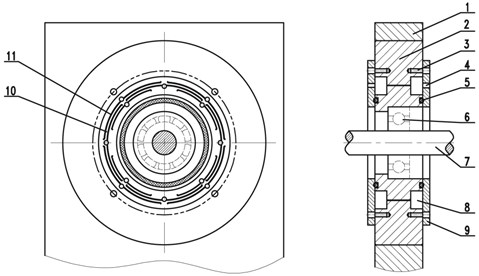

The IERSFD described here uses a three-layer oil film, double elastic ring structure, as shown in Fig. 1. The oil film gap is 0.3 mm. Each layer of oil film is circumferentially divided into four sections, and the twelve sections of the three-layer oil film are staggered. The thickness of each elastic ring is 1mm, and its axial width is 10 mm. The oil storage cavity on both sides of the elastic ring is used for storing the damping fluid, and is sealed by the sealing cap and O-type rubber rings. The elastic ring structure reduces the radial stiffness of IERSFD, and the oil film absorbs the vibration energy.

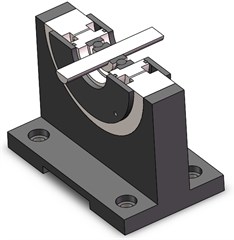

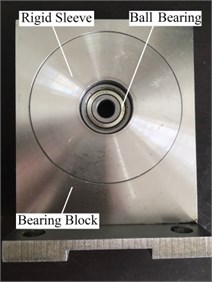

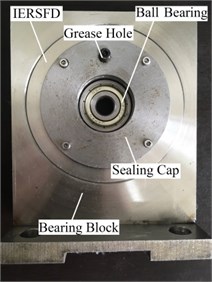

The outer race of the IERSFD is a transition fit with the bearing block. The inner race of the IERSFD has an interference fit with the outer race of the ball bearing. The IERSFD elastic damping support assembled with IERSFD, bearing block and ball bearing is shown in Fig. 2. The manufactured IERSFD is shown in Fig. 3.

Fig. 1The structure of the IERSFD and its assembly diagram with the shaft: 1 – bearing block, 2 – IERSFD, 3 – bolt hole, 4 – grease hole, 5 – O-type rubber ring, 6 – ball bearing, 7 – shaft; 8 – oil storage cavity, 9 – sealing cap, 10 – elastic ring, 11 – squeeze film region

Fig. 2IERSFD elastic damping support

Fig. 3The manufactured IERSFD

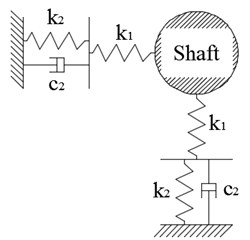

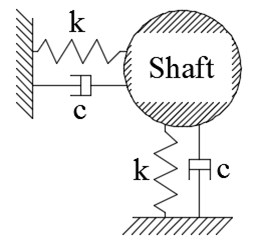

2.2. The IERSFD mechanical model

The IERSFD support is modeled as a set of dampers and springs with a mass at the shaft location. The oil film of IERSFD has a gap of 0.3 mm, which is large as compared to a similar-diameter journal bearing’s gap. When there is no oil supply pressure, the oil film stiffness can be ignored, and only the damping force generated by squeezing the oil film is considered. Also, the damping of ball bearing is negligible, so only its stiffness is considered. The mechanical model of IERSFD support system is shown in Fig. 4.

Fig. 4The mechanical model of IERSFD support system

Fig. 5The simplified mechanical model of IERSFD support system

In Fig. 4, k1 is the stiffness of the ball bearing, and k2 and c2 are the stiffness and damping coefficient of the IERSFD respectively. The stiffness of the ball bearing and the IERSFD are in series, and the assembly stiffness is k=(k1k2)/(k1+k2). As k2≪k1, the introduction of the IERSFD reduces the overall stiffness of the bearing support system. The damping coefficient of the assembly needs to include the damping of ball bearing, but in this work the ball bearing has negligible damping compared to the IERSFD itself: c=c2. This support system damping coefficient is greatly increased by adding the IERSFD. The simplified mechanical model of IERSFD support system is shown in Fig. 5.

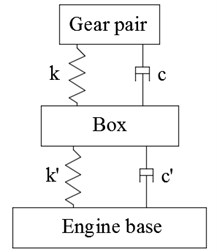

3. Vibration model of the assembled gear system

For a convenient analysis, a simplified vibration model of gear system was developed. This is shown in Fig. 6. Among them, the meshing gear pair can be simplified as the concentrated mass of the vibration source, and the gearbox can be simplified as another concentrated mass being excited. The bearing between the gear and box can be regarded as a spring with a certain stiffness k and damping c. Generally, the gearbox is connected with the engine base elastically, and the shaft alignment requires that the stiffness value k' should be large [15]. The dynamic excitation of the gear system is mainly transmitted to the box through the bearing. Taking measures in the bearing part can effectively reduce the vibration transmission. According to the vibration theory [16], in order to reduce the vibration response of the gearbox, it is generally necessary to reduce the radial stiffness k of the bearing appropriately and increase the bearing damping c. As a result, the natural frequency of the gear system is reduced, and the vibration transmission of the system is decreased.

Fig. 6Vibration model of gear system

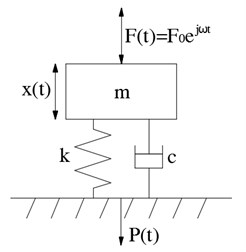

Fig. 7Vibration isolation system with a single degree of freedom in damping

Considering the vibration of the gearbox as an investigation index, a single-degree-of-freedom vibration isolation system in damping for the gear system is established, as shown in Fig. 7.

The equation of motion of this system is:

where m, k, c denote the mass, stiffness and damping of the vibration isolation system, respectively. The amplitude of the equation of motion mentioned above is:

where ω0=√k/m denotes the natural frequency of the system. The variable z=ω/ω0 is the frequency ratio, and ζ=c/(2√mk) is the damping ratio of the system. The force transmitted to the box is written as:

The force amplitude is:

This leads to the vibration transmission coefficient of the system:

According to Eq. (5), when the excitation frequency ω is much larger than the natural frequency of the system ω0, the vibration transmission coefficient of the system is less than 1, and the system has the vibration isolation effect. The gear meshing vibration and its high harmonics are all high-frequency components, which are much larger than the natural frequencies of the gear system. Therefore, the vibration isolation measure is effective. In addition, the introduction of damping c can limit the resonance of gear system.

4. Introduction of experimental setup

4.1. Two support structures

To study the vibration reduction characteristics of gear shafts with an IERSFD, two support structures were designed: rigid support and IERSFD elastic damping support, as shown in Fig. 8. The rigid support structure includes bearing block, rigid sleeve and ball bearing. The IERSFD support structure consists of a bearing block, IERSFD, ball bearing, O-type rubber ring and sealing cap. When using the IERSFD elastic damping support, dimethyl silicone oil with viscosity of 500 cs, 1000 cs and 5000 cs was added to the oil storage cavity respectively. By comparing the vibration of the gear shafts under the two support structures, the vibration reduction characteristics of gear shafts with IERSFD are studied.

Fig. 8Two support structures

a) Rigid support

b) IERSFD elastic damping support

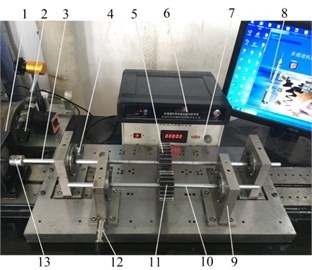

4.2. Test rig design

The experimental setup for testing of gear vibration reduction with the IERSFD is shown in Fig. 9. It is a single-stage involute spur gear system. Technical data for the test gears are listed in Table 1. The driving shaft and driven shaft are 10 mm in diameter. The driving shaft span is 440 mm, and the driven shaft 260 mm. The shaft is driven by a DC variable frequency motor. To reduce the influence of motor vibration on the dynamic characteristics of the gear transmission system, a flexible coupling was used. The gear pair is lubricated by dripping oil during the experiment.

A LC-8008 fault diagnosis system was used for the vibration tests. The system has eight input channels, and can analyze and store vibration signal data. Vibration signals are collected by the acceleration sensor mounted on the bearing block, and the vibration along the horizontal direction of the two shafts’ bearing blocks is measured. The photoelectric sensor was used to measure the shaft speed. The analysis frequency of the LC-8008 was set to 2000 Hz, and the number of sampling points per period used was 1024.

Fig. 9Gear test rig: 1 – motor, 2 – photoelectric sensor, 3 – driving shaft, 4 – acceleration sensor 1, 5 – driving gear, 6 – acquisition system LC-8008, 7 – motor speed controller, 8 – computer, 9 – IERSFD elastic damping support, 10 – driven shaft, 11 – driven gear, 12 – acceleration sensor 2, 13 – flexible coupling

Table 1Technical data for the test gears

Gear parameters | Value |

Number of driving gear teeth Z1 | 30 |

Number of driven gear teeth Z2 | 20 |

Gear ratio i | 2/3 |

Gear modulus m / (mm) | 3 |

Pressure angle α/ (°) | 20 |

Tooth thickness of driven gear b2 /(mm) | 30 |

Tooth thickness of driving gear b1 / (mm) | 28 |

Theoretical center distance d / (mm) | 75 |

5. Results and discussion

5.1. Analysis of gear shafts’ vibration suppression with IERSFD

By adjusting the speed controller, the driving shaft speed n1 was set in the range from 900 r/min to 2200 r/min respectively. The driven shaft speed, for those driving shaft speeds, was n2 from 1350 r/min to 3300 r/min, respectively.

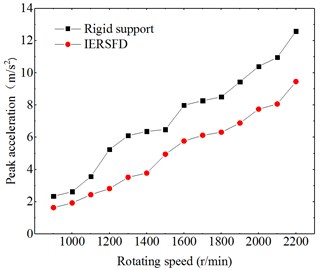

The vibration of the gear shafts was measured both for the base case of installation on rigid supports and the test case with the IERSFD elastic damping supports filled with the 500cs viscosity damping fluid. The data was recorded at driving shaft speed increments of 100 r/min. Figs. 10(a) and 10(b) show the vibration acceleration peaks of the two shafts’ measuring points under two different types of supports.

As shown in Fig. 10, the vibration of the gear shafts increases with increasing rotational speed. Compared to the rigid support base case, the vibration amplitude of each measuring point is reduced with the IERSFD elastic damping support. It can be seen that the vibration reduction characteristics of the gear shafts are useful over a range of speeds after installing IERSFD elastic damping supports. The IERSFD support can effectively guarantee the smooth operation of the gear transmission system over a large range of speeds. Considering the vibration data from the measured point on driving shaft when n1= 1200 r/min as an example, when the rigid support is changed to IERSFD support, the peak of vibrational acceleration was reduced from 5.25 m/s2 to 2.82 m/s2, for a decrease of 46.3 %.

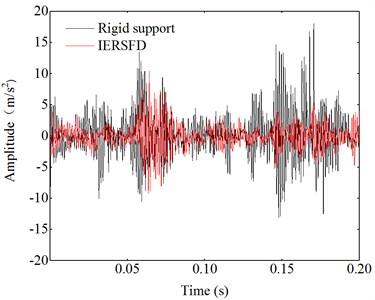

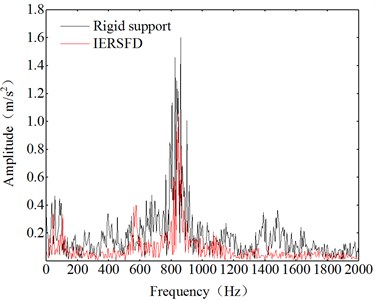

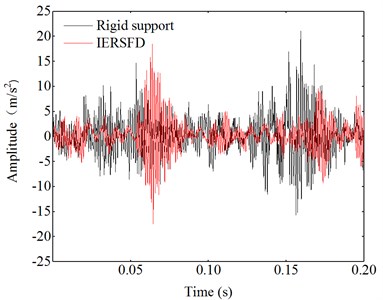

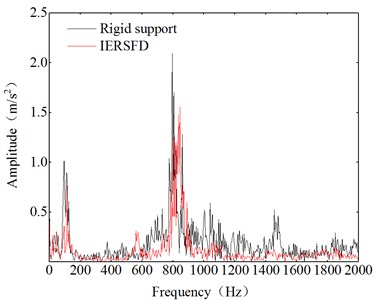

To further understand the vibration reduction characteristics of the IERSFD elastic damping support on the gear shaft, the time and frequency domain waveforms for each measuring point were extracted. Due to space limitations, time and frequency domain waveforms for two measuring points are analyzed when n1= 1200 r/min, as shown in Figs. 11 and 12.

Fig. 10Vibration comparison under two kinds of supports

a) Comparison of driving shaft’s measuring point

b) Comparison of driven shaft’s measuring point

Fig. 11Comparison of vibration of driving shaft’s measuring point

a) Time domain waveform

b) Frequency spectrum

Fig. 12Comparison of vibration of driven shaft’s measuring point

a) Time domain waveform

b) Frequency spectrum

As can be seen from the time domain waveforms shown in Figs. 11(a) and 12(a), the modulation phenomenon in the time domain waveform decreases to a certain extent after the rigid support is replaced by an IERSFD support. This indicates that the IERSFD elastic damping support can inhibit the shock and vibration of the gears’ meshing.

In Figs. 11(b) and 12(b), the frequency spectrum contains many frequency components. After installing the IERSFD support, the vibration of most frequency components is attenuated, indicating that IERSFD has a good vibration suppression of the gear shaft in a wide frequency range. The meshing frequency of the gear system is fr=Z1n1/60=Z2n2/60= 600 Hz, but the vibration amplitude of the meshing frequency is small. However, the vibrations in the vicinity of 90 Hz and 820 Hz are large, with a wide frequency band. According to the vibration theory [17], this is a resonance modulation phenomenon of the gear shaft. When the rigid support is replaced by the IERSFD support, the vibration at those frequency components is significantly reduced.

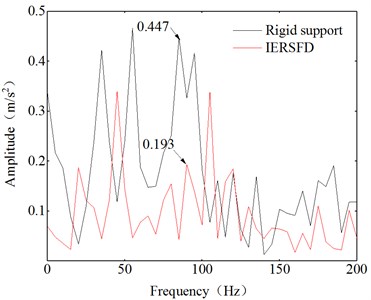

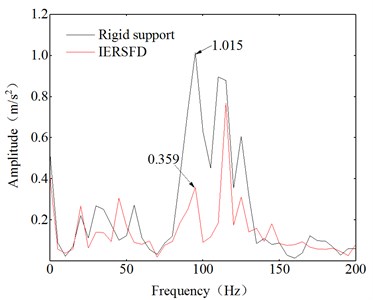

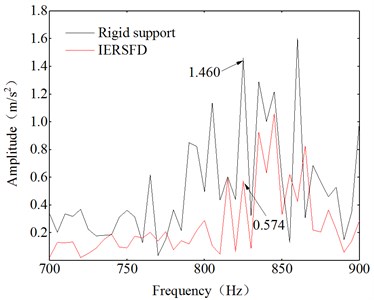

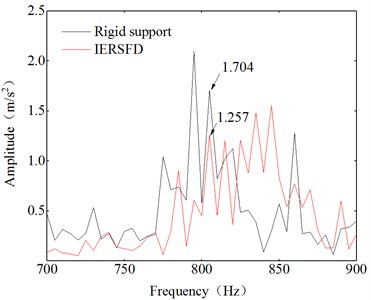

For the sake of a clear comparison, frequency spectrum ranges between 0-200 Hz, and 700-900 Hz are shown in Figs. 13 and 14, respectively. Tables 2, 3 list the vibration data at the frequency components which have large vibration amplitude.

Fig. 13Frequency spectrum ranges between 0-200 Hz

a) Frequency spectrum of driving shaft

b) Frequency spectrum of driven shaft

Fig. 14Frequency spectrum ranges between 700-900 Hz

a) Frequency spectrum of driving shaft

b) Frequency spectrum of driven shaft

Table 2Vibration data with different supports (driving shaft)

Frequency (Hz) | Vibration amplitude (m/s2) | Decrease (%) | |

Rigid support | IERSFD support | ||

90 | 0.447 | 0.193 | 56.8 |

820 | 1.460 | 0.574 | 60.7 |

The experimental results above show that the vibration amplitude at these frequency points decreases considerably. Considering the driven shaft’s vibration at 90 Hz as an example, when the rigid support is changed to the IERSFD support, the vibration amplitude is reduced from 1.015 m/s2 to 0.359 m/s2, thus having a decrease of 64.6 %.

Table 3Vibration data with different supports (driven shaft)

Frequency (Hz) | Vibration amplitude (m/s2) | Decrease (%) | |

Rigid support | IERSFD support | ||

90 | 1.015 | 0.359 | 64.6 |

820 | 1.704 | 1.257 | 26.2 |

5.2. Vibration reduction characteristics based on the damping fluid’s viscosity

The above experimental results show that IERSFD elastic damping support has good vibration attenuation performance for the gear transmission system. The influence of the damping fluid’s viscosity on the vibration reduction characteristics of the IERSFD was also explored.

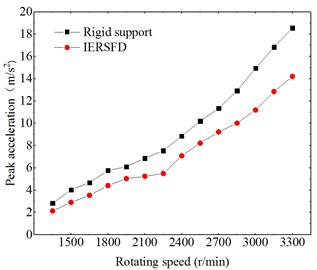

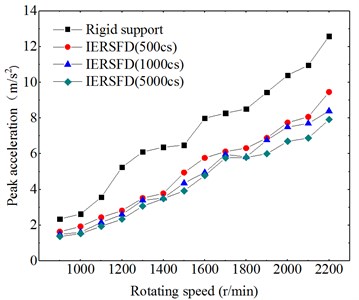

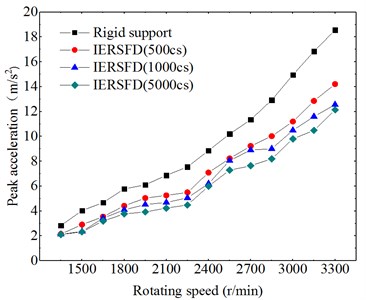

The motor speed was set from 900 r/min to 2200 r/min. The vibration data of gear shafts equipped with the IERSFD elastic damping support filled with two other viscosity damping fluids (1000 cs, 5000 cs) were measured. Figs. 15, 16 show the peak of vibrational acceleration of the driving shaft and driven shaft for these different damping fluid viscosities.

Fig. 15Comparison of driving shaft’s measuring point

Fig. 16Comparison of driven shaft’s measuring point

According to the data in Figs. 15, 16, it can be seen that within a limited range of viscosity, as the viscosity of IERSFD damping fluid increases, the decreasing reduction of gear shafts’ vibration improves. Taking the measuring point on the driving shaft as an example, when the motor speed is 1200 r/min, the vibration under the rigid support is 5.25 m/s2. As the viscosity of IERSFD damping fluid increases from 500cs to 1000cs and then to 5000cs, the vibration amplitude decreases from 2.82 m/s2 to 2.6 m/s2 and then to 2.34 m/s2, respectively, resulting in a decrease from 46.3 % to 50.5 % and then to 55.4 %.

6. Conclusions

Integral elastic ring squeeze film damper (IERSFD) was designed, and the application of IERSFD in the vibration control of gear shafts was experimentally studied.

1) IERSFD support can effectively reduce and isolate the vibration of the gear shaft caused by the gear mesh excitation.

2) Comparing IERSFD’s vibration reduction characteristics at different speeds, the IERSFD elastic damping support can effectively guarantee significantly smooth operation of the gear transmission over a range of speeds.

3) The IERSFD support can improve the shock load characteristics of the gears’ meshing.

4) The IERSFD support has good vibration attenuation effect on most frequency components in the gear transmission.

5) Within a limited viscosity range, the vibration reduction is more effective with the higher-viscosity IERSFD damping fluids tested.

References

-

Xiao W. Q., Huang Y. X., Li W., et al. Influence of particle damper configurations on the dynamic characteristic for gear transmission system. Journal of Mechanical Engineering, Vol. 53, Issue 7, 2017, p. 1-12.

-

Ding K., Zhu X. Y., Chen Y. H. Typical fault vibration characteristics and diagnosis strategy of gearbox. Journal of Vibration and Shock, Vol. 20, Issue 3, 2001, p. 7-12.

-

Yuan Z., Sun Z. L., Wang D., et al. GA-based optimum profile modification of spur gears for vibration damping. Journal of Northeastern University (Natural Science), Vol. 31, Issue 6, 2010, p. 873-876.

-

Li H. K., Guo C., Fang S. L., et al. Optimization design method for gearbox’s vibration and noise reduction. Journal of Vibration and Shock, Vol. 32, Issue 17, 2013, p. 150-154.

-

Shao C. J., Sun T., Shen Y. W., et al. A study on vibration depression of gear system by modification reanalysis of structural dynamics. Journal of Aerospace Power, Vol. 13, Issue 3, 1998, p. 305-309.

-

Subramanian R. B., Srinivasan K. Vibration analysis of an influence of groove in the bottom land of a spur gear. Journal of Vibration and Control, Vol. 20, Issue 6, 2014, p. 847-858.

-

Kim S. J., Lee S. K. Experimental identification on a gear whine noise in the axle system of a passenger van. International Journal of Automotive Technology, Vol. 8, Issue 1, 2007, p. 75-82.

-

Wang Q. Y., Cao D. Q., Yang J. B. Axial vibration reduction characteristics of a gear system with a damping ring. Journal of Vibration and Shock, Vol. 32, Issue 6, 2013, p. 190-194.

-

Zhong Y. T., Wang L. Q., Li W. L. Study on vibration reduction of gear drives based on damping technology. Journal of Mechanical Transmission, Vol. 35, Issue 11, 2011, p. 17-20.

-

Mao B. Q., Lin L., Cao T. J. Study on reducing vibration and noise of the gear transmissions by using damped ring. Journal of Machine Design and Research, Vol. 21, Issue 1, 2005, p. 46-49.

-

Sutton T. J., Elliott S. J., Brennan M. J., et al. Active isolation of multiple structural waves on a helicopter gearbox support strut. Journal of Sound and Vibration, Vol. 205, Issue 1, 1997, p. 81-101.

-

Guan Y. H., Lim T. C., Shepard W. S., et al. Experimental study on active vibration control of a gearbox system. Journal of Sound and Vibration, Vol. 282, Issue 3, 2005, p. 713-733.

-

Huang X. J., He L. D., Xia X. R., et al. Experimental study of viscous damper vibration reduction technology of gear shafting. Journal of Mechanical Transmission, Vol. 39, Issue 2, 2015, p. 99-103.

-

Dai G. H., Yu X. H., Yin X. M., et al. The applied research of damping supporting structure in the gearbox. Ship Science and Technology, Vol. 36, Issue 9, 2014, p. 141-145.

-

Wang G. Z., Sun P. L., Fang K. X. A research on the reduction of vibration and noise of the gearbox by using damping alloys. Journal of Jiangsu University of Science and Technology (Natural Science Edition), Vol. 8, Issue 3, 1994, p. 14-20.

-

Vance J., Zeidan F., Murphy B. Machinery Vibration and Rotordynamics. First Edition, John Wiley and Sons Inc., New Jersey, 2010.

-

Ding K., Li W. H., Zhu X. Y. Gears and Gearbox Fault Diagnosis Practical Technology. First Edition, Machinery Industry Press, Beijing, 2005.

Cited by

About this article

This work is supported by the National Basic Research Program of China (2012CB026000) and Key Laboratory Fund for Ship Vibration and Noise (614220406020717).