Abstract

The numerical modeling and experimental test are carried out to analyze the effects of the coupling between the structure of the hydrocyclone and the internal spiral flow on the structure motion of the hydrocyclone, and the interaction of the fluid and the structure is fully considered. The model of fluid structure interaction (FSI) of the hydrocyclone with variable diameter circular pipe is presented in this paper, and the related numerical simulation and experimental research are also carried out. Using the established fluid-structure interaction model, the dynamic characteristic of the hydrocyclone under the FSI condition is discussed, which obtained the vibration characteristics and the inter facial stress distribution characteristics. The maximum value of deformation is at the small cone-shaped part and the tail part connection of the hydrocyclone. The inter facial stress distribution is showed non symmetric state, and the maximum value of stress is located in the large cone-shaped part. After compared analysis the numerical results and the measured results, the numerical simulation is the same as the distribution trend of the test results at the maximum acceleration and position. The above analysis shows that the two-way FSI calculation model of hydrocyclone with variable diameter circular pipe is reasonable, and the motion characteristics of the structure are changed under the interaction of fluid and structure each other. The influence of the motion of the structure on the flow field of the hydrocyclone cannot be ignored. This is a problem that should be considered in the future design and application of hydrocyclone.

1. Introduction

Hydrocyclones are mainly composed of circular tubes and variable diameter circular tubes segments, which are widely used in the separation of two-phase or multiphase media in the field of oil and chemical industry [1]. When hydrocyclones work, the pulsation of the internal spiral flow makes the structure of the hydrocyclone vibrate or deform. While the structure of vibration or deformation, in turn, acts on the internal fluid, thereby changing the flow state of the internal spiral flow. Because of the coupling between fluid and structure, the motion law of internal fluid and the dynamic characteristics of structure will be changed, which will influence the performance of the equipment and the reliability of the structure.

Currently, many scholars at home and abroad have carried out researches on the flow characteristics [2] and engineering applications [3] of the hydrocyclone. The researches of hydrocyclone based on fluid structure interaction is less, and the similar researches mainly focus on the study of pipes and the cylindrical shell system [4-6]. In the numerical analysis of fluid structure interaction, the scholars have done further research on the coupling algorithm and the interface information transfer [7-9].

At present, for hydrocyclones, there is also the interaction between the fluid and the structure. We consider the influence of fluid structure interaction, the structural vibration characteristics of hydrocyclone are analyzed by means of numerical simulation and experimental test. It provides the basis for further understanding the motion characteristics of the hydrocyclone structure, the working state of the equipment and the optimum design of the structure.

2. The FSI model and method

2.1. The geometric model and fluid parameter

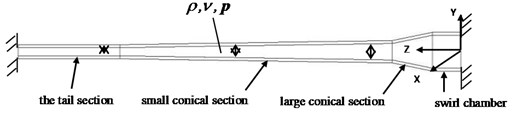

The variable diameter circular pipe structure of hydrocyclone whose main diameter is 28 mm is selected as the research object. The length of tail pipe part is 570 mm, the large cone angle and small cone angle are 20 degrees and 1.5 degrees respectively. The model consists of fluid domain and solid domain. The material of solid domain is organic glass, the wall thickness of organic glass tube is 5.5 mm, the density is 1.18×103 kg/m3, modulus of elasticity is 3×109Pa, and the Poisson’s ratio is 0.347. The fluid domain uses water as the flow medium, the density is 998.2 kg/m3, the viscosity of water is 1.0 mPa s. When the structure is working, both ends of the pipe are fixed. The vibration of the variable diameter circular tube structure under the internal fluid pulsation is considered. And the spiral turbulence in the same pipe constitutes a FSI system. Its mechanical model is shown in Fig. 1.

Fig. 1The fluid structure interaction mechanics model of variable diameter pipe

2.2. FSI calculation model and method

In the fluid microelectronics of the hydrocyclone, the mass conservation and the conservation of momentum should be satisfied.

Governing equations for the fluid part.

The continuous equation is:

The momentum conservation equation is:

Governing equations for the solid part.

The balance equation is:

Dynamic equation is:

Fluid-structure interaction interface equation is:

where, the temperature change of the fluid in the hydrocyclone is not considered, and at the interface of fluid domain and solid domain, the force and the displacement are equal.

Where, is a local acceleration vector in the solid domain (m/s2); and are volume force vector of fluid and solid (N), respectively; and are density of fluid and solid (Kg/m3), respectively; is velocity vector of fluid (m/s); is cauchy stress tensor (N); , and are mass matrix, damping matrix and stiffness matrix, respectively; is the load of the fluid to the structure; , are interface stress of fluid and solid (N), respectively; and are interface displacement of fluid and solid (m), respectively.

The numerical simulation applies the Ansys FEM and the Fluent platform. Based on the small deformation assumption, the finite volume method is adopted in the fluid domain, and the RSM model is adopted in the turbulent model for the flow field computation. The ALE method is adopted in the dynamic mesh. The finite element theory is applied in the solid domain, and the New-mark time integral method is used to solve the dynamic equation of the variable diameter circular tube structure of a hydrocyclone. And the calculation method of interlaced iterative coupling solution is adopted to realize the two-way coupling numerical calculation of the variable diameter circular tube of a hydrocyclone. The inlet of the hydrocyclone adopts velocity entrance boundary (m/s), and the underflow outlet and the overflow outlet both use the full development of boundary condition.

2.3. Two-way fluid-structure coupling iteration method

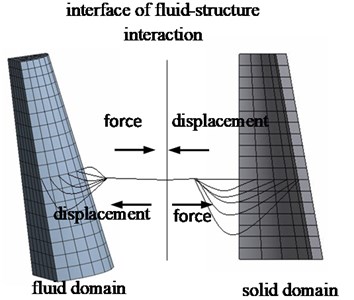

The interaction between fluid and structure is considered, that is, the effect of fluid pressure change on the distribution of structural stress and displacement, and the disturbance of the structure vibration to the internal fluid will also affect the distribution of the fluid pressure. The relation between the interfacial force of the structure and displacement transfer of the variable diameter circular pipe fluid is shown in Fig. 2.

Fig. 2Force and displacement transitive relation at coupling interface

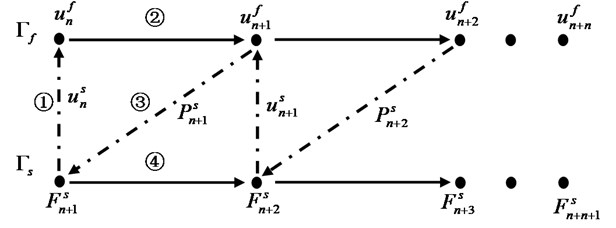

Fig. 3Two-way FSI solution iterative process

The calculation method and interface equation of fluid domain and structure domain are established respectively. To achieve two-way coupling calculation of variable diameter pipe of hydrocyclone, it depends on iterative calculation method. The characteristics are that the fluid domain and the structure domain are integrated in time domain by the application of their respective solution methods, and the response of the FSI is promoted in a time interlaced way. In this way, the fluid domain and the solid domain can be calculated by different operators, such as the finite volume method in the fluid domain, and the finite element method in the solid domain. The flowchart of the interlaced iteration is shown in Fig. 3.

3. Result analysis

Numerical calculation and experimental analysis were performed for the inlet velocity of 6.8 m/s, 8.2 m/s and 10.2 m/s, respectively.

3.1. Analysis of structure deformation under coupling action

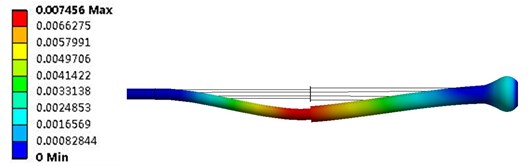

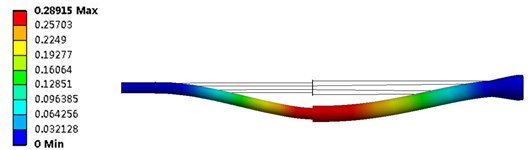

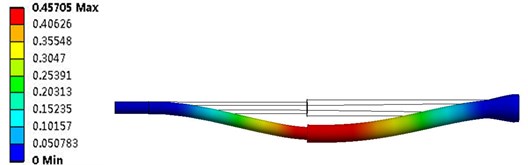

Figs. 4-6 are the equivalent deformation diagrams of the variable diameter circular tube structure of the hydrocyclone under coupling action, when the inlet velocity is 6.8 m/s, 8.2 m/s and 10.2 m/s respectively. As can be seen from the figure, the maximum deformation position of the structure is back-end of the small conical section, namely junction of small conical section and the tail section. With the increase of the inlet velocity, the maximum deformation value of hydrocyclone is increasing, and the maximum deformation values of three kinds of inlet velocity are 0.007456 mm, 0.28915 mm and 0.45705 mm, respectively. When the inlet velocity is 6.8 m/s, the influence on the structural deformation is very small. Compared with the inlet velocity 8.2 m/s and 10.2 m/s, the difference is nearly two orders of magnitude, which indicates that the influence on the deformation of the structure is becoming more significant when the inlet velocity is greater than 8.2 m/s.

Fig. 4Structural displacement diagram at 6.8 m/s

Fig. 5Structural displacement diagram at 8.2 m/s

Fig. 6Structural displacement diagram at 10.2 m/s

3.2. Interfacial stress distribution under coupling action

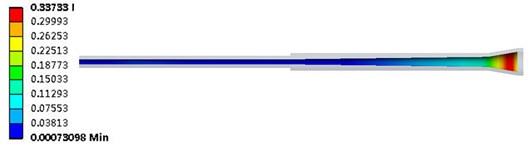

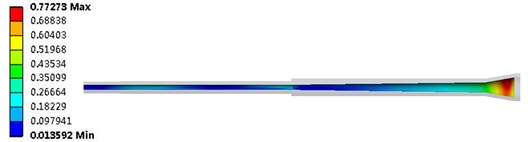

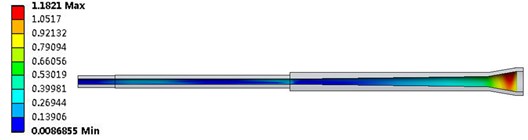

Figs. 7-9 is the equivalent stress distribution cloud diagram at the interface between the fluid and the structure of a hydrocyclone’s variable diameter circular tube under three kinds of inlet velocity. As can be seen from the diagrams, the maximum stress position of the structure is mainly concentrated in the large cone-shaped part. With the increase of the inlet velocity, the stress is increasing, and the maximum stress values corresponding to the three kinds of inlet velocity are 0.34 MPa, 0.77 MPa and 1.18 MPa respectively. It can also be seen that the stress is not symmetrical at the interface, and the greater the inlet velocity is, the more obvious the asymmetry is. And in the high inlet velocity, there is also a asymmetric relatively large stress distribution in the intersection of the small cone and the tail pipe. These phenomena indicate that the coupling of fluid and structure has an influence on the distribution of forces on the structure.

Figs. 7-9 are the equivalent stress distribution diagram at the interface between the fluid domain and the solid domain in the hydrocyclone under three kinds of inlet velocity. From the graph, we can see that the location of the maximum stress is mainly concentrated in the large conical section. With the increase of the inlet velocity, the maximum stress value of hydrocyclone is increasing. The maximum stress values of the three kinds of inlet velocity are 0.34 MPa, 0.77 MPa and 1.18 MPa respectively. At the same time, we can also see that the stress at the interface are not symmetrical, with the inlet velocity greater, the asymmetry is more obvious, and at high inlet velocity, there are bigger stress distribution at junction of small conical section and the tail section. These phenomena indicate that it has an impact on the distribution of forces in the structure under FSI.

Fig. 7The interface stress distribution of fluid and structure at 6.8 m/s

Fig. 8The interface stress distribution of fluid and structure at 8.2 m/s

Fig. 9The interface stress distribution of fluid and structure at 10.2 m/s

3.3. Comparative analysis of measured data and simulated data

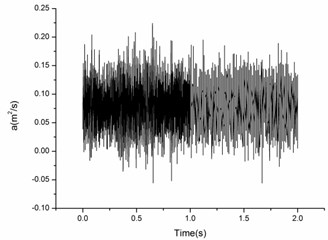

The test instrument applies the 24 channel SCADAS Mobile data acquisition system of Belgium LMS company, and LMS Test.Lab testing and analysis software is used. Fig. 10 is a hydrocyclone entity for experimental test. The piezoelectric sensor is directly installed on the variable diameter pipe of the hydrocyclone. The sensor uses PCB company’s ICP accelerometer, and the sensitivity is 100 mV/g and 1000 mV/g, respectively, two types. The sampling frequency range is 0-500 Hz, and the frequency resolution precision is 0.5 Hz. After the data acquisition analyzer is processed, the display shows the vibration waveform as shown in Fig. 11.

Fig. 10Entity structure of hydrocyclone

Fig. 11Signal gathering analytical instruments

Fig. 12Original time domain signal

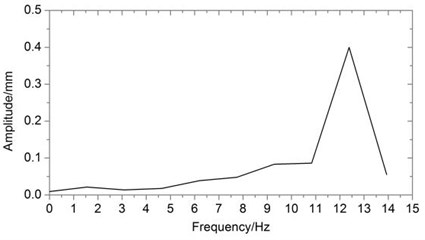

Fig. 13amplitude frequency curve when velocity is 10.20 m/s

Fig. 12 shows original time domain signal of position 2 at inlet velocity of 8.2 m/s, and the value of the maximum acceleration is about 2.3 m2/s. Fig. 13 shows the amplitude frequency curve of the structure subjected to the impact of the fluid, when the inlet velocity is 10.2 m/s. The vibration frequency of the structure is increasing with the flow velocity increases. Through the amplitude frequency curve, the excitation frequencies of the three kinds of inlet velocities are 0.511 Hz, 2.01 Hz and 12.38 Hz respectively. Modal analysis has obtained that the natural frequency of low order structure under working condition is about 36 Hz, and with the inlet velocity increases, the natural frequency is decreased, and the structure vibration frequency under the action of fluid is increasing with the flowrate increases, if the inlet velocity of fluid flow is too large, it will cause the resonance of the structure, which is need to pay attention to in the actual the problem.

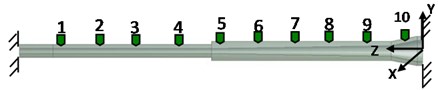

(1) Measuring-point arrangement.

Ten measuring points are arranged on the variable diameter circular tube of the hydrocyclone, and the position of the measuring points is shown in Fig. 14. Because the geometric model is symmetrical around the circle, the structure is simplified into rods. The positions are measured at the horizontal axis ( axis) and the vertical axis ( axis) of the same axis section position. The final result of the average data of ten measurements is taken.

(2) Comparison and analysis.

Table 1 gives the absolute values of the maximum acceleration of each measurement point at axis direction and axis direction. The T and S represent the measured data, and the numerical simulation data respectively.

1) In both axial directions, the variation trend of values of the maximum acceleration at different inlet velocities is similar. Namely, the acceleration values at position 1 and position 10 near the fixed constraint are smaller, while the acceleration value is larger in the middle area, similar to the parabolic form, which reflects the first order vibration mode of the structure.

Fig. 14Measuring point distribution of hydrocyclone

2) The measured values at both ends are generally greater than the simulated values, while those in the central region are lower than the simulated values. This is mainly due to the difference between the boundary conditions of the simulated and the measured. At the time of simulation, the both ends are fixed constraints. However, due to the manufacturing and installation errors and the fluid load, there is a slight displacement at the two ends of the structure at the time of measuring.

3) With the increase of the inlet velocity, the differences between the measured data and the numerical simulation data increases slightly. But the variation trend between simulated and the measured is consistent. In addition to positions of both ends, the maximum response values of measured and simulated points are in agreement, indicating that the established FSI model is reasonable.

Table 1The maximum acceleration absolute value of the measured and simulated at each point

Inlet velocity (m/s) | Position (m/s2) | ||||||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

6.8 | S-Dx/m/s2 | 0.0039 | 0.264 | 0.81 | 1.3 | 1.6 | 1.6 | 1.48 | 1.11 | 0.57 | 0.097 |

T-Dx/m/s2 | 0.057 | 0.287 | 0.785 | 1.125 | 1.323 | 1.245 | 1.18 | 0.956 | 0.487 | 0.168 | |

S-Dy/m/s2 | 0.0075 | 0.0062 | 0.0094 | 0.016 | 0.02 | 0.02 | 0.019 | 0.014 | 0.0066 | 0.0009 | |

T-Dy/m/s2 | 0.0105 | 0.0092 | 0.0092 | 0.014 | 0.016 | 0.019 | 0.0145 | 0.011 | 0.0054 | 0.0035 | |

8.2 | S-Dx/m/s2 | 0.0042 | 0.28 | 0.86 | 1.38 | 1.69 | 1.7 | 1.57 | 1.18 | 0.6 | 0.1 |

T-Dx/m/s2 | 0.0556 | 0.35 | 0.69 | 1.128 | 1.456 | 1.65 | 1.239 | 1.03 | 0.456 | 0.289 | |

S-Dy/m/s2 | 0.0063 | 0.15 | 0.47 | 0.78 | 0.95 | 0.91 | 0.78 | 0.51 | 0.23 | 0.03 | |

T-Dy/m/s2 | 0.0295 | 0.23 | 0.43 | 0.712 | 0.84 | 0.86 | 0.69 | 0.43 | 0.195 | 0.076 | |

10.2 | S-Dx/m/s2 | 0.013 | 0.1 | 3.26 | 5.49 | 5.85 | 7.0 | 6.43 | 4.63 | 2.12 | 0.27 |

T-Dx/m/s2 | 0.218 | 0.87 | 4.195 | 5.32 | 5.44 | 6.08 | 6.15 | 4.59 | 3.5 | 0.61 | |

S-Dy/m/s2 | 0.015 | 0.89 | 2.8 | 4.61 | 5.12 | 5.73 | 5.26 | 3.86 | 1.84 | 0.26 | |

T-Dy/m/s2 | 0.0575 | 1.278 | 3.63 | 4.59 | 4.35 | 5.14 | 4.8 | 3.05 | 2.24 | 0.64 | |

4. Conclusions

1) Based on the small deformation assumption, the finite volume method is adopted in the fluid field, and the RSM model is used to calculate the turbulent flow field, and the ALE method is adopted in the fluid dynamic grid. The finite element theory is applied to the solid domain, and the Newmark time integration method is adopted. Considering effect of FSI, a model of two-way FSI analysis of a hydrocyclone is established.

2) With the increase of the inlet velocity, the maximum deformation value of the hydrocyclone is increasing. The maximum deformation position is in the junction of small conical section and the tail section. The calculated value is close to the measured one.

3) The maximum value of the equivalent stress on the coupling interface is mainly concentrated in the large conical section. With the increase of inlet velocity, the value of stress increases, and the stress distribution at the interface between the fluid and the structure is asymmetrical under the FSI. The inlet velocity is greater, the asymmetry is more obvious.

4) Under the effect of FSI, the structural deformation of the hydrocyclone and the stress distribution on the interface are asymmetrical. It is suggested to increase the support near the junction of small conical section and the tail section in the practical application of the hydrocyclone, that can increase the stability of the equipment and reduce the fluctuation of flow field.

References

-

Pang Xueshi Semi-empirical method of calculation hydrocyclone diameter based on classification size. Modern Mining, Vol. 26, Issue 7, 2010, p. 46-47, 117.

-

Xu Yanxia, Tang Bo, Song Xingfu, et al. Computational study and PIV validation of flow field in a hydrocyclone. Journal of East China University of Science and Technology, Vol. 39, Issue 1, 2013, p. 1-7.

-

Amini S., Mowla D., Golkar M., et al. Mathematical modelling of a hydrocyclone for the down-hole oil-water separation (DOWS). Chemical Engineering Research and Design, Vol. 90, Issue 12, 2012, p. 2186-2195.

-

Ji Jia Dong, Ge Pei Qi, Bi Wen Bo Numerical analysis on flow-induced vibration responses of elastic tube bundle. Journal of Vibration and Shock, Vol. 35, Issue 6, 2016, p. 80-84.

-

Yu Meng Analysison characteristics of fluid-structure interaction for fluid conveying pipes by ANSYS. Chinese Journal of Ship Research, Vol. 2, Issue 5, 2007, p. 54-57.

-

Xu Heli, Jiang Yankun Research on flow characteristics of fluid-solid coupling in bent pipe. Journal of Wuhan University of Technology, Vol. 32, Issue 2, 2008, p. 343-346.

-

Stella F., Giangi M., Paglia F., et al. A numerical simulation of fluid-structure interaction in internal flows. Numerical Heat Transfer Part B Fundamentals, Vol. 47, Issue 5, 2005, p. 403-418.

-

Takizawa K., Bazilevs Y., Tezduyar T. E. Computational fluid mechanics and fluid-structure interaction. Computational Mechanics, Vol. 50, Issue 6, 2012, p. 665-665.

-

Sotiropoulos F., Yang X. Immersed boundary methods for simulating fluid-structure interaction. Progress in Aerospace Sciences, Vol. 65, Issue 5, 2014, p. 1-21.

About this article

This work was supported by the National Natural Science Foundation of China (Grant No. 11402051, 11172061).