Abstract

In this paper, ideal and general kinematics and models of roller bearing were built, and the oil film thickness for a roller bearing under a light load was analyzed with different slip factors. And then a new method to calculate the oil film thickness by considering a double slip ratio was developed, and the effects of different slip factors such as the slip ratio, inner ring speed, and radial load on the oil film thickness were investigated systematically. Under a zero slip ratio, the results showed that the film thickness increases with the inner ring speed. The radial load shows the reverse trend, and different slip factors affect the oil film properties differently. In the case with double slip ratio, the results showed that the film thickness slightly decreases as the roller slip ratio increases, whereas the cage slip ratio shows the reverse trend. The roller and cage slip ratios have different effects on the oil film thickness. The oil film distribution is affected by the combined action of the two slip ratios, the inner ring speed, and the radial load. The cage slip ratio can often be considered to be the main factor for calculating the oil film thickness.

1. Introduction

The reliable performance of roller bearing can only be sustained over long periods when a lubricant film fully separates the two bodies, and asperities do not interact [1]. The failure or absence of a lubricant film can cause wear and even the eventual failure of the bearing [2, 3]. Many scholars have studied the lubrication behavior of oil films on roller bearing since the 1940s. Dowson [3] and Grubin [4] developed a fundamental understanding of the working performance of machine elements with non-conformal lubricated contacts by proposing the elastohydrodynamic lubrication theory. In addition, Dowson [3] and Hamrock [5] presented film thickness equations using a Newtonian fluid model for elastohydrodynamic lubrication (EHL) line and point contacts, respectively. In many cases, roller bearing are elastohydrodynamically lubricated and thus work under conditions where sliding has a significant effect [6]. When a sliding motion is superimposed on rolling, such as the kinematic sliding of roller bearing, it introduces high stresses in the lubricant in the slip direction. This is harmful to the bearing working properly. Moreover, skidding may result in an initial crack, which can cause spalls on the contact surface between the races and roller.

In the previous study, the oil film thickness distribution and its performance were found to be key performance indicators that reflect the lubrication condition of the roller bearing. In particular, determining whether or not the oil film is broken is essential to understanding the skidding damage mechanism for a roller bearing at different slip ratios. However, there has been relatively a little research on the oil film thickness of roller bearing under light loads at different slip factors. In the present study, the oil film thickness on a roller bearing under light loads at different slip factors was analyzed. A new method to calculate the oil film thickness that considers double slip ratios was developed and used to investigate the effects of different slip ratios, inner ring speed, radial load, etc. on the oil film thickness systematically.

2. Methods

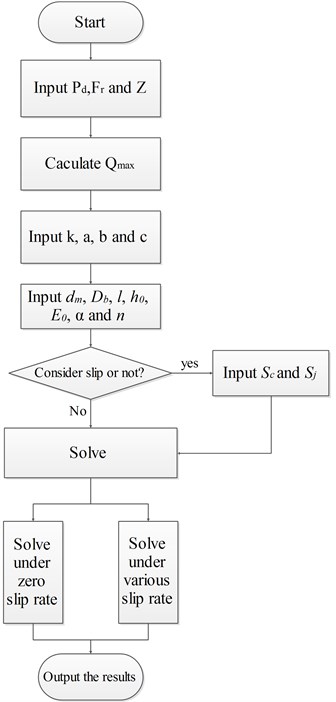

In this paper, ideal and general kinematics models of roller bearing were built. Bearing load distribution was then calculated to obtain the maximum rolling element load, and the minimum oil film thickness with and without slip was solved and analyzed [7, 8]. Fig. 1 shows the calculation flow for the oil film thickness of a roller bearing. First, the initial values of the bearing movement parameters need to be inputted. Then, the bearing load distribution is calculated to obtain Qmax, and the oil film thickness is solved at various slip ratios.

Fig. 1Calculation flow for oil film thickness of roller bearing

3. Results and discussion

3.1. Calculation of oil film thickness under zero slip ratio

The effects of different parameters on the oil film thickness, such as the inner ring speed, radial load, roller diameter, roller length, and lubricating oil viscosity, were analyzed. Here, Sc= 0 and Sj= 0. Table 1 lists the default input parameters.

Table 1Default parameters

dm [m] | Db [m] | l [m] | Z |

0.065 | 0.01 | 0.01 | 16 |

η0[Pa·s] | α [m2/N] | E0[Pa] | G=α∙E0 |

0.08 | 2.19 × 10-8 | 2.21 × 1011 | 4839.9 |

3.1.1. Effects of different inner ring speeds and radial loads on oil film thickness

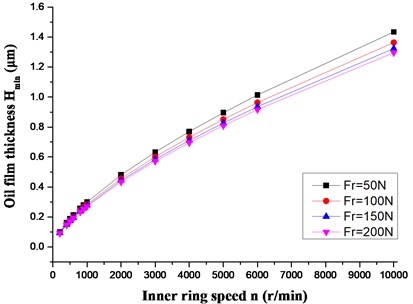

Previous studies show that the Hmin values from Dowson’s improved 1977 formula were closest to the experimental data, particularly for roller bearing under light loads. Thus, this improved formula was adopted, and the effects of different inner ring speeds and radial loads on the oil film thickness were analyzed, as shown in Fig. 2. The oil film thickness was found to increase with the inner ring speed, whereas it decreased as the radial load increased.

Fig. 2Effects of different inner ring speed and radial load on oil film thickness

3.1.2. Effects of different parameters on oil film thickness based on orthogonal experiment

In this study, the radial load, slip, inner ring speed, roller diameter, roller length, and lubricating oil viscosity were the major factors. Each factor had four levels, as given in Table 2.

Table 2Levels and factors

Level | Factors | ||||

Radial load [N] | Inner ring speed [rpm] | Roller diameter [m] | Roller length [m] | Lubricating oil viscosity [Pa.s] | |

1 | 50 | 1000 | 0.09 | 0.09 | 0.02 |

2 | 100 | 3000 | 0.01 | 0.01 | 0.04 |

3 | 150 | 5000 | 0.011 | 0.011 | 0.06 |

4 | 200 | 7000 | 0.012 | 0.012 | 0.08 |

Table 3Results of range analysis data on minimum oil film thickness

Variable | Radial load [N] | Inner ring speed [rpm] | Roller diameter [m] | Roller length [m] | Lubricating oil viscosity [Pa.s] |

¯K1 | 0.617 | 0.203 | 0.505 | 0.524 | 0.275 |

¯K2 | 0.439 | 0.426 | 0.462 | 0.465 | 0.437 |

¯K3 | 0.517 | 0.609 | 0.488 | 0.478 | 0.583 |

¯K4 | 0.439 | 0.774 | 0.557 | 0.546 | 0.718 |

Rj | 0.178 | 0.571 | 0.095 | 0.081 | 0.443 |

Table 3 shows that different factors had different effects on the minimum oil film thickness. The inner ring speed had the most significant influence on the minimum oil film thickness, followed by the lubricating oil viscosity, radial load, roller diameter, and roller length. The roller diameter and roller length had similar influences on the minimum oil film thickness.

3.2. Calculation of oil film thickness under various slip ratios

Based on the calculation of the oil film thickness under a zero slip ratio, only the inner ring speed affected the results, while the roller speed and cage speed did not. This is because the simplified algorithm does not consider the slip factors. In this study, therefore, the oil film thickness empirical formula was improved to develop a calculation method that considers double slip factors. With this method, the effects of different slip factors, the inner ring speed, and the radial load on the oil film thickness can be investigated systematically.

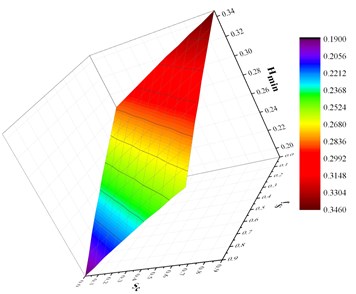

3.2.1. Effects of different slip factors on oil film thickness

Fig. 3 shows that the oil film thickness slightly decreased as the roller slip ratio increased, whereas the cage slip ratio showed the reverse trend. Here, all possible combinations of roller and cage slip ratios were hypothesized to analyze the effects of different slip factors on the oil film thickness. In practice, however, there is often a corresponding relationship between the roller and cage slip ratios; these should be analyzed under specific operating conditions in detail. In addition, large slip ratios should be prevented if possible to inhibit skidding damage to roller bearing under light loads.

Fig. 3Effects of different slip factors on oil film thickness (Fr= 100 N, n= 1000 rpm)

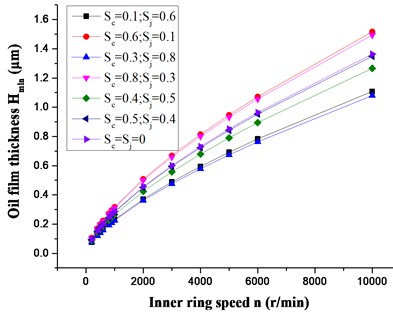

3.2.2. Effects of different inner ring speeds and slip factors on oil film thickness

Fig. 4 show that the oil film thickness increased with the inner ring speed, and the roller and cage slip ratios had different effects on the oil film thickness. The oil film distribution was affected by the combined actions of the two slip ratios, inner ring speed, and radial load. The oil film thickness was less than the calculated result under a zero slip ratio when the cage slip ratio was smaller, whereas a larger cage slip ratio showed the reverse trend. The cage slip ratio can often be considered as the main factor when calculating the oil film thickness of a roller bearing.

Fig. 4Effects of different inner ring speeds and slip factors on oil film thickness (Fr= 100 N)

4. Discussion on oil film and the vibration features of the roller bearing

When the roller rotates, an oil-film is generated to separate the roller and the races. The oil-film acts as a spring between the roller and race. Su [9] investigates the vibration signature of a roller bearing under various lubricating conditions. The oil-film stiffness under different lubricating conditions is also studied from the empirical equation of minimum oil-film thickness. The results shown that the lubricating condition (especially the oil film thickness) plays an important role in deciding the vibration properties of roller bearing. The oil film performance is a key indicator for the vibration analysis of roller bearing, especially under slip conditions.

Skidding damages of roller bearing under high-speed and light-loading conditions is a key factor that affects the service of roller bearing. Determining whether the oil film is broken or not is essential to clarifying the mechanism for the skidding damage of a roller bearing under different slip ratios. In the process of skidding analysis, the fluid frictional drag forces Fij and Foj are very important, which obtained by elastohydrodynamic lubrication theory [8]. For the steel rollers lubricated by a mineral oil, the semi-empirical relationships for the dimensionless forces ˉFij and ˉFoj are given below:

Eqs. (1) and (2) shows that the accuracy of oil film thickness Hij and Hoj determine the ˉFij and ˉFoj. Therefore, if the thickness is obtained, the cage speed and cage slip fraction can be obtained by combining the kinematic equations, load equations, Dowson-Higginson formulae, and other related equations and solving by the Newton-Raphson method [7]. Then the vibration features of the roller bearing under slip conditions can be analyzed in details.

5. Conclusions

1) The effects of different inner ring speeds and radial loads on the oil film thickness under a zero slip ratio were analyzed. The results showed that the oil film thickness increases with the inner ring speed, whereas the radial load produces the reverse trend.

2) Different slip factors were found to have different effects on the minimum oil film thickness under a zero slip ratio. The inner ring speed had the most significant influence on the minimum oil film thickness followed by the lubricating oil viscosity, radial load, roller diameter, and roller length. The roller diameter and roller length had similar influences on the minimum oil film thickness.

3) Under slip conditions, the oil film thickness decreased slightly as the roller slip ratio increased, whereas the cage slip ratio showed the reverse trend. If possible, large slip ratios should be prevented to inhibit skidding damage to roller bearing under light loads.

4) Under slip conditions, the oil film thickness increased with the inner ring speed, and the roller and cage slip ratios had differing effects on the oil film thickness. The film distribution was affected by combined actions of the two slip ratios, inner ring speed, and radial load. The thickness was less than that calculated result under a zero slip ratio when the cage slip ratio was smaller, whereas a larger cage slip ratio showed the reverse trend. The cage slip ratio can often be considered as the main factor when calculating the oil film thickness of a roller bearing.

In the future, the proposed calculation method can be integrated with relevant knowledge to acquire the oil film thickness for the analysis of skidding damage to roller bearing.

References

-

Jacobson B. Thin film lubrication of non-smooth surfaces. Proceedings of the 82nd Meeting of the AGARD SMP on Tribology for Aerospace Systems, Sesimbra, Portugal, 1996, p. 1-7.

-

Sibley L. B., Orcutt F. K. Elasto-hydrodynamic lubrication of rolling-contact surfaces. ASLE Transactions, Vol. 4, Issue 2, 1961, p. 234-249.

-

Dowson D., Higginson G. R. Elasto-Hydrodynamic Lubrication. Pergamon Press, Oxford, 1966.

-

Grubin A. N., Vinogradova I. E. Investigation of the contact of machine components. Central Scientific Research Institute for Technology and Mechanical Engineering, Moscow, 1949.

-

Hamrock B. J., Dowson D. Ball Bearing Lubrication – the Elastohydrodynamics of Elliptical Contacts. John Wiley and Sons, New York, 1981.

-

Ciulli E., Stadler K., Draexl T. The influence of the slide-to-roll ratio on the friction coefficient and film thickness of EHD point contacts under steady state and transient conditions. Tribology Letters, Vol. 42, Issue 4, 2009, p. 526-534.

-

Li J. N., Chen W. Effects of different structure parameters on skidding of high-speed roller bearing considering bearing whirling. Journal of Vibroengineering, Vol. 16, Issue 2, 2014, p. 748-760.

-

Harris T. A. An analytical method to predict skidding in high speed roller bearings. ASLE Transactions, Vol. 9, Issue 3, 1966, p. 229-241.

-

Su Y. T., Lin M. H., Lee M. S. The effects of surface irregularities on roller bearing vibrations. Journal of Sound and Vibration, Vol. 165, Issue 3, 1993, p. 455-466.

About this article

This work was partly supported by National Natural Science Foundation of China under the Grant No. 51505361, the Fundamental Research Funds for Central Universities (Xi’an Jiaotong University), and Young Talent fund of University Association for Science and Technology in Shaanxi, China (No. 20160121).