Abstract

The article presents the examples of practical application of the procedure for non-stationary signals processing. The developed method – procedure of linear decimation (PLD), short-time PLD and other enhancements to the standard PLD were applied for signal analysis of vibrations of turbine engines in unstable operating conditions. The rotational speed of driving shaft was adapted as a reference signal. The results were enclosed for turbine running-up and coasting state.

1. Introduction

Diagnosing rotary-machine states in variable real-time conditions is vital for their operation safety. Early detection of conditions of incorrect operational processes, as well as of arising damage development can often prevent from failures or serious accidents [2]. The procedure of linear decimation (PLD) [4, 10] has been successfully tested in diagnostic systems for non-stationary cyclical machines. Appling the PLD offers the possibility to increase the energy contributions of time- and frequency- symptomatic components of the signal.

Early detection of failure is determined not solely by a proper detection procedure but also by electronic implementation of diagnostic device [9]. Hardware (FPGA) implementation of the PLD compared to microprocessors or digital signal processors (DSP) can significantly reduce the calculations time. Furthermore, FPGA implementation of the PLD allows increasing signal sampling frequency, which results in more accurate spectra selectivity [8, 11].

2. Procedure of linear decimation (PLD)

Procedure of linear decimation involves the dynamic signal resampling in accordance with rotation speed variations [1]. It assumes linear approximation of cycle variations curbed by values representing its beginning cycle time and its end cycle time . In other words, it involves the deletion of sample-cluster variations proportional to the cycle and maintaining the constant sample-per-cycle number.

The key element is to define decimation coefficient . This coefficient characterizes the increment of signal resampling [1]. It changes in accordance with the increase or decrease of the rotation speed, i.e. with the cycle variations. By adapting the final decimation coefficient, we can determine its variations in accordance with linear signal trend. Selecting final decimation coefficient enables to reduce the signal to the stationary form in the observation window for the last cycle, which is very convenient in real-time analysis.

3. Research object

After successful laboratory tests on rotary machines in full frequency-band range, it was decided to test the method on a device of much greater rotation speed. For those tests a LM 2500 turbine was selected. This turbine normally works as engines of Navy Academy ships [7]. Cross section of the tested engine is enclosed in Fig. 1 along with the descriptions of its individual elements. Rotation speed of the shaft was a reference speed of the executed decimation procedure algorithm.

Fig. 1Cross section engine LM 2500 [7]

![Cross section engine LM 2500 [7]](https://static-01.extrica.com/articles/16545/16545-img1.jpg)

4. PLD capabilities

Experiment was conducted in stabilized turbine operating conditions, during its run-up. It also included variable work loading of tested LM 2500 engine.

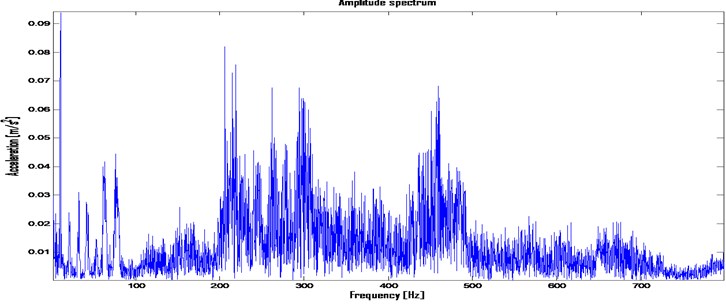

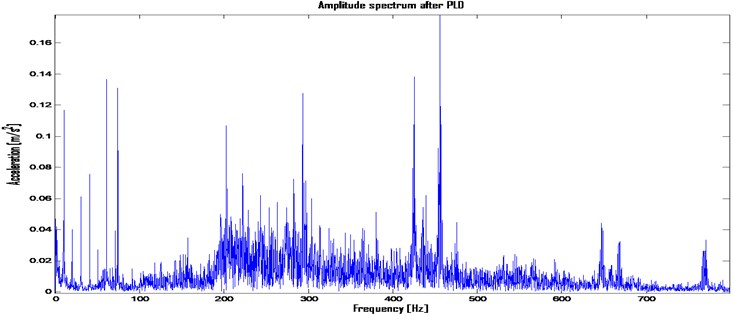

Fig. 2Amplitude spectrum of LM 250 engine in rotational frequency band in ron-up conditions: a) amplitude spectrum, b) amplitude spectrum after PLD

a)

b)

Fig. 2 presents amplitude spectrum of vibration acceleration for non-stable working conditions. Fig. 3 presents amplitude spectrum of vibration acceleration for non-stable working conditions in rotation frequency band.

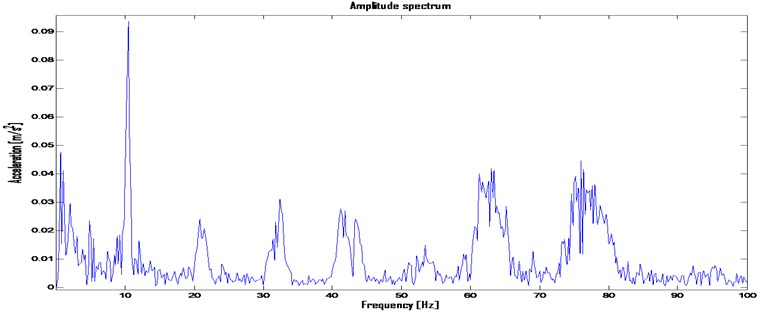

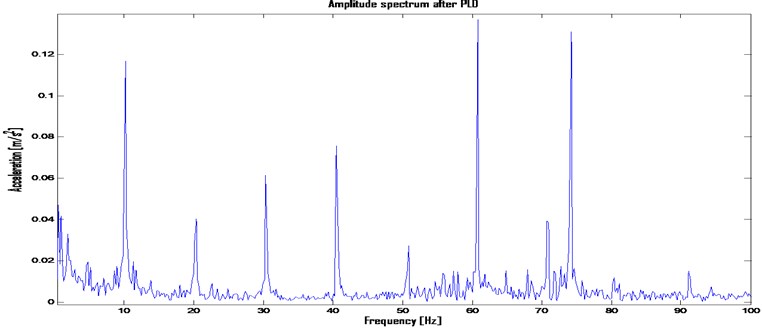

Fig. 3Amplitude spectrum of LM 250 engine in rotational frequency band in ron-up conditions in rotation frequency band: a) amplitude spectrum, b) amplitude spectrum after PLD

a)

b)

Fig. 2 and Fig 3. contains amplitude spectrum of vibration acceleration during run-up: a) spectral analysis, b) spectral analysis after applying procedure of linear decimation. Enhancement of spectral selectivity occurs at shaft frequencies corresponding with reference speed. After applying decimation procedure, components not synchronized formerly with reference speed become fuzzy and the components representing vibrations of propelling shafts, earlier fuzzy, now become distinct. Therefore, the PLD is efficient for linear change of rotational speed. For non-linear change of rotational speed, a short time procedure of linear decimation (STPLD) was developed. The STPLD was employed e.g. in the vibration analysis of GTD-350 engine which is incorporated in MI-2 helicopter [4]. Hardware implementation of the STPLD and its employment for vibration analysis of tooth gear was presented in [11].

5. Conclusions

Experiments conducted on LM 2500 engine brought positive assessment of the effects of applying innovative method of processing non-stationary signals – procedure of linear decimation. The PLD hardware implementation based on FPGA programmable systems gives the possibility of diagnosing cyclical machines at variable operating conditions in real time. The benefit of implementing this method in FPGAs is parallel signal processing [5]. This results are much shorter analysis time in comparison to the processor implementations, especially when high sampling frequency is considered.

Designed and constructed device (PUD) contains analog-to-digital converters with sampling frequency of 10 MS/s, which enabled to test the developed procedures in high-frequency band at great variations of rotational frequencies. Besides, a novel short-time PLD method was developed, enabling to adapt the approximation to the cycle changes. That put an end to the problem of non-linear trend change and minimized the error resulted from the original PLD assumption of linear cycle trend in the observation window.

This solution has brought the method nearer to the order analysis without the necessity of applying interpolation filters.

References

-

Adamczyk J., Cioch W., Krzyworzeka P. Effect of interpolation on linear decimation procedure. Diagnostyka, Vol. 27, 2002.

-

Burdzik R. Monitoring system of vibration propagation in vehicles and method of analysing vibration modes. Communications in Computer and Information Science, Vol. 329, 2012, p. 406-413.

-

Cioch W., Knapik O., Leśkow J. Finding a frequency signature for a cyclostationary signal with applications to wheel bearing. Mechanical Systems and Signal Processing, Vol. 38, Issue 1, 2013, p. 55-64.

-

Cioch W., Krzyworzeka P. Analysis of running-up vibrations of turbine engine GTD-350. Diagnostyka, Vol. 4, 2007.

-

Dąbrowki D., Cioch W. Analysis of signals pre-processing algorithm in case of hardware and software implementation on diagnostic programmable device PUD-2. Acta Physica Polonica A, Vol. 123, Issue 6, 2013, p. 1020-1023.

-

Dybała J. Use of task-oriented dynamic resampling in reduction of signal non-stationarity. Diagnostyka, Vol. 48, 2008.

-

Grządziela A. Analysis of vibration parameters of marine gas turbine engines. Diagnostyka, Vol. 35, 2007.

-

Jamro E., Cioch W. Digital signal acquisition and processing in FPGAs. Przegląd Elektrotechniczny, Vol. 85, Issue 2, 2009.

-

Jamro E., Wielgosz M., Bieniasz S., Cioch W. FPGA – ARM heterogeneous system for high speed signal analysis. Solid State Phenomena, Vol. 180, 2012, p. 207-213.

-

Krzyworzeka P., Adamczyk J., Cioch W., Jamro E. Monitoring of Nonstationary States in Rotating Machinery. Instytut Technologii i Eksploatacji, Radom, 2006.

-

Krzyworzeka P., Cioch W., Jamro E. Hardware abilities of linear decimation procedure in practical applications. Journal of Polish Cimac, Gdańsk, Vol. 2, Issue 2, 2007.

-

Lyons R. G. Understanding Digital Signal Processing. Addison Wesley Longman Inc., 1997.