Abstract

The paper presents an assessment of diagnostic usefulness of the vibration measurements and analysis of selected components of the common rail system in the diesel engine. Measurements were performed of the selected components of the CR system and changes were determined in the time and frequency structure of the recorded vibration signals. The research has shown that vibration recorded on the injector's housing and the rail of the common rail system is useful diagnostic information for the evaluation of the technical condition of the fuel supply system of a compression ignition engine.

1. Introduction

Injection systems of compression ignition engines are currently some of the most precise subassemblies used in engines. The main requirements these systems are expected to meet include ensuring fuel injection at a very high pressure and in several phases. Meeting these requirements is not always possible because the quality of fuel may cause accelerated wear of the components of these systems. This contributes to the deterioration of the quality of the course of the combustion process, worsening of the engine operation dynamics as well as the increased emission of toxic components of exhaust fumes and may contribute to an in increase in fuel consumption [1-6]. In critical situations failures of the fuel supply system may cause highly degradative damage to the engine, which manifests itself in, for example, the burn-out of the piston head.

The development of new methods for diagnostics of combustion engine injection systems, which use measurements and analyses of vibration signals, may expand the stream of information processed by OBD systems [7-11]. The usefulness of vibration signals combined with the stream of data flowing from mechatronic components of the engine enables the construction of new platforms for processing and analysing diagnostic data [12-22].

The paper presents the initial examinations of the evaluation of the diagnostic usefulness of vibration signals generated by the components of the common rail system of a compression ignition engine. Test-stand measurements of vibration generated by the rail of the common rail system and injectors were made and then changes were determined in the time and frequency structure of the recorded signals. The study also evaluated the diagnostic usefulness of the measurements of vibration made at the selected measurement points of the common rail fuel injection system.

2. Stand tests

The object of the study was the diesel engine of Renault Master 2.5 DCI with 88 kW and the mileage 102000 km, equipped with the common rail system.

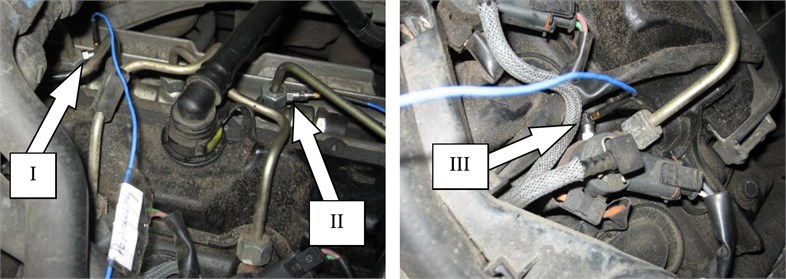

During the tests the acceleration of the vibration of the components of the common rail system was recorded at the location of the supply from a high-pressure pump, designated (I), at the outlet to injector 4 (II) and on the injector housing (III). Furthermore, engine body vibration was recorded in order to evaluate the impact of the combustion process on the time and frequency structure of the recorded vibration signals. The diagram of the layout of piezoelectric transducers is shown in Figure 1. During the experiments the referential signal position of the crankshaft was recorded. The measures were conducted with the sampling frequency 25 kHz. The signal transformation was conducted in the Matlab-Simulink program.

Fig. 1The piezoelectric transducers lay-out

3. Examples of research results and their analysis

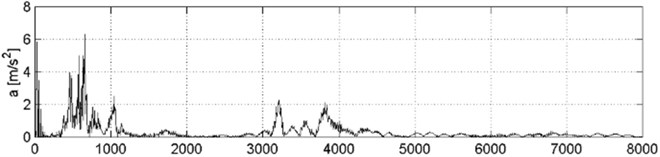

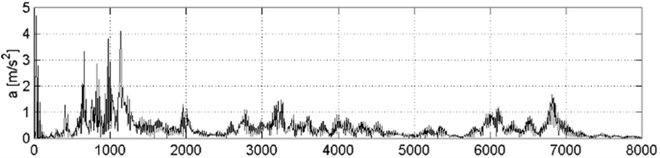

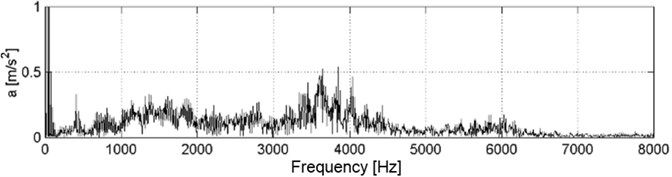

In order to identify the frequency structure of the recorded vibration signals their spectra were determined using the fast Fourier transform. The results of these calculations are shown in Fig. 2.

Fig. 2The spectrum of the acceleration of vibration recorded on: a) injector housing (I), b) outlet from the common rail system rail to injector 4 (II), c) on the engine head

a)

b)

c)

According to the presented results of calculations the frequency structure of vibration recorded on individual components of the engine varies. In the case of the examined engine the resonance of the components of the common rail system is observed in the frequency range below 2.2 kHz, whereas vibration recorded on the engine block are characterised by resonance at higher frequencies (approximately 3.75 kHz).

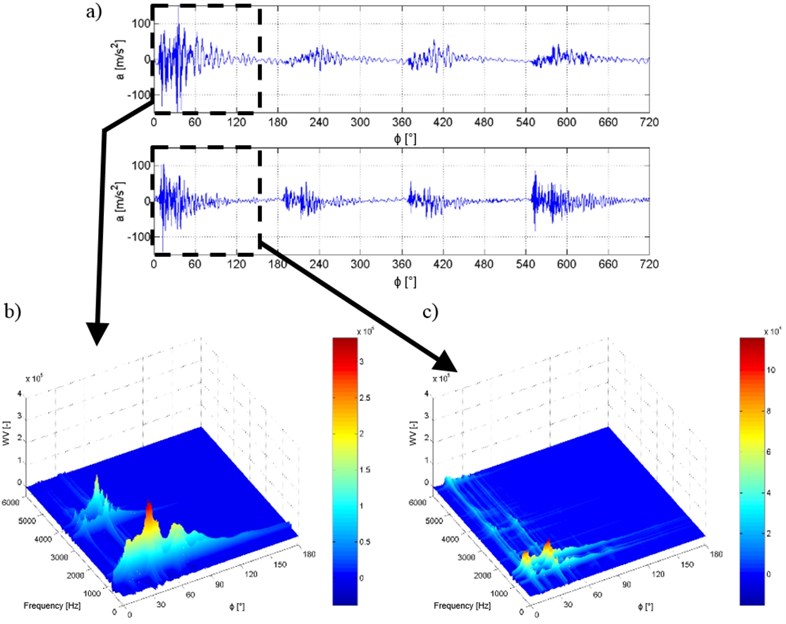

Fig. 3 shows examples of the results of measurements of the acceleration of vibration recorded on the cylinder 4 injector housing (III) and at the outlet from the common rail system rail to injector 4 (II) as well as Wigner-Ville time-frequency distributions.

According to signal processing and measurements the vibration signal recorded directly on the injector shows the course of vibration generated by the injector during fuel injection (frequency range: approximately 0.75 kHz), subjected to further interference caused by the combustion process (frequency range: approximately 3.75 kHz). The measurement of vibration on the injector housing does not include, however, significant local increases in amplitude, which should be considered direct interference with vibration transferred from adjacent cylinders. Measurements made at the outlet from the common rail system rail to injector 4 (II) include comprehensive information on the course of rail vibration, which is caused mainly by a change in pressure in the injection system (frequency range: approximately 1 kHz), caused by the injection of fuel to consecutive engine cylinders.

Fig. 3Time (a) and Wigner-Ville time-frequency (b, c) courses of the acceleration of vibration recorded on the cylinder 4 injector housing (III) and at the outlet from the common rail system rail to injector 4 (II)

4. Conclusions

An analysis of the technical condition of combustion engines is a very complicated and complex diagnostic activity. Looking for symptoms of wear or damage to engine components requires in-depth knowledge of its operation as well as, frequently, intuition and vast practical knowledge. The authors of the paper propose expanding the existing engine diagnostics systems by adding systems for measuring and processing vibroacoustic signals. Such an approach makes it possible to diagnose early symptoms of damage to engine components which until now were difficult to detect.

The paper presents the initial results of tests whose aim was to evaluate the diagnostic usefulness of vibration signals in the process of the evaluation of the technical condition of the common rail system of a compression ignition engine. The results of the tests lead to an unambiguous conclusion that the vibration signal recorded on the common rail system rail or injector differs from the signal recorded traditionally on the engine head in terms of the transient and frequency response. At the same time, these vibration signals are only to a small extent subjected to interference caused by vibration generated by the combustion process, but they can be clearly observed when measuring vibration on the engine head. The obtained results will be used in further research to evaluate the technical condition of the components of the common rail injection system of a combustion engine.

References

-

Sebok M., Ostrica L., Gutten M., Korenciak D., Makyda M. Diagnostics of ignition systems. Journal of Electrical Engineering, Vol. 13, Issue 4, 2013, p. 181-186.

-

Droździel P., Komsta H., Krzywonos L. An analysis of costs of vehicle repairs in a transportation company, part 1. Transport Problems, Vol. 7, Issue 3, 2012, p. 67-75.

-

Droździel P., Komsta H., Krzywonos L. An analysis of costs of vehicle repairs in a transportation company, part 2. Transport Problems, Vol. 7, Issue 4, 2012, p. 7-11.

-

Šarkan B., Skrúcaný T., Majerová Z. Possibilities of measuring the brake specific fuel consumption in road vehicle operation. Machines, Technologies, Materials, Vol. 8, Issue 5, 2014, p. 19-21.

-

Merkisz J., Jacyna M., Merkisz-Guranowska A., Pielecha J. Exhaust emissions from modes of transport under actual traffic conditions. WIT Transactions on Ecology and the Environment, Vol. 190, Issue 2, 2014, p. 1139-1150.

-

Sim A. X. A., Sitohang B. OBD-II standard car engine diagnostic software development. Proceedings of 2014 International Conference on Data and Software Engineering, 2014, p. 7062704

-

Ostrica L., Jurcik J. Detection of faults gasoline injection system for new OBD systems. 10th International Conference, ELEKTRO, 2014, p. 202-207.

-

Czech P., Ba̧kowski H. Diagnosing of car engine fuel injectors damage using dwt analysis and PNN neural networks. Transport Problems, Vol. 8, Issue 3, 2013, p. 85-91.

-

Dąbrowski Z., Zawisza M. Investigations of the vibroacoustic signals sensitivity to mechanical defects not recognised by the OBD system in diesel engines. Solid State Phenomena, Vol. 180, 2012, p. 194-199.

-

Albarbar A. An investigation into diesel engine air-borne acoustics using continuous wavelet transform. Journal of Mechanical Science and Technology, Vol. 27, Issue 9, 2013, p. 2599-2604.

-

Albarbar A., Gu F., Ball A. D. Diesel engine fuel injection monitoring using acoustic measurements and independent component analysis. Measurement: Journal of the International Measurement Confederation, Vol. 43, Issue 10, 2010, p. 1376-1386.

-

Górnicka D. Vibroacoustic symptom of the exhaust valve damage of the internal combustion engine. Journal of Vibroengineering, Vol. 16, Issue 4, 2014, p. 1925-1933.

-

Dziurdź J. Application of correlation and coherence functions in diagnostic systems. Diffusion and Defect Data Pt.B: Solid State Phenomena, Vol. 196, 2013, p. 3-12.

-

Krzyworzeka P., Cioch W. Demodulation of non-stationary machine vibration using cycle-time scale. Archives of Acoustics, Vol. 31, Issue 2, 2006, p. 167-177.

-

Dziedziech K., Staszewski W. J., Uhl T. Time-frequency analysis of time-variant systems. Diagnostyka, Vol. 14, Issue 1, 2013, p. 37-42.

-

Wyłomańska A., Zimroz R. Signal segmentation for operational regimes detection of heavy duty mining mobile machines – a statistical approach. Diagnostyka, Vol. 15, Issue 2, 2014, p. 33-42.

-

Cioch W. Machine vibrations analysis working in non-stationary states. Vibroengineering Procedia, Vol. 3, 2014, p. 380-382.

-

Amarowicz M. Diagnostic systems design process with using the sets of requirements. Diagnostyka, Vol. 15, Issue 2, 2014, p. 19-26.

-

Jedliński Ł., Caban J., Krzywonos L., Wierzbicki S., Brumerčík F. Application of vibration signal in the diagnosis of IC engine valve clearance. Journal of Vibroengineering, Vol. 17, Issue 1, 2015, p. 175-187.

-

Tomaszewski F., Szymański G. M. Analysis of measurement points sensitivity of vibration signals on the engine head in impact tests. 19th International Congress on Sound and Vibration, Vol. 4, 2012, p. 2737-2744.

-

Figlus T., Liščák Š. Assessment of the vibroactivity level of SI engines in stationary and non-stationary operating conditions. Journal of Vibroengineering, Vol. 16, Issue 3, 2014, p. 1349-1359.

-

Figlus T., Wilk A. Application of a continuous wavelet transform for the diagnosing of excessive valve clearance of the combustion engine. Solid State Phenomena, Vol. 236, 2015, p. 153-160.