Abstract

In the course of a vehicle passing over a turnout, a high dynamical response appears during passing over the turnout frog. The increased loading of this turnout part negatively influences its wear and finally its service life too. The methodology for determination of the equivalent loading of a turnout frog in the course of a vehicle passing has been developed just for the evaluation of the frog loading. A vertical acceleration measured on the wheelset axle box of a vehicle passing over the frog is an input parameter for the calculation of the equivalent loading. Actually the turnouts of several types built in modernized station Ústí nad Orlicí are monitored since 2014 in a cooperation with a turnout producer and one of the train operator with application of the mentioned methodology. The reference vehicle for the evaluation of these turnouts is an electric locomotive of axle load 22 t. The verification of optimized design of some turnouts in terms of loading of their frogs is the purpose of this project.

1. Introduction

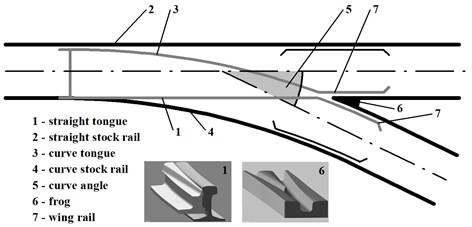

Presently, the issue of effective reduction of noise emission and vibrations of railway vehicle operation is very current topic especially due to protection of human health and due to reduction of operational dynamical forces acting on a track and vehicle parts. Perfect knowledge of operational conditions is the basic presumption of ensuring of operational reliability of a railway track structure if we need to increase a maximum operational speed. Passing of railway vehicle presents a significant source of noise emission, but it also causes a high dynamic loading in wheel-rail contact in the course of passing over a turnout frog (Fig. 1) in straight direction. This effect appears especially in cases of turnouts with unmovable frogs, which are installed mostly in main tracks of the corridor stations, where train passes in maximum speed of 160 kmph.

Fig. 1Schema of simple turnout and real form of frog part

Actually, there is no relevant universal theoretical model of rail vehicle, which would be able to evaluate the vibration in the course of running over a turnout. Modelling of this phenomenon is very difficult because a turnout is an inhomogeneous element in common track, which is a place of dynamical impact in the course of contact of wheel with the frog. Therefore to explanation of these dynamical phenomena, we deal with experimental research in this field many years.

The main reasons of increased dynamical loading of frog part of turnout are the following:

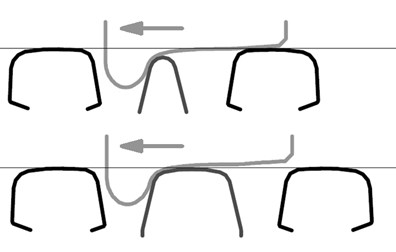

– operational geometrical differences of wheelset dimensions caused by its wear (wheel tread wear, nonalignment and unroundness of wheel, rail wear – frog and wing rail); these differences causes an acute shift of longitudinal and lateral trace of a wheel-rail contact point (see Fig. 2),

– change of track stiffness in a frog area along the vehicle movement (due to longitudinal change of rail profile, change of fixing stiffness of frog parts – frog nose, wing rail, sleeper pads, change of sleeper structure).

Due to repeated loading by high dynamical contact forces, damage of rail surface and occurrence of a contact defects appear and in result also degradation of whole turnout becomes.

Fig. 2a) Wheel-rail contact in frog area in condition of new wheel; b) worn wheel with groove of a tread

a)

b)

2. Methodology of evaluation of turnout frog area loading with help of vehicle dynamical response

Measurement of a vehicle dynamic response is carried out to obtaining of response of track structure on operational loading by railway vehicles. Assessment of behavior and functionality of track components in given conditions is the main aim of this type of measurement.

2.1. Determination of a vehicle dynamical response in the course of passing over a turnout

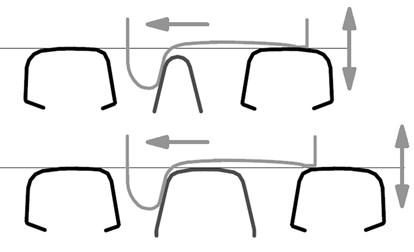

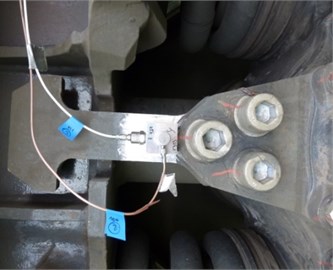

There was chosen acceleration measuring on wheelset axle boxes as an input quantity for detecting vehicle dynamic effects. Wheelset axle box have close mechanical connection with wheelset and it is also friendly to installation of measuring chain (sensors, cable connections). It is necessary to find such place which has unsuspended connection with the axle box. The sensors shall be placed as soon as closest to wheelset axis (Fig. 3).

Fig. 3Position of accelerate sensors on the wheelset axle box of a vehicle (illustration photo)

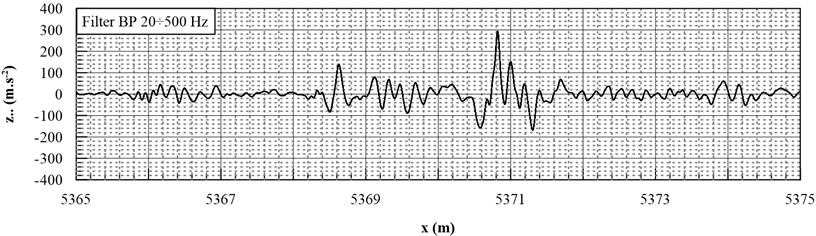

Signals of acceleration are recorded with the sampling rate of 20 kHz. For the next assessment, the signals are filtered by a band pass filter in the range 20-500 Hz. Example of the filtered vertical acceleration signal measured on a wheelset axle box in the course of passing over a turnout frog is presented in Fig. 4.

Fig. 4Signal of vertical acceleration in the course of passing of a vehicle over a turnout frog

2.2. Evaluation of dynamical response of a vehicle in the course of passing over a turnout using statistical methods

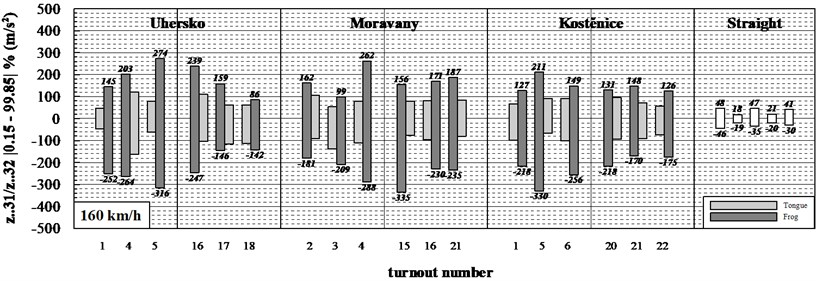

Evaluation of the vehicle dynamical response size in the course of passing over a turnout is based on the filtered measured acceleration signals of the individual sections, which represents a frog area. Two important statistical characteristics, 0.15 % percentile and 99.85 % percentile (similarly like evaluation of vehicle running behavior according UIC 518 and EN 14363), are calculated from the measured accelerate values.

There is possibility to compare all selected turnouts in same operational condition with help of both statistical characteristics. Fig. 5 presents a chart, where each column represents tongue or frog of turnout. The bottom level of the column corresponds to the value of 0.15 % percentile of acceleration and top level of the column corresponds to the value of 99.85 % quantile of acceleration. There are 5 columns in the right part of that chart which representing passing outside of turnout (straight track) in the same operational condition (speed, vehicle, direction, …). The speed was in this case the criterion for evaluation – all turnouts section outside turnouts included was passed in the same speed (with 5 kmph tolerance). This method of measurement evaluation is suitable for detection of turnouts which show increased dynamical response with comparison with others and with passing outside a turnout.

Fig. 5Statistical evaluation of measured acceleration in the course of passing over turnouts

2.3. Evaluation of dynamical response of a vehicle in the course of passing over a turnout using calculation of equivalent loading

Within the project “Competence Center of Rail Vehicles” of Technological agency of Czech Republic, the new methodology was created for evaluation of the vehicle dynamical response in the course of passing over a turnout. This methodology is based on calculation of equivalent loading between wheel and rail [5].

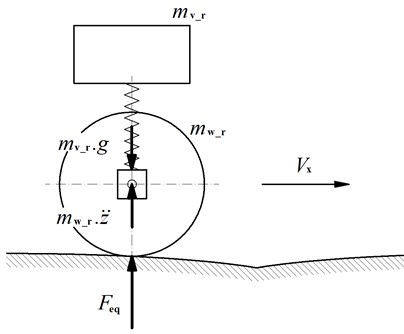

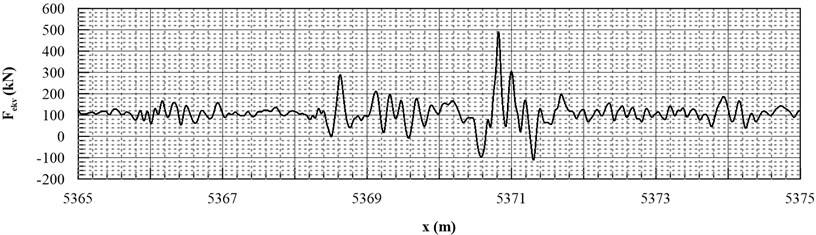

The calculation of the equivalent dynamical force between wheel and rail in the course of passing of appropriate wheel over a frog area utilises the vertical acceleration measured on a wheelset axle box of a vehicle (according EN 14363) (see Fig. 4).

Due to the fact that natural frequencies of vertical motion of suspended vehicle parts are multiply lower than frequency of the vertical motion of a wheel in the course of passing over a turnout frog area, the calculation of the dynamic component of the equivalent force is carried out only with respect to inertia forces of unsuspended vehicle parts, i.e. relative mass of wheelset axle boxes included mwr per a wheel (see Fig. 6).

Dynamical component of the equivalent force (¨z – measured acceleration):

Equivalent loading of a frog area part (mvr – relative mass of a vehicle per a wheel):

Fig. 6Simple dynamical model of vehicle passing over a turnout frog – calculation of equivalent loading

Fig. 7Equivalent force calculated from the accelerate signal (Fig. 4) in the course of passing over a frog

3. Actual results of determination of dynamical response of vehicle passing over frog area

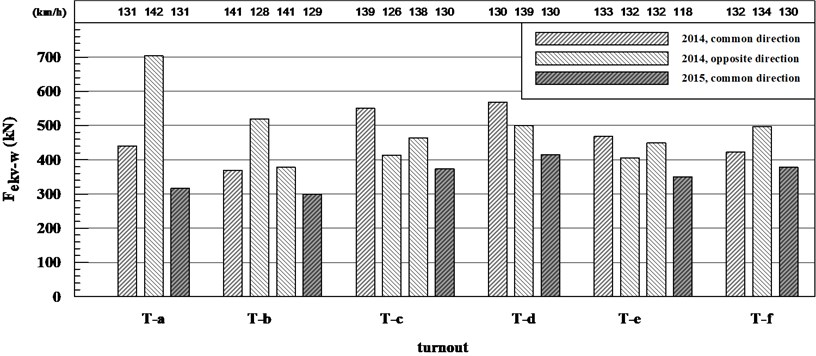

In years 2014 and 2015, the two measurements in station “Ústí nad Orlicí” and their evaluation was carried out according the methodology mentioned above. The first measurement was carried out in terms of verification of the completely modernized station with locomotive class 380 (Fig. 3), the second measurement was implemented to operational conditions of same type of locomotive with common scheduled trainset. The results of both measurements are presented in Fig. 8.

Fig. 8Results of the equivalent dynamical force evaluation for 6 turnouts (a÷e)

The evaluation of equivalent dynamical force between a wheel and rail in the course of vehicle passing over a turnout frog area (Fig. 8) shows the following results:

– there is noticeable increased dynamical loading of a frog after mounting of new turnouts (year 2014),

– repeated measurement after six months shows decreased dynamical loading which is probably caused by stabilization of turnout structure.

Measurements in next few years will be used for analysis of changes of the equivalent loading of turnout parts with respect to wear state of a frog area and to wear of wheel profiles of passing vehicle too.

4. Conclusion

Increasing of maximum speed of railway lines is closely connected with hard requirements to operational safety, reliability and service life of railway track components. Turnouts and their parts included frogs are heavily loaded by dynamical forces acting between wheel and rail. Wear state of the frog area significantly influences the value of dynamical forces which can lead to development of profile and material defects of rail head as well as wheel tread. The indication of increased dynamical response in the course of vehicle passing over a frog area and the following cause analysis of that response is very important in terms of development of new turnout design as well as in terms of maintenance steps which prevent creation and propagation of vehicle and track defects.

The described methodology is used for determination of equivalent loading of turnout frog area. This equivalent loading will be monitored in operation in dependence of vehicle speed and operational load of the track. Obtained information about maximum values of equivalent loading of turnout frog area will be used to assessment of frog wear and to determination of necessary maintenance action term.

The main benefit of this methodology is not concerned to decreasing of dynamical measurement cost, but to increasing of reliability in-time prediction of such frog wear degree which is economically optimal in terms of necessary maintenance action.

References

-

Zelenka J., Hába A., Kohout M. Vehicle-track interaction by passing through turnouts. Proceedings of the 7th International Conference on Railway Bogies and Running Gears, 2007, p. 161-170.

-

Hába A., Zelenka J., Kohout M. Experimental and theoretical analysis of wheel-rail contact in the course of passing over turnout frog. Proceedings of 8th International Conference on Contact Mechanics and Wear of Rail/Wheel Systems, Vol. 3, 2009, p. 969-975.

-

Gerber U., Zoll A., Fengler W. Fahrzuegbasierte Beurteilung des Herzstückverschleßes. Eisenbahningenieur, 2013, p. 26-30.

-

Müller R., Nelain B., Nielsen J., Said S., Rücker W., Bongini E. Description of the Vibration Generation Mechanism of Turnouts and the Development of Cost Effective Mitigation Measures. Report RIVAS_UIC_ WP3-3_D3_6_V02, 2013.

-

Zelenka J., Hába A., Kohout M. Determination of equivalent loading of railway turnout frog area in the course of vehicle passing based on EN 14363 approaches. Certified Methodology, 2014.

About this article

This paper was supported by Technological Agency of Czech Republic within the Project No. TE 01020038.