Abstract

Appliances equipped with single-cylinder combustion engines generate noise which may have an adverse effect on human health. Lawnmowers are one of the most popular examples of appliances utilising a drive of this type. This paper presents the results of measurements of sound levels emitted by such mowers and received in the whereabouts of their users. The effect was analysed of a change in the technical condition of their drive on the sound level and a method was proposed to assess its impact on users. The basis of the method is the summation of selected 1/3 octave bands, in which the main energy of noise generated by mowers with single-cylinder combustion engines is radiated.

1. Introduction

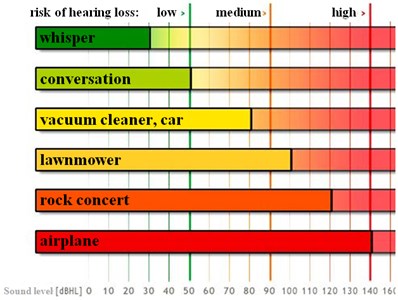

Noise and vibration are among the most negative environmental factors affecting the health and comfort of human existence (Fig. 1).

Fig. 1The influence of sound level on the risk of losing hearing by human

Research on the effects of noise on humans is conducted in many research centres and scientific establishments. Its scope includes an assessment of the harmful impact of noise on the condition of human health in different working environments [1-14], as well as the construction of new solutions of low vibration machines [15-23]. The research also facilitates development of new standards setting the noise limits, above which rises the risk to human health.

The main sources of environmental noise include primarily traffic noise and noise in the workplace [11, 24-32]. The noise level is being limited by legislation, with gradually introduced more and more stringent noise emission standards. In the case of noise present in the areas of human habitat, reducing its level is often difficult [32-33].

The machinery used in households and service companies in a variety of ways raises the sound level. In the case of machines with electric motors, there is only a slight increase in the sound level and a slight negative impact on human hearing. Such a drive, however, has limited mobility.

There is a number of appliances whose work requires mobility and independence from a source of power. These include power generator units, water pumps and lawnmowers. To propel them, popular solutions with single-cylinder internal combustion engines are used, which, by virtue of their design and operation principle, are characterised by considerable vibroactivity.

Lawnmowers are one of the most popular examples of appliances utilising a drive of this type [34-44]. These are, according to the definition enclosed in the directive 2000/14/WE of the European Parliament and in the Council of the European Union dated on 8th May 2000, machines having cutting element working on plain and using the ground level to specify the height of cutting regulated by wheels, air bag, etc.

In accordance with this directive, these devices have a fixed maximum sound power emission level, depending on the width of the cut L, which amounts to:

- L< 50 cm – 96 dB,

- 50 cm<L<120 cm – 100 dB,

- L> 120 cm – 105 dB.

The permissible sound power level in these cases refers to a brand new equipment and does not take into account any changes in the technical condition of the lawnmowers caused by their long-term use.

The noise level in this case depends on the place of measurement, and in the case of the research on its impact on users presented in [42-43], it always exceeded the value of 80 dB(A). According to the guidelines [10-11, 13] concerning the assessment of noise impact on humans, it may cause a decrease in productivity, harm to internal organs or headaches. In some cases, the noise level exceeded 86 dB(A), which may cause a number of organic diseases, cardiovascular disorders, balance disorders or nausea.

As presented in [43], the value of the equivalent sound level of lawnmowers recorded in the 1/3 octave bands is influenced by:

- increased wear and tear: the noise increases by more than 6 dB(A) in band 800 Hz,

- increased engine cubic capacity in mowers: the noise level decreases by ca. 8 dB(A) in band 630 Hz,

- increased mower engine power: the noise increases by as much as ca. 8 dB(A) in band 250 Hz.

Hearing injury to which the mower user is exposed is not caused by a single exposure to noise of a very high sound pressure level, but by the long-term noise of moderate to elevated sound levels. This type of noise is frequently present in the working environment and, in addition, its level varies depending on the technical condition of the machines and equipment used. The hearing injury which occurs in such case is called the noise-induced hearing loss, NIHL.

Accordingly, directives and safety standards require employers to provide their staff with personal protective equipment where the noise exceeds the threshold values (LEX,8h> 80 dB). Moreover, if the values characterising the noise reach or exceed the maximum permissible noise levels (LEX,8h≥85 dB and/or LAmax≥115 dB and/or LCpeak≥135 dB), these standards oblige employers to monitor their correct application [44]. The guidelines are, however, often ignored by employers, whereas in the case of individual users of mowers, the regulations on hearing protection are either unknown or ignored as not a major problem.

The aims of the study were:

- the results were presented of noise measurements of lawnmowers powered by single-cylinder combustion engines, each representing a various technical condition,

- analysis was made of the effect of a change in the drive condition on the sound level in 1/3 octave frequency bands,

- a method was proposed to assess the impact of noise generated by lawnmowers powered by single-cylinder combustion engines on their users, which consists in the summation of the sound energy in the selected 1/3 octave bands.

2. Methods

The emission of hand lawnmowers, in which they use internal combustion engine, was examined. In Fig. 2, the exemplary lawnmowers assigned to the research is presented.

Fig. 2Husqvarna M145SV example of lawnmower used in the study

After initial verification of different lawnmowers, five mowers were selected for further comparative studies, with the following parameters:

- engine power: 2.4 kW,

- rotational speed during normal operation: ca. 2900 rpm,

- different technical condition, marked as TC0-TC4, where: TC0 – a new lawnmower, TC4 – the most worn out lawnmower.

The estimation of their condition was carried out in the subjective way by the service as there is no possibility to read the time of their use. During the initial examination the lawnmowers were grouped according to their estimated number of hours of their used (from the last repair), estimated working hours in the season, current technical condition. A detailed selection of lawnmowers for the research and their parameters are discussed in [42-43].

Fig. 3Analyser Sonopan DSA 50

The measurements of equivalent sound level (LAeq) was conducted by using the sound analyser SONOPAN DSA-50, with the adjustments 1/3 octave filter and the A characteristics (Fig. 3). During the measurements the weather was controlled with the use of Terdens Moon BSP 1201.

The noise emission measurement was carried out in the following weather conditions:

- ambient temperature 14.2-16.5oC,

- air-pressure 983-985.7 hPa,

- air humidity 62-87 %.

With regard to comparatively narrow changes range of atmospheric conditions which perturb the measurements, it was accepted that they were not important for the research.

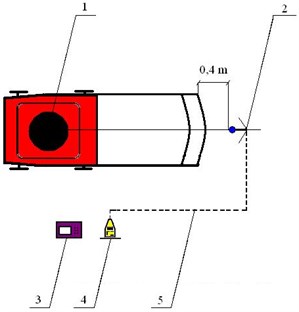

The measurements emission of noise of the lawnmowers were conducted in the open area free from any obstacles which could echo of the sound. For the research, they accepted that the microphone had to be set on a tripod and directed at the axis coming through the noise source. The outline of the measurement work stand is presented in Fig. 4.

In the first part of the research, the measure of the background surrounding was conducted in order to define the possibilities of its influence on the quality and quantity changes of the acoustic pressure, around the lawnmowers. The measurement results of the equivalent background sound level LAeq and the temporary sound level value LA of these measurements showed that the sound level in that case was within the range of 42-46 dB(A). Similarly, the results of the obtained measurements have not fundamental influence on the possibility of introducing errors during proper lawnmowers measurements.

Fig. 4The diagram of the measurement site: 1 – lawnmower, 2 – measurement microphone set on the tripod on the level of 167 cm above the ground, 3 – the weather station, 4 – the sound level meter, 5 – wire connecting the meter with the microphone

3. Results and discussion

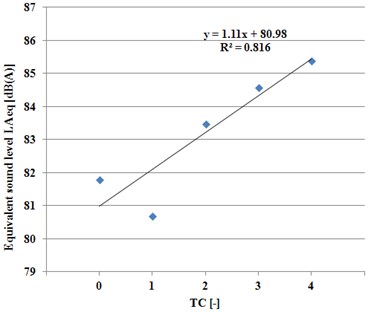

In the first stage of the study a comparison was carried of the results of the sound level measurements across the entire frequency band analysed. The results presented in Fig. 5 indicate a growing sound level with an increasing degree of wear of the mowers. The recorded sound levels in these cases demonstrate the negative impact of noise on the operator’s hearing and require the use of ear protection.

Fig. 5A change in the equivalent sound level of mowers representing a various technical condition

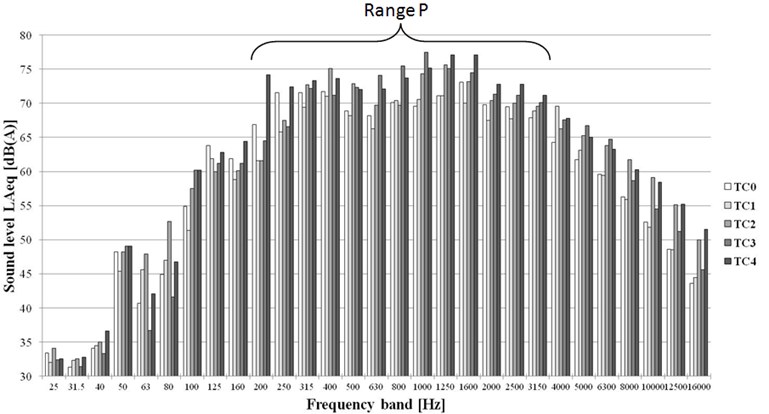

In further studies an assessment was made of a change in the sound level of the analysed lawnmowers in 1/3 octave bands.

The results shown in Fig. 6 indicate that there is an elevated sound level in the medium-frequency bands, which adversely affects the hearing in people. The sound level increases as the technical condition of a mower changes, and exceeds 70 dB(A) in the selected thirds from 200 Hz to 3.15 kHz – which is marked as “Range P”.

Fig. 6A change in the sound level of individual thirds, depending on the change in the technical condition of a mower

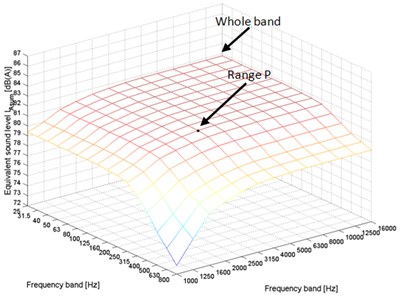

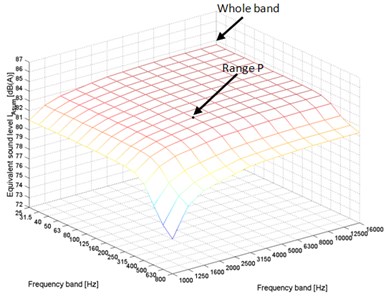

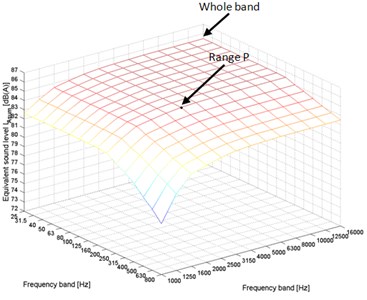

In order to assess the impact of the sound energy in each 1/3 octave band on the overall sound level and human hearing, further studies were conducted.

On the frequency-frequency distributions (Fig. 7), examples are presented of the overall sound energy levels attributable to the increasing signal frequency ranges for 3 mowers, each in a different technical condition. It was assumed in the calculations that the middle band, for which the base noise level was determined, ranged from 800 to 1000 Hz. Further bands added to the above-mentioned one expanded its range towards high and low frequencies. The total sound level value calculated for bands from 25 to 16000 Hz was the total sound level in the frequency range under consideration, and thus the sum of all 1/3 octave bands in the range of 25-16000 Hz.

The following relationship was applied for the calculation of the sum sound level:

where, n – number of frequency bands, LAeq – equivalent sound level in the selected 1/3 octave band [dB(A)].

The results of these calculations show that the total value of sound level is influenced mostly by the energy contained in 1/3 octave frequency bands in range P (Fig. 6). Further expansion of the frequency band adopted to calculate the sum sound level did not cause its further significant increase.

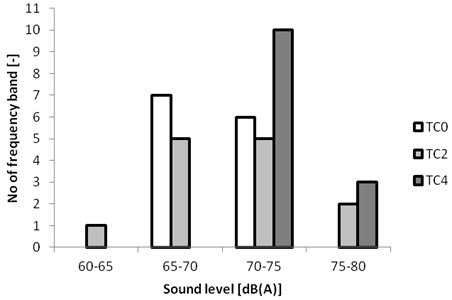

An assessment was carried out of a change in the sound level of individual thirds of range P (Fig. 6), depending on the degree of wear of the mowers. Fig. 8 shows a change in the number of bands of 1/3 octave frequencies attributable to the individual sound level ranges, depending on the technical condition of three mowers varying in the degree of use: TC0, TC2 and TC4.

Fig. 7Sum of the 1/3 octave band sound levels, where: a) TC0, b) TC2, c) TC4

a)

b)

c)

Fig. 8A change in the number of frequency bands depending on the recorded sound level

The calculations show that as the wear of the mower increases, the sound energy increases in the presented 13 frequency bands from 200 Hz to 3.15 kHz (range P).

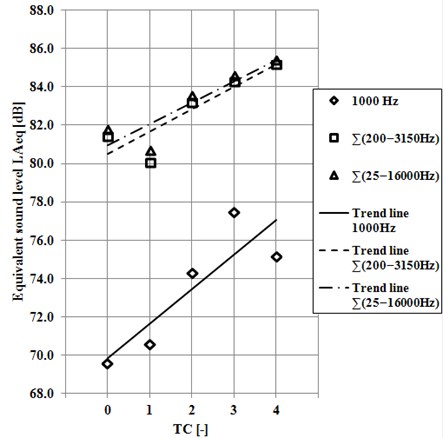

The noise level determined in this frequency range can therefore be used to identify exposure of human health caused by the lawnmowers under consideration. This is corroborated by the calculations presented in Fig. 9, which shows the sound level changes, depending on the degree of use of the lawnmowers in the bands of 1000 Hz and 200-3150 Hz, and in the entire frequency range of 25-16000 Hz.

The noise levels calculated in the frequency range of 200-3150 Hz are lower by less than 1 dB than the values in the whole frequency range analysed, i.e. 25-16000 Hz.

Fig. 9Sound levels of selected 1/3 octave bands

4. Conclusions

Noise belongs to one of the factors that pose a threat to human health. Among its sources are popular appliances used in both households and service companies. Lawnmowers powered by single-cylinder combustion engines are a significant source of noise emission. The developed standards concerning noise emissions apply to brand new solutions only, without taking into account changes in the noise level resulting from the changing technical condition of the appliance, caused by its wear and tear.

The measurements of the equivalent sound level generated by lawnmowers at the place of sound reception by the user indicate exposure of human health. A method was developed to assess the harmfulness of noise to the mower operator’s hearing, which is based on an analysis of the sound energy distribution in the selected 1/3 octave bands. In such case, it is proposed to carry out measurements and analyse the effects in the frequency range from 200 Hz to 3.15 kHz.

At the same time, the results of the study indicate the need to develop ear protection solutions which should dampen the sound in this frequency range as much as possible. Solutions of this type would therefore be dedicated to users of the investigated lawnmowers powered by single-cylinder combustion engines

References

-

Augustyńska D., Zawieski W. Protection against noise and vibration in the working environment. Central Institute for Labour Protection, Warszawa, Polska, 1999.

-

Engela Z. W., Sadowskiego J. Environmental protection against noise in Poland in the light of the provisions of the European. Central Institute for Labour Protection, National Research Institute, Warszawa, Polska, 2005.

-

Makarewicz R. Noise and wave. Scientific Publishing, Poznan, 2011.

-

Dudarewicz A., Toppila E., Pawlaczyk-Łuszczyńska M., Śliwinska-Kowalska M. The influence of selected risk factors on the hearing threshold level of noise exposed employees. Archives of Acoustics, Vol. 35, Issue 3, 2010, p. 371-382.

-

Starck J., Toppila E., Pyykkö I. Hearing Protectors: Noise and Its Effects. John Wiley & Sons, London, 2007, p. 667-680.

-

Daniell W. E., Stover B. D., Takaro T. K. Comparison of criteria for significant threshold shift in workplace hearing conservation programs. Journal of Occupational and Environmental Medicine, Vol. 45, Issue 3, 2003, p. 295-304.

-

Alberti P. Noise-induced hearing loss – A global problem. Advances in Noise Research, Protection against noise, London I, Whurr Publisher, Vol. 1, 1998, p. 7-15.

-

Henderson D., Bielefeld E. C., Lobarinas E., Tanaka C. Noise-induced hearing loss: Implication for tinnitus. Textbook of Tinnitus, Berlin, Springer Science + Business Media, 2011, p. 301-309.

-

Davis R. What do we know about hearing protector comfort. Noise Health, Vol. 10, 2008, p. 83-89.

-

European Agency for Safety and Health at Work. Data to describe the link between OSH and employability. Luxembourg, Office for Official Publications of the European Communities, 2002.

-

Potužníková D., Hellmuth T., Bednarčík P., Fiala Z. Experience in health risk assessment of exposure to noise from road traffic. Hygiena, Vol. 57, Issue 3, 2012, p. 100-104.

-

Tint P., Tarmas G., Koppel T., Reinhold K., Kalle S. Vibration and noise caused by lawn maintenance machines in association with risk to health. Agronomy Research, Vol. 10, 2012, p. 251-260.

-

Huang Y., Huang J. Exploring various health beliefs concerning hearing loss and noise prevention among workers in relation to their personal protective behavior. Taiwan Journal of Public Health, Vol. 30, Issue 6, 2011, p. 573-581.

-

Schreckenberg D., Griefahn B., Meis M. The associations between noise sensitivity, reported physical and mental health, perceived environmental quality, and noise annoyance. Noise and Health, Vol. 12, Issue 46, 2010, p. 7-16.

-

Jia H., Sheng L., Dou X., Deng L., Guanand K., Fan J. Anonymous Wavelet packet noise reduction algorithm based near-bit resistivity measurement method and device. Society of Petroleum Engineers, Asia Pacific Drilling Technology Conference, Catching the Unconventional Tide, Winning the Future Through Innovation, 2012, p. 428.

-

Rudzyn B., Fisher M. Performance of personal active noise reduction devices. Applied Acoustics, Vol. 73, Issue 11, 2012, p. 1159-1167.

-

Matsumoto M., Hashimoto S. Internal noise reduction from dependent signal mixtures using microphones and a piezoelectric device under blind condition. Journal of the Acoustical Society of America, Vol. 125, Issue 3, 2009, p. 1518-1528.

-

Mu C., Gao C., Ge Z. Noise decreasing methods of gearing vibration for a idling construction machine. Applied Mechanics and Materials, 2012, p. 427.

-

Paulsen R. Noise exposure in construction trades: The results of noise measurements over 30 years, European Conference on Noise Control, p. 252-256.

-

Vigran T. E. Sound transmission in multilayered structures – introducing finite structural connections in the transfer matrix method. 8th European Conference on Noise Control, Proceedings of the Institute of Acoustics, 2009.

-

Figlus T., Wilk A. Comparison of the sound pressure measurement and the speed measurement of the gearbox vibrating surface. Transport Problems, Vol. 7, Issue 1, 2012, p. 37-42.

-

Wilk A., Madej H., Figlus T. Analysis of the possibility to reduce vibroactivity of the gearbox housing. Maintenance and Reliability, Vol. 50, Issue 2, 2011, p. 42-49.

-

Burdzik R., Konieczny L. Application of vibroacoustic methods for monitoring and control of comfort and safety of passenger cars. Diffusion and Defect Data Pt.B: Solid State Phenomena, Vol. 210, 2014, p. 20-25.

-

Basner M., Müller U., Griefahn B. Practical guidance for risk assessment of traffic noise effects on sleep. Applied Acoustics, Vol. 71, 2010, p. 518-522.

-

Sørensen M., Hvidberg M., Andersen Z. J., Nordsborg R. B., Lillelund K. G., Jakobsen J., et al. Road traffic noise and stroke: A prospective cohort study. European Heart Journal, Vol. 32, 2011, p. 737-744.

-

Babisch W., Ising H., Gallacher J. E. J., Sweetnam P. M., Elwood P. C. Traffic noise and cardiovascular risk: The caerphilly and speedwell studies, third phase-10-year follow up. Archives of Environmental Health, Vol. 54, 1999, p. 210-216.

-

Stansfeld S. A., Haines M.M., Berry B., Burr M. Reduction of road traffic noise and mental health: An intervention study. Noise Health, Vol. 11, 2009, p. 169-175.

-

Avsar Y., Gumus B. D. The application of noise maps for traffic noise reduction. Noise Control Engineering Journal, Vol. 59, Issue 6, 2011, p. 715-723.

-

Agarwa S., Swami B. L. Road traffic noise, annoyance and community health survey – A case study for an Indian city. Noise and Health, Vol. 13, Issue 53, 2011, p. 272-276.

-

Li F., Cai M., Liu J. K., Yu Z. Dynamic traffic noise simulation at a signalized intersection among buildings. Noise Control Engineering Journal, Vol. 59, Issue 2, 2011, p. 202-210.

-

Li Q., Yang Z., Wang Y., He Y. Experimental and numerical studies on aerodynamic noise of automotive rear view mirror. Noise Control Engineering Journal, Vol. 59, Issue 6, 2011, p. 613-621.

-

Samara T., Tsitsoni T. The effects of vegetation on reducing traffic noise from a city ring road. Noise Control Engineering Journal, Vol. 59, Issue 1, 2011, p. 68-74.

-

Brown A. L. Soundscapes and environmental noise management. Noise Control Engineering Journal, Vol. 58, Issue 5, 2010, p. 493-500.

-

Leinert J., Griffin R., Blackburn J., McGwin G. Jr. The epidemiology of lawn trimmer injuries in the United States: 2000-2009. Journal of Safety Research, Vol. 43, 2012, p. 137-139.

-

Nguyen A., Raymond S., Morgan V., Peters J., Macgill K., Johnstone B. Lawn mower injuries in children: A 30-year experience. Australian and New Zealand Journal of Surgery, Vol. 78, Issue 9, p. 759-763.

-

Ying Hao K., Xin Mei L., Mohd Ripin Z. Tuned vibration absorber for suppression of hand-arm vibration in electric grass trimmer. International Journal of Industrial Ergonomics, Vol. 41, 2011, p. 494-508.

-

Ying Hao K., Lu Ean O., Mohd Ripin Z. The design and development of suspended handles for reducing hand-arm vibration in petrol driven grass trimmer. International Journal of Industrial Ergonomics, Vol. 41, 2011, p. 459-470.

-

Weiss-Cohen M., Sirotin I., Rave E., Lawn mowing system for known areas. International Conference on Computational Intelligence for Modelling Control and Automation, 2008, p. 539-544.

-

Ahn Y. K., Song J. D., Bo-Suk Y. Optimal design of engine mount using an artificial life algorithm. Journal of Sound and Vibration, Vol. 261, 2003, p. 309-328.

-

Goth Y. Vibroacoustic characterization of a lawnmower using the noise synthesis technology approach. The 6th European Conference on Noise Control, Advanced Solutions for Noise Control, 2006.

-

Directive 2000/14/WE of the European Parliament.

-

Figlus T., Wilk A., Franke P. The estimation of changes in the noise level generated by devices equipped with two-stroke internal combustion engines with small displacement volume. FME Transactions, Vol. 41, Issue 3, 2013, p. 216-221.

-

Figlus T., Wilk A. The influence of drive parameters and technical condition on the vibroactivity of devices with single-cylinder internal combustion engines. Transport Problems, Vol. 8, Issue 1, 2013, p. 79-85.

-

Regulation of the Minister of Economy and Labour of 5 August 2005 on health and safety at work related to exposure to noise or vibration, 2005, No. 157/1318.