Abstract

This study presents problems of material handling equipment drives as objects of vibration diagnostics, as well as the concept of sensors integrated with a surface exposed to damage on an example of a DiaForce sensor integrated with the surface of the inner race of a rolling bearing according to the solution proposed by Fraunhofer Institute in Braunschweig.

1. Introduction

The increase in the production efficiency forces the development in the scope of construction and operation of high-performance material handling systems, especially various types of belt conveyors. The development in operation of such equipment is based on modern methods of technical diagnostics. The progress in technical diagnostics resulting from the development of virtual measuring devices and sensors allows developing new methods for formulating more reliable forecasts of changes in the technical condition, which thus enable decisions concerning their operation with a considerable advance [1].

This paper presents the problems of material handling equipment drives as objects of vibration diagnostics and emphasizes a significant impact of measuring disturbances on the accuracy of diagnostic decisions. In particular, the aim of the study was to present the concept of sensors integrated with a surface exposed to damage on an example of a sensor integrated with the surface of the inner race of a rolling bearing according to the solution proposed by Fraunhofer Institute in Braunschweig.

2. Diagnostics of material handling equipment

Gear transmissions are included in most transmission systems of transport machines and high requirements concerning their operating durability apply. The condition of this equipment determines the functioning of the entire transport system and therefore gear transmissions are often the subject of technical diagnostics.

In the case of high power gear transmissions, the condition of bearings and teeth of gears is determined most frequently. This is usually done with the use of the following methods [1]:

- vibration diagnostics (most commonly used),

- acoustic diagnostics,

- thermal diagnostics,

- oil diagnostics.

In vibration diagnostics of gear transmissions, piezoelectric acceleration transducers installed on the gear housing near the bearing mounting are used most frequently. Figure 1a shows a diagram of the mounting of a piezoelectric sensor on a bearing housing [2], while Figure 1b illustrates an example of practical implementation of transmission gear measurement using a portable device for collection of vibration signals and measuring the temperature.

The assessment of the condition of a rotating machine can be carried out by analysing, inter alia, the following values [1] characterizing a vibration signal:

- root mean square value of accelerations and vibration velocities,

- peak value of accelerations and velocities,

- crest factor of accelerations and velocities,

- harmonics of the rotational speed (order analysis),

- spectrum of vibration velocities and accelerations,

- spectrum of the envelope of vibration velocities and accelerations.

Fig. 1Diagnostic signal measuring systems: a) diagram of mounting the piezoelectric sensor on the bearing housing [2], b) example of practical implementation of transmission gear measurement using a portable device for collection of vibration signals and measuring the temperature

![Diagnostic signal measuring systems: a) diagram of mounting the piezoelectric sensor on the bearing housing [2], b) example of practical implementation of transmission gear measurement using a portable device for collection of vibration signals and measuring the temperature](https://static-01.extrica.com/articles/10032/10032-img1.jpg)

a)

![Diagnostic signal measuring systems: a) diagram of mounting the piezoelectric sensor on the bearing housing [2], b) example of practical implementation of transmission gear measurement using a portable device for collection of vibration signals and measuring the temperature](https://static-01.extrica.com/articles/10032/10032-img2.jpg)

b)

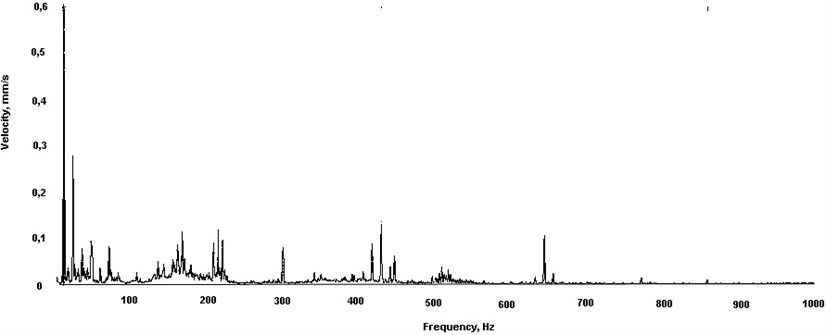

A sample frequency spectrum of vibrations of the drive shaft of an actual gear transmission (shown in Figure 1b) is presented in Figure 2. There are visible dominant frequencies associated with the rotational speed of the shaft and the meshing frequency (in this case the spectrum includes, apart from the main meshing frequency, also its harmonics). Due to a good condition of the gear transmission, no significant increase in the values of the frequencies associated with the operation of bearings is observed.

Fig. 2A sample frequency spectrum of vibrations of the drive shaft of an actual gear transmission

Additionally, it is very useful in diagnostic analysis to determine the temperature of bearings and the values of parameters characterising drive loads, such as: motor winding temperature, motor current during start-up and stable operation, instantaneous change in the rotational speed. Thermal state of drive units is measured with the use of thermal resistance transducers (most common are Pt100 or Pt1000 sensors).

3. Characteristics of sensors integrated with the surface

It should be noted that the vibration signal generated by the element being diagnosed is usually disrupted by other components of the device, and thus the signal coming from the damaged component may be "masked" by other damage. In the case of an acoustic signal, it may be additionally disturbed by acoustic effects associated with environmental properties [3].

The best solution that eliminates the problem of disturbances is to place a sensor in the immediate vicinity of the element exposed to damage (or even, if possible, exactly on its surface) and to transmit directly (without the need to use sliding systems for transmitting the signal) the information about the state of the element. These requirements are fulfilled by sensors integrated with the surface exposed to damage.

An example of such an approach to technical diagnostics is a solution proposed by Fraunhofer Institute in Braunschweig, which is based on application of thin sensory films, which have piezoelectric and thermal resistance properties and at the same time are highly wear resistant, onto the surface of the element to be diagnosed, i. e. onto the inner race of a rolling bearing. Such a combination of features allows measuring the force acting on the bearing and the temperature inside it. An example of such a sensor applied on the surface of a bearing is shown in Figure 3.

The DiaForce integrated sensor with the surface of the diagnosed element [4] consists of three layers (see Figure 4). In terms of the performance of the sensor, the most important of them is the DLC (Diamond Like Carbon) ceramic coating with a thickness of 6 µm (trade name: DiaForce). It consists of hydrogenated amorphous carbon a-C: H. The coating is applied using the PACVD technology (problems associated with DLC materials are discussed in detail in [5]). It is characterized by a high wear resistance and by piezoresistive properties.

Under this layer, there is a nanolayer of metallic chromium with a thickness of 200 µm (obtained with the use of PVD methods), which is characterized by thermal resistance properties. In addition to the mentioned layers, the sensor has also a transparent insulating film (SICOM) with a thickness of 3.5 µm, characterized by high wear resistance properties. Similarly as in the case of the DiaForce layer, it is also applied onto the bearing surface with the use of the PACVD technology and is composed of amorphous carbon (a-C:H:Si:O). The signals used to determine the forces acting on the surface of a bearing and the temperature inside it are transmitted to the measuring equipment using special electrodes. Schematic diagram of an integrated sensor is shown in Figure 4.

Fig. 3View of a sensor integrated with the surface of the inner race of a rolling bearing built according to the solution proposed by the Fraunhofer Institute in Braunschweig [6]

![View of a sensor integrated with the surface of the inner race of a rolling bearing built according to the solution proposed by the Fraunhofer Institute in Braunschweig [6]](https://static-01.extrica.com/articles/10032/10032-img4.jpg)

![View of a sensor integrated with the surface of the inner race of a rolling bearing built according to the solution proposed by the Fraunhofer Institute in Braunschweig [6]](https://static-01.extrica.com/articles/10032/10032-img5.jpg)

Figures 5a and 5b present the characteristics of the dependence of the force acting on the surface of the bearing and the temperature on the resistance. As it can be seen in the drawings, the presented characteristics are highly linear.

Some examples of measurements of the force acting on the race of a rolling bearing are shown in Figure 6, while Figure 7 illustrates the course of temperature changes during the operation of the bearing.

Fig. 4Schematic diagram of an integrated sensor [6]: 1 – DIAFORCE layer, 2 – chromium layer, 3 – SICOM layer

![Schematic diagram of an integrated sensor [6]: 1 – DIAFORCE layer, 2 – chromium layer, 3 – SICOM layer](https://static-01.extrica.com/articles/10032/10032-img6.jpg)

Fig. 5Characteristics of the dependence of: a) the force acting on the bearing surface and b) the temperature on the resistance [6]

![Characteristics of the dependence of: a) the force acting on the bearing surface and b) the temperature on the resistance [6]](https://static-01.extrica.com/articles/10032/10032-img7.jpg)

a)

![Characteristics of the dependence of: a) the force acting on the bearing surface and b) the temperature on the resistance [6]](https://static-01.extrica.com/articles/10032/10032-img8.jpg)

b)

Fig. 6Sample course of the force acting on the race of a rolling bearing [6]; (axis x – time, sec; axis y – resistance, Ohm)

![Sample course of the force acting on the race of a rolling bearing [6]; (axis x – time, sec; axis y – resistance, Ohm)](https://static-01.extrica.com/articles/10032/10032-img9.jpg)

Fig. 7Sample course of temperature changes during the operation of the bearing [6]; (axis x – time, sec; axis y – resistance, Ohm)

![Sample course of temperature changes during the operation of the bearing [6]; (axis x – time, sec; axis y – resistance, Ohm)](https://static-01.extrica.com/articles/10032/10032-img10.jpg)

4. Conclusions

In order to fully and effectively use the functional capabilities of transport equipment drives it is necessary to employ technical diagnostic methods. The development of diagnostic methods enables more and more accurate and reliable forecasting of the equipment service life and dates of overhauls. Placement of measuring sensors as close as possible to the elements exposed to damage is a direction that ensures an increase in the correctness of the diagnostic decisions.

Sensors integrated with the surface of elements to be diagnosed can be a possible solution to the problem of the operation of measuring sensors in a place exposed to wear factors. This study presents the characteristics of DiaForce integrated sensors used for the diagnostics of rolling bearings. They are built using modern wear resistance coatings with piezoresistive properties.

References

-

Mączak J., Roszczewski A. Autonomous diagnostic system of hazard identification and minimize the risk of technical systems. Diagnostyka, Vol. 36, 2005.

-

Oehlmann H., Brie D., Tomczak M., Richard A. A method for analysing gearbox faults using time-frequency representations. Mechanical Systems and Signal Processing, Vol. 11, Issue 4, 1997.

-

Wojnar G. Selection of the vibration signal space-oriented diagnosis gears. Diagnostyka, Vol. 36, 2005.

-

Peiner E., Tibrewala A., Holger L., Bandorf R., Biehl S., Doering L. Piezoresitive diamond-like carbon micro strain gauges. 18 Imeko World Congress Metrology for a Sustainable Development, Rio De Janeiro, Brazil, 2006.

-

Mercado Y. A. P. Diamond-Like Carbon and Ceramic Materials as Protective Coatings Grown by Pulsed Laser Deposition. Dissertation RWTH Aachen, 2003.

-

Annual Report 2007. Fraunhofer-Institut für Schicht- und Oberflächentechnik (IST) Braunschweig.