43rd International Conference on VIBROENGINEERING is an integral part of Vibroengineering Series Conferences and was held in Greater Noida (Delhi), India.

Conference was dedicated to researchers, scientists, engineers and practitioners throughout the world to present their latest research results, foster discussion, new ideas and develop partnerships. All JVE Conferences are integral part of the Series of Vibroengineering Conferences started in 1999. Vibroengineering Procedia is indexed in major scientific databases: Scopus, EI Compendex, Inspec, Gale Cengage, Google Scholar and EBSCO.

JVE conferences feature a broad range of high-level technical presentations, vibrant discussions and key experts and scientists from all over the world. The conference provides an opportunity to communicate your recent research advances, exchange ideas in innovative engineering technologies and enjoy endless networking advantages.

Keynote speakers

In the most commonly used low pressure steam turbines, during certain summer exploitation conditions, a problem concerning high level vibrations in unshrouded last stage low pressure (LP) blades was reported. The numerical and experimental studies of mistuned last stage steam turbine bladed discs is presented. The mistuning pattern was taken from tip-timing measurements in real turbines. Generally the modes of mistuned bladed disc is classified in a similar way to those of the tuned bladed disc but only with a small number of mode diameters. However, this was not possible in the case of larger nodal diameter modes as the mistuned blades distorted the nodal lines of the mode shapes. The smaller mistuning than the distortion of modes is smaller. It was shown that in case of long (last stage turbine) blades even very small mistuning 0.5% completely distorts nodal diameters and only separate blades vibrate in modes. Complete shaft with four bladed discs was created to analyse multistage coupling and the influence of the whole shaft on mistuned bladed disc modes. Multistage coupling through the rotor influences only bladed discs with zero- and one-nodal-diameter modes. This increases the number of resonances and changes the Campbell diagram. The experimental results from the tip-timing analysis show that that nodal diameters in mistuned bladed disc modes do not appear in the first mode family associated with the natural frequencies of a cantilever blade and only individual blades vibrate. The numerical results confirm this.

The measurements of blade response and frequencies are presented for various condenser pressure and for nominal working condition. These frequencies and amplitudes depend on condenser pressure and static pressure in front of the LP stage. The conclusion is that by changing the regimes in a LP steam turbine last stage, the blades vibrate with different frequencies and modes.

Numerical calculations of the 3D transonic flow of an ideal gas through last stage with exhaust hood of steam turbine with taking into account the blades oscillations is presented. The polytropic index was assumed 1.11 to model wet steam. The approach is based on the solution of the coupled aerodynamic-structure problem for the 3D flow through the turbine stage in which fluid and dynamic equations are integrated simultaneously in time, thus providing the correct formulation of a coupled problem, as the blades oscillations and loads, acting on the blades, are a part of solution. An ideal gas flow through the mutually moving stator and rotor blades with periodicity on the whole annulus is described by the unsteady Euler conservation equations, which are integrated using the explicit monotonous finite-volume difference scheme of Godunov-Kolgan and moving hybrid H-H grid. The structure analysis uses the modal approach and 3D finite element model of a blade. The blade motion is assumed to be constituted as a linear combination of the first natural modes of blade oscillations with the modal coefficients depending on time. The algorithm proposed allows to calculate turbine stages with an arbitrary pitch ratio of stator and rotor blades, taking into account the blade oscillations by action of unsteady loads caused both outer flow non-uniformity and blades motion. The pressure distribution behind the rotor blades were non-uniform as the result of the exhaust hood. It was found that rotor blades vibrate in selexcited vibration for non-nominal condition. The tip-timing mesurements conform numerical results. The blades vibrate with different frequencies and modes.

The new theory of mistuned bladed disc with long blades is presented using numerical and experimental analysis.

The Internet of Things (IoT) of Industry 4.0, big data analysis, Machine Learning (ML), Artificial Intelligence (AI), etc are gaining momentum in current research to further improve industrial performance. Considering advancement in technologies both in software and hardware, it is possible to replace the manual approach of the vibration-based condition monitoring (VCM within industries to a centralised vibration-based condition monitoring (CVCM). Machine learning approach using physics based input parameters of machine vibration together with the big data analysis and the IoT concept can realise the concept of th CVCM. The CVCM can access data from machines around the world. It can then capable to detect the faults in any machines and initiates eMaintenance planning from a cenralised monitoring location. The presentation is discussing such a possibility based on the current research carried out.

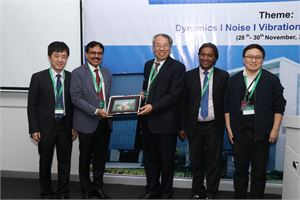

Organizing Comittee

Conference Program

Gallery

Sponsors and Partners

Conference in Greater Noida (Delhi), India was organized by JVE International with the partnership of Bennett University.