Abstract

Additive manufacturing technology has become quite widespread and produces solutions in many areas. Although it is much more advantageous than machining, this technology continues to be developed every day to increase productivity. In additive production systems with different production processes, it may be necessary to improve the system in order to increase the quality of the products that are desired to increase the sensitivity. In this study, it is aimed to determine the vibration behavior of the screw used in the screw extruder method, which will eliminate the errors caused by the continuous filament technology used in FDM technology in layered production.

1. Introduction

Additive manufacturing can produce products ranging in size from nano/micro structures [1] to macro structures [2]. The production of a nanostructure or the construction of a building is possible with this production method [3]. The advantages of additive manufacturing are not limited to the manufacturing process. At the same time, it has crucial advantages in processes such as the storage and transportation of raw materials, delivery to the production area and waste material management [4-7].

In additive manufacturing, the preparation of the product is the same as the traditional method. The product is created by software. However, production can be realized in a very advantageous way by creating a design and producing the product, disparate from the traditional method [8-12] (Fig. 1).

Fig. 1Additive manufacturing process [8-12]

![Additive manufacturing process [8-12]](https://static-01.extrica.com/articles/22465/22465-img1.jpg)

Although it has many advantages, problems can be experienced in additive manufacturing technologies [13, 14]. One of these problems is the problem encountered in systems that produce continuous film. In order to eliminate this problem experienced in FDM systems, screw fed systems are started to be used instead of continuous filament fed systems. The layered production of the system, inspired by traditional plastic injection systems, is realized by applying it vertically in technology. The most probable system problem in this system is vibration-related wear, which is a type of soft wear. Adhesive removal on the system; Decreased productivity, variations in the melt quality and mixing quality, decrease in pressure stability, increase in the temperature inside the hive and increase yellowing and burning can take away the advantages of the innovative method [15-20].

In this publication, it is aimed to determine the behavior and optimum operating values of screw extrusion systems, which are developed for the elimination of frequently encountered mechanical errors in FDM technology, by vibration analysis.

2. Materials and methods

Extrusion screws are produced according to the proportional relationship between diameter and length. Parameters such as temperature and pressure, especially the type of material to be used in production, are very decisive on efficiency. In addition, the operating conditions of the system are also very important [21]. Effects such as vibration and external environment characteristics will directly affect the quality. Nitriding steel (8550) is the most widely used material as screw material in the development of screw fed system in additive manufacturing.

Nitriding steels are generally preferred where high wear resistance, high fatigue strength and high corrosion resistance are required. Nitriding steels are delivered pre-hardened between 27-35 HRc.

When using as a screw for material-layered production, a temperature of approximately 350 °C can be applied to the 40 W heater and extruder supplied by the system and supplied to the nozzle tip. The screw can withstand the bending effect up to a torque of 88.9278 N.m. In addition, the yield strength value is 680 N/m2 [21]. The vibrations that may occur in the operation of this material depending on the system parameters were investigated using the finite element analysis method.

Table 1Nitriding steel (8550) chemical composition

C | Si | Mn | P | S | Al | Cr | Mo | Ni | ||

1.8550 | Min. | 0.30 | 0.00 | 0.40 | 0.00 | 0.00 | 0.80 | 1.50 | 0.15 | 0.85 |

DIN34CrAlNi7 | Max. | 0.37 | 0.40 | 0.70 | 0.03 | 0.03 | 1.20 | 1.80 | 0.25 | 1.15 |

3. Result and discussion

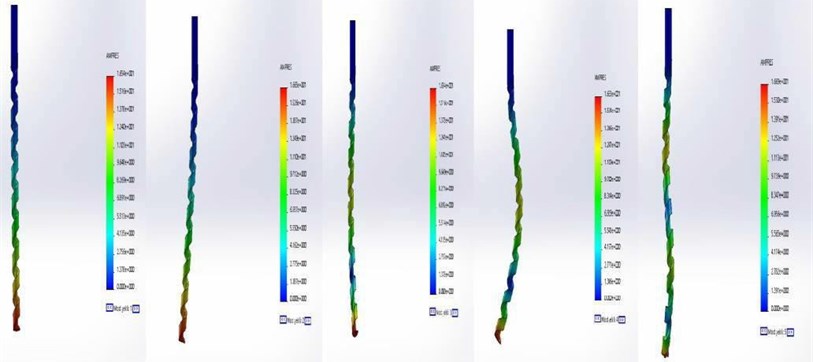

A real model has an infinite number of natural frequencies. However, a finite element model (SolidWorks) has a finite number of natural frequencies equal to the number of degrees of freedom considered in the model. Only the first few modes are needed for most applications. Natural frequencies and corresponding mode shapes depend on geometry, material properties, and support conditions. The calculation of natural frequency and mode shapes is known as modal, frequency and normal mode analysis. In layered production technology, the average of the highest natural vibration frequency values at full occupancy rate is between 150 Hz, which is the reference value for this study.

The analysis results on the screw are given in Fig. 2. According to the analysis results, the vibration values on the screw are given in Table 2.

Table 2Modal frequency values of the screw

Mode numbers | 1. | 2. | 3. | 4. | 5. |

Frequency (Hz) | 185.6 | 190.8 | 1146.4 | 1175.2 | 3150.7 |

Fig. 2Frequency analysis values of the feed screw

4. Conclusions

According to the results of the analysis on the material whose properties are given in the study, the vibration effect that the screw will be exposed to within the working parameters is not expected to affect the production process. The influence of the printing parameters on the natural vibration frequency is neglected.

The results show that the designed screw design is usable for all thermoplastics. However, this does not apply to metal powder added thermoplastics. Metal powders can have adhesion, friction, and wear effects.

This improved screw design is part of an innovative 3D printing system. In this study, it is seen that the vibration effect does not affect the production quality when using the extrusion model and 3D printing method.

References

-

R. Wang et al., “Cost-effective fabrication of transparent strain sensors via micro-scale 3D printing and imprinting,” Nanomaterials, Vol. 12, No. 1, p. 120, Dec. 2021, https://doi.org/10.3390/nano12010120

-

S. Mamatha, P. Biswas, P. Ramavath, D. Das, and R. Johnson, “3D printing of complex shaped alumina parts,” Ceramics International, Vol. 44, No. 16, pp. 19278–19281, Nov. 2018, https://doi.org/10.1016/j.ceramint.2018.07.153

-

B. Mueller, “Additive manufacturing technologies – rapid prototyping to direct digital manufacturing,” Assembly Automation, Vol. 32, No. 2, Apr. 2012, https://doi.org/10.1108/aa.2012.03332baa.010

-

I. A. Ferreira, R. Godina, and H. Carvalho, “Waste valorization through additive manufacturing in an industrial symbiosis setting,” Sustainability, Vol. 13, No. 1, p. 234, Dec. 2020, https://doi.org/10.3390/su13010234

-

M. Javaid, A. Haleem, R. P. Singh, R. Suman, and S. Rab, “Role of additive manufacturing applications towards environmental sustainability,” Advanced Industrial and Engineering Polymer Research, Vol. 4, No. 4, pp. 312–322, Oct. 2021, https://doi.org/10.1016/j.aiepr.2021.07.005

-

A. Romani, V. Rognoli, and M. Levi, “Design, materials, and extrusion-based additive manufacturing in circular economy contexts: from waste to new products,” Sustainability, Vol. 13, No. 13, p. 7269, Jun. 2021, https://doi.org/10.3390/su13137269

-

M. Sahu, S. Hajra, H.-G. Kim, H.-G. Rubahn, Y. Kumar Mishra, and H. J. Kim, “Additive manufacturing-based recycling of laboratory waste into energy harvesting device for self-powered applications,” Nano Energy, Vol. 88, p. 106255, Oct. 2021, https://doi.org/10.1016/j.nanoen.2021.106255

-

Z. Liu et al., “Additive manufacturing of metals: Microstructure evolution and multistage control,” Journal of Materials Science and Technology, Vol. 100, pp. 224–236, Feb. 2022, https://doi.org/10.1016/j.jmst.2021.06.011

-

C. Reintjes and U. Lorenz, “Bridging mixed integer linear programming for truss topology optimization and additive manufacturing,” Optimization and Engineering, Vol. 22, No. 2, pp. 849–893, Jun. 2021, https://doi.org/10.1007/s11081-020-09541-8

-

H. Turkcan, S. Z. Imamoglu, and H. Ince, “To be more innovative and more competitive in dynamic environments: The role of additive manufacturing,” International Journal of Production Economics, Vol. 246, p. 108418, Apr. 2022, https://doi.org/10.1016/j.ijpe.2022.108418

-

Patalas-Maliszewska J. and Topczak M., “A new management approach based on additive manufacturing technologies and Industry 4.0 requirements,” Advances in Production Engineering and Management, Vol. 16, No. 1, pp. 125–135, 2021.

-

D. Khorsandi et al., “Manufacturing of microfluidic sensors utilizing 3d printing technologies: a production system,” Journal of Nanomaterials, Vol. 2021, pp. 1–16, Aug. 2021, https://doi.org/10.1155/2021/5537074

-

Dharnidharka M., Chadha U., Dasari L. M., Paliwal A., Surya Y., and Selvaraj S. K., “Eklemeli imalatta optik tomografi: bir inceleme, süreçler, açık problemler ve yeni fırsatlar,” The European Physical Journal Plus, Vol. 136, No. 11, pp. 1–28, 2021.

-

Viguerie A. and Ve Auricchio F., “İki seviyeli bir yöntem kullanarak eklemeli imalat problemlerinin sayısal çözümü,” Uluslararası Mühendislikte Sayısal Yöntemler Dergisi, 2021.

-

I. Gibson, D. W. Rosen, and B. Stucker, Additive Manufacturing Technologies. Boston, MA: Springer US, 2010, https://doi.org/10.1007/978-1-4419-1120-9

-

B. V. Reddy, N. V. Reddy, and A. Ghosh, “Fused deposition modelling using direct extrusion,” Virtual and Physical Prototyping, Vol. 2, No. 1, pp. 51–60, Mar. 2007, https://doi.org/10.1080/17452750701336486

-

S. H. Masood and W. Q. Song, “Thermal characteristics of a new metal/polymer material for FDM rapid prototyping process,” Assembly Automation, Vol. 25, No. 4, pp. 309–315, Dec. 2005, https://doi.org/10.1108/01445150510626451

-

James W. Comb, J. William R. Priedeman, Paul J. Leavitt, Robert L. Skubic, John Samuel Batchelder, and Stratasys Inc, “High-precision modeling filament,” Patent US6866807B2, 2005.

-

A. Bellini, S.U. Gu¨C. ¸Eri, and M. Bertoldi, “Liquefier dynamics in fused deposition,” Journal of Manufacturing Science and Engineering, Vol. 126, No. 2, pp. 237–246, May 2004, https://doi.org/10.1115/1.1688377

-

N. Venkataraman et al., “Feedstock material property – process relationships in fused deposition of ceramics (FDC),” Rapid Prototyping Journal, Vol. 6, No. 4, pp. 244–253, Dec. 2000, https://doi.org/10.1108/13552540010373344

-

S. Ersoy, B. Ekinli, and M. Kaba, “Manufacturing of complex geometric structure metal matrix structures used for special purposes,” Journal of Mechatronics and Artificial Intelligence in Engineering, Vol. 2, No. 2, pp. 96–101, Dec. 2021, https://doi.org/10.21595/jmai.2021.22335