Abstract

The civil aircraft health management system is being attached more and more importance to improve the effectiveness of the maintenance and decrease probability of the occurrence of catastrophic incidents. The airborne quick access recorder (QAR) recording the information of aircraft position, status and performance parameters becomes significant to the study. This paper introduces the QAR data feature and its application and then proposes to utilize the QAR data for fault diagnosis and condition assessment of typical airborne system. In one case, the diagnosis of environment control system (ECS) heat exchanger is achieved by digging the relationship between the corresponding QAR parameter and failure mode. In another case, the self-organizing map (SOM) is used to map the corresponding QAR parameter into a confidence value (CV) which represents the health state of hydraulic system. The experimental results demonstrate that the proposed method is reliable and pragmatic.

1. Introduction

The civil aircraft health management system is being attached more and more importance as the significant basis of the autonomic logistics system adapting to high-tech local wars in the 21st Century. Having gone through anomaly detection, diagnostics and prognostics and immerged with the state of arts reasoning technologies, aircraft health management system monitors and controls the function of critical systems and subsystems/components in order to improve the effectiveness of the maintenance and decision-support system, reduce the cost of run and logistics, and decrease probability of the occurrence of catastrophic incidents [1].

There are more and more attentions in the architecture, algorithms and prototypes of aircraft health management system recently. Most of the current research of health management technology is based on ground test data, simulation data and flight-test data due to the fact that the raw flight data is hard to acquire. So QAR is more popular for health management research engineer with the extensive application of QAR in Maintenance Operation Quality Assurance (MOQA) and Flight Operation Quality Assurance (FOQA). The information about the aircraft position, status, and performance parameters recorded in QAR is significant to the safety and health of the aircraft.

The paper is organized as follows. Section 2 presents the QAR data feature and main application. In Section 3 and 4 two experimental studies about fault diagnosis for environment control system and condition assessment for hydraulic system are indicated. Conclusions are followed in Section 5.

2. QAR data feature and application

QAR data is an important source of data for civil aircraft health management. The civil aircraft health management system can obtain a lot of information about aircraft operation, status and performance through QAR for fault diagnosis, key equipment prediction and ground maintenance.

The airborne quick access recorder is airborne equipment for recording the data from aircraft data acquisition system and sending the same data to the airline data processing center by GSM (Global System for Mobile Communications) or manual. QAR system varies between different aircraft model, however, the principle is almost the same, which is composed by data acquisition system and quick-release memory recorder. The data acquisition system collects and transmits airborne system data according to customer requirements to the disc of quick-release memory recorder. The typical appearance is shown in Fig. 1. Currently the most popular storage of QAR is 3-inch rewritable magnetic-optical (MO) disc made by Rockwell and Teledyne in domestic airlines. The MO disc can record thousands of parameters of airborne system up to 100 hours with a large storage of 128 M, 230 M, or 630 M.

Fig. 1The typical appearance of quick access recorder

QAR data has its notable feature. Firstly, the data amount is amazing. QAR data is stream dataset obtained from all kinds of sensors one sample per second during the flight. Secondly, the data is time-sensitive. On one hand, the data is real-time due to aircraft early-warning have to be real-time in order to make responds to anomalies happened. On the other hand, the data is sequential as the QAR data and time is tight coupling. Thirdly, the data has experiential knowledge. Experts in maintenance can analyze the data to realize fault isolation and make maintenance plan. Fourthly, the data has a lot of noise and disturbance, which is difficult for accurate analysis [2].

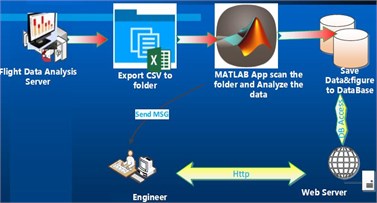

Currently most airlines use QAR data for MOQA and FOQA. Also, QAR data is useful for airborne system fault diagnosis, prediction and assessment, which is more and more important in the case of raw flight data difficult to obtain. Fig. 2 shows the main application step of the QAR data. The flight data analysis server decodes QAR data to ‘csv’ format firstly, and then export the ‘csv’ to a special folder. The MATLAB App scans the folder and analyzes the data for diagnosis, prediction and assessment, and the main conclusion is saved in database, which could be passed to maintenance engineer through web server.

Fig. 2The application step for aircraft health management

3. Fault diagnosis for ECS heat exchanger base on QAR data

3.1. Fault diagnosis for ECS heat exchanger

The civil aircraft passengers often complain the temperature in cabin is too high in summer. The main reason is that heat exchanger of environment control system is dirty statistically.

The heat exchanger is an important part of environment control system, which is responsible for making heat exchange between the hot air after the compressor and the outside air. However, it happens that the cooling efficiency of ECS is bad and the temperature is higher than pre-set. Airlines often receive customer complaints on this issue especially in summer. To solve the problem, airlines have to make a plan of washing the heat exchanger regularly to improve the cooling efficiency. The work is heavy due to 3 hours for one side and 6 hours for two sides per two months. It is a big project for the fleet. However, regular washing could not absolutely prevent the occurrence of poor cooling, passenger complaints and flight delays. Besides, airlines sometimes have to replace the heat exchanger to shorten the delay when washing is not useful, which will cause an increase in the cost of spare parts.

If the engineers can monitor the status of the heat exchanger based on QAR data, they will make the right plan to wash or replace the bad heat exchanger to lower the cost. The temperature parameters of different parts of ECS are the key parameters for the monitoring and diagnosis of heat exchanger. The engineer can analyze data and establish a diagnosis model based on the temperature parameters collected by QAR to alarm before failure and remind the airlines to wash or replace the heat exchanger properly.

3.2. Experimental verification

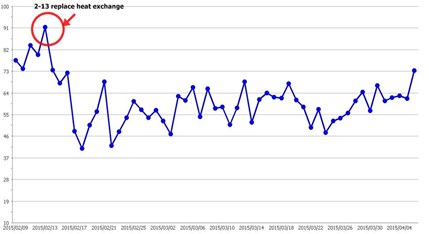

One aircraft was chosen in the case. The temperature of left compressor and left package of ECS were recorded by QAR. We monitored the temperature difference between left compressor and left package of ECS from 2/2015 to 4/2015. As shown in Fig. 3, the heat exchanger was replaced on 2/13/2015 when the temperature was higher than an empirical value and then the parameter returned normal as a result. The QAR data was proved to be effective in engineering application in this study.

Fig. 3The change of temperature difference

4. Condition assessment for hydraulic system based on QAR data & SOM

4.1. The method of SOM-based condition assessment

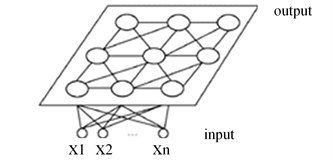

Self-organizing map (SOM) network is a kind of competitive artificial neural network that is suitable for data clustering. The SOM network combines an input layer with a competitive layer of processing neurons, which typically organized as a two-dimensional grid. The structure of the SOM network is shown in Fig. 4. As shown in Fig. 4, the SOM network is an array of M=m×m processing neurons, which maps high dimensional input vectors onto a two-dimensional surface, in which each neuron is represented by one-dimensional weight vector. Neurons of the map are connected to adjacent neurons by a neighborhood relation, which indicates the topology of the map.

The weight vector is enhanced during training procedure by the learning rule:

where wi(t) is the weight vector, α(t) is the learning rate of SOM network, hBMU,i(t) is the neighborhood function determined by the distance between the Best Matching Unit (BMU) and the neighbor neurons.

All the neurons are grouped in clusters by their distance through the training process, which form a new kind of topology structure. After that, each group of test data inputted to the well-trained SOM can match with a BMU. Finally, the Minimum Quantization Error (MQE) can be obtained by calculating the Euclidean distance between the BMU and the real-time measurement data.

In the study, the confidence value (CV), which can be formulated as below, is used to represent the condition state of system:

where, α is a scale parameter determined by the averaged MQE under normal condition and the corresponding CV, and the MQE is generated by using the online input measurement data, which will be normalized into the CV ranging from 0 to 1. The CV ranges from 1-normal to 0-unaccetable as system components usually undergo gradual degradation processes up until the time they fail, or scheduled to be replaced [3, 4].

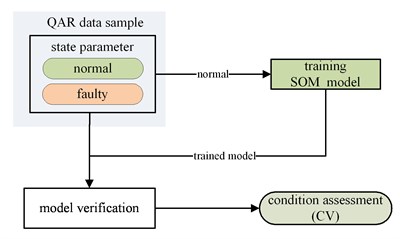

In this experiment, the normal QAR data were used to train a SOM for establishing the health condition assessment model. For model verification, the normal and the faulty data were taken and sequentially imported into the trained SOM-based condition assessment model. And then the CV of condition assessment was obtained. The step was shown in Fig. 5.

Fig. 4The SOM network

Fig. 5Step for condition assessment based on QAR data

4.2. Experimental verification

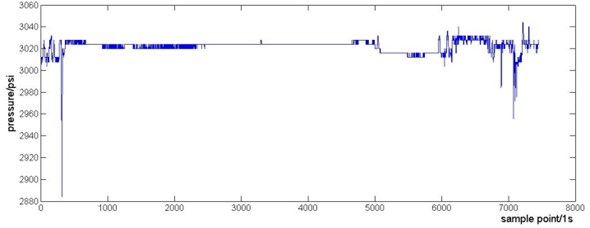

Firstly, we chose the state parameter of the hydraulic system. The output pressure signal is the main state parameter of hydraulic system, which represents the power provided to support the flight control system and landing gear system. In the experiment, we extracted the pressure signal of hydraulic system from the QAR data of one 737-800 flight. The raw data was shown in Fig. 6 as bellow.

Fig. 6The raw data from QAR

As shown in Fig. 6, the recording process of QAR was inevitably subject to electromagnetic interference and the signals were irregular especially when taking-off and landing. In this experiment, we extracted data of more stable cruise stage and made smoothing, normalization and reduction of the raw data. Besides, we simulated the faulty pressure data below the normal threshold of 3000 psi.

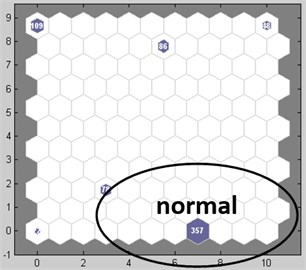

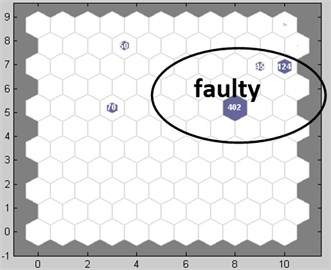

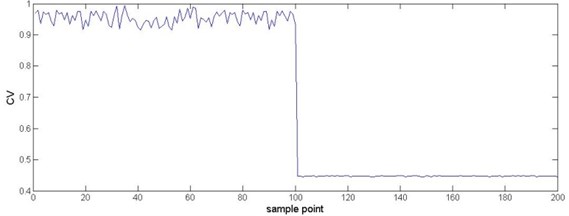

After that, the normal QAR data were used to train a SOM for establishing the health condition assessment model. For model verification, another set of normal data and simulated faulty data were taken and sequentially imported into the trained SOM-based condition assessment model. The SOM topology graph of the model testing process was shown in Fig. 7 and Fig. 8. And then the condition assessment result was shown in Fig. 9.

Fig. 7SOM topology of normal data

Fig. 8SOM topology of faulty data

The CV of hydraulic system shown in Fig. 9 was clear based on the QAR data. The first 100 samples indicating the normal state obtained a CV close to 1, and the after 100 samples indicating the faulty state obtained a CV much lower than 1. The trend of CV indicated the degradation of the hydraulic system. If we set a threshold ‘CV = 0.5’ for the degradation state, we could judge that certain fault occurred.

Fig. 9The condition assessment by CV of hydraulic system

In summary, the proposed SOM-based condition assessment model is useful for airborne system condition assessment based on QAR data, especially in the case that failure samples or full life-cycle degradation samples are hard to acquire in practical applications. The QAR data of normal state is essential and fundamental for system condition assessment, of course combined with the SOM model, which is pragmatic and useful in airlines. In future, the method can be used in the aircraft health management system on ground to realize diagnosis and condition assessment online [5].

5. Conclusions

QAR data is being attached more and more importance for health management research engineer due to QAR can record rich information of the aircraft position, status, and performance parameters. However, successful application cases are rare. The paper proposed two useful methods and verification cases in fault diagnosis and condition assessment for civil airborne system based on QAR data. In one case, ECS heat exchanger fault diagnosis could be carried out through the analysis of the relationship between the pattern parameters and failure mode, of course which required engineer experience. In the other case, the SOM-based condition assessment method was proposed to realize an online health assessment for hydraulic system, using only the QAR data under normal condition without dependence on the full life-cycle of degradation dataset. The experiments results demonstrated that the proposed methods were pragmatic and reliable.

References

-

Wang Yi, Zhao Guangtao, Liu Zhifang, Qing Xinlin The review of the integrated vehicle health management. Civil Aircraft Technology Highlights, Vol. 3, 2012, p. 4-6.

-

Yang Guifu Introduction to QAR and flight safety. Jiangsu Airlines, Vol. 3, 2011, p. 15-16.

-

Tang Youning, Sun Qian, Lv Zhenbang, Qiu Jinhao Signal processing and health assessment techniques in structural health monitoring. Vibroengineering Procedia, Vol. 4, 2014, p. 11-16.

-

Kumar K. P., Rao K. V. N. S., Krishna K. R., Theja B. Neural network based vibration analysis with novelty in data detection for a large steam turbine. Shock and Vibration, Vol. 19, 2012, p. 25-35.

-

Wang Zhaobing, Qin Xinlin, Liu Zhifang, Wang Yi Verification and validation of integrated vehicle health management system. Vibroengineering Procedia, Vol. 4, 2014, p. 324-328.