Abstract

The paper presents chosen solutions and technical elements for minimising of vibration effects in special vehicles. Due to volume and scope of the impact, forces and load generated in special vehicle during operating these elements are extremely important for isolation and absorbing of vibration affecting human or load. As the example of such solutions frame, suspension of car-body and cabin adopt in high mobility wheeled platform were described.

1. Introduction

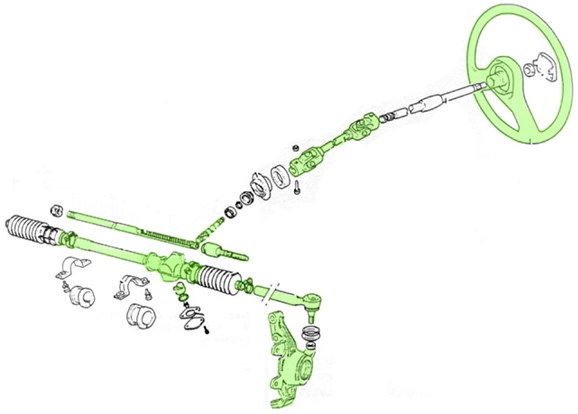

In a typical steering gear there is a reduction of movement between the steering wheel and road wheels. Thus permitting the road wheels to be turned with a limited muscular effort on the steering wheel. In automotive engineering at present by far the predominant proportion of rack-and-pinion steering systems are used as steering gears. This applies both for hydraulic or electrically servo-assisted steering systems and for non-servo-assisted steering systems. These steering gears generally have a steering housing with a rack and pinion mounted therein displaceably in the longitudinal direction. A steering pinion is rotatably arranged in a pinion housing and engages in compatible gearing of the rack. The steering pinion in turn is connected to a steering column and a steering-wheel for operating the steering system [1].

The steering system should be considered as path of forces and vibration transferred from road into driver and in the opposite way. On the other side the same way road shocks to the front wheels of a great intensity, but or small amplitude, are transmitted through the steering gear to the driver’s hands. Thus the measurement of vibration on steering gear can be source of interesting information [2-4]. Starting from analysis of damping of vibration transferred from road roughness into steering system, through evaluation of technical condition of steering gear and finishing on identification of vibration properties of gear.

2. Research on vibration of steering gear

Due to the aim and the scope of research the investigation was conducted on steering system adopt into experimental stand. The scheme of the steering system used during research have been depicted in Figure 1. The horizontal and vertical vibration has been measured in chosen location of steering system elements. The directional distribution of vibration allows to analysis of perception in different directions or torsional [5, 6]. The paper presents result of vibration measured on steering gear housing.

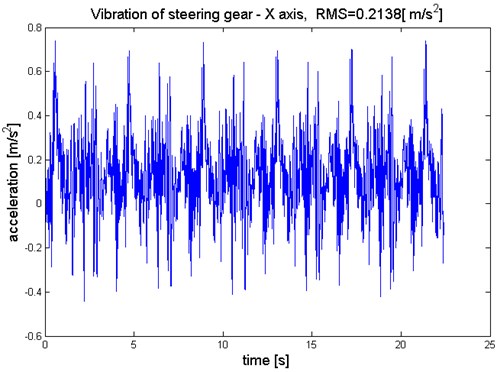

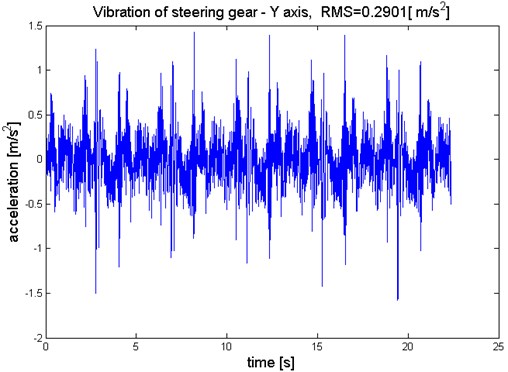

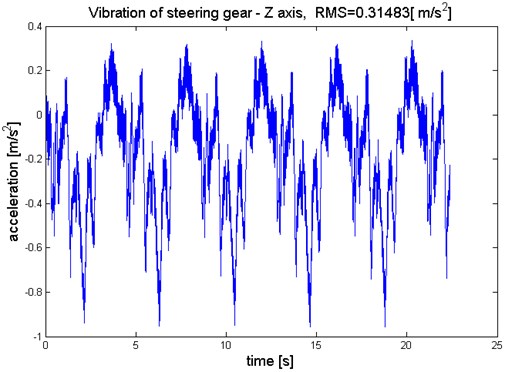

The example of results as the waveforms of orthogonal vibration in 3 axes have been presented in Figures 2-4. The estimators of vibration energy directional distribution can be compared based on root mean square (RMS) values.

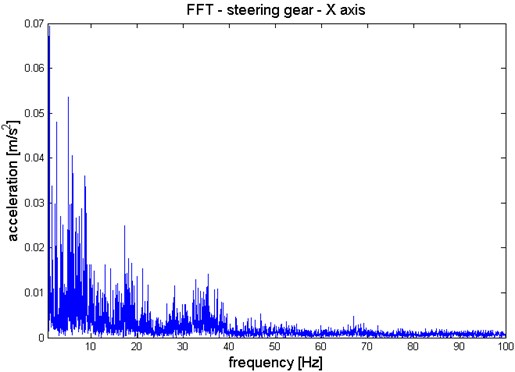

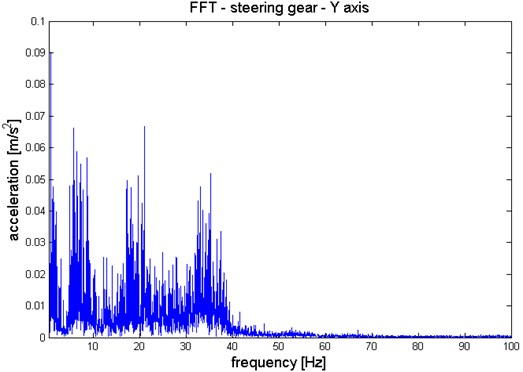

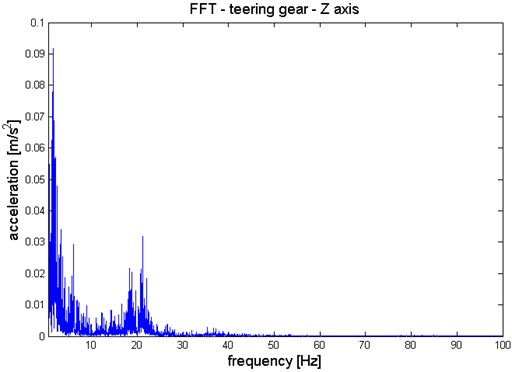

Additional for the analysis of dynamic properties of steering gear vibration the spectrums as the Fast Fourier Transformation have been calculated. The results have been presented in Figures 5-7.

Fig. 1Construction of steering system

Fig. 2Waveform of steering gear vibration, X axis

Fig. 3Waveform of steering gear vibration, Y axis

Fig. 4Waveform of steering gear vibration, Z axis

Fig. 5Waveform of steering gear vibration, X axis

Fig. 6Waveform of steering gear vibration, Y axis

Fig. 7Waveform of steering gear vibration, Z axis

3. Conclusions

The paper presents result of preliminary research on vibration of steering system. The main element of this system is steering gear. It determined functionality of steering system and the efficient of steering ratio. Vibration research allows analysis of steering gear properties and probably fault diagnosis, as steering gear backlash. Also observation of distribution of vibration transmitted through steering system into driver allows monitoring of hand-vibration affecting driver and current evaluation of the exposure [7, 8].

References

-

Davis F. Vibration-Absorbing Means for Steering Gears for Motor Vehicles. Patent US 1572519A, 1926.

-

Dąbrowski Z., Dziurdź J., Klekot G. Studies on propagation of vibroacoustic energy and its influence on structure vibration in a large-size object. Archives of Acoustics, Vol. 32, Issue 2, 2007, p. 231-240.

-

Dąbrowski Z., Zawisza M. Investigations of the vibroacoustic signals sensitivity to mechanical defects not recognised by the ODB system in diesel engines. Mechatronic Systems, Mechanics and Materials, Solid State Phenomena, Vol. 180, 2012, p. 194-199.

-

Burdzik R. Identification of Sources, Propagation and Structure of Vibrations Affecting Humans in Means of Transport Based on the Example of Automotive Vehicles. JVE Book Series on Vibroengineering, Vol. 1, JVE International Ltd., Kaunas, Lithuania, 2014.

-

Burdzik R. Research on structure and directional distribution of vibration generated by engine in the location where vibrations penetrate the human organism. Diagnostyka, Vol. 14, Issue 2, 2013, p. 57-61.

-

Homišin J., Kaššay P., Čopan P. Possibility of torsional vibration extremal control. Diagnostyka, Vol. 15, Issue 2, 2014, p. 7-12.

-

BrammerA. J. Vibration Effects on the Hand and Arm in Industry. John Wiley and Sons, NY, 1982.

-

Griffin M. J. Handbook of Human Vibration. London Academic Press, 1999.