Abstract

Based on vibration data monitoring, by factors including vibration intensity and fault probability, system health state can be characterized, factors’ weight coefficients can be calculated, and health state function can be established, which are formal representation of system health state. Health state is divided into five levels, each level obtains its membership function by analyzing the characteristic of each factor. Using system health state as input of maintenance decision-making, predictive maintenance decision can be established. Good maintenance decision can efficiently reduce the maintenance cost and improve system availability. In this thesis, research on function expression of system health state based on vibration data was conducted. Then, using opportunity-group maintenance function based on system health state, maintenance decision was made.

1. Introduction

Based on neural networks and support vector machines, research on fault diagnosis of engine are widely developed, and many dramatic breakthroughs can be seen currently. Most of diagnosis result given by these algorithms are probability of that a curtain malfunction occur in the system, or even coefficients with no physical meanings. In this thesis, health state level is used to describe the health state of system. Each level stands for specific meaning of safety and dangerousness, for which there are curtain maintenance policies, advanced engineering background and maintenance level. With system health state corresponding to maintenance decision-making, certain maintenance task item and maintenance decision are determined by the system health state function value and opportunity maintenance model.

2. Parameter selection of system health state characterization

Current research on assessment of system health state based on vibration only take vibration intensity into account sometimes, hence, the result is one-side. There are some other factors, which also effect the system health state, must be taken when assessing the health state level.

1) Fault probability: Probability of system stay in different fault mode is the main factor in assessment of system health state, which can be given by intelligence algorithm for classification. Smaller probability of system stay in fault indicate that the system working state is better, and the health state safety is higher.

2) Vibration intensity: It is the most direct description of the fault degree of system structure. Higher vibration amplitude means higher system health state risk, while the lower vibration amplitude means higher system health state safety. Different system has different vibration standard. The result of the difference, which between system absolute value of vibration amplitude and alarm value on specific observation point of the system, divided by the alarm value, is the relative value of system vibration amplitude. Using this relative value to reflect the system fault degree will eliminate the influence of the system type, sensor type and installation position of sensors.

3) Loss risk: Different fault mode lead to different result and loss. Under the circumstances that system vibration is the same, fault state cause by unbalance and blade damage, may cause different loss. Unbalance is absolute for the system rotor, while balance is relative. Sometimes system can keep on fulfilling a task under a finite unbalance state, but blade damages may probably cause a crash. Therefore, different fault modes lead to different loss risk, which is a factor that must be taken for assessment of system health state.

There are many other factors effecting assessment of system health state. In this thesis, only three factors were used to explain fuzzy comprehensive evaluation method, supposing that the influences of these factors are the same, for assessment of system health value. As a consequence, the weighted value of these three factors is all 0.33.

2.1. Fault degree description based on vibration intensity

Fault degree is an important factor that determines system health level. In this paper, vibration intensity is used to describe fault degree. To eliminate the influence of system type, sensor type and installation position of sensors, vibration amplitude is transformed to relative vibration amplitude as:

where is absolute vibration amplitude, which is given by experiments, is alarm value of same type engine at same observation point, is a relative value of amplitude.

2.2. Modification of failure rate of system

Aging failure of system not only have transient excess stress, but also have a gradually degradation progress. Therefore, real-time modification function should be used to modify failure rate of engine system. The speed of aging failure used to slow down gradually, so to describe it accurately, modification function should be as:

where (, ) is slow failure time, (, ) is fast aging time, value of are determined by specialist experiences and actual degradation data.

3. Health level and it’s subordinate function

Because of fuzziness and randomness of the vibration intensity and risk loss [5], this paper uses fuzzy set method to build the function. Based on analysis and research, health level of the system has been divided into health, sub-health, qualified, abnormal and failure.

3.1. Membership functions of vibration intensity

Normally, even if the engine vibration amplitude value is not large, it may be in any level of health state. The fuzzy distribution model should be a smooth function on the whole domain, and we modify triangular fuzzy distribution to gain the five membership functions of each health state:

3.2. Membership functions of fault probability

Concurrent faults are not discussed in this paper. System health is determined by the highest level of single fault estimation results. The membership functions of fault probability as below:

3.3. Membership functions of risk loss

The system loss for different failure modes have corresponding membership value. The main failure modes including unbalance, collision between movable and stationary parts, spin-lattice relaxation, bearing failure, flow-induced oscillation, shaft crackle, and drop piece and so on. The membership functions of risk loss can be obtained by expert evaluation method. This paper does not do in-depth study.

3.4. Vector of health status

The weight coefficient of fault probability, vibration data, and risk loss are equal, , combined with the membership functions of these three factors, health state vector can be obtained:

Health state vector is the system membership degree, system is determined by the maximum membership degree.

4. The maintenance decision based on health state vector

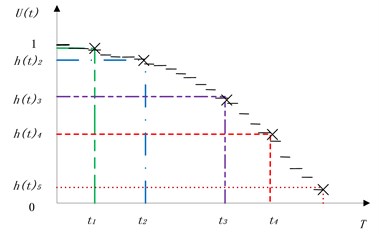

According to the maximum membership degree principle, health state vector can be calculated. Based on the analysis of system status, as well as the preset threshold value, the maintenance decision studied in this paper is shown in Fig. 1, is the health value, is the age reduction.

Fig. 1The maintenance decision based on health state vector

1) The engine system should be checked, if health value is between and 1;

2) The engine system should be clean and overhaul, if health value is between and ;

3) The engine system should be disassembled for troubleshooting, if health value is between and ;

4) The engine system should be returned to depot repair, if health value is between and ;

5) The engine system should be replaced, if health value is between 0 to .

5. Conclusion

Engine system health assessment is one kind of fuzzy evaluation, in this paper, study on the influencing factor set of health assessment was conducted, and weight coefficient of fault probability, vibration data, and risk loss were calculated. Five health levels were divided, on the basis of fuzzy theory, the subordinate functions of health states were established. Finally, the maintenance Decision-making model based on vibration data was built. Conclusions were:

1) With the vibration intensity to evaluation health status is one-sided, and it is necessary to increase the failure probability and the risk of loss factor;

2) Five health level is scientific;

3) Evaluation vector indicates the membership degree of the five-level health states, it is significant according to the maximum membership degree principle;

4) The maintenance strategy is reasonable.

References

-

Tang Genglin, Charlie L. Y., Chen Daguang Comparative study of two neural networks applied to jet engine fault diagnosis. 34th Joint Propulsion Conference and Exhibit, Cleveland, 1998.

-

Hao Ying, Sun Jianguo, Yang Guoqing The application of support vector machines to gas turbine performance diagnosis. Chinese Journal of Aeronautics, Vol. 18, Issue 1, 2005, p. 15-18.

-

Wang Yan-kai, Liao Ming-fu Study on grading of health condition of aerospace propulsion system. Journal of Aerospace Power, Vol. 23, Issue 5, 2008, p. 939-945.

-

Liu Chunhe, Lu Zujian Weapon System Reliability Assessment Methods. Beijing, China Astronautic Publishing House, 2009, p. 10-11.

-

Xu Kaili, Chen Baozhi, Chen Quan Characteristic quantity of safety grade and its calculation method. China Safety Science Journal, Vol. 9, Issue 6, 1999, p. 6-12.