Abstract

In this study, a phase-controlled vibration was applied to a laser percussion drilling process to improve the depth of penetration. To investigate the effects of phase-controlled vibration on the depth of penetration, a novel method that controls the phase offset between the accelerating motion and the emission of the laser beam was developed. The method is based on coaxial sensing of the working surface using a photodiode, coupled with microcontroller control of the drilling laser operation. Through real-time optical signal acquisition and analysis of laser machining processes, correlations between the accelerating motion and the emission of the laser beam were simultaneously obtained. All of the processing work was performed in air at standard atmospheric conditions, and gas assist was not used. This study showed that the application of phase-controlled vibration improved the depth of penetration in laser percussion machining and can contribute to the development of precision drilling in the industry.

1. Introduction

Laser percussion drilling has gained considerable attention in the industry owing to its wide industrial applicability and usage in the processing of various materials such as metals, glass, and ceramics. Laser percussion drilling is also characterized as a non-contact machining process, and produces small beam spot sizes, can be operated at high speeds, and exhibits great flexibility and accuracy. In laser machining, blind hole drilling is one of the critical problems due to the flow of melted material back to the bottom of the hole and the re-solidification of the material [1]. As reported in [2], the ultrasonic-aided laser machining technique not only increases the depth-of-drill but also improves the quality of the hole by reducing the size of the heat-affected zone. In [3], deeper holes with a much smaller recast layer are obtained when ultrasonic aid is used. It is hypothesized that ultrasonic vibration strengthens liquid expulsion in laser drilling and increases the depth of drill owing to the removal of more material from the bottom of the hole [4]. In [5], the experimental results demonstrate that ultrasonic-assisted laser drilling produces a better surface finish and higher aspect ratio in comparison to laser drilling without the assistance of ultrasonic vibration. The above studies confirm that ultrasonic-assisted laser beam machining is advantageous for improving the quality of machining [6]. In [7], ultrasonic vibration is applied to a nanosecond laser machining process; the results show that the surface finish is improved by the near-field surface cooling enhancement induced by ultrasonic vibration.

Another approach to improving laser machining quality on metals is to vibrate the optical objective lens with a fixed frequency and various displacements during a femtosecond laser machining process [8]. It is demonstrated that the wall surface finish of the machined structures and the aspect ratio obtained using the frequency-vibration-assisted laser machining are improved compared to when laser machining without vibration assist is used.

In the above studies, re-solidified material remains in laser-drilled holes because the recoil pressure is not sufficiently high to expel the viscous material. The ultrasonically aided laser drilling technique is found to improve the drilling quality and performance; the depth of drill is increased owing to the reduced amount of recast material [5]. In this study, we explored the effect of the vibration and controlled the time delay between the accelerating motion and the emission of the laser beam. All of the processing work was performed in air at standard atmospheric conditions, and gas assist was not used. The depth of penetration and the inlet diameter were measured and examined.

2. Experimental setup

2.1. Ultrasonic-assisted laser percussion drilling

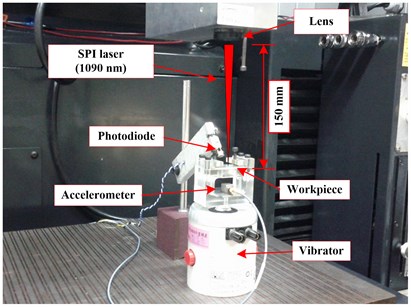

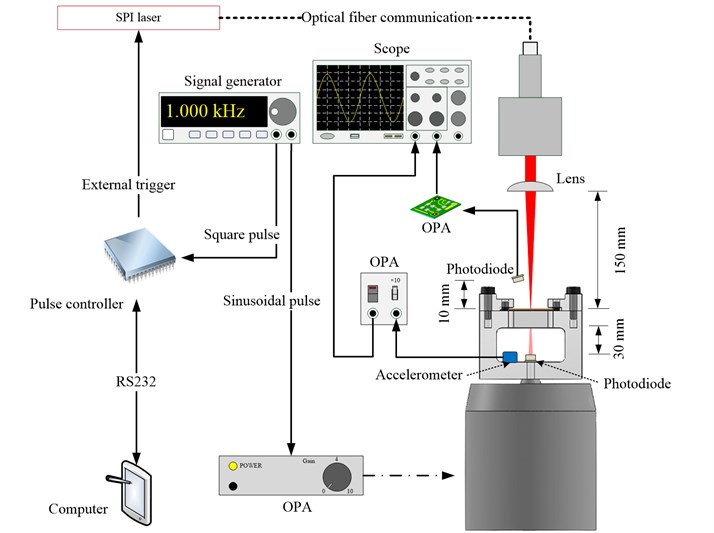

In this study, the effect of the time delay between the vibration acceleration and the laser-triggered time interval on liquid expulsion was investigated. The setup for studying the phase-controlled vibrational laser percussion drilling is shown in Fig. 1. The entire experimental setup was assembled on a Sodick AP1L Micro Precision EDM machine. A fixture connected the holders of the optical components, a mirror, and a lens, to the column of the EDM machine. The focal lens was placed on each precision stage to tune the laser direction and adjust the focal point of the laser. The mirror reflected the laser beam to the sample, whereas the lens with a z-axis stage focused the laser beam onto the workpiece. The workpiece was made of SUS 304 with a thickness of 1.0 mm. A lens with a focal length of 150 mm was used for focusing.

Fig. 1Schematic of phase-controlled vibrational laser percussion drilling setup

The laser drilling parameters are listed in Table 1, and the parameters of the vibration device employed are listed in Table 2. The workpiece was rigidly fixed on the top of a vibrator. The vibration device excited the workpiece at a frequency of 1 kHz with an amplitude of approximately 10 μm. In these experiments, the depth of penetration was determined after a couple of hours of careful grinding along vertical planes of the workpiece until the drilled cavity became visible and the sections were carefully checked to determine the accurate depth of machining. The depth of the penetration, diameters of the holes, and thickness of the recast were investigated by optical microscopy (OM). All experiments were performed in air without the use of additional process gas. The depth of the penetration and the hole diameter were determined by averaging the results from three separate drilling holes on the same workpiece.

Table 1Laser machining parameters

Item | Parameter |

Wavelength | 1090 nm |

Frequency | 1 kHz |

Focal length | 150 mm |

Radiation energy | 30 W, 40 W |

Process time | 10 s |

Pulse duration | 0.5 ms |

Table 2Parameters of vibrating device

Item | Parameter |

Gain | 8 |

Vibration frequency | 1 kHz |

Vibration amplitude | ±5 μm |

2.2. Synchronization

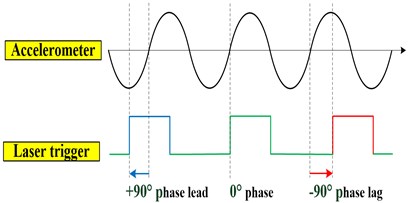

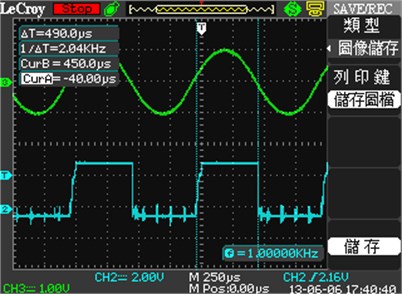

The vibration of the workpiece and the emission of the laser beam were synchronized to accelerate the workpiece at the time of drilling. For synchronization, the laser was operated in the external trigger mode. The time delay between the vibration acceleration and the duty of the emission of the laser beam was precisely synchronized by a pulse generator. To verify this synchronization, a photodiode (Hamamatsu S1223 Si PIN photodiode) was positioned on the front side of the workpiece to acquire the refraction of laser radiation after the emission of the laser beam. An accelerometer (Brüel and Kjær Type 4507) was mounted on the workpiece, as shown in Fig. 2, to measure vibration coaxial to the laser beam. As shown in Fig. 3, the zero phase synchronization (i.e., 0°) was defined when the workpiece started to accelerate positively and the laser was triggered. The lead phase synchronization was defined when the laser was triggered (e.g., +60°) before the workpiece was accelerated positively. The lag phase synchronization was defined when the laser was triggered (e.g., –60°) after the workpiece was accelerated positively. As depicted in Fig. 4, the phase offset between the accelerated motion and the laser pulse was synchronous with high accuracy. The output signal was measured by a digital oscilloscope (Lecroy WaveAce 234).

Fig. 2Installation of photodiode and accelerometer to verify synchronization between vibration of workpiece and emission of laser beam

3. Results and discussion

The expulsion of the liquid in a laser-drilled hole can be improved by the vibration; that is, molten material at the bottom of the drilling channel can be made to flow from the center toward the sidewall of the drilled hole so that the material is eventually expelled out of the cavity entrances. Two types of synchronization, i.e., half cycle synchronization and phase-controlled synchronization, were conducted to verify the improvement as well as to compare the two control strategies.

Fig. 3Precise synchronization of lead phase, zero phase, and lag phase between vibrator and triggered laser

Fig. 4Precise synchronization of phase offset between accelerated motion (green line) and laser pulse (blue line)

3.1. Half cycle synchronization

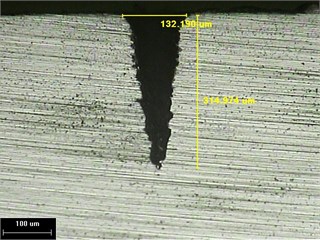

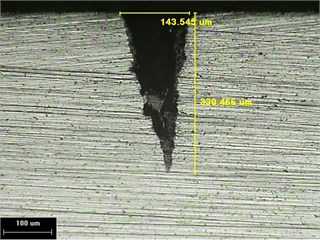

According to the synchronization of offsets for the half cycle phase lag (i.e., –180° phase) and half cycle phase zero (i.e., 0° phase) cases, the effect of the acceleration and deceleration vibration due to the vibrator and the emission period of the laser beam are examined. During the half cycle phase zero of the vibration, more molten material would be expelled out of the hole owing to the molten material being pressed against the wall. It is apparent from the photographs shown in Figs. 5 and 6 that by applying the half cycle synchronized vibration drilling technique, deeper holes can be obtained. The experimental results show good agreement with those presented in literature [3]. Owing to the flow of molten material alongside the wall of the hole, a deeper hole is formed during the half cycle phase zero (i.e., 0° phase) vibration cycle than during the half cycle phase lag (i.e., –180° phase) vibration cycle, as listed in Table 3.

Table 3Effect of laser radiation energy on depth of hole

Radiation energy | Vibration | Average depth (μm) | Depth increased (%) |

30 W | No | 255.1 | 0.0 |

–180° lag | 259.2 | 1.6 | |

0° lead | 269.2 | 5.5 | |

40 W | No | 325.4 | 0.0 |

–180° lag | 328.8 | 1.0 | |

0° lead | 343.2 | 5.5 |

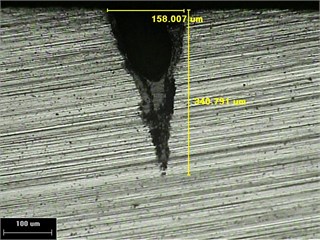

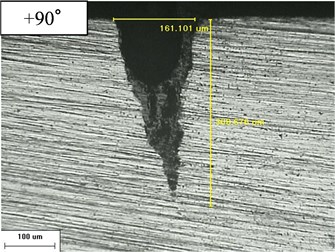

3.2. Phase-controlled synchronization

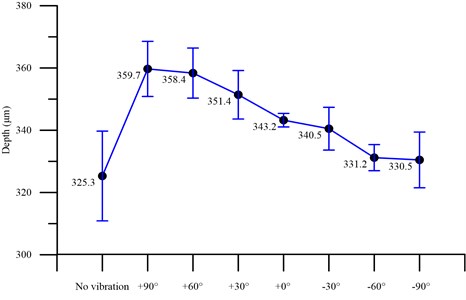

In this paper, the variation of phase offset is proposed to evaluate the removal of molten material. From the results shown in Fig. 7, it is apparent that by applying the phase-controlled synchronized vibration drilling technique, deeper holes can be obtained. In phase lead vibrational laser percussion drilling, a relative phase lead between the accelerated motion and the laser pulse is employed to accommodate a lead vibration per pulse and expel more molten material owing to the vibration. A deeper hole is formed during the 90° phase lead (i.e., 90° phase) vibration cycle than during the –90° phase lead lag (i.e., –90° phase) vibration cycle, as listed in Table 4. As plotted in Fig. 8, the experimental results show that the depth of drilling increases with the phase lead angle before the workpiece is accelerated positively. With a further increase in the phase lead angle, the amount of molten material expelled would increase considerably and the depth of drilling could be increased by as much as 10.6 %.

Fig. 5Results of laser-drilled holes with and without vibration of 30 W laser: a) without vibration; b) –180° phase lag synchronization; c) 0° phase synchronization

a)

b)

c)

Fig. 6Results of laser-drilled holes with and without vibration of 40 W laser: a) without vibration; b) –180° phase lag synchronization; c) 0° phase synchronization

a)

b)

c)

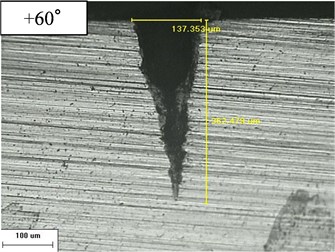

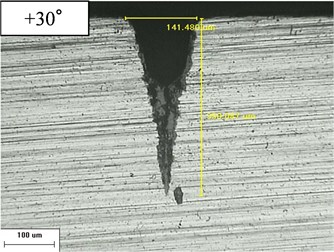

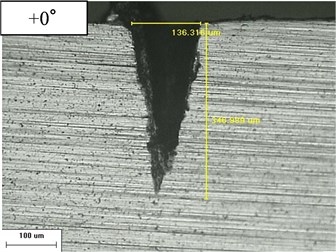

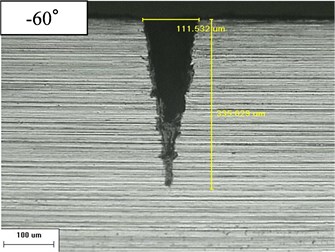

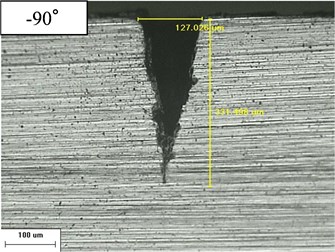

Fig. 7Results of laser-drilled holes with and without vibration of 40 W laser: a) +90° phase lead vibration; b) +60° phase lead vibration; c) +30° phase lead vibration; d) 0° phase vibration; e) –60° phase lag vibration; f) –90° phase lag vibration

a)

b)

c)

d)

e)

f)

Fig. 8Effect of phase offset on depth of hole

Table 4Effect of phase offset on depth of hole

Phase | Average depth (μm) | Depth increased (%) |

No | 325.3 | 0 |

+90° | 359.7 | 10.6 |

+60° | 358.4 | 10.2 |

+30° | 351.4 | 8.0 |

0° | 345.3 | 6.1 |

–60° | 331.2 | 2.0 |

–90° | 330.5 | 2.0 |

4. Conclusions

To improve the depth of penetration, phase-controlled vibration was applied to laser percussion drilling. It was experimentally verified that the depth of penetration when applying the phase-controlled vibration was greater than that when using the conventional laser machining method. The results show that the effect of phase-controlled vibration on the depth of drill becomes apparent at +90° phase lead; with a further increase in the phase lead angle, the depth of drill could be increased by as much as 10.6 %.

References

-

Jiang C. Y., Lau W. S., Yue T. M., Chiang L. On the maximum depth and profile of cut in pulsed Nd: YAG laser machining. CIRP Annals – Manufacturing Technology, Vol. 42, Issue 1, 1993, p. 223-226.

-

Lau W., Yue T., Wang M. Ultrasonic-aided laser drilling of aluminum-based metal matrix composites. CIRP Annals – Manufacturing Technology, Vol. 43, Issue 1, 1994, p. 177-180.

-

Yue T., Chan T., Man H., Lau W. Analysis of ultrasonic-aided laser drilling using finite element method. CIRP Annals – Manufacturing Technology, Vol. 45, Issue 1, 1996, p. 169-172.

-

Chan T. W., Yue T. M., Man H. C. Ultrasonically aided laser drilling of particle reinforced aluminum based composites. Materials Science and Technology, Vol. 14, Issues 9-10, 1998, p. 1039-1044.

-

Zheng H. Y., Huang H. Ultrasonic vibration-assisted femtosecond laser machining of microholes. Journal of Micromechanics and Microengineering, Vol. 17, Issue 8, 2007, p. N58-N61.

-

Dubey A. K., Yadava V. Laser beam machining – A review. International Journal of Machine Tools and Manufacturing, Vol. 48, Issue 6, 2008, p. 609-628.

-

Kang B., Woo Kim G., Yang M., Cho S. H., Park J. K. A study on the effect of ultrasonic vibration in nanosecond laser machining. Optics and Lasers in Engineering, Vol. 50, Issue 12, 2012, p. 1817-1822.

-

Park J. K., Yoon J. W., Cho S. H. Vibration assisted femtosecond laser machining on metal. Optics and Lasers in Engineering, Vol. 50, Issue 6, 2012, p. 833-837.

About this article

This research was partially supported by the National Science Council in Taiwan under Grant NSC 102-2221-E-224-039. Special thanks to anonymous reviewers for their valuable suggestions.